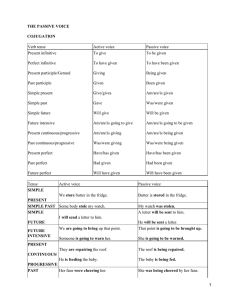

Ocean Engineering 29 (2002) 849–869 www.elsevier.com/locate/oceaneng Strength modelling in stiffened FRP structures with viscoelastic inserts for ocean structures J.I.R. Blake a, R.A. Shenoi a,*, J. House b, T. Turton b a Fluid Structure Interactions Research Group, School of Engineering Science, University of Southampton, Highfield, Southampton, SO17 IBJ, UK b Mechanical Sciences Sector, DERA, Farnborough, Surrey, GU14 OLX, UK Received 4 October 2000; received in revised form 17 May 2001; accepted 3 June 2001 Abstract The purpose of this paper is to investigate the static structural response of a new type of composite stiffener containing a viscoelastic insert. The introduction of this material has proven benefits in terms of noise and vibration attenuation across the joint. House, 1997 describes the use of this material in sonar dome/hull connections — equipment sensitive to noise and vibration. Structural stiffeners incorporating this material would have positive implications for not only marine and ocean structures but for structural applications in general. The effects of introducing this new material on the structural response of the joint are numerically examined by using a progressive damage model. Application of this method allows the initiation and progression of failure and ultimate failure load to be predicted. Experimental results show good qualitative and quantitative agreement with the predictive damage model. 2002 Elsevier Science Ltd. All rights reserved. Keywords: Stiffeners; Progressive damage; Tsai–Hill; Viscoelastic; Finite element analysis; Failure criteria 1. Introduction Fibre-reinforced plastics (FRP) have been used in the marine industry for over 50 years — increasing in popularity in the last 20 years. The main advantages of using FRP over the more traditional materials is down to cost, reduced maintenance and * Corresponding author. Tel.: +44-2380-592316; fax: +44-2380-593299. E-mail address: r.a.shenoi@ship.soton.ac.uk (R.A. Shenoi). 0029-8018/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved. PII: S 0 0 2 9 - 8 0 1 8 ( 0 1 ) 0 0 0 5 7 - 9 850 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 repair, and the ability to form complex shapes. However for larger ocean-going craft and structures, cost of fabrication typically made the use of FRP prohibitive. This is becoming less of an obstacle with improved fabrication techniques and new fibre and resin systems. Longevity and survivability of marine FRP structures are affected by the harsh conditions prevalent in the ocean–environment — effects such as humidity, temperature, impact, wave-slamming loads and cyclic loads. Subsequent damage may take the form of resin cracking, fibre splitting and delamination. Damage in areas that experience high stress concentrations, such as joints and stiffener connections, will dramatically affect the global strength and integrity of the structure (Junhou and Shenoi, 1996). Investigation into the structural performance of joints and stiffeners can therefore provide huge insight into the characterisation of global structural strength. Large fibre-reinforced plastic structures, by necessity of design and production constraints, have a number of in-plane and out-of-plane joints in their topologies. In-plane joints have been the subject of attention of many researchers, for example, Godwin and Matthews (1980) and Matthews et al. (1982), with attention being focused on analytical treatments, numerical analyses, experimental studies, failure criteria and material aspects. Arguably, the more difficult problem is the one that pertains to load transfer between two orthogonally placed members meeting at a joint. One particular example of this type of joint can be seen in a top hat stiffener used to stiffen large spans of unsupported plating in marine structures. The stiffener, illustrated in Fig. 1, is formed by placing laminated strips of reinforcement cloth over a U-shaped former laid on top of the plate. The former acts as a support to the cloth during the curing process and is usually non-structural. The reinforcements are usually alternate layers of woven roving (WR) and chopped strand mat (CSM). The numbers of plies or laminae will depend on the required stiffness for the stiffener structure. The resulting gap formed between the cloth, former (core) and plate (flange) is filled with an appropriate resin, i.e. one which is compatible with the cloth material and is generally one Fig. 1. Basic constituents of a viscoelastic inserted top hat stiffener and dimensions (mm). J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 851 with a high yield strength. The weakness in this case is due to the lack of reinforcement across the connected surfaces and through the occurrence of stress concentrations associated with joint geometry and production considerations. There is now a growing body of literature on the behaviour of laminated out-ofplane connections. Early work concerned theoretical modelling using simple approaches with plane strain (Smith, 1972) and plane stress (Gillespie and Pipes, 1978); these corresponded to marine and aircraft applications respectively. These efforts were rather restrictive owing to the relatively immature finite element analysis (FEA) capabilities at the time. More recent effort, incorporating layered (finite) elements and a variety of failure criteria, has successfully characterised through numerical analyses both single skin (Shenoi and Hawkins, 1992) and sandwich (Shenoi and Violette, 1990; Theotokoglou and Moan, 1996) tee-joints under representative static loadings. This work has been supplemented by experimental programmes studying failure mechanisms (Hawkins et al., 1993) and stress patterns (Dulieu-Smith et al., 1997). The work has been extended to studying the long-term effects of such joints under repetitive, cyclic loadings (Shenoi et al., 1995) including inception and progression of failure as well as approaches to life modelling. All such work has formed the basis of writing a procedure for the synthesis of design variables for typical single skin tee joints in ship and civil construction (Clark, 1996). What is now being envisaged is to better utilise the joints and stiffeners in a dynamic response mode. One way to achieve this is to investigate the influence of high strain-to-failure, viscoelastic materials. It has been shown that the use of such materials could lead to better energy absorption capabilities in structures. Preliminary work (House, 1997) has demonstrated that a tapered viscoelastic layer placed between a GRP beam and a steel supporting substrate can produce a significant absorption of vibrational energy. The purpose of this report is to consider the placement of such material in a top hat stiffener typically used onboard ships on the strength and stiffness characteristics. 2. Concepts in energy absorbent joints There are many instances in structural applications where noise and vibration transmission is unwelcome. One such example can be seen in sonar domes employed on various ocean-going vessels. Once installed on an operational boat, hydrodynamic flow and supporting structural induced vibrations cause the dome to vibrate thus radiating noise and interfering with sonar sensor response. The introduction of a composite viscoelastic joint produces a vibration sink that can absorb flow-generated and structureborne noise within the dome (House, 1997). In conventional FRP, the resins tend to have a relatively high modulus with as high a glass transition temperature, Tg, as possible. When matrix resins of this type are used with fibre reinforcements, the result is a composite with high specific stiffness but relatively low intrinsic damping. Indeed all efforts to seek matrix resins with higher Tg (particularly in the aircraft industry) only exacerbate the problem, resulting in composites with lower and lower damping. This paper is aimed at con- 852 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 sidering the use of resin matrices with high intrinsic damping and damage tolerance, which can be optimised for specific frequencies and temperatures. Such composites may find applications in the fabrication of new and novel structural connection concepts. House (1997) describes previous work on acoustic interaction at a simple joint. It is shown that high vibration reflection losses can be obtained at a GRP/steel interface provided the joint input impedance is matched. This is generally coupled with a low transmission loss but at the expense of a good reflection loss. In all these cases vibration energy is not lost or absorbed but merely redirected or altered by mode conversion. An alternative approach is to provide a joint that actually absorbs the energy. Currrent research shows that the introduction of a vibrational sink such as a viscoelastic polymeric interlayer between the GRP and steel significantly attenuates the transmissibility of noise and vibration. House (1997) concluded that the use of a viscoelastic wedge absorbs compression wave energy, i.e. little energy was reflected at the joint interface and little was transmitted across. Furthermore, the radiated noise characteristics were much lower than those of conventional butt technology. Whereas the dynamic behaviour of the material and structure have and are being assessed elsewhere, there is currently no knowledge of the strength and load bearing capability of structures incorporating such materials. Furthermore, although coupon tests can and do indicate innate strength of the material itself, there is a weakness related to the manner in which it behaves within a structure. It is important therefore to understand load transfer, damage initiation and progressive build-up of damage in generic structures, such as top hat stiffeners, incorporating these viscoelastic materials. 3. Progressive damage model 3.1. Background Structural response of composite structures with intrinsic flexibility and non-linear material stiffness characteristics requires a non-linear finite element (FE) analysis. A linear analysis would assume that despite the material failure at a point inside the stiffener, the global properties of the stiffener are not compromised in any way and the stiffener can be subjected to further increasing loads. In reality, there are many mechanisms for failure within the composite stiffener, that whilst not necessarily leading to ultimate failure at a given load, will affect the stiffener characteristics as the load is increased. There has been much experimental and numerical work on the failure behaviour of composite laminates. However these investigations have concentrated on in-plane load conditions of tension, compression and shear (Chang and Chang, 1987; Chang and Lessard, 1991; Lessard and Chang, 1991; Shahid and Chang, 1995; Sleight et al., 1997). Out-of-plane loading of laminated plates has received much less attention due to the material and geometric non-linearites, but some important investigations J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 853 can be found in Reddy and Reddy (1993), Kam and Sher (1995), Echaabi et al. (1996), Tolson and Zabaras (1991) and Padhi et al. (1998). The progressive damage of out-of-plane composite structures other than laminated plates has not been investigated in an entirely rigorous manner. Phillips (1997) investigated the progressive damage of tee joints and top-hat stiffeners by considering the manual insertion of delaminations within the structure. At each load step, a visual inspection of the stress distributions determined the applicability and subsequent location of an inserted delamination. This work produced an insight into the failure mechanism of the two types of structure but was not accurate in simulating the structural response. Padhi et al. (1998) successfully used FE modelling incorporating a progressive damage subroutine. This automated progressive damage modelling first determines the load and location at which a material in the structure first fails. From that stage onwards, the failure at that point is included in subsequent analyses. The progression of damage is therefore determinable and so too the ultimate collapse load. Progressive failure analysis is based on the assumption that the damaged material can be substituted with an equivalent material with degraded properties. This can be accomplished in two principal ways: 1. Total Discount method: the stiffness and strength of a failed material ply is reduced to zero. This approach may lead to an underestimation of the laminate strength because it does not recognize that ply failure is localised and that the remaining stiffness of the laminate ply is not necessarily zero. 2. Limited Discount method: the reduction of stiffness depends upon the failure mode in action. For fibre failure, the longitudinal stiffness is degraded, whereas for matrix failure, zero stiffness and strength are assigned to the failed ply for the transverse mode. The actual method used is the limited discount, or stiffness reduction approach and is based upon the work of Chang and Chang (1987). The method for stiffness reduction is simple but effective. For matrix cracking at a material integration point, the transverse modulus Ey, and Poisson’s ratio nyx, are reduced to zero.1 However, the longitudinal modulus Ex and the shear modulus Gxy remain unchanged. When fibre–matrix shearing is predicted at a material point, the transverse modulus Gxy and Poisson’s ratio nyx are reduced to zero. However the longitudinal modulus Ex and transverse modulus Ey remain unchanged. If fibre failure is detected, then the material is deemed to have lost complete stiffness at the integration point. 3.2. Polynomial failure criteria The next question is how to predict failure? In general, failure criteria can be categorized in two classes: independent and interactive (or polynomial). The former 1 The 2D xy-plane element coordinate system is orientated such that the x-axis lies in the fibre direction. 854 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 is simple to apply and gives the mode of failure, but it neglects the effect of stress interactions in the failure mechanism. The latter includes stress interactions in the failure mechanism, but it does not give the mode of failure. Most failure criteria for composite materials can be expressed in terms of a single tensor polynomial failure criterion such as that proposed by Tsai. Failure is assumed to occur if the following condition is satisfied: Fisi ⫹ Fijsisj ⫹ Fijksisjsk ⫹ …ⱖ1 (1) The two dimensional form of the above polynomial is expressed as: F1s1 ⫹ F2s2 ⫹ 2F12s1s2 ⫹ F11s21 ⫹ F22s22 ⫹ F66s26ⱖ1 (2) In the expressions, the notations, s1, s2, s6 (s6=s12) are the in-plane stresses in the material coordinate directions. The Fij terms are the failure indices and are weighted according to the importance of individual stress components. There are different methods for deriving the failure indices but in this paper only the Tsai–Hill criterion (1980) is used. The failure indices for the Tsai–Hill criterion are F1 ⫽ 0, F2 ⫽ 0, F12 ⫽ ⫺ 1 1 1 1 , F11 ⫽ 2, F22 ⫽ 2, F66 ⫽ 2 2 2X X Y SC (3) where if s1⬎0 then X=XT, otherwise X=XC, and if s2⬎0 then Y=YT, otherwise Y=YC. XT, XC, YT, YC and SC are strength parameters (ultimate tensile strength and ultimate compressive strength in the X, Y and XY directions). 3.3. Progressive damage assessment For the interactive polynomial criterion, if failure occurs the following expressions are used to determine the failure mode: H1 ⫽ F1s1 ⫹ F11s21 H2 ⫽ F2s+2F22s22 H6 ⫽ F66s (4) 2 6 The largest Hi term is selected as the dominant failure mode and the corresponding modulus is reduced to zero. Thus, H1 corresponds to fibre failure, H2 corresponds to matrix cracking and H6 corresponds to fibre–matrix shearing failure. The stiffness reduction method is applied and depending upon the mode of failure, the material properties are degraded accordingly. 4. Numerical modelling 4.1. Modelling basis The numerical model has been constructed and analysed using ABAQUS 5.8. The model is two dimensional and made up of 3747 four-noded CPS4 elements. A plane J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 855 stress analysis is used with specimen thickness of 150 mm. The joint geometry is given in Fig. 1 and the material properties in Table 1. A large number of finite element models have been constructed and tested in order to optimize the final progressive damage model. The progressive damage model in essence requires the stiffness degradation of localised points within the structure to represent damage. The less refined the finite element mesh, the more significant the effect of localised stiffness reduction on the global strength of the joint. Therefore while a coarse mesh reduces computational expense, its adverse effect on the accuracy of the progressive damage model maybe significant. The final adopted model thus reflected these two opposing considerations. Previous experimental and numerical studies (e.g Phillips, 1997; Shenoi and Hawkins, 1992) showed that large through-thickness stresses are expected in the frame radius prior to delamination. The density of elements is increased in the frame, focussing the attention of the structural response and aiming to improve the accuracy of the progressive damage model. Each ply of the frame is modelled by one element of thickness 0.61 mm. Fig. 2 shows the adopted mesh layout. 4.2. Loads, material properties and boundary conditions In the context of a marine environment and more specifically application in oceangoing vessels, the stiffener is subjected to in-plane loading (compressive or tensile) resulting from longitudinal bending of the hull girder and out-of-plane loading resulting from hydrostatic pressure, berthing and docking, tank pressure testing and explosion trials. Experiments and analyses of the observed failure mechanisms, theoretically and experimentally (Shenoi and Hawkins, 1992; Junhou and Shenoi, 1996), show the importance of investigation into the bond strength of the frame to the flange and not in the in-plane buckling of the stiffener. With this in mind, the application of an out-of-plane load is required. This is typically achieved either in a three-point bend, a reverse bend or a straight pull-off load condition (Junhou and Shenoi, 1996). Shenoi and Hawkins (1992) discuss the applicability of these types of load conditions in Table 1 Material properties of constituents in a top hat stiffener (stiffness moduli of insert materials given in Fig. 3) Material Location Property Value Polyester/woven roving glass Frame, flange Balsa Core Ex Ey Gxy Density Poisson ratio Ex Ey Density Poisson ratio 17100 MPa 7400 MPa 4400 MPa 1650 kgm⫺3 0.15 150 MPa 150 MPa 200 kgm⫺3 0.11 856 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 Fig. 2. Adopted mesh for flexible top hat stiffener (detail of frame radius shown in inset). Viscoelastic insert mesh not shown for clarity. Loading conditions also shown. characterising the typical failure pattern. Despite the lowest failure load being produced by the straight pull-off condition, the failure is not representative of that seen in an in-service environment. The three-point bend test, whilst leading to a higher failure load, does produce the premature delaminations seen in practice. Fig. 2 describes the boundary conditions applied in the numerical models. Following the above discussion, the numerical model is therefore constrained at nodes on the upper surface of the flange, 500 mm apart. Both nodes are prevented from translation in the y-direction (plane perpendicular to the flange) but to restrict a rigid body motion, one of the nodes is restricted in the x-direction also (in the plane of the flange). The progressive damage model increases the displacement from 0 to 35 mm in steps of 1 mm. The displacement rate is considered small and so the response of the joint is quasi-static. Constantly increasing displacement as opposed to increasing load is used in order to attempt to pick up any stress relief. Linear material properties have been used for the frame overlaminate, the balsa core and the flange. The viscoelastic insert exhibits nonlinear stress–strain characteristics and is modelled using a bilinear stress–strain curve illustrated in Fig. 3. This particular viscoelastic material was produced and tested at DERA Farnborough and is custom made for noise attenuation at specific frequencies and temperatures. The abscissa is foreshortened for clarity of the initial stiffness of this particular elastomer, but infinite strain is considered for numerical analysis. 4.3. Incorporation of progressive damage model The procedure for progressive failure analysis adapted in this context is given below. This is programmed into a FORTRAN standard user subroutine USDFLD, J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 857 incorporated and used in the ABAQUS 5.8 processor. This routine allows the user to define material properties as functions of the field variables at a material point. The material properties of the joint were defined to be dependent upon three field variables. The first field variable was the contribution of s1 (H1) towards the failure index. The second and third field variables were the contributions of s2 and s12 (H2 and H6 respectively) to the failure index. 1. At the load step, a geometric non-linear analysis is performed until a converged solution is obtained. 2. The stresses at every integration point are evaluated, 3. the failure polynomial is determined and if larger than 1… 4. …the contribution of each stress component towards the failure index (Hi) is computed and the stress component which contributes the maximum is identified. 5. Depending on the largest Hi term, the failure mode is determined and the corresponding material properties are degraded accordingly. 6. A geometrically non-linear analysis is again performed for the degraded structure to re-establish equilibrium. If no more failure is detected then… 7. …the next load step is applied, 8. …otherwise the structure is degraded again according to steps 3 to 6. At any load step, a ply failure load is the load at which the failure index (Fisi+Fijsisj) reaches a value of unity at any material integration point. At some point in the analysis, the global stiffness becomes zero or negative and this is taken as the inability of the structure to support additional load. This location is identified as the ultimate failure load. Global failure can also be interpreted based upon the degree of failure, mode and location that exists. This interpretation is important if there is likely to be considerable residual strength of a restrained substructure that remains loaded. For example, stiffener debonding does not lead to full structural failure as there still exists residual stiffness from the flange, however the stiffener itself is now considered useless. The numerical models are based upon continuum mechanics and as such do not consider the discontinuity produced by physical debonding and the related redistribution of stress. Therefore, whilst the predicted model response shows the existence of positive global stiffness, in real terms the predicted amount of material failure in specific regions would have produced complete redundancy of the physical structure. This method of interpreting specific failure to cause structural redundancy was employed in the experimental tests. 5. Validation and results 5.1. Experimental results The numerical model is validated using the results of the experiments upon the physical stiffener. Due to the scarcity of these unique joints and the cost of producing 858 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 the viscoelastic insert material and manufacturing the joints, only one destructive experiment was performed. The physical specimens were fabricated in Vosper Thornycroft shipyard. Half the total flange thickness is formed from a single laminated plate produced using a resin infusion process. The viscoelastic insert was bonded on top of the flange underneath a balsa core. The frame overlaminate was then laid up over the balsa core, insert material and the cured half-flange (which is abraded to provide a good bond). The overlaminate material therefore constitutes the other half of the total flange thickness. The frame overlaminate is then resin infused. The specimens were loaded in a standard three-point bend described in Fig. 2. This type of loading is considered representative of an UNDEX2 shock event experienced in marine environments (Junhou and Shenoi, 1996). The hull plating either side of the stiff joint is subjected to large negative pressures caused by shock bubble implosion. Rollers with a 30 mm diameter were used at the contact points on the specimen, 500 mm apart. A displacement was applied at the structure’s centreline and the reaction load at the point of application was measured against increasing displacement. The tests were recorded on video so that the failure events from the video could be related to the load against displacement curve. Fig. 4 describes the experimental results of load versus displacement and shows a series of load drop-offs when substantive failure leads to progressive increase in structural flexibility. The events corresponding to the various load drops are listed in Table 2. Fig. 5 illustrates the final failure of the stiffener and position of initial failure. The initial response of the stiffener is fairly linear to a deflection at the point of applied load of around 7 mm corresponding to a reaction load of 7 kN. Correlation of the response curve with the video record shows that at a reaction load of 7 kN, location x, two vertical cracks formed in the balsa core on either side of the centreline, shown by the annotation in Fig. 5. This cracking accounts for the load Fig. 3. Stress–strain curves comparing relative stiffness of the standard crestomer insert material used in in-service top hat stiffeners and the viscoelastic insert material. 2 Underwater explosion J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 859 Fig. 4. Comparison of experimental and predicted load-displacement results. The letters correspond to the failure events shown in Table 2. Table 2 Failure events during three-point bend testing: numerical and experimental results. Events correspond to those marked in Fig. 4 Numerical Mark in Fig. 4 Failure event a Shear failure initiates in balsa core close to frame/core interface and close to core/insert interface Matrix and shear failure propagates throughout balsa core. As core stiffness reduces, matrix cracking occurs within frame radius and propagates through the thickness. Full matrix failure through radius depth is accompanied by fibre/matrix shear failure (17 mm) Large matrix and shear failure with little further degradation of balsa core sees fibre failure occurring in frame radius — predicted ultimate failure mode Balsa cracks on either side Balsa crack grows into viscoelastic material; debond at frame to viscoelastic material interface; debond at balsa to frame interface Delamination occurs in curved region of frame a–b b Experimental x x–y y Disp. (mm) 5.00 – 24.00 7.00 – 27.00 drop at x. Between x and y, the cracks in the balsa core propagated towards the balsa core/viscoelastic insert interface, whereupon the cracks extended into the viscoelastic material. Throughout this propagation of the initial cracks between x and y, the bond between the FRP frame overlaminate and the viscoelastic insert failed. These failure events are accompanied by the failure of the bond between the overlaminate and the balsa core. Location y in Fig. 4 signifies the point at which delaminations in the overlaminate 860 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 Fig. 5. Final failure of viscoelastic inserted stiffener. Event y in Fig. 4. frame initiated, correlated by root whitening observed from the video record. This corresponds to a reaction load of 12 kN and a deflection of 27 mm. With increasing deflection, the frame to flange bond started to fail and the crack propagated away from the centreline to the extremities of the specimen. This marks the point of structural redundancy, and therefore ultimate failure, even though the structure can take additional load through the deformation of the flange. 5.2. Validation of global structural response Comparisons between numerical and experimental results are made with regard to load versus displacement curve and the initiation and progression of failure and ultimate failure load. Numerical and experimental results of load against displacement are shown in Fig. 4. Fig. 4 and Table 2, which correlates the failure events in Fig. 4 with physical observations, demonstrates that the predicted response of the top hat stiffener agrees favourably with the experimental results. Initial stiffness of the numerical model is comparable to the experimental result above 1 mm deflection, however below this deflection the predicted stiffness is 65% greater than experiment (1.82 kN mm⫺1 compared to an experimental value of 1.10 kN mm⫺1) due to the simplified description of the viscoelastic material with a bilinear modulus. The predicted increase in flexibility of the top hat stiffener between a and b is comparable with that determined experimentally (between x and y). However the large stress reliefs exhibited in the experiment are not modelled well, leading to a higher predicted load for an equivalent deflection. The final failure predicted by the progressive damage model occurs at a deflection J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 Fig. 6. 861 Initial failures (red) in shear at 5 mm deflection. equivalent to experiment. However, final failure is predicted at a reaction load that is 20% less than experiment. 5.3. Internal load transfer and failure patterns To understand the global structural response predicted by the numerical models, it is necessary to investigate the causal factors, namely internal load transfer mechanisms and failure patterns. Examination of the numerical results leads to initial failure within the joint occurring at a deflection of 5 mm, corresponding to a reaction load of around 6 kN. This initial failure, shown in Fig. 6 by the degree of red colouration, is predicted to occur within the balsa core at either side near to the frame/core bond. Fig. 7 describes the maximum principal strain in the structure prior to failure at a deflection of 4 mm to be concentrated mainly within the viscoelastic insert. How- Fig. 7. Principal strain distribution at 4 mm deflection. 862 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 Fig. 8. Principal stress distribution within balsa core at 5 mm deflection. ever the peak value of the maximum principal strain occurs within the balsa core close to the frame/core bond, reflecting the origin of the balsa cracks. The principal stress distribution at a deflection of 5 mm corresponding to initial failure is given in Fig. 8. The maximum principal stresses are located at the base of the balsa core on either side of the specimen centreline and on the bond line with the viscoelastic insert. A high stress gradient is also evident at the frame/core bond. The distribution of principal stress after the initial failures have formed is given in Fig. 9 for a 6 mm deflection and demonstrates the migration of peak principal stress values to the locations where failure has initiated, i.e. at the frame/core bond. The large increase in stress magnitude and location of these peak values would be expected to promote damage propagation on increasing deflection. Fig. 9. Principal stress distribution within balsa core at 6 mm deflection. J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 863 Fig. 10. Through-thickness stress within FRP at 6 mm deflection. Fig. 10 describes the distribution of through-thickness stress within the FRP material at a deflection of 6 mm. It is clear to see that the maximum stress concentrations, which increase with increasing deflection, exist within the outer plies of the overlaminate radius. The degree of damage within the balsa core increases as the specimen deforms, with shear failure propagating up the frame/core bond and towards the viscoelastic insert. As the core becomes increasingly more flexible, the maximum through-thickness stress in the outer plies of the overlaminate radius rises to a level that cannot be sustained and matrix cracking occurs at a deflection of 12 mm, which is shown by the red colouration in Fig. 11. The matrix cracking within the overlaminate propagates down through the overlaminate radius towards the viscoelastic/overlaminate bond. At a deflection of 17 mm, Fig. 12 demonstrates that the full depth of the overlaminate radius, on both sides of the specimen, has experienced matrix cracking. With little more cracking in the balsa core evident, stress is concentrated within the radius and the fibres and matrix start to shear, illustrated in Fig. 13. Fig. 11. Initiation of matrix cracking within FRP at 12 mm deflection. 864 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 Fig. 12. Progression of matrix cracking within FRP to 17 mm deflection. Fig. 13. Initiation of fibre/matrix shear failure at 17 mm deflection. From a deflection of 17 mm to 24 mm, the shear mechanism continues throughout the overlaminate radius until the fibres themselves fail at 24 mm at the base of the overlaminate radius, shown in Fig. 14. The combined incidents of matrix cracking, fibre/matrix shear and fibre failure are associated with delamination (seen experimentally by root whitening at 27 mm). With the onset of fibre failure and delamination in the base of the overlaminate radius, the structure’s flexibility is now dependent upon the stiffness of the flange and as such the structure is deemed to be redundant. 5.4. Discussion The progressive damage model has provided good qualitative and quantitative agreement with experimental results. However, it is important to treat the results with caution given the limited number of experiments that could be performed. The conclusions drawn are based on the supposition that the experimental data is completely representative of this specific stiffener design, incorporating these materials and under the described form of loading. The confidence in the numerical modelling is reflected by the agreement with the available experimental data for these specific J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 Fig. 14. 865 Initiation of fibre failure within FRP at 24 mm deflection. stiffeners (bearing in mind the above supposition) and between the progressive damage methodology and a set of experimental tests, carried out simultaneously with the top hat stiffener sections, on tee joints (Blake et al., 2000). To improve the modelling further, the material strength limits require refined definition. Phillips (1997) demonstrated the importance of tolerance specifications for published material properties on numerical modelling. Furthermore, production processes rarely result in two specimens ever being the same, thereby providing some uncertainty as to which material strength limits to employ. These uncertainties exist in the numerical modelling of the specimen described herein. As described in Section 4.1, the adopted finite element mesh is a compromise between computational expense and accuracy. The number of elements was increased in the progressive damage model until a state of convergence in terms of load– displacement result was reached. The only effect of increasing the number of elements past this point was to increase the amount of CPU time for solution. Therefore, to increase correlation between experiment and theory in the initial location of failure, the numerical strength limits for interlaminar tensile strength (ILTS) and shear strength (ILSS) in the balsa core were attributed accordingly. Table 3 describes the assumed strengths used in the progressive damage model throughout the FRP material and within the balsa core. The convergence of ultimate strength limits to Table 3 Failure limits applied in progressive damage predictive models Failure limits In-plane strength (MPa) Through-thickness strength (MPa) Shear strength (MPa) Location Frame, flange 261 31 40 Balsa core 261 1 0.5 866 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 provide the experimentally observed initiation of cracking within the balsa core has an importance consequence. Insight into real material properties can be achieved based upon the agreement of the predictive progressive damage model with experimental observations. The progressive damage model allows for variations of particular material properties and geometric differences to be investigated. Importantly, the introduction of a viscoelastic layer within the joint can be assessed on comparison with previous work on a typical in-service top hat stiffener, the configuration of which is demonstrated by Fig. 15 (Phillips, 1997). The design of a typical in-service stiffener differs from the design of the stiffener described herein in both geometry and material properties of the insert material. Fig. 15 illustrates the differences in geometry of a typical standard stiffener with a viscoelastic stiffener (Fig. 1) stem from the design of the frame to flange bond. In the standard design, the frame to flange connection is much narrower than the stiffener with the viscoelastic insert. In fact the frame for the viscoleastic inserted stiffener forms half of the total flange thickness. The fabrication of the viscoelastic-inserted stiffener, within a ship’s hull for example, would therefore require localised hull skin thickness reduction so that upon addition of the stiffener frame, the full skin thickness is achieved. The design of the viscoelastic stiffener also accommodates more insert resin than in the standard stiffener. Fig. 3 compares the modulus curves of the viscoelastic insert resin with the standard crestomer insert resin. The difference in material properties of the insert material described in Fig. 3 shows that the standard crestomer resin is much stiffer than the viscoelastic material. Fig. 16 compares the load–displacement response for the viscoelastic joint and the standard stiffener under the same three-point load condition. For the same specimen width the stiffener with the viscoelastic insert is around two and a half times more flexible than the standard stiffener. Fig. 16 also shows that under quasi-static loading, the energy absorbed by the viscoelastic top hat stiffener to total failure is comparable to that absorbed by the standard in-service stiffener. Progressive damage analysis on the standard stiffener (Blake et al., 1999) describes a different failure mechanism to that observed in the viscoelastic specimen. High stress concentrations are still exhibited in the frame radius and again the initial failure Fig. 15. Standard in-service top hat stiffener dimensions (mm). J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 867 Fig. 16. Comparison of responses of a standard in-service stiffener with a viscoelastic inserted stiffener. Both curves relate to experimental tests, (Turton, personal communication). occurs in the balsa core. However, there are no obvious delaminations within the frame radius and the stiffener fails through detachment of the frame to the flange. Previous work on standard stiffeners for example, Phillips (1997) and Elliot (1994), show that the failure mode is in the form of delamination in the frame radius where the high stress concentrations exist and not sub-structural debonding. This discrepancy can be explained by the resin infusion process which has been used in the more recent specimens (Blake et al., 1999) and produces much higher FRP strength limits (ILTS and ILSS). The large amount of insert material in the viscoelastic inserted stiffener, bounded by relatively thin FRP skins, leads to a structure that has sandwich-type characteristics. The viscoelastic insert material has low stiffness and is capable of withstanding large strains. Since the flexible “core” has little capacity for evenly distributing the applied load across the structure, the stress distribution within the stiffener is concentrated within the skins (i.e. the flange and the frame). The design of the standard stiffener is such that the amount of insert material used is much lower in comparison to the viscoelastic-inserted stiffener. The role of the insert resin is reduced in relative importance and sandwich-type characteristics are not observed. Furthermore the standard insert material is much stiffer and high stress gradients are reduced. The progressive damage analysis of the viscoelastic inserted top hat stiffener agrees favourably with experimental results, not just in gross behaviour but in the mechanisms that cause that behaviour. The ability to assess load transfer mechanisms and failure patterns successfully allows the structural design to be varied and the subsequent response investigated without necessarily producing costly specimens. The consequence of adding a viscoelastic material into a joint that experiences quasi-static structural loading highlights the need to investigate alternative joint geometric design and production to make full use of the advantages an energy absorbing material provides in terms of attenuation of noise and vibration. 868 J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 6. Closure Incorporation of a material that can be tuned for specific frequency response into a structure where its longevity, survivability, detectability and operability are affected by noise and vibration transmission has huge advantages. Some examples of application may include: 앫 the join between a ship’s hull and a sonar dome — increasing the effectiveness of the sonar sensors, 앫 Mine Counter Measure Vessels (MCMV’s) experience shock loading having significant frequency content — attenuated across the vessel structure by the modification of the joints and stiffeners, 앫 increasing the stealth capability of submarines by the material modification of ring frames, 앫 attenuation of noise and vibration, originating from vessel machinery spaces, through the use of flexibised joints. The primary structural function of these joints and stiffeners must, however, remain uncompromised. With this in mind, a progressive damage methodology has been presented in this paper and applied with success to an example of a specific top hat stiffener undergoing a three-point bend, representative of a stiffened hull panel experiencing an UNDEX-type event. In particular the novel aspects of the top hat stiffener design were assessed, namely the influence of the viscoelastic insert material and the geometric variations upon the structural response to quasi-static loading. Importantly the cause and effect of failure within the joint was identified and provided insight into the global response of the structure that correlated well with experimental observations and highlighting areas requiring further structural design. References Blake, J.I.R., Shenoi, R.A., Price, W.G. Padhi, G.S., 1999. Structural response of top hat stiffeners with a viscoelastic or standard insert material undergoing a three-point bend. University of Southampton (in press). Blake, J.I.R., Shenoi, R.A., House, J. Turton, T., 2000. Progressive damage analysis of tee joints with viscoelastic inserts. Composites: Part A., (submitted for publication). Clark, J.L. (Ed.), 1996. Structural Design of Polymer Composites — EUROCOMP Design Code and Handbook. E & FN Spon, London. Chang, F.K., Chang, K.Y., 1987. A progressive damage model for laminated composites containing stress concentrations. J. Comp. Mat. 21, 834–855. Chang, F.K., Lessard, L.B., 1991. Damage tolerance of laminated composites containing an open hole and subjected to compressive loadings: Part I Analysis. J. Comp. Mat. 25, 2–43. Dulieu-Smith, J.M., Shenoi, R.A., Read, P.J.C.L., Quinn, S., Moy, S.S.J., 1997. Thermoelastic stress analysis of a GRP tee joint. J. Appl. Comp. Mater. 4, 283. Echaabi, J., Trochu, F., Pham, X.T., Ouellet, M., 1996. Theoretical and experimental investigation of failure and damage progression of graphite-epoxy composites in flexural bending test. J. Reinf. Plast. Comp. 15, 740–755. J.I.R. Blake et al. / Ocean Engineering 29 (2002) 849–869 869 Elliot, D.M., 1994. Mechanical Testing of Composite Joints — Interim Report, April 1994, DRA/AW/AWS/TR94212. Gillespie, J.W., Pipes, R.B., 1978. Behaviour of integral composite joints — finite element and experimental evaluation. J. Comp. Mater. 12, 408. Godwin, E.W., Matthews, F.L., 1980. A review of the strength of joints in fibre reinforced plastics: Part 1 Mechanically fastened joints. Composites 11 (3), 155. Hawkins, G.L., Holness, J.W., Dodkins, A.R., Shenoi, R.A., 1993. The strength of bonded tee joints in FRP ships. Plastics, Rubber, Comp. Process. Applic. 19, 279. House, J.R., 1997. Energy absorbing joints and their application to noise reduced sonar domes. In: Proc. ICCM-11, Gold Coast, Australia, vol. VI, July 1997, pp. 74–83. Junhou, P., Shenoi, R.A., 1996. Examination of key aspects defining the performance characteristics of out-of-plane joints in marine structures. Composites: Part A 27A, 89–103. Kam, T.Y., Sher, H.F., 1995. Non-linear and first ply failure analyses of laminated composite cross ply plates. J. Comp. Mat. 29, 463–482. Lessard, L.B., Chang, F.K., 1991. Damage tolerance of laminated composites containing an open hole and subjected to compressive loadings: Part II Experiment. J. Comp. Mat. 25, 44–64. Matthews, F.L., Kilty, P.F., Godwin, E.W., 1982. A review of the strength of joints in fibre reinforced plastics: Part 2 Adhesively bonded joints. Composites 13 (1), 29. Padhi, G.S., Shenoi, R.A., Moy, S.S.J., Hawkins, G.L., 1998. Progressive failure and ultimate collapse of laminated composite plates in bending. Composite Structures 40, 277–291. Phillips, H.J., 1997. Assessment of Damage Tolerance Levels in FRP Ship Structures, PhD thesis. Reddy, Y.S.N., Reddy, J.N., 1993. An accurate prediction of failures in composite laminates using a layer-wise model. In: Proc. Int. Conf. on Comp. Mat., ICCM-9, vol. 3, pp. 15–22. Shahid, I., Chang, F.K., 1995. An accumulative damage model for tensile and shear failures of laminated composites plates. J. Comp. Mat. 29, 926–981. Shenoi, R.A., Hawkins, G.L., 1992. Influence of material and geometry variations on the behaviour of bonded tee connections in FRP ships. Composites 23, 335–345. Shenoi, R.A., Read, P.J.C.L., Hawkins, G.L., 1995. Fatigue failure mechanisms in fibre-reinforced plastic laminated tee joints. Int. J. Fatigue 17, 415–426. Shenoi, R.A., Violette, F.L.M., 1990. A study of structural composite tee joints in small boats. J. Comp. Mater. 24, 644. Sleight, D.W., Knight, N.F., Wang, J.T., 1997. Evaluation of a Progressive Failure Analysis Methodology for Laminated Composite Structures, AIAA paper 97-1187, AIAA. Smith, C.S., 1972. Structural problems in the design of GRP ships. In: Proc. Symp. GRP Ship Construction, R.I.N.A., London, October, pp. 33–56. Theotokoglou, E.E., Moan, T., 1996. Experimental and numerical study of composite T-joints. J. Comp. Mater. 30, 190–209. Tolson, S., Zabaras, N., 1991. Finite element analysis of progressive failure in laminated composite plates. Comput. Struct. 38, 361–376.