1 Ecuacion Cocentracion DewP Pcont

Anuncio

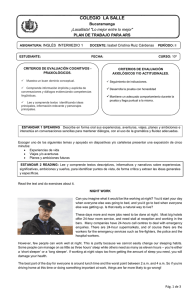

Fluid Phase Equilibria 228–229 (2005) 213–221 Advanced equation of state method for modeling TEG–water for glycol gas dehydration Chorng H. Twua∗ , Vince Tassoneb , Wayne D. Simb , Suphat Watanasiric b a Aspen Technology, Inc., 2811 Loganberry Court, Fullerton, CA 92835, USA Aspen Technology, Inc., Suite 900, 125 9th Avenue SE, Calgary, Alta., Canada T2G 0P6 c Aspen Technology, Inc., Ten Canal Park, Cambridge, MA 02141, USA Abstract An advanced equation of state has been developed for modeling triethylene glycol (TEG)–water system for glycol gas dehydration process. The dehydration of natural gas is very important in the gas processing industry. It is necessary to remove water vapor present in a gas stream that may cause hydrate formation at low-temperature conditions that may plug the valves and fittings in gas pipelines. In addition, water vapor may cause corrosion difficulties when it reacts with hydrogen sulfide or carbon dioxide commonly present in gas streams. The most effective practice to remove water from natural gas streams is to use TEG in the gas dehydration process. In modeling such a process, it is crucial that the phase behavior of the TEG–water–natural gas system is correctly modeled, with methane being the predominant component in natural gas. Of the three binaries, methane–water, methane–TEG and TEG–water, the methane binaries can be adequately modeled by an equation of state, e.g. [J.R. Cunningham, J.E. Coon, C.H. Twu, Estimation of aromatic hydrocarbon emissions from glycol dehydration units using process simulation, in: Proceedings of the 72nd Annual Gas Processors Association Convention, San Antonio, TX, March 15–17, 1993]. For the TEG–water binary, the Parrish’s empirical hyperbolic correlation [W.R. Parrish, K.W. Won, M.E. Baltatu, Phase behavior of the triethylene glycol–water system and dehydration/regeneration design for extremely low dew point requirements, in: Proceedings of the 65th Annual GPA Convention, San Antonio, TX, March 10–12, 1986] is recommended by GPSA [GPSA Engineering Data Book, 10th ed., First Revision, Gas Processors Suppliers Association, Tulsa, OK, 1994] and is currently widely used in the industry. In this work, we applied the TST (Twu–Sim–Tassone) equation of state to model this binary system. A methodology was also developed to determine the water dew point and calculate water content for this system. The TST equation of state is shown to accurately represent the activity coefficients of TEG–water solutions as well as water dew point temperatures and water content of gas over the entire application range of temperature, pressure and concentration encountered in a typical TEG dehydration unit. © 2004 Elsevier B.V. All rights reserved. Keywords: Triethylene glycol; Water; Water dew point; Water content; CEoS; TST; Cubic equation of state; Excess energy mixing rule; Activity coefficient; Gas dehydration 1. Introduction The dehydration of natural gas is an important operation in the gas processing industry. The standard method for nat- ∗ Corresponding author. Tel.: +1 403 303 1000; fax: +1 403 303 0914. E-mail addresses: chorng.twu@aspentech.com (C.H. Twu), vince.tassone@aspentech.com (V. Tassone), wayne.sim@aspentech.com (W.D. Sim), suphat.watanasiri@aspentech.com (S. Watanasiri). 0378-3812/$ – see front matter © 2004 Elsevier B.V. All rights reserved. doi:10.1016/j.fluid.2004.09.031 ural gas dehydration is by absorption of water using TEG. Glycol dehydration units typically consist of a contactor, a flash tank, heat exchangers and a regenerator. The lean TEG liquid stream enters at the top of the absorber or the contactor while the natural gas stream containing water to be removed (wet gas) enters at the bottom of the absorber. The lean TEG liquid absorbs water as it progresses toward the bottom of the column. A dry gas exits at the top of the absorber. The rich TEG stream is sent to the regenerator where water is removed and the lean TEG liquid is returned to the absorber. 214 C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 The most important aspect of modeling any dehydration unit is to correctly model the methane–glycol–water ternary [1]. This ternary controls the predicted glycol circulation rates, purities of the lean glycol and the water content of the dry gas. Of the three binaries, methane–water, methane–TEG and TEG–water, the methane binaries can be adequately modeled by an equation of state (e.g. [1]). At one time, only graphical data from vendors were available in the literature to model the TEG–water binary. These data often were in disagreement at low water concentration portion resulting in confusion. Since the concentration of water in the natural gas is typically low, less than 0.2 mol%, and the concentration of TEG in the lean TEG solution is high, normally higher than 98 wt.%, highly concentrated TEG solutions higher than 99.50 wt.% are usually required if the water concentration in the effluent gas stream is specified to be very low. Therefore, in order to have an accurate design of a dehydration unit, vapor–liquid equilibrium data for TEG–water need to be accurate, especially in the dilute region of water. Parrish et al. [2] gave an extensive review of the available equilibrium data. Based on the data reviewed, they found the data of Herskowitz and Gottlieb [4] to be the most reliable. Herskowitz and Gottlieb [4] measured the activity coefficients of water in TEG at two temperatures, 297.60 and 332.60 K. The lowest mole fraction of water for which activities were measured was 0.1938 and 0.2961 at 297.60 and 332.60 K, respectively. They fit their measured activity coefficients to the van Laar equation. They did not measure data in the infinite dilution region. In order to predict the equilibrium behavior in the infinite dilution region, most researchers simply extrapolated the measured data at low water concentrations to infinite dilution using an activity coefficient model such as van Laar. However, extrapolating the van Laar, or any other activity coefficient model will yield erroneous results for the infinite dilution activity coefficients. To help better define the TEG–water system, Parrish et al. [2] measured activity coefficients at infinite dilution as a function of temperature. These data, shown in Fig. 1, were used to evaluate the existing data. The data of Herskowitz and Gottlieb [4] were found to be in good agreement with the measured infinite dilution activity coefficient data. Bestani and Shing [5] subsequently measured activity coefficients of water in TEG at infinite dilution, but their data are 13–17% higher than those of Parrish as shown in Fig. 1. Based on the Bestani extrapolation method to 477.15 K, the predicted water activity coefficient is above 1.0. A value of water activity coefficient that is greater than unity at 477.15 K implies that TEG would be a poor dehydrating agent at around this temperature, which is contrary to plant experience [6]. Therefore, Bestani data are not used in this work. Parrish et al. [2] combined their infinite dilution activity coefficients data with the finite-concentration activity coefficients of Herskowitz and Gottlieb and then fit them to the activity coefficient model of a four-suffix Margules equation over the entire range of composition at each temperature for Fig. 1. Infinite dilution activity coefficient of water in water–TEG system: () Exp., Parrish et al. [2]; () Exp., Bestani and Shing [5]; (—) this work; (- - -) Parrish et al. [2]. the TEG–water system. However, since the Margules activity coefficient model is unable to fit the activity coefficients over an extended temperature range for process design calculations, Parrish et al. proposed an empirical hyperbolic equation to predict the activity coefficients of TEG (1) and water (2) over the entire range of temperatures and compositions: ln γ1 = B2 ln[cosh(τ)] x2 B tanh(τ) − Cx22 − A x1 ln γ2 = B[tanh(τ) − 1] − Cx12 (1) (2) where τ= Ax2 Bx1 (3) and tanh and cosh are hyperbolic tangent and cosine functions. The subscript number represents component: 1 for TEG and 2 for water. A, B, and C are temperature-dependent parameters: A = exp(−12.792 + 0.03293T ) (4) B = exp(0.77377 − 0.00695T ) (5) C = 0.88874 − 0.001915T (6) where T is the temperature in Kelvin. Both Herskowitz and Gottlieb, and Parrish used activity coefficient models to fit the activity coefficient data as a function of mole fraction and temperature. However, using an activity coefficient model to describe the liquid phase still requires the use of an equation of state to handle the nonideality of the gas phase and a Poynting correction factor to account for the effect of pressure. In addition, the standard state fugacity as a function of temperature ranging from the temperatures below 273.15 K to critical temperature need to be correlated for water for the TEG gas dehydration. Since different models are used for vapor and liquid, the approach has limitations. For example, no critical conditions can be calculated, the K-values near critical region is not reliable, C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 other thermodynamic properties such as density cannot be calculated, modeling light gases requires the use of Henry’s law constants, etc. Besides, the results of extrapolation to high temperatures and high pressures may not be reliable. For example, using the van Laar equation with the given binary interaction parameters from Herskowitz and Gottlieb for extrapolation to 477.15 K, the van Laar predicts a water activity coefficient of 1.1. As mentioned earlier in the analysis of Bestani and Shing data, a value of water activity coefficient that is greater than unity is not realistic. Using the empirical hyperbolic function of Parrish, a water activity coefficient of 0.9477 is obtained at 477.15 K, which is below unity, but is still too high. The activity coefficient of water at this temperature is expected to be below 0.80 [6]. Furthermore, Eqs. (1) and (3) contain mole fraction of component 1, x1 , in the denominator. These equations will break down when x1 approaches zero. Although the TEG mole fraction is unlikely to be zero in practical natural gas dehydration process, it is a notable deficiency that engineers should be aware of. The Parrish’s correlation is recommended by the GPSA [3] and is currently widely used in the industry. In this work, we applied the TST (Twu–Sim–Tassone) equation of state model [7,8] to describe the phase behavior of the TEG–water system. We also presented a methodology to determine water dew point and calculate water content for this system. The TST equation of state represents accurately the activity coefficients for water and TEG, the water dew point temperatures and water content over the entire range of temperature, pressure and composition encountered in a typical TEG dehydration unit. 215 The TST cubic equation of state is represented by the following equation: P= a RT − v − b v2 + 2.5bv − 1.5b2 (7) Eq. (7) can be rewritten in another form as P= RT a − v − b (v + 3b)(v − 0.5b) (8) The values of a and b at the critical temperature are found by setting the first and second derivatives of pressure with respect to volume to zero at the critical point resulting in ac = 0.470507 R2 Tc2 Pc (9) RTc Pc (10) bc = 0.0740740 Zc = 0.296296 (11) where subscript c denotes the critical point. It is noted that the values of Zc from the Soave–Redlich–Kwong [9] and Peng–Robinson [10] models are both larger than 0.3 (0.333333 and 0.307401, respectively), but that for TST is slightly below 0.3, which is closer to the typical value of Zc for most compounds. The parameter a is a function of temperature. The value of a at any temperature a(T) can be calculated from a(T ) = α(T )ac (12) where the alpha function, α(T), is a function only of reduced temperature, Tr = T/Tc . We use the Twu alpha function [11]: 2. Advanced TST (Twu–Sim–Tassone) equation of state model Twu, Sim and Tassone (TST) recently developed CEoS/AE mixing rules [7,8] that permit a smooth transition of the mixing rules to the conventional van der Waal’s one-fluid mixing rules. They also proposed a cubic equation of state for better handling of polar and heavy components and a GE model, which when combined with the CEoS/AE mixing rules allows both a van der Waal’s fluid and highly non-ideal mixtures to be described over a broad range of temperatures and pressures in a consistent and unified framework. It is extremely desirable to have the CEoS/AE mixing rules reduce to the classical quadratic mixing rules because the classical mixing rules work very well for nonpolar and slightly polar systems. Introducing this capability into an excess energy model ensures that the binary interaction parameters for the classical mixing rules available in many existing databanks for systems involving hydrocarbons and gases can be used directly in the new excess energy mixing rules. In other words, it allows the equation of state to describe some binaries in a multi-component mixture using the van der Waal’s one-fluid mixing rules, while other pairs with more non-ideal interactions are described by the excess energy mixing rules. NM ) α = TrN(M−1) eL(1−Tr (13) Eq. (13) has three parameters, L, M and N. These parameters are unique to each component and are determined from the regression of pure component vapor pressure data. Table 1 lists the L, M and N parameters for TEG and water for use with the TST equation of state in this paper. The values of L, M and N for N2 , CO2 , H2 S and light hydrocarbons in natural gas from methane to n-decane are also included in the table for future applications. The TST zero-pressure mixing rules for the mixture a and b parameters are ∗ E E A a A 1 0 a∗ = b∗ vdw + − 0vdw (14) ∗ bvdw Cr RT RT b = bvdw (15) The parameters a* and b* in Eq. (14) are defined as a∗ = Pa R2 T 2 (16) b∗ = Pb RT (17) 216 C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 Table 1 L, M and N parameters of Twu α function with the TST CEoS ID Component Tc (K) Pc (kPa) L M N 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 TEG H2 O N2 CO2 H2 S CH4 C2 C3 NC4 NC5 NC6 NC7 NC8 NC9 NC10 769.50 647.13 126.20 304.21 373.53 190.564 305.32 369.83 425.12 469.70 507.60 540.20 568.70 594.60 617.70 3320.00 22055.00 3400.00 7383.00 8962.90 4599.00 4872.00 4248.00 3796.00 3370.00 3025.00 2740.00 2490.00 2290.00 2110.00 0.196667 0.430058 0.0649944 0.945951 0.231877 0.0813821 0.147335 0.172517 0.515633 0.385772 0.119904 0.658164 0.486147 0.477371 0.436564 0.863521 0.870932 0.892385 0.888652 0.784346 0.905296 0.879706 0.879570 0.846523 0.817594 0.858552 0.829578 0.809629 0.796573 0.800707 5.10947 1.67211 2.34000 0.65000 1.12000 2.13000 1.98500 2.20000 1.02632 1.35710 3.17252 1.11729 1.49823 1.58848 1.82508 Note that the temperature-independent van der Waal’s mixing rule bvdw is used for the b parameter in Eq. (15). The expression of bvdw is given below in Eq. (22). The TST zero-pressure mixing rules assume that AE0vdw , the excess Helmholtz energy of van der Waal’s fluid at zero pressure, can be approximated by AE∞vdw , the excess Helmholtz energy of van der Waal’s fluid at infinite pressure: ∗ a∗ AE∞vdw avdw AE0vdw i = (18) xi ∗ = C1 ∗ − RT RT bvdw bi i With this assumption, the zero-pressure mixing rule transitions smoothly to the conventional van der Waal’s one-fluid mixing rule. The C1 in Eq. (18) is a constant and is defined as 1 1+w C1 = − ln (19) (w − u) 1+u where u and w are equation-of-state-dependent constants used to represent a general two-parameter cubic equation of state. For the TST equation of state, u is 3 and w is −0.5 as shown in Eq. (8). Cr in Eq. (14) is a function of a parameter r, which is the reduced liquid volume at zero pressure: r+w 1 Cr = − ln (20) w−u r+u The value of r = 1.18 is recommended by Twu et al. [12]. Using r = 1.18, Cr = −0.518850 is used in this work. AE∞ and AE0 in above equations are the excess Helmholtz free energies at infinite pressure and zero pressure, respectively. The subscript vdw in AE∞vdw and AE0vdw denotes that the properties are evaluated from the cubic equation of state using the van der Waal’s mixing rule for its a and b parameters, avdw and bvdw : √ avdw = xi xj ai aj (1 − kij ) (21) i j bvdw = i xi xj j 1 (bi + bj ) 2 (22) Since AE0 in these equations is at zero pressure, its value is identical to the excess Gibbs free energy GE at zero pressure. Therefore, any activity model such as the NRTL equation can be used directly for the excess Helmholtz free energy expression AE0 in Eq. (14). The TST zero-pressure mixing rule assumes that the excess Helmholtz free energy of the van der Waal’s fluid (AE0vdw , Eq. (18)) is independent of pressure. This approximation is required to allow a smooth transition to the conventional van der Waal’s one-fluid mixing rule. Therefore, a binary interaction parameter kij is introduced in Eq. (21) to correct for this approximation. In this work, kij is not needed to adequately fit the TEG–water VLE data and is set equal to zero. Twu et al. [7,8] proposed a multi-component equation for a liquid activity model for use in the TST excess energy mixing rules: n n GE j xj τji Gji = xi n (23) RT k xk Gki i Eq. (23) has the same functional form as the NRTL equation, but there is a fundamental difference between them. NRTL assumes that Aij , Aji and αij are the parameters of the model, but the excess Gibbs energy model proposed by Twu et al. [7,8] assumes that τ ij and Gij are the binary interaction parameters. More importantly, any appropriate temperaturedependent function can be applied to τ ij and Gij . For example, to obtain the NRTL model, τ ji and Gji are calculated as usual from the NRTL parameters Aji , Aij and αji : τji = Aji T Gji = exp(−αji τji ) (24) (25) In this way, the NRTL parameters reported in the DECHEMA Chemistry Data Series can be used directly in our mixing C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 Table 2 Binary interaction parameters for use in TST zero-pressure mixing rule Binary TEG(1)/H2 O(2) A12 A21 B12 B21 α12 −141.490 158.166 0.254489 5.83380 0.278879 rule and there is no difference between NRTL model and our model in the prediction of phase equilibrium calculations. We also note that Eq. (23) can recover the conventional van der Waal’s mixing rules when the following expressions are used for τ ji and Gji : τji = Gji = 1 2 δij bi C1 δij = − RT (27) √ √ √ √ 2 aj ai ai aj − + 2kij bi bj bi bj (28) Eqs. (26) and (27) are expressed in terms of cubic equation of state parameters ai and bi , and the binary interaction parameter kij . The above discussion demonstrates that Eq. (23) is more generic in its form than the NRTL model. Both the NRTL and van der Waal’s one-fluid mixing rule are special cases of our excess Gibbs free energy function. 3. Correlation of activity coefficients The TST equation of state and mixing rules described in the previous section are used to correlate the infinite dilution activity coefficient data of Parrish et al. [2] and the finiteconcentration activity coefficients of Herskowitz and Gottlieb [4]. To cover the entire application range of temperature, Eq. (24) is modified to include a temperature-dependent binary interaction parameter Bji as follows: τji = Table 3 Comparison of Parrish et al. [2] measured infinite dilution activity coefficients of water (2) in TEG (1) solution with those calculated using TST CEoS and Parrish’s hyperbolic equation T (K) γ2∞ (measured) This work γ2∞ 300.43 311.71 323.26 333.76 343.43 355.93 364.93 378.32 AAD% 0.5510 0.575 0.5900 0.6170 0.6240 0.6360 0.6690 0.6920 (calc.) 0.5565 0.5773 0.5979 0.6159 0.6318 0.6515 0.6651 0.6845 Parrish et al. [2] Devi% γ2∞ (calc.) Devi% 0.99 0.41 1.34 −0.19 1.25 2.44 −0.58 −1.08 0.5587 0.5826 0.6072 0.6296 0.6503 0.6772 0.6966 0.7257 1.40 1.32 2.91 2.04 4.21 6.47 4.13 4.87 1.03 3.42 (26) bj bi where 217 Aji + Bji T T error of ±1.03%. Parrish’s model systematically overpredicts the data with a positive average error of +3.42%. Fig. 1 also indicates that Eq. (2) represents data at low temperatures better than those at higher temperatures. The TST EoS, on the other hand, more accurately fits the data over the entire temperature range. Table 4 shows the finite-concentration activity coefficients of water in TEG measured by Herskowitz and Gottlieb as functions of temperature and composition. For comparison, the table again includes results from this work and those using Eq. (2). Data in Table 4 are also shown graphically in Fig. 2. Reviewing Fig. 2, it is observed that the data of Herskowitz and Gottlieb are not quite consistent with the data of Parrish. Due to the curvature of Herskowitz data, the extrapolation to water mole fraction of zero (i.e., TEG mole fraction of 1.0) will give infinite dilution activity coefficients of water in TEG of about 0.65 at 297 K. This is much larger than the infinite dilution activity coefficient data of Parrish at the same temperature (<0.55). Since both the TST EoS and Eq. (2) fit the infinite dilution activity coefficient data well, the fit to Herskowitz and Gottlieb data at high TEG concentration is quite (29) where T is the temperature in K. The unit of Aji is in K and Bji is dimensionless. Table 2 lists the values of the binary interaction parameters Aij , Aji , Bij , Bji and αij obtained for the TEG–water system. Table 3 compares measured and calculated infinite dilution activity coefficients of water in TEG as a function of temperature. Also shown in the table are the infinite dilution activity coefficients calculated from Parrish’s empirical hyperbolic equation (Eq. (2)) for comparison. Data in Table 3 are also shown graphically in Fig. 1. Results shown in Table 3 and Fig. 1 indicate that the TST equation of state can accurately correlate the infinite dilution activity coefficients of water in TEG covering a wide range of temperature with an average Fig. 2. Activity coefficient of water vs. liquid mole fraction TEG. Exp., Herskowitz and Gottlieb [4]: () T = 297.6 K, () T = 332.6 K; (—) this work; (- - -) Parrish et al. [2]. 218 C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 Table 4 Comparison of Herskowitz and Gottlieb [4] measured activity coefficients of water (2) in TEG (1) solution with those calculated using TST CEoS and Parrish’s hyperbolic equation T (K) X (1) γ 2 (measured) This work γ 2 (calc.) Devi% γ 2 (calc.) Devi% 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 297.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 332.60 0.8062 0.7838 0.6731 0.6731 0.5809 0.5449 0.5001 0.4967 0.3996 0.3898 0.3057 0.2505 0.2187 0.1894 0.1657 0.1575 0.1157 0.1077 0.1051 0.1026 0.0657 0.0641 0.0549 0.0541 0.7039 0.5107 0.4970 0.4562 0.3759 0.3614 0.2886 0.2853 0.2429 0.1993 0.1562 0.1212 0.1170 0.0808 0.0796 0.0454 0.6604 0.6640 0.6760 0.6871 0.7062 0.7201 0.7407 0.7371 0.7823 0.7876 0.8264 0.8608 0.8784 0.8994 0.9177 0.9225 0.9507 0.9526 0.9542 0.9563 0.9802 0.9811 0.9836 0.9866 0.8022 0.8215 0.8504 0.8571 0.8839 0.8901 0.9088 0.9133 0.9276 0.9451 0.9641 0.9767 0.9768 0.9893 0.9897 0.9980 0.6299 0.6394 0.6875 0.6875 0.7290 0.7456 0.7664 0.7680 0.8138 0.8184 0.8585 0.8849 0.9000 0.9139 0.9252 0.9292 0.9494 0.9534 0.9547 0.9559 0.9745 0.9753 0.9799 0.9803 0.7254 0.8029 0.8085 0.8252 0.8581 0.8640 0.8934 0.8947 0.9115 0.9283 0.9447 0.9580 0.9596 0.9737 0.9741 0.9877 −4.62 −3.71 1.71 0.06 3.23 3.54 3.47 4.19 4.02 3.91 3.89 2.80 2.46 1.62 0.82 0.72 −0.13 0.08 0.05 −0.04 −0.58 −0.59 −0.37 −0.63 −9.58 −2.26 −4.93 −3.72 −2.92 −2.93 −1.69 −2.03 −1.74 −1.77 −2.01 −1.91 −1.76 −1.58 −1.57 −1.04 0.6255 0.6338 0.6742 0.6742 0.7078 0.7210 0.7378 0.7390 0.7777 0.7819 0.8220 0.8545 0.8765 0.8994 0.9198 0.9272 0.9649 0.9716 0.9736 0.9756 0.9957 0.9961 0.9980 0.9982 0.7597 0.8611 0.8687 0.8911 0.9328 0.9397 0.9686 0.9697 0.9811 0.9889 0.9937 0.9963 0.9966 0.9984 0.9984 0.9995 −5.28 −4.55 −0.26 −1.87 0.22 0.13 −0.40 0.26 −0.58 −0.72 −0.53 −0.74 −0.22 0.00 0.23 0.51 1.50 1.99 2.04 2.01 1.58 1.53 1.47 1.17 −5.30 4.82 2.15 3.97 5.54 5.57 6.58 6.17 5.77 4.64 3.07 2.01 2.02 0.92 0.88 0.15 AAD% poor. The predicted trend from the two correlations as the mole fraction of TEG approaches unity will be very different from what this set of experimental data would suggest. Fig. 2 also indicates that Eq. (2) was fitted preferentially to the data at 297.6 K while the fit to the data at 332.6 K is significantly poorer. The TST EoS is less accurate at 297.6 K, but is more accurate at the higher temperature of 332.6 K. Another important observation can be made from Fig. 2. The TST EoS predicts slightly lower activity coefficients than the experimental data at higher temperature. On the other hand, Parrish’s model predicts higher activity coefficients at higher temperature. This difference in the predicted trend can have significant consequences in the extrapolation of activity coefficients to high temperatures. To test the ex- Parrish et al. [2] 2.27 2.23 trapolation capability, both the TST equation of state and the Parrish model are extrapolated to 204 ◦ C (477.15 K). The ability to extrapolate the model to high temperatures to predict accurate activity coefficients is quite important for stripping processes. Ref. [6] reports that at 204 ◦ C (477.15 K) and 1.2 atm (121.59 kPa), experience shows approximately 1.2 wt.% water in the lean glycol. The TST equation of state predicts 1.2 wt.% of water in the lean glycol at 477.15 K under pressure of 123.91 kPa, which is very close to the observed 121.59 kPa, a deviation of only 1.91%. This result corresponds to a water activity coefficient of approximately 0.7960 at 204 ◦ C. At the same temperature of 204 ◦ C, the Parrish model gives a value of 0.9477 for the water activity coefficient. This activity coefficient value will predict a pres- C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 sure well over the expected value of 121.59 kPa. The TST EoS provides a clear advantage to the use of Eq. (2) because it can (1) accurately correlate the infinite dilution activity coefficients data over a wide temperature range, (2) correlate finite concentration activity coefficients data with reasonable accuracy and (3) extrapolate well to higher temperatures. 4. Prediction of water dew point and water content VLE data for TEG–water system commonly are represented as charts of water dew point lines as a function of contactor temperature and liquid TEG concentrations [3]. The water dew point is the dew point of the gas, Td , which would be obtained if the gas were brought to equilibrium with the TEG solution at the contactor temperature, T. In this work, the TST equation of state is used to predict the water dew point and the water content of the TEG–water system as an alternative to using the water dew point charts [3]. At phase equilibrium, the fugacities of TEG and water in the liquid and vapor phases are the same: L V fTEG = fTEG (30) fwL = fwV (31) where fi is the fugacity of component i in the solution. The fugacity of component i is calculated from the TST equation of state presented in this work. Assuming that the liquid compositions and the system temperature, T, are known, Eqs. (30) and (31) can be used to determine the equilibrium pressure P and vapor-phase compositions. In the context of gas dehydration, the equilibrium temperature T is referred to as the contact temperature (temperature of the top tray of the contactor). The vapor mixture at the contact temperature is at its dew point. However, the specification for the equilibrium vapor in gas dehydration is normally in term of its water dew point (Td ), i.e. the temperature at which pure liquid water may condense out of the gas phase. One can view this temperature as a hypothetical temperature. In order to compute Td , TEG is excluded from the gas phase during the dew point temperature calculation. Since it is assumed that the first drop of liquid condensed from the vapor at the water dew point is pure water, we have fw0L (Td ) = fwV (Td ) (32) where fw0L (Td ) is the liquid fugacity of pure water at the water dew point temperature Td and equilibrium pressure P and fwV (Td ) the vapor fugacity of water in the mixture without TEG at the dew point temperature Td , equilibrium pressure P and equilibrium vapor-phase compositions yi . Note that when the dew point temperature is below the triple point of water, 273.16 K, the condensed phase is either solid ice or subcooled water. Following the work of Parrish et al. [2], subcooled water was used as the standard state fugacity in this work. The equilibrium P and yi are solved from Eqs. 219 (30) and (31) as discussed above. Rewrite Eq. (32) as 0L V (Td ) = fwV (Td ) = yw Pφw (Td ) fw0L (Td ) = Pφw (33) or yw = 0L (T ) φw d V (T ) φw d (34) where yw is the vapor mole fraction of water (without TEG) in equilibrium with the TEG solution at equilibrium temperature (contact temperature) T. The vapor and liquid fugacity coefficients of water are calculated using the TST equation of state at Td and at the equilibrium pressure P. Since TEG is removed from the gas mixture when the water dew point is performed, the vapor mole fraction of water is normalized to give yw = 1.0 in this case. Eq. (34) is used to solve for the water dew point temperature Td . After that, the liquid fugacity of pure water at Td , fw0L (Td ), can then be calculated from the equation of state. When the value of fw0L (Td ) at the water dew point temperature Td is obtained, the water content in lbH2 O /MMSCF at standard condition of T0 = 60 ◦ F (288.71 K) and the equilibrium pressure P can be calculated from the following equation: P n (35) = V Z0 RT0 where Z0 is the gas compressibility factor at T0 and P, and n the number of moles in vapor volume V. The number of moles of water, nw , in the vapor then becomes P nw = yw V Z0 RT0 (36) where yw is the mole fraction of water in the gas phase without TEG. Rewrite Eq. (36) using Eq. (33) and assuming that the vapor fugacity coefficient of water is 1.0, nw yw P fwV = ≈ V Z0 RT0 Z0 RT0 (37) Substituting Eq. (32) into Eq. (37), we obtain nw fw0L = V Z0 RT0 (38) Given T0 = 60 ◦ F (288.71 K), the gas constant R and assuming Z0 = 1.0, we obtain the water content in lbH2 O /MMSCF in terms of fw0L (Td ) at the water dew point temperature Td , Water content in lbH2 O /MMSCF = 222 72.23fw0L (Td ) (39) The water content in SI units is expressed in kg/106 scm: Water content in kg/106 scm = 356 765.00fw0L (Td ) (40) where fw0L (Td ) is in the pressure unit of kPa. Since the water content of lbH2 O /MMSCF is commonly used in the US and in the field, this unit is used in Table 6. The typical application range is shown in Tables 5 and 6. Table 5 shows the prediction of the water dew point temperatures of vapor in equilibrium with TEG solutions from the 220 C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 Table 5 Prediction of the water dew point temperature of vapor containing TEG and water in equilibrium with TEG solutions from TST equation of state and prediction from GPSA recommended model 99.97 wt.% TEG Contact temperature (K) Water dew points of vapor (K) GPSA TST 277.59 288.71 299.82 310.93 322.04 333.15 344.26 208.15 208.86 214.26 214.99 220.37 221.00 225.93 226.91 232.04 232.74 237.59 238.52 243.15 244.30 277.59 288.71 299.82 310.93 322.04 333.15 344.26 232.04 232.66 239.82 240.47 247.59 248.16 255.93 255.75 263.15 263.22 270.93 270.58 278.71 277.84 99.50 wt.% TEG Contact temperature (K) Water dew points of vapor (K) GPSA TST tact temperature at various TEG concentrations ranging from 95.00 to 99.99 wt.% TEG. The result from the TST equation is quite interesting because it illustrates that the water dew point is a linear function of the contact temperature at a constant wt.% of TEG. This plot is similar to those presented in Refs. [2,3] and is useful for practical use in estimating the water dew point without actually solving the equation of state. 5. Conclusions The TST cubic equation of state has been developed successfully to represent the TEG–water binary, which is an industrial important system for modeling TEG gas dehydration. This work is an improvement over the empirical hyperbolic equation of Parrish et al. We also present a methodology for using the TST equation of state to calculate water dew point and water content in natural gas systems. The infinite-dilution and finite-concentration activity coefficients of water in TEG, water dew point temperatures and water content over the entire application range of temperature, pressure and composition encountered in a typical TEG dehydration unit predicted from the TST equation of state match the reported data very closely. Fig. 3. Equilibrium water dew point vs. contact temperature at various TEG concentrations in wt.%. TST equation of state. The water dew points from GPSA are also included for comparison. Both GPSA and TST equation of state predict very similar water dew point temperatures, generally within 1 K. Table 6 shows the equilibrium water content in lbH2 O /MMSCF gas in equilibrium with 99.50 wt.% TEG. The results predicted from the TST equation of state are compared with the reported data [13,14], which cover the range of temperature from 222 to 277 K. The predicted water content from the equation of state model agrees with the reported data very closely over the entire range of temperature. The calculated equilibrium pressure is also included in Table 6. Fig. 3 presents the water dew point predicted from the TST equation of state developed in this work as a function of con- List of symbols a, b cubic equation of state parameters A Helmholtz energy Aij , Aji , Bij , Bji NRTL binary interaction parameters Table 6 Prediction of the equilibrium water content in lbH2 O /MMSCF from TST equation of state in equilibrium with 99.50 wt.% TEG T dew (K) Reported by Predicted from TST equation of state McKetta and Wehe [13] Bukacek [14] Water content Pressure (Pa) 277.59 266.48 255.37 244.26 233.15 222.04 390 170 70 28 9.2 2.4 396 176 72 27 9.1 2.8 393 174 71 26 9 2.6 838.0 370.0 151.0 56.1 18.7 6.0 C.H. Twu et al. / Fluid Phase Equilibria 228–229 (2005) 213–221 Cr C1 G kij L, M, N P r R T xi yi defined in Eq. (20) defined in Eq. (19) Gibbs energy binary interaction parameter parameters in the Twu’s α function pressure reduced liquid volume gas constant temperature liquid mole fraction of component i vapor mole fraction of component i Greek letters α cubic equation of state alpha function αij NRTL binary interaction parameters γi activity coefficient of component i characteristic of the interaction between molecules δij i and j φi the fugacity coefficient of component i in the mixture ∞ infinite pressure Subscripts c critical property i, j property of component i, j ij interaction property between components i and j vdw van der Waals 0 zero pressure Superscripts * reduced property E excess property L V 221 liquid phase vapor phase References [1] J.R. Cunningham, J.E. Coon, C.H. Twu, Estimation of aromatic hydrocarbon emissions from glycol dehydration units using process simulation, in: Proceedings of the 72nd Annual Gas Processors Association Convention, San Antonio, TX, March 15–17, 1993. [2] W.R. Parrish, K.W. Won, M.E. Baltatu, Phase behavior of the triethylene glycol–water system and dehydration/regeneration design for extremely low dew point requirements, in: Proceedings of the 65th Annual GPA Convention, San Antonio, TX, March 10–12, 1986. [3] GPSA Engineering Data Book, Tenth Edition, First Revision, Gas Processors Suppliers Association, Tulsa, OK, 1994. [4] M. Herskowitz, M. Gottlieb, J. Chem. Eng. Data 29 (1984) 173–175. [5] B. Bestani, K.S. Shing, Fluid Phase Equilib. 50 (1989) 209–221. [6] GPA Editorial Review Board, Recent developments in gas dehydration and hydrate inhibition, in: Proceedings of the Laurance Reid Conference, Norman, Oklahoma, 1994. [7] C.H. Twu, W.D. Sim, V. Tassone, Fluid Phase Equilib. 65–74 (2001) 183–184. [8] C.H. Twu, W.D. Sim, V. Tassone, Fluid Phase Equilib. 194–197 (2002) 385–399. [9] G. Soave, Chem. Eng. Sci. 27 (1972) 1197–1203. [10] D.Y. Peng, D.B. Robinson, Ind. Eng. Chem. Fundam. 15 (1976) 58–64. [11] C.H. Twu, D. Bluck, J.R. Cunningham, J.E. Coon, Fluid Phase Equilib. 69 (1991) 33–50. [12] C.H. Twu, J.E. Coon, D. Bluck, B. Tilton, M. Rowland, Fluid Phase Equilib. 153 (1998) 39–44. [13] J.J. McKetta, A.H. Wehe, GPA Engineering Data Book Fig. 15-10, Ninth Edition, Fourth Revision, Gas Processors Suppliers Associations, Tulsa, OK, 1979. [14] R.F. Bukacekm, Equilibrium moisture content of natural gases, Research Bulletin 8, Institute of Gas Technology, Chicago, IL, 1955.