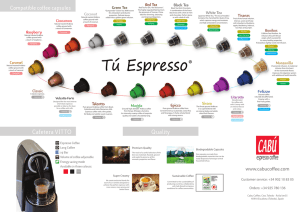

Equilibrium Data for the Extraction of Coffee and Sunflower Oils with Ethanol Dados de Equilíbrio para o Processo de Extração de Óleos de Café e Girassol Usando Etanol AUTORES AUTHORS Suely Pereira FREITAS Universidade Federal do Rio de Janeiro Escola de Química Ilha do Fundão, Cidade Universitária Bloco E, Sala 207 CEP: 21949-900 Rio de Janeiro/RJ - Brasil e-mail: freitasp@eq.ufrj.br Regina Celi Araujo LAGO Embrapa Agroindústria de Alimentos e-mail: lago@ctaa.embrapa.br SUMMARY The extraction of vegetable oils using ethanol may be a good solution for countries where small oil mills are economically feasible. Furthermore, ethanol is environmentally more attractive than hexane. In this work, experimental solid-liquid equilibrium data for vegetable oil extraction with ethanol have been investigated as a function of the oil content in the raw material and the sample to ethanol mass ratio. The maximum solute concentrations obtained in the micelle were 11.4 and 18.6%, respectively, for coffee and sunflower oils. These results are inferior to the typical values of between 20 and 30% obtained with the countercurrent flow processes used in the food industry, with hexane as the solvent. To estimate the theoretical stages, the tie lines can be ascertained using the distribution curves and solubility diagrams simultaneously. RESUMO A extração de óleos vegetais com etanol pode ser uma solução potencial para os países onde a operação de usinas comerciais de pequeno porte é economicamente viável. Além disso, do ponto de vista ambiental, o etanol é um solvente mais atraente que o hexano. Neste trabalho, os dados de equilíbrio para extração de óleos vegetais com etanol foram avaliados em função do teor de óleo na matéria-prima e da relação solvente/substrato. A concentração máxima de soluto na micela foi de 11,4 e 18,6% para extração dos óleos de café e girassol, respectivamente. Estes resultados são inferiores aos valores típicos, entre 20 e 30%, alcançados para o processo de extração contínua em fluxo contra-corrente, usado nas usinas comerciais de extração de óleos vegetais com hexano. As linhas de amarração, para cálculo do número de estágios teóricos, podem ser construídas usando-se, simultaneamente, as curvas de distribuição e os diagramas de solubilidade. PALAVRAS-CHAVE KEY WORDS Solid-liquid extraction; Equilibrium data; Ethanol; Oleaginous seeds; Coffee oil; Sunflower oil. Extração sólido-líquido; Dados de equilíbrio; Etanol; Óleo de café; Óleo de girassol. Autor Correspondente Corresponding Author Braz. J. Food Technol., Campinas, v. 10, n. 3, p. 220-224, jul./set. 2007 220 Recebido/Received: 22/12/2005. Aprovado/Approved: 05/11/2007. FREITAS, S. P. e LAGO, R. C. A. 1. INTRODUCTION The vegetable oil processing industry continues to expand. Today, about thirteen vegetable oils have been used for industrial food formulations around the world, specially from soybean, palm, rapeseed, sunflower, cottonseed and peanut. Vegetable oils have been conventionally obtained combining pressing and organic solvents extraction. From those hexane-based extractions, it is possible to achieve oil yields greater than 95% (JOHNSON and LUSAS, 1983). In the last years, the authorities have become more and more aware of the environmental matters concerning the use of large amounts of toxic organic solvents. As a result, disposal regulations have become very strict and, as a consequence, processing costs increased. In many countries, most toxic organic solvents have already been banned in food processing. Thus, in developing safer processes, the substitution of hexane has been highly recommended (EPA, 2000). The potential use of ethanol for vegetable oil extraction has already been investigated (FREITAS et al., 2001; RITTNER, 1991; RAO et al., 1955). As ethanol is derived from a renewable source it is regarded as an environmentally cleaner solvent. So, ethanol may represent a good alternative for countries in which small oils mills are economically feasible and where ethanol availability turns less expensive than hexane. The use of ethanol for green coffee and sunflower oil extraction has been previously studied on bench scale (KOHL et al., 2003; FREITAS et al., 2001). In those works, the following independent variables were considered: extraction temperature, sample to ethanol ratio, moisture present in the seeds and particle size. Extraction kinetics showed that the highest yields have resulted with incubation time of 20 and 40 min, respectively to green coffee and sunflower oils. Time increasing up to 60 min had small influence on extraction yield. The optimized conditions for these processes for coffee beans and sunflower seeds, respectively, have been determined: temperature of 75 and 70 °C, particle size inferior to 1.0 and 1.7 mm, sample to ethanol ratio 1:3 and moisture of the seed inferior to 3%. Under these conditions, the amount of solute obtained was higher than the lipids fraction extracted with petroleum-ether. According to the authors, extraction temperatures above 70 °C have probably favored wax removal by ethanol. The extraction mechanism is a combination of diffusion and mixing of soluble material in the solvent. The distribution relationship in solid-liquid extraction depends mainly on the temperature and the chemical nature of the species involved. At about 85 °C, above the boiling point of ethanol at atmospheric pressure (78 °C), vegetable oils are totally miscible with ethanol. As a consequence, the solubility of oil in ethanol at temperatures below 78 °C becomes the limiting extraction parameter, requiring greater solvent to sample ratio than the hexane-based process, which seems to be controlled by diffusion. According to Rittner (1991), ethanol as a solvent is compatible with the equipment currently used in vegetable oils industries and would require minor changes in operating conditions and plant layout to be implemented on a large scale. To enhance oil solubility, the extractor can be operated at pressures slightly superior to atmospheric (20 to 30 psig) and temperature about 85 °C. The equilibrium condition between the cake (raffinate phase) and miscella (solvent phase) is a very important aspect of vegetable oil extraction. Solid-liquid equilibrium data is necessary for both design and process simulation of extractors used in Braz. J. Food Technol., Campinas, v. 10, n. 3, p. 220-224, jul./set. 2007 Equilibrium Data for the Extraction of Coffee and Sunflower Oils with Ethanol food industry. Until now, no expressive data are available in the literature concerning ethanol-based vegetable oil extractions. In this work, solid-liquid equilibrium results for coffee and sunflower oils extraction with ethanol 99.2% are presented. In order to obtain equilibrium data, the effects of sample to ethanol mass ratio were evaluated. 2. MATERIAL AND METHODS Commercial Robusta coffee beans, commercial sunflower seeds and ethanol 99.2% were used. Oil content in the samples was determined using petroleum ether 30-60 °C, after 16 h of reflux, in a Butt type extractor (AOCS, 1996). Proximate composition was determined according to AOAC methods (AOAC, 1995). Ethanol extracts obtained were filtered and fatty acid composition was determined by gas chromatography of methyl esters prepared according to Hartman and Lago (1973). The fatty acid analysis of oils was performed on a HP5890 gas chromatography equipped with a fused silica capillary column SP2340 (60 m x 0.32 mm x 0.25 µm). The temperature program was 150 up to 200 °C at a rate of 1.3 °C/min. Sample dilution was 2%, the volume injected was 1 µL and the carrier gas was H2 at 2.5 mL/min. The samples were ground in a pilot hammer mill. Green coffee beans and sunflower seeds with size particle ranges of 0.5 mm < d < 1.0 mm and 0.85 mm < d < 1.70 mm, respectively, were selected. Due to high oil content in the sunflower seed (about 45%) particle size reduction below 0.85 mm led to oil loss in the milling. In order to enhance the efficiency of the ethanol extraction process, the initial moisture of all samples was reduced to 3% in a tray dryer with hot air flow at 60 °C. 2.1 Extraction experiments and concentrations at equilibrium The sample and ethanol were placed in an erlenmayer flask and maintained in a temperature-controlled bath under continuous stirring to homogenize the mixture. The mixture, after 16 h, was filtered under vacuum through filter paper and both fractions, miscella and cake, were weighed. The ethanol in the miscella was removed in a rotary evaporator while the solvent retained in the cake was removed at 60 °C in an oven with hot air flow. The yield of lipid extraction and solute concentration in both phases at equilibrium was correlated, at 70 and 75 °C, with mass ratios of sample to solvent. The maximum amount of solute (Mo), present in both samples, was determined using ethanol at infinite dilution (solvent to sample mass ratio as 20:1). The equilibrium data were recorded by macroscopic mass balance of the solute in the cake and miscella phases. 3. RESULTS AND DISCUSSION The proximate composition of commercial Robusta green coffee beans and sunflower seeds, given in Table 1, was similar to the values reported in the literature (FOLSTAR, 1985; MACRAE, 1993; HARTMAN et al., 1999). The fatty acids composition of coffee extracts consisted of saturated and unsaturated acids while fatty acids of sunflower extracts were predominantly unsaturated acids (Table 2). The results 221 FREITAS, S. P. e LAGO, R. C. A. Equilibrium Data for the Extraction of Coffee and Sunflower Oils with Ethanol TABLE 1. Proximate composition of Robusta coffee and sunflower seeds [g.100 g–1]. Oil Protein Moisture Total ash Starch Crude fibre Carbohydrates** Commercial Robusta coffee* 10.50 ± 0.15 13.53 ± 0.04 11.40 ± 0.17 3.63 ± 0.08 3.14 ± 0.04 14.49 ± 0.60 - Literature data1 9.00 to 12.60 11.00 to 15.60 10.20 to 11.00 4.20 18.50 - Sunflower seeds* 44.34 ± 0.62 23.04 ± 0.28 5.40 ± 0.001 3.75 ± 0.35 nd nd 23.47 Literature data2 47.83 to 54.80 18.34 to 22.16 4.41 to 5.87 3.06 to 3.69 1.97 to 2.32 15.47 to 19.83 Sunflower oil* 5.25 ± 0.19 3.79 ± 0.49 33.57 ± 0.51 56.11 ± 1.47 traces traces 1.00 ± 0.02 Literature data2 4.88 to 5.41 2.97 to 4.41 32.55 to 41.67 46.54 to 56.11 0.11 to 0.20 0.27 to 0.39 0.82 to 0.99 1 Trugo (2001) and Folstar (1985); 2 Hartman (1999). nd - no determined *Average of three replicates ± standard deviation. **by difference. TABLE 2. Fatty acids composition of coffee and sunflower oils (%). Fatty acids C16:0 C18:0 C18:1 C18:2 C18:3 C20:0 C22:0 Coffee oil* 32.26 ± 2.15 7.76 ± 0.40 11.21 ± 0.89 42.69 ± 2.43 1.17 ± 0.14 2.92 ± 0.32 traces Literature data1 32.1 to 33.2 7.5 to 8.2 8.2 to 12.5 42.6 to 46,2 0.9 to 1.4 2.6 to 3.3 - *Average of three replicates ± standard deviation; 1Folstar (1985); 2Hartman et al. (1999). obtained are in agreement with the literature data for coffee and sunflower oils extracted with petroleum-ether (FOLSTAR, 1985; HARTMAN et al., 1999). Figure 1 presents extraction yields (M/Mo) of coffee and sunflower oils as a function of sample to ethanol mass ratio. M is the amount of solute extracted at equilibrium and Mo is the amount of solute present in the raw material. At the same sample to solvent mass ratio, the coffee oil yield is higher than that of sunflower oil. That fact is due to higher oil content present in the sunflower seeds (44.3%) than in the coffee beans (10.5%) promoting the faster ethanol saturation in the first case. M/Mo (%) The equilibrium diagrams are presented in Figures 2 and 3 for the system: solute (a) + inert (b) + solvent (c). Equilibrium is reached when the maximum amount of solute is transferred to the solvent phase. The concentration in the two phases expressed as mass ratio (X for the raffinate phase and Y for the solvent phase) is defined on an inert free basis (GEANKOPLIS, 2003): ma mb Xa = Xb = m + m a m a +mc cake c cake 100 90 ma mb Ya = Yb = ma + mc miscella ma + mc miscella 80 70 60 50 As expected, the equilibrium yield M/Mo decreases if the sample to solvent mass ratio increases. On the order hand, the miscella retained in the cake increases as the sample to solvent mass ratio increases and higher is the oil loss remaining with in the cake (Figure 2 and 3). The results shown are in accordance with the findings of Dibert et al. (1989). 10 20 30 40 50 Sample/ethanol ratio (% w/w) 60 green coffee (0.5 mm <d<1 mm) sunflower (0.8 mm <d <1.7 mm) FIGURE 1. Coffee and sunflower oil yield as a function of sample/ ethanol mass ratio at equilibrium. M - amount of solute extracted at equilibrium; Mo - amount of solute in the sample. Braz. J. Food Technol., Campinas, v. 10, n. 3, p. 220-224, jul./set. 2007 where mi represents the mass of component i in equilibrium (DIBERT et al., 1989). For both samples, the distribution curve, Xa= f(Ya), has shown that the cake (a porous media) has a higher concentration of solute than the solvent phase (miscella), due to the low solubility of solutes in ethanol at 70 and 75 °C and also to the adsorption of solute on the solid matrix. For both samples, complete oil extraction was reached for sample to ethanol mass ratio of up to 0.05. In this case, on an inert free basis, the miscella has the same solute concentration than the cake, (Ya = Xa) as can be observed in Figures 3 and 4. As sample to ethanol mass ratio increases, the cake presents a higher concentration of solute component than the miscella due to low oil yield. As a consequence, the experimental data in the distribution curve deviate from the diagonal line (X = Y). The auxiliary lines, shown in 222 FREITAS, S. P. e LAGO, R. C. A. Solubility diagram: coffe oil in ethanol at 75 °C; 0.5 < dp < 1 mm 3.50 1.00 3.00 0.80 2.50 Xb Xb 1.20 Solubility diagram of sunflower oil in ethanol at 70 °C; 0.85 < dp < 1.7 mm 0.60 2.00 1.50 0.40 1.00 0.20 0.00 0.00 0.50 0.05 0.10 0.15 0.20 Xa or Ya 0.25 0.30 0.35 0.00 0.00 0.40 0.05 0.08 Xa or Ya 0.10 0.13 0.15 0.40 0.40 0.35 0.30 0.30 0.25 Xa 0.35 0.25 Xa 0.03 Distribution curve: coffe oil in cake (Xa) and miscella (Ya) at 75 °C; 0.5 < dp < 1 mm Distribution curve: sunflower oil in cake (Xa) and miscella (Ya) at 70 °C; 0.85 < dp < 1.7 mm 0.20 0.20 0.15 0.15 0.10 0.05 0.10 0.00 0.00 0.05 0.00 0.00 Equilibrium Data for the Extraction of Coffee and Sunflower Oils with Ethanol 0.05 0.10 0.15 0.20 Ya 0.25 0.30 0.35 0.40 FIGURE 2. Equilibrium data for sunflower oil extraction with ethanol. The diagonal line (dashed line) representing equilibrium diagram where solute is infinitely soluble in solvent. Figures 2 and 3, illustrate the graphical procedure to obtain pairs of points representing the two phases in equilibrium. The maximum solute concentrations in the miscella have been found as 11.4 and 18.6%, respectively to coffee and sunflower oils. The higher value achieved in the last case is due to a higher oil content in the sunflower raw material. These values are greater than the ones reported by Dibert et al. (1989). According to Figures 2 and 3, the inert concentration in the cake, on an inert free basis, depends on the oil content in the raw material. It can be observed that solvent drains better from the coffee beans than from the sunflower seeds, which can be explained by the occurrence of a higher amount of residual oil in the sunflower cake and its smaller porosity. 4. CONCLUSIONS The experimental equilibrium curves presented in this work could be useful in determining the number of theoretical stages on the design of a continuous extraction column. The maximum solute Braz. J. Food Technol., Campinas, v. 10, n. 3, p. 220-224, jul./set. 2007 0.03 0.05 0.08 0.10 0.13 0.15 Ya FIGURE 3. Equilibrium data for coffee oil extraction with ethanol. The diagonal line (dashed line) representing equilibrium diagram where solute is infinitely soluble in solvent. concentrations in the miscella were 11.4 and 18.6%, respectively to coffee and sunflower oils. These results are inferior to typical values (between 20 and 30%) reached from countercurrent flow processes, used in the food industry, having hexane as solvent. As expected, the poor solubility of vegetable oil in ethanol in the temperature range from 70 to 75 °C is the limiting extraction factor. REFERENCES AOAC. Official methods of analysis of the Association of Official Analytical Chemists, 40 ed., (Washington, DC) 1995. AOCS. Official methods and recommended practices of the American Oil Chemists, Society, 4 ed., (Champaign, IL.) 1996. DIBERT, K.; CROS, E.; ANDRIEU, J. Solvent Extraction of Oil and Chlorogenic Acid from Green Coffee: Equilibrium Data. Journal of Food Engineering, England, v. 10, n. 1, p. 1-6, 1989. EPA. Publishes proposed hexane emission rules. Inform, Champaign, IL, v. 11, (suplemento especial), p. 675-676, 2000. FOLSTAR, P. Lipids. In: CLARKE and MACRAE [Ed]. Coffee Chemistry, v. 1, London: Elsevier Applied Science, p. 203-222,1985. 223 FREITAS, S. P. e LAGO, R. C. A. FREITAS, S. P.; GARCIA, T. N.; LAGO, R. C. A. Green coffee oil extraction with ethyl alcohol. In: Proceedings of Lipidex Sudamerica, 2001. Proceedings… Asaga dmg, Buenos Aires (Argentina), 2001, p. 35. GEANKOPLIS, C. J. Transport and Separation Process Principles, 4 ed., New Jersey: Prentice-Hall PTR, 2003, 1026 p. HARTMAN, L.; ANTONIASSI. R.; FREITAS, S. P. Characterization of five sunflower varieties cultivated in Brazil. Boletim do Centro de Pesquisa e Processamento de Alimentos, Curitiba, PR, v. 17, n. 2, p. 145-152, 1999. JOHNSON, L. A.; LUSAS, E. W., Comparison of alternative solvents for oil extraction. Journal American Oil Chemichal Society, Champaign, IL, v. 60, n. 2, p. 181A-191A, 1983. MACRAE, R. Encyclopedia of Food Science: Technology and Nutrition. London: Academic Press, v. 1, 1993. RAO, R. K. et al. Alcoholic extraction of vegetable oils: I. Solubilities of cottonseed, peanut, sesame, and soybean oils in aqueous ethanol. Journal American Oil Chemichal Society. Chicago, v. 32, n. 7, p. 420-423, 1955. RITTNER, H. Extraction of vegetable oils with ethyl alcohol. In: Proceedings of International Meeting on Fats and Oils Technology, FEA/GTZ, 1991. Proceedings… Campinas, 1991, p. 17-26. TRUGO, L. C. Café: Composição Química e Potencial Nutracêutico. In: MERCADANTE, A. Z. et al. [Ed]. Ciência de Alimentos: avanços e perspectivas, v. 2, p. 206-208, Campinas: UNICAMP, 2001. KOHL JR., E. et al. Extração de óleo de girassol com etanol comercial. In: Congresso Iberoamericano de Ingenieria de Alimentos, 4., 2003. Proceedings... Valparaiso (Chile), 2003. p. 152. Braz. J. Food Technol., Campinas, v. 10, n. 3, p. 220-224, jul./set. 2007 Equilibrium Data for the Extraction of Coffee and Sunflower Oils with Ethanol 224