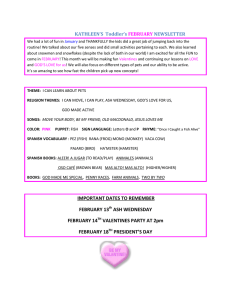

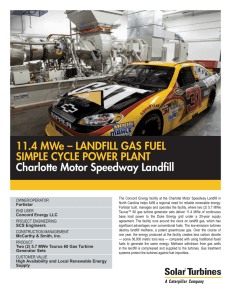

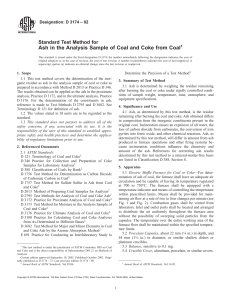

Waste Management 107 (2020) 191–200 Contents lists available at ScienceDirect Waste Management journal homepage: www.elsevier.com/locate/wasman Waste type, incineration, and aeration are associated with per- and polyfluoroalkyl levels in landfill leachates Helena M. Solo-Gabriele a,⇑, Athena S. Jones a, Andrew B. Lindstrom b, Johnsie R. Lang c a Department of Civil, Architectural, and Environmental Engineering, University of Miami, Coral Gables, FL 33146-0630, USA U.S. Environmental Protection Agency, Research Triangle Park, NC 27709, USA c Oak Ridge Institute for Science and Education, 100 ORAU Way, Oak Ridge, TN 37830, USA b a r t i c l e i n f o Article history: Received 4 November 2019 Revised 22 March 2020 Accepted 27 March 2020 Keywords: PFAS Leachate Ash Municipal solid waste Construction and demolition Gas condensate a b s t r a c t Per- and polyfluoroalkyl substances (PFAS) are found in many consumer products which will be ultimately disposed in landfills. Limiting environmental contamination and future exposures will require managing leachates from different types of landfills, each with different PFAS levels depending upon the source of the waste. The objective of this study was to evaluate the influence of waste type and on-site treatment on PFAS levels in landfill leachates. Eleven PFAS species (7 carboxylic acids, 3 sulfonic acids, and 5:3 fluorotelomer carboxylic acid) were evaluated in leachates from municipal solid waste (MSW), construction and demolition (C&D), MSW ash (MSWA), and a mixture of MSWA and MSW with landfill gas condensate (MSWA/MSW-GC). Leachates were also analyzed before and after on-site treatment at two of these facilities. Results indicate that MSWA leachate had significantly lower PFAS levels relative to other leachate types. Lower total PFAS concentrations in MSWA leachates were correlated with an increase in incineration temperature (R2 = 0.92, p = 0.008). The levels of PFAS in untreated C&D and untreated MSW leachate were similar. The levels of targeted PFAS species in MSW leachate for one of the facilities evaluated increased after on-site landfill treatment presumably due to the conversion of PFAS precursors in the untreated leachate sample. Ó 2020 Elsevier Ltd. All rights reserved. 1. Introduction Landfill leachate presents a unique challenge for managing perand polyfluoroalkyl substances (PFAS) from products that have reached the end of their service life. PFAS are used in many consumer products, including sealants (Favreau et al. 2017), sprays for textiles (Ye et al. 2015), Teflon parts (U.S. EPA 2018), clothing, carpet (Lang et al. 2016), ski waxes (Kotthoff et al. 2015), and in non-stick surfaces such as cookware (U.S. EPA 2018). They are also found in food packaging such as paper food wrappers and cups (Wang et al. 2017, Schaider et al. 2017). Aqueous film forming foam (AFFF) represents another source of PFAS release to the environment (Dauchy et al. 2017, Backe et al. 2013, Houtz et al. 2013). Widespread uses and their resistance to degradation make management of PFAS in consumer products difficult at the end of their service lives. ⇑ Corresponding author at: 1251 Memorial Drive, McArthur Engineering Building, Room 252, Coral Gables, FL 33146 USA. E-mail addresses: hmsolo@miami.edu (H.M. Solo-Gabriele), a.jones18@umiami. edu (A.S. Jones), Lindstrom.Andrew@epa.gov (A.B. Lindstrom), Johnsie.lang@arcadis. com (J.R. Lang). https://doi.org/10.1016/j.wasman.2020.03.034 0956-053X/Ó 2020 Elsevier Ltd. All rights reserved. The carbon and fluorine bonds in PFAS are the strongest bond that is possible with carbon due to the highly electronegative nature of the fluorine (O’Hagan 2008). As a result of the strong bonds, the C-F chain portion of the molecule is resistant to degradation, including resistance to hydrolysis, photolysis, and biodegradation (U.S. EPA, 2014, Schultz et al. 2003, OECD, 2002). While thousands of PFAS exist in commerce, perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS) are the most widely studied. PFAS have been linked to human health effects. PFAS have been detected in the blood serum of up to 98% of samples collected between 1999 and 2004 in a population that is representative of the U.S. (Calafat et al. 2007). In in-vivo studies with rodents, PFAS have been linked to thyroid diseases and negative impacts on immune system responses (Yang et al. 2002). They have been linked to liver cancers (Lau et al. 2007) and renal cancers among occupationally exposed individuals (Steenland and Woskie 2012). In exposed communities, PFAS have also been linked with thyroid disease (Li et al. 2017b), asthma, impaired lung function (Qin et al. 2017), and testicular tumors (Barry et al., 2013) and cancers of the kidney and bladder (Li et al. 2017a). As a result of the public health concerns associated with PFAS, effective May 2016, a drinking water health advisory of 70 ng/L 192 H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 was issued by the U.S Environmental Protection Agency (U.S. EPA) for the sum of PFOA and PFOS (U.S. EPA 2016a, Hamid et al. 2018). Some U.S. states have adopted stricter drinking water guidelines. For example, Vermont has adopted a guideline of 20 ng/L for the sum of PFOA and PFOS plus three additional species (PFNA, PFHxS, and PFHpA, defined in Fig. 1). Similarly, New Jersey has adopted a guideline of 14 ng/L for PFOA and 13 ng/L for PFOS (ASDWA, 2019) and California has adopted guidelines of 5.1 ng/L for PFOA and 6.5 ng/L for PFOS (CWB, 2019). Municipal solid waste (MSW) leachates have been documented with PFOA concentrations on the order of 10000 s ng/L and PFOS on the order of 1000 s ng/L in the U.S. (Huset et al. 2011, Lang et al. 2017), Canada (Benskin et al. 2012), and Europe (Fuertes et al. 2017, Busch et al. 2010, Perkola and Sainio 2013). A landfill known to have received waste from PFOA and PFOS industrial processes documented leachate levels as high as 82,000 ng/L and 31,000 ng/L, respectively (Oliaei et al. 2013). The highest levels were measured in leachates collected from five landfills in China with PFOA levels up to 214,000 ng/L (Yan et al. 2015). The types of landfills used for disposal of waste vary in terms of their composition and PFOA and PFOS levels. MSW landfills in the U.S. evaluated by Lang et al. (2017) accepted household waste including organics, cardboard, glass, paper and plastics. This can be compared with an Australian study on the presence of PFAS compounds in landfill leachate (Gallen et al. 2017). Average PFOA and PFOS levels in the Lang et al. (2017) study were 800 ng/L and 90 ng/L, respectively, whereas for the Gallen et al. (2017) study the levels were 300 ng/L and 200 ng/L respectively. Gallen et al. (2017) also evaluated a second class of landfills containing cardboard, glass, paper and plastics plus construction and demolition (C&D) wastes (defined as concrete, soil, metals, timber, and plastics) which generated average PFOA and PFOS concentrations of 1400 ng/L and 1100 ng/L, respectively. Landfill leachates are typically managed via transfer to a wastewater treatment plant (WWTP). In WWTPs, some PFAS tend to bioaccumulate in the sludge (typically PFAS with 8 carbon fluoroalkyl chains) (Venkatesan and Halden 2013). Exposures to humans can occur when PFAS-containing sludge is land applied which can then runoff into adjacent waterways, impact surficial aquifers and also possibly impact crops and grazing animals for Fig. 1. Defined acronyms and structural configuration of a PFAS species analyzed during the current study. sludges used on agricultural fields. Lang et al. (2017) and Busch et al. (2010) found that PFAS concentrations were higher in leachate in comparison to lower levels found in domestic WWTP outflows. As a result, PFAS in leachates can impact receiving water bodies including wastewater treatment plants and may limit opportunities for downstream water reuse. The objective of this study was to evaluate the influence of waste type and on-site landfill treatment on PFAS levels in landfill leachates. Samples were analyzed for 11 PFAS species (Fig. 1) in leachate samples from landfills composed of different waste types including MSW and C&D as well as MSW ash (MSWA) and a mixture of MSWA and MSW containing gas condensate (MSWA/ MSW-GC), of which MSWA and GC have never been previously evaluated for PFAS content. Gas condensate originates from vapor-liquid separator (knock-out pot) that receives gas from the landfill gas collection system. This condensate was discharged to the leachate collection system. At facilities where leachates were treated on-site at the landfill, samples were collected immediately prior to and after on-site treatment for comparison. 2. Methods 2.1. Landfill sites Samples were collected at five different landfill facilities within Florida, USA (Table 1). Pre-treatment and the ultimate disposal of leachate differed for each facility. Ultimate disposal at two landfill facilities consisted of on-site aeration with disposal to a WWTP. For two other landfill facilities, the leachate was discharged to a WWTP without on-site treatment. At one facility, the leachate was discharged to deep well injection without on-site treatment. Some of the facilities had access to leachate flows from distinct waste types by landfill cell. Leachate was obtained from cells containing predominantly MSW, predominantly C&D, predominantly MSWA, and combinations thereof. The characteristics of the incineration facilities producing the ash varied. These variations included differences in the boiler temperatures used to incinerate the waste. Although the cells accepted both bottom and fly ash, the treatment of the fly ash also differed between facilities prior to its disposal within the landfill cell. A sample was also collected of leachate (75% MSWA and 25% MSW) mixed with gas condensate. The ratio of leachate to gas condensate was unknown. C&D landfills are designed to accept wastes from construction and demolition activities. Historically the majority of C&D landfills do not have bottom liners designed to capture leachate. As of 2010, bottom liners are now required within the State of Florida. These C&D landfills, referred to as Class III in Florida, were included within the C&D category. Class III landfills accept waste (yard trash, C&D debris, processed tires, asbestos, carpet, cardboard, paper, glass, plastic, and furniture other than appliances) that are not expected to produce leachates that pose a threat to public health or the environment as per Florida statutes (FAC, 2016). MSWA landfills accept ash from incineration for either volume reduction or wasteto-energy purposes. These landfills are also required to maintain bottom liners. Although not all C&D (inclusive of Class III) landfills have bottom liners, the landfills targeted as part of this study had bottom liner systems. Sample collection was initiated at the participating facilities after two interviews: a telephone interview and an interview in person with the facility managers. During the interviews questions were asked about the type of waste disposed and the possibility of collecting leachates that corresponded to specific waste types. From these interviews, a sampling plan was devised to optimize the isolation of leachates by their types (MSW, C&D, MSWA, MSWA/MSW-GC) and categorized by leachate age. Leachate age H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 193 Table 1 Description of: (a) waste in landfill cells from which leachate was collected, (b) age of cell, (c) pre-treatment of ash, and (d) on-site leachate treatment processes. Additional landfill characteristics such as landfill acreage and yearly average leachate volumes are included in supplemental Table S1. Facility ID Sample ID Waste Type Age of cell (years) Pre-treatment of Ash and On-site Leachate Treatment A C&D(100%) C&D(100%) MSWA/MSW-GC Untreated C&D (Class III) only. Untreated C&D (Class III) only. Gas condensate mixed with leachate from several cells composed of approx. 75% MSWA & 25% MSW. MSW ash from cell containing 98% ash and 2% MSW. 26 25 20 Ash: The incinerator that produces the ash runs at a boiler temperature of 760 to 870 °C. Fly ash is treated with spray dryer absorbers, activated carbon, selective non-catalytic reduction, and bag house filtration. Overall the landfill contains 75% MSW & 25% C&D. Landfill was separated into old (27-year old) versus new (6-year old) cells. The leachate from the first sampling point was a combination from old and new cells (averaged). Leachate from the second sampling point came from the old cell only. Waste at this landfill facility consists of MSWA mixed with MSW at an approximate proportion of 65:35.The first sample corresponded to leachate entering the onsite treatment system and the second sample corresponded to leachate after on-site treatment. 27 27 Ash: Not applicable. No ash disposal at this facility. 34 34 Ash: The incinerator that produces ash runs at a boiler temperature of 815 to 870 °C. Fly ash is treated with spray lime absorption, activated carbon, and bag Ash monofill. Samples came from two different manholes at the site. 21 18 MSWA(98%) B C D MSW(75%)/ C&D(25%) MSW(75%)/ C&D(25%) MSWA(65%)/ MSW(35%)_U MSWA(65%)/ MSW(35%)_T MSWA(100%) MSWA(100%) 9 Leachate: There is no on-site treatment of leachate. The leachate is disposed on-site via deep well injection. Leachate: No on-site treatment. Leachate sent to regional wastewater treatment plant (WWTP). house filtration. Leachate: Leachate was treated onsite using a continuous flow biological aeration process designed to lower ammonia. The effluent from the on-site treatment process was sent to a regional WWTP. Ash: The incinerator that produced ash runs at a boiler temperature of 930 to 980 °C. Fly ash was treated with spray dryer absorption, activated carbon, nitrogen oxide reduction, and bag house filtration. Leachate: No on-site treatment. Leachate sent to a regional WWTP. E MSW(100%)_U MSW(100%)_T The majority of the waste was MSW. The first sample corresponded to leachate entering the on-site treatment system and the second sample corresponded to leachate after on-site treatment. is defined as the number of years that the contributing landfill area started to receive waste. If the leachate is a combination of leachates from multiple cells, the age is defined by the date the oldest cell started to receive waste. A total of 12 samples were collected across five facilities. They consisted of one MSWA/MSW-GC sample from predominantly an ash cell (75% MSWA/25% MSW), two samples from C&D landfills, four samples from predominantly MSW (2 with 100% MSW and 2 with a mix of 75% MSW/25% C&D) and five samples from predominantly ash landfills (2 with 100% MSWA, 1 with 98% MSWA/2% MSW, and 2 with 65% MSWA/35% MSW) (Table 1). 2.2. Sample collection methods Leachate was collected in two half-liter high density polyethylene (HDPE) bottles per sampling location. One collection bottle was used for subsequent PFAS analysis and the other was used to measure pH and chemical oxygen demand (COD). The purpose of these analyses was to define bulk physical–chemical characteristics as the leachates are produced by different waste types. Samples were poured directly into the collection bottles if spigots were available. A new primary collection bottle, also made of HDPE, was used when samples were to be collected from manholes or pump stations. The primary collection bottle was attached to a stainless-steel hose clamp, which in turn was attached to a zinccoated chain. The primary collection bottle was then lowered into the manhole/well using the chain and bottle attachment. This allowed for the collection of leachate samples in wells up to 10 m deep and containing leachate that was only a few centimeters deep at the bottom. The lower end of the chain was detachable allowing for replacement of the primary sample collection bottle 39 39 Ash: Not applicable. Leachate: Leachate is treated onsite for ammonia removal using sequential batch reactors and biological aeration. The effluent from the on-site treatment process is sent to a regional WWTP. and lowest chain portion between sampling stations to avoid cross-contamination. One trip blank was processed per facility visited. The trip blank consisted of an HDPE bottle that contained deionized water and was closed throughout sample collection, storage, and shipment. In addition, for each leachate sample a sample blank was also collected by opening a bottle containing deionized water during the time of sampling and then closing it after the sample was collected. Upon collection, samples were placed in a cooler with ice. 2.3. Laboratory analysis After collecting samples at each facility, sample bottles were immediately transported to the University of Miami (UM) laboratory (Coral Gables, FL). An aliquot was removed for the basic physical–chemical parameters of pH and COD at UM. The remaining sample (earmarked for PFAS analysis) was frozen. The aliquot was analyzed for pH (Orion Star A211) and for COD using predispensed ampules (Bioscience Inc.) to which 1 mL of 1:10 diluted sample was added and analyzed spectrophotometrically (Milton Roy, Spec 20 with calibration standards from 0 to 4,500 mg/L of COD) as per standard methods (APHA, 2018). The frozen samples were batched into two sets for PFAS analysis at the U.S. EPA Research Triangle Park (RTP) laboratory (Raleigh, NC), with one set shipped for analysis during January 2018 and the second set shipped for analysis during July 2018. The samples were collected over the course of six months (from December 2018 to May 2019). The maximum time the samples were stored frozen was 7 months. Samples at EPA-RTP were placed in a 5°C freezer upon receipt. Samples were thawed in the refrigerator overnight prior to analysis of PFAS concentrations. Pre-processing of the samples for each batch was slightly different. All samples were 194 H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 analyzed in the second batch with the exception of the MSWA/ MSW-GC sample. The pre-processing of the samples after shipment included the addition of internal standards that were isotopically labeled (Wellington Laboratories, MPFAC-MXA and MFTA-MXA), followed by a filtration step (Whatman GF/A glass fiber), and then followed by a solid phase extraction (SPE) process using Oasis WAX cartridges (Huset et al. 2011, Backe and Field 2012). Transfer of the samples from the sampling bottles used in the field to the filtration flask followed EPA standard protocols requiring volume measurement and a methanol rinse (U.S. EPA 2016b). For the first batch only, 200 mL of sample were processed using Envi-carb cartridges (Sigma Aldrich). Eluates (5 mL of ammonium hydroxide and methanol solution at a ratio of 1:1000) from the Oasis WAX/Envi-Carb cartridge (batch 1) and Oasis WAX (batch 2) were concentrated to 2 mL by evaporation using nitrogen gas. Sample aliquots of 100 mL were prepared for analyses with the addition of 300 mL of 2.5 mM ammonium acetate. For the first batch a calibration curve was prepared using the purchased standards (Wellington Laboratories, PFAC-MXA: fluorinated acid/sulfonate mix, FTA-MXA: native telomer mix, 5:3 fluorotelomer carboxylic acid (FTCA)) with an analytical range of 300–1200 ng/L. The second batch of samples were diluted with an equal volume of PFAS-free deionized water after the filtration step but prior to passing 200 mL of the diluted sample through SPE. The purpose of the dilution was to bring the leachate concentrations to levels that would fall within the linear portion of the calibration curves. For the second analysis date, the calibration curve prepared at EPA-RTP consisted of a wider range of concentrations (10– 2000 ng/L for FTA-MXA, 50 to 5000 ng/L 5:3 FTCA: fluorotelomer carboxylic acid, PFAC-MXA 10 to 2000 ng/L). The solid phase extraction for this batch was pH-adjusted with 2.5 mL of nitric acid on the WAX cartridge to optimize the recovery of short chain PFAS. Thus the pre-processing of samples analyzed in the first batch failed to recover the short chain PFAS species as determined from low R2 values from the calibration curves resulting from low recovery for the higher concentration standards. The short chain PFAS species (PFBA and PFPeA) were captured in the second batch. Since short chain PFAS are less hydrophobic than long chain PFAS, their retention at higher pHs was lower. Sample extracts were analyzed by isotopic dilution on a Time of Flight-Liquid Chromatograph/Mass Spectrometer TOF-LC/MS (Agilent, 1100 Series). Compound identification was established using the exact mass of the target PFAS species and the expected retention time. Extracts from the second batch of samples were analyzed in duplicate (extracts were analyzed twice). The column consisted of a Poroshell 120 EC-C8 (2.1 50 mm, 2.7 mm). The flow rate was 300 mL/min with a gradient consisting of an aqueous phase (A: 95% deionized water and 5% MeOH in 0.4 mM ammonium formate) and an organic phase (B: 95% methanol and 5% of deionized water in 0.4 mM ammonium formate). The initial gradient (75% A, 25% B) was ramped to 80% B over 5 min and held for 5 min. This was followed by a second ramp to 100% B for 2 min and held for 3 min. For both analysis batches, analytical blanks were also added to the process (300 mL of 2.5 mM ammonium acetate + 100 mL of MeOH) as a check for contamination during analysis. Quality control samples showed that all trip blanks, field blanks, and analytical blanks were below the limits of detection, except for PFHxS, which was detected in all trip and field blanks at a factor of 10 below the limit of quantification. For this study, the limit of quantification (LOQ) was defined as 300 ng/L. Species that were detected but below the LOQ represent best estimates based upon the measured signal. The limit of detection (LOD) was defined as any transition ion peak that was three or more times the noise level at that compound’s specific retention time. PFHxS was not detected in the analytical blanks. The presence of PFHxS in the trip blanks and field blanks, but not the analytical blanks indicates the source of contamination was related to sample handling or the extraction procedure. All calibration curves (ranges listed in methods section) were characterized by correlation coefficients (R2 values) of 0.99 with the exception of the calibration curve for PFDA for which the R2 value was 0.98 and for 5:3 FTCA for which the R2 value was 0.91. Duplicate analyses of the standards were characterized by coefficients of variation of 2.4% on average. Percent recoveries were between 95% and 100% for all mass labeled PFAS species measured except for PFDA for which recovery was 89% and 5:3 FTCA for which recovery was 86%. 2.4. Statistical analysis Statistical differences in the mean values for categories compared were evaluated by t-tests assuming the categories had unequal variances and applying alpha equal to 0.05. Correlations between PFAS and environmental factors were computed using the coefficient of determination, R2, and were considered strong for R2 greater than 0.7 and weak if less than 0.3. Correlations were considered significant for p values less than 0.05. Correlations were tested for significance using t-tests with the null hypothesis that the independent variable had no correlation with the dependent variable. 3. Results and discussion 3.1. Leachate characterization Overall landfill age was not significantly correlated with total measured PFAS (R2 = 0.16, p = 0.19), whereas the correlations of physical–chemical parameters, pH and COD, varied with total measured PFAS. Overall a significant and positive correlation was observed between pH and total PFAS (R2 = 0.55, p = 0.005, Fig. S1). The pH of the leachates varied from 6.2 to 8.1, with MSWA leachate at the lowest pH and MSW leachate at the highest pH (Table 2). The observed trend may therefore be due to the fact that ash landfills had lower pH as opposed to the impacts of pH directly. Also notable is the significant and positive correlation between pH and landfill age (R2 = 0.57, p = 0.004, Fig. S1). These results were consistent with the low pH for landfills undergoing the younger acidic phase whereas the higher pH values were consistent with landfills undergoing the methanogenic phase (Kjeldsen et al. 2002). Thus landfill age, in addition to waste type, may also be confounding the positive correlation between leachate pH and total PFAS. In the case of ash landfills, the low pH may be due to either the low buffering capacity of the ash resulting in leachate pH more consistent with the natural lower pH of rainwater or the age of the ash monofill (18–21 years) for which the alkalinity may have leached from the ash. Specifically, experiments should be conducted subjecting a waste type (e.g., MSWA, C&D, and MSW) to solutes of different pH to determine whether PFAS sorption increases at lower pH. The correlation between COD and total PFAS concentrations was weak and not significant (R2 = 0.005, p = 0.83, Fig. S1). The COD of the samples ranged from 700 mg/L for the treated MSWA/MSW leachate, to 14,000 mg/L for the MSWA/MSW-GC leachate (Table 2). The association between landfill age and COD was also weak and insignificant (R2 = 0.27, p = 0.08). The COD values tended to be low in comparison to landfills undergoing acidic phase decomposition. These values were more consistent with the typical values observed during methanogenic phases (3,000 COD mg/L on average) (Kjeldsen et al. 2002). 195 H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 Table 2 Landfill cell composition, age, leachate pH, leachate COD and individual PFAS concentrations for the five facilities visited. Facility ID Waste Type COD PFAS (ng/L)à Waste Age Proportions (years) pH (mg/L) PFBA PFPeA PFHxA PFHpA PFOA PFNA PFDA PFBS A C&D 100% 26 A C&D 100% 25 B MSW and C&D 75:25 17 B MSW and C&D 75:25 27 E MSW untreated 100% 39 100% 39 c E MSW treated C MSWA/MSW untreated 65:35 34 C MSWA/MSW treatedc 34 65:35 d A A MSWA/MSW-GC MSWA/MSW 75:25 98:2 21 12 D Ash 100 18 D Ash 100 18 7.6 2700 1170 1150 7.6 2000 1250 1200 7.7 3800 1460 688 7.7 3800 ND 2200 8.1 4600 1410 1660b 8.0 4100 2710 2560 7.5 1800 1380 1450 8.1 700 1290 1380 7.3 14,000 NDe 6.9 8800 1040 917 6.2 4200 421 512 6.4 4300 450 470 1620 1790 1720 322 NDa ND ND ND ND ND 2950 3140 990 1150 1050 1040 NDe 1360 1230 652 567 437 477 2190 2250 2200 2130 3560 1830 4270 4240 3570 3590 4290 4295 1691 1720 1610 1630 1140 1770 1680 742 726 589 637 1160 1120 1260 1160 1060 1090 1310 1320 1180 1182 17710 1760 695 722 819 791 299 546 485 328 292 256 255 1720 1740 1750 1680 2200 2290 2860 2860 2620 2643 2990 2960 1177 1166 1610 1596 609 1010 964 360 387 259 269 59 56 58 66 104 116 144 116 119 125 146 154 108 101 106 99 159 160 136 ND ND ND ND 40 40 51 51 121 104 121 167 169 189 256 318 ND ND ND ND 81 105 99 ND ND ND ND 781 828 529 560 3150 3220 ND ND 3420 3351 2670 2630 331 363 388 386 3800f 5510 4900 508 547 534 552 PFHxS PFOS 5:3 FTCA Total 4130 4230 4630 4530 2250 2330 3560 3580 651 635 643 612 994 992 1400 1390 313 606 540 182 184 179 176 875 874 965 1000 557 600 770 736 875 870 1230 1180 330 319 296 305 720 342 347 166 158 120 124 1930 1900 1650 1760 2540 2540 2990 3050 1590 1600 314 306 748 736 ND ND 2710 1000 954 ND ND ND ND 15,670 15,960 16,060 14,450 17,010 14,800 16,030 18,270 15,610 15,840 19,970 19,920 8450 8730 8570 8600 9830 13,450 12,260 3360 3370 2820 2960 à Results correspond to the second batch of analyses for which extracts were analyzed in duplicate (same sample extract which was analyzed twice). The only exception was the MSWA/MSW-GC sample, which was analyzed with the first batch of samples and only one analysis was available. a Not Detected. b The internal standard for this sample was in error and so the value listed corresponds to the value without the correction for the internal standard. c Leachates that were treated on-site are shown in italics. d The proportion of GC in the MSWA/MSW-GC sample is unknown. A thick layer of viscous fluid, presumably GC, was observed at the top of this sample. e In the first batch of analyses, the extraction was not optimized to measure the low carbon PFAS (PFBA and PFPeA) and so these measured as non-detects for the gas condensate. f The PFBS concentration for the gas condensate sample was above the limit of the calibration curve so the value listed is an estimate. 3.2. Total PFAS by leachate type and MSWA trends with incineration temperature Among the factors evaluated, waste type appears to have the largest impact on leachate total PFAS levels (sum of the 11 PFAS measured in the current study) (Fig. 2). The largest concentration differences were observed between waste types with MSWA samples characterized by the lowest total PFAS levels (as low as < 3,400 ng/L) and MSW and C&D leachates characterized by the highest (greater than 18,000 ng/L). Within waste type, incineration temperature was inversely correlated with total PFAS levels. To begin with, the ash leachate from facility D had the lowest levels of total PFAS (<3400 ng/L) relative to other landfills that also contained predominantly ash (p < 0.001). This landfill is a pure ash monofill with no integration of other waste types. Additionally, the incinerator temperature (930 to 980 °C) that produced the ash for this monofill was the highest among all the landfills that accepted ash. The MSWA landfills that received ash incinerated at intermediate temperatures (facility C, 815 to 870 °C) had intermediate levels of total PFAS, at 8,400 to 8,700 ng/L. The MSWA landfill that received ash incinerated at the lowest temperatures (facility A, 760 to 870 °C) had the highest total PFAS levels among the MSWA leachates, at 12,300 to 13,500 ng/L. The differences in total PFAS levels between facility C and facility A was dominated by a relatively large difference in the concentration of PFBS at facility A (~5,000 ng/L) versus facility C (~350 ng/L). One hypothesis is that all PFAS species are destroyed by incineration in the same proportion. If this were to be the case, given that not all of the PFAS species were decreased in a similar proportion between facility A and C, the differences in total PFAS concentrations may be coincidental. Alternatively, there is a possibility that incineration of PFAS may result in the production of shorter carbon chain compounds such as PFBS which would explain the large proportion of this species for the MSWA samples for facility A. Regardless of possible conversions, the correlation between total PFAS and incineration temperature for the ash leachates was significant (R2 = 0.92, p = 0.008), with lower total PFAS concentration associated with an increase in incineration temperature (Fig. 3). More work is needed to confirm the trend of decreasing total PFAS concentrations with incineration temperature. The trend with incineration temperature is consistent with laboratory studies that have shown that PFAS are transformed within the 500 to 1000 °C range (Krusic et al. 2005, Yamada et al. 2005, Taylor et al. 2014, Merino et al. 2016). For example, Ellis et al. (2001) found that fluoropolymers at 500 °C decompose and rearrange to form halogenated organic acids and produce polyfluoro(C3-C14) carboxylic acids. Garcia et al. (2007) found that at 850 °C, C2F6 and CF4 are formed. Feng et al. (2015) described a thermolysis mechanism for a perfluorosulfonic acid membrane that involved cleavage of both the polymer backbone and its side chains to produce perfluorocarboxylic acids. As such, the results observed in Fig. 3 are consistent with the transformation of PFAS to other species or to the partial destruction of PFAS during the waste incineration process. Further evidence of transformation is provided by evaluating the ratios of PFBA/PFOA and PFPeA/PFOA (Fig. S2). These ratios were greater than one, on average, for ash leachate samples (1.25 and 1.20, respectively) and less than one, on average, for MSW and C&D leachate samples (0.87 and 0.68, respectively) in the current study. When evaluating the ash samples in more detail, the low and medium temperature ash samples (facilities A and C) showed ratios of PFBA/PFOA of 0.99 to 1.2 and ratios of PFPeA/PFOA of 0.91 to 1.32, on average by facility. For high 196 H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 Fig. 2. Overall PFAS results for leachates collected from five facilities. All results provided in duplicate on the same sample extract and correspond to the second batch (July 2018) with the exception of the sample containing gas condensate which was analyzed once and corresponded to the first batch (January 2018). Brackets of 2 samples correspond to duplicates on the extracts of the same leachate sample. The ‘‘U” and ‘‘T” set of samples correspond to untreated (U) leachates and the corresponding treated (T) effluents. The temperatures indicate the average operating temperature of the facility where the ash was generated. mation of PFAS species, direct measurement of the exhaust gases from the waste-to-energy incinerators is warranted to confirm that PFAS are not being transferred to the gaseous phase and lost to the atmosphere. All possible releases of PFAS from incineration facilities should be evaluated in addition to gaseous emissions, including fly ash, bottom ash, and scrubbing solutions. This should be a priority for future studies. 3.3. Observations from the MSWA/MSW-GC sample Fig. 3. Total measured PFAS in ash leachates versus incineration temperatures (R2 = 0.92, p = 0.008). Horizontal error bars correspond to the range of incineration temperatures. Vertical error bars correspond to the standard deviation of duplicate analyses. temperature ash (facility D) the ratio of PFBA/PFOA was computed as 1.49 and ratio of PFPeA/PFOA was computed as 1.68. It is possible that the higher incineration temperature resulted in more PFAS transformation towards shorter C-F chain species relative to the lower incineration temperature causing this shift in the proportions, with higher proportions at higher temperatures. Given the evidence from laboratory-based studies concerning the transfor- The MSWA/MSW-GC sample from facility A originated from a leachate stream that was receiving predominantly MSWA (75%). This sample was the only one from the set that was analyzed during the first analysis round (January 2018) that did not capture the lower carbon chain alkylated PFAS (PFBA and PFPeA), suggesting that the total PFAS levels could have been higher than those shown in Fig. 2. Overall, the levels for the MSWA/MSW-GC sample are consistent with the levels observed in the samples from facility A (MSWA, 98%) except for the levels of shorter chain PFAS. The total PFAS levels for the MSWA/MSW-GC sample are consistent with the total PFAS levels for the MSWA samples at the corresponding landfill (right hand side of Fig. 2). With respect to PFAS species, the sample with the lowest total levels of measured PFAS (facility D leachate, high temperature ash monofill) had the lowest levels of all 11 individual PFAS species. Individual PFAS species for leachate from the 98% MSWA and the 75:25 MSWA/MSW-GC from facility A 197 H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 were also low for all but the PFBS species. The PFBS levels were elevated for these three samples (Fig. S3). Overall the MSWA/ MSW-GC sample was very similar to the characteristics of the corresponding leachate sample (MSWA at facility A). This comparison excludes shorter chain PFCAs which were not captured and analysed in the MSWA/MSW-GC sample. Additional MSWA/MSW-GC samples should be collected to confirm trends. 3.4. MSW versus C&D leachates The total PFAS concentration for the non-ash cells varied from 14,000 to 20,000 ng/L. The total PFAS levels between C&D (mean of 15,530 ng/L, standard deviation (SD) of 740 ng/L) and MSW landfill (mean of 15,730 ng/L, SD of 170 mg/L) types were not statistically different (p = 0.65). The finding that total PFAS levels in C&D and MSW leachates were similar in this study differs from the results in the studies by Gallen et al. (2016, 2017) who found that C&D leachates had higher levels of PFAS than the MSW leachates by about a factor of 3. The elevated levels of PFAS in C&D is relevant given that many C&D landfills are not designed to the same standards as MSW landfills. Liners at C&D landfills tend to be less elaborate (e.g., single liners with single drainage systems) with some of the older C&D landfill facilities without bottom liners. Groundwater in the vicinity of both MSW and C&D landfills should be monitored for PFAS to evaluate the impacts of the combined effects of bottom systems and waste type. 3.5. On-site landfill leachate treatment With respect to on-site leachate treatment via aeration, one onsite treatment system resulted in an increase in PFAS concentrations (MSW(100%) at facility E, p = 0.02) whereas the other facility with leachate treatment (MSWA(65%)/MSW(35%) at facility C) did not result in total PFAS levels that were statistically different (p = 0.99) between before and after treatment. This difference may be due to differences in leachate types. Facility E treated 100% MSW leachate and had an increase in PFAS levels. Facility C treated predominantly MSWA, the chemistry of which could have responded differently to aeration. The similar concentrations in the untreated and treated leachate from facility C suggests that the ash contained fewer precursors. The mean concentrations of total PFAS for facility E were 15,730 ng/L and 19,940 ng/L, before and after treatment, respectively. These results of on-site leachate treatment are consistent with studies at WWTPs (Arvaniti and Stasinakis 2015). For example, Bossi et al. (2008) found that PFAS increased in the effluent water at a plant that received municipal wastewater. This increase was attributed to the degradation of fluorinated precursors such as 8:2 FTOHs to form PFOA and 6:2 FTOH to form PFHxA (Xiao et al. 2012). et al. 2017, Allred et al. 2015). Lang et al. (2017) found that, 5:3 FTCA represented a major component of PFAS in untreated landfill leachate (400 to 1,500 ng/L). Among the different leachate types, MSW in the current study had the highest levels of 5:3 FTCA (maximum of 3050 ng/L for facility B). Ash leachates had no measurable levels of 5:3 FTCA suggesting the loss or conversion of this precursor during the incineration process. Treated leachates also had lower 5:3 FTCA levels relative to untreated leachates (p < 0.001). This difference is particularly evident for the MSW (100%) leachate where concentrations of 5:3 FTCA decreased by a factor of 5 (from 1600 to 310 ng/L, Fig. 4, top panel) after treatment. There could be several reasons for the lower values of 5:3 FTCA in leachates after treatment. The lower values could be due to volatilization resulting in a loss of 5:3 FTCA to the atmosphere, differential sorption resulting in greater adherence to the particulate phase thus removing 5:3 FTCA from solution, or the conversion of FTCA to other PFAS species, in particular to possibly a species with the same perfluorinated five carbon chain backbone, PFPeA. For PFPeA (Fig. 4, bottom panel), a marked increase in this species was observed for one of the facilities (Facility E) between untreated and treated MSW leachate. The results observed at facility E are consistent with studies that focused on transformation pathways in activated sludge WWTP processes (Wang et al. 2012, Xiao et al. 2012) that showed a conversion of PFAS from 5:3 FTCA to PFPeA during the treatment process. Similarly, studies using landfill leachates have observed the loss of 5:3 FTCA during aeration in constructed wetland systems (Yin et al. 2017). Given the evidence of this conversion, it would be of interest to evaluate the influence of aeration conditions (temperature, time, air flow rates) on the transformation of PFAS species. Future studies should include an evaluation of additional PFAS precursors and the possibility of their conversion to PFAS species. Also research should focus on evaluating the role of leachate type (100% MSW versus 65:35 MSWA/MSW) as the increase in PFPeA was observed for only one of the two facilities. When comparing levels of individual PFAS species to the national average of MSW leachates identified by Lang et al. 5:3 FTCA PFPeA 3.6. PFAS species When evaluating the carboxylated PFAS species, the treated MSW leachate from facility E had the highest carboxylated PFAS concentrations of all 12 leachate samples examined in this study, from the shortest chain carboxylated PFAS (PFBA, mean concentration of 2640 ng/L) to the longest chain (PFDA, mean concentration of 290 ng/L) measured. The only exception was PFNA where the highest concentration was observed in the leachate sample from facility A (MSWA/MSW-GC) that contained the gas condensate. Treated MSW leachate concentration (150 ng/L) was still elevated in PFNA but slightly below the level observed for MSWA/MSW-GC leachate from facility A (159 ng/L). Although the number of samples is limited in the current study, the results are consistent with the findings in other studies (Lang Fig. 4. Levels of 5:3 FTCA (top panel) and PFPeA (bottom panel) in different types of landfill leachate. A significant increase in PFPeA is observed between untreated and treated MSW leachate suggesting a transformation of 5:3 FTCA to this species during landfill leachate treatment. 198 H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 Fig. 5. Sum of PFAS species for all samples collected, organized by functional groups of carboxylated, sulfonic and FTCA and by number of carbons in the carbon–fluorine chain. Error bars correspond to two times standard deviations of the sums of the duplicate analyses. The value in the stacked bar corresponds to the sum of the duplicates. (2017), PFHxS was over an order of magnitude higher in C&D leachates (means of 4,380 ng/L compared to the national average of 350 ng/L). Even for landfills with C&D mixed with MSW, the PFHxS concentrations were noticeably high (greater than 2,200 ng/L) overall, suggesting that the source may be associated with C&D types of waste (Fig. S3). The elevated levels of PFHxS in C&D leachates are consistent with the use of PFHxS as a surfactant coating for carpets and other building materials (Jin et al. 2011). Such materials are commonly found in C&D waste and can serve as a possible source for the elevated PFHxS levels. An additional source of PFHxS may have included AFFF. PFHxS has been found at firefighting facilities that use these materials during training activities (Bräunig et al. 2019) and waste contaminated with AFFF, such as C&D materials disposed from a facility that caught fire, could possibly impact the quality of landfill leachate. For PFOA and PFOS, two of the most widely studied PFAS, levels were 2 to 9 times higher in the current study in comparison to other studies conducted at MSW landfills in the U.S. (Huset et al. 2011, Lang et al. 2017) and in European countries (Fuertes et al. 2017, Busch et al. 2010). However, the concentrations were lower in comparison to landfill leachates measured in China (Yan et al. 2015). The treated MSW leachate samples were observed to have the highest PFOA level (~3000 ng/L) and the highest PFOS level (~1200 ng/L) (Fig. S4). These results are consistent with the predominance of PFOA and PFOS in treated wastewaters (Kwon et al. 2017). Additionally, PFOA and PFOS were observed in all leachates even for the oldest (39 years) landfill consistent with prior studies that show that PFOA and PFOS are stable in the environment (Arvaniti and Stasinakis 2015, Hamid et al. 2018), with landfills serving as concentrated sources when discharged to aqueous systems. Overall, considering all samples, the 8-carbon species (PFOA and PFOS) were not the most abundant species (Fig. 5). The 6carbon carboxylated (PFHxA) and sulfonate (PFHxS) species were the most abundant, with 4-carbon sulfonate (PFBS) a close second. The U.S. EPA has not released health-based guidance for shortchained PFAS. It would be of interest to develop health-based toxicity values for shorter chain PFAS given their higher abundance in the leachates evaluated. 4. Conclusion Overall this study suggests that leachates from ash landfills had lower levels of PFAS relative to leachates from MSW and C&D land- fills. The degree to which total measured PFAS levels decreased correlated with the incineration temperatures used to generate the ash. However, not all PFAS species decreased with increasing temperature and work is needed to evaluate the impact of incineration on the distribution of PFAS species in ash leachates. This is the first paper to show that leachates from ash landfills have lower PFAS levels relative to leachates from other waste types. Furthermore, the total PFAS levels were correlated with the incineration temperature of the waste. More work is needed to confirm the correlation with incineration temperature. As part of future work the fate of PFAS at full-scale incineration facilities should be evaluated to determine whether the decreased PFAS in ash leachate is due to destruction of PFAS, transformation to volatile species, or transformation to non-volatile species that were not measured. Total PFAS levels in C&D and MSW leachates were observed to be at similar concentrations, indicating that wastes in C&D landfills could also serve as a source of PFAS release to the environment. Additionally, C&D leachates exhibited unusually high levels of PFHxS, compared to other landfill types and consistent with their use as sealants and water repellants in building materials, emphasizing the need to evaluate all waste types, not only MSW. Given the observed levels of PFAS in C&D leachates, the impact of C&D landfills, in particular unlined landfills, to groundwater should be evaluated in future studies. This study is also the first to report on PFAS leachate concentrations at field-scale on-site landfill leachate treatment systems. As observed in other studies at WWTPs, on-site leachate treatment using aeration processes increased PFAS concentrations presumably due to the conversion of precursors. To further evaluate the role of precursor conversion, future studies should consider implementing the total oxidizable precursor (TOP) assay which provides information about all precursors in samples. Such analysis may be useful in understanding why PFAS may have increased after aeration for facility E but not for facility C. Additionally, precursor data might add value in terms of differentiating wastes within MSW versus C&D. Additional work is needed to confirm trends, to evaluate alternative treatment systems, and to establish a mass balance analysis to determine the efficacy for removal of PFAS from the environment through on-site leachate treatment. Of interest would be to include non-targeted PFAS analysis to track the majority of PFAS species through the incineration and/or leachate pretreatment process. This type of analysis would be useful for identifying the major PFAS species that can be analyzed on a more routine basis. H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 Four of the facilities included in the current study discharge their leachates (~3,000 – 20,000 ng/L) to WWTPs, two after onsite treatment and two without on-site treatment. One facility included in the current study disposed its leachate to deep well injection (~10,000–17,000 ng/L). The fate of PFAS handled through deep well injection is not known, nor is the overall long-term impact of this practice. More work is needed to track the fate of PFAS in leachates currently discharged from landfills. Declaration of Competing Interest The authors declared that there is no conflict of interest. Acknowledgements Funding for this study was received through the Hinkley Center for Solid and Hazardous Waste Management. We are thankful to the landfill staff who facilitated landfill access and appreciate the input and feedback received from the project Technical Awareness Group, from the U.S. EPA, and anonymous reviewers. This article was reviewed in accordance with the policy of the National Exposure Research Laboratory, U.S. Environmental Protection Agency, and approved for publication. Approval does not signify that the contents necessarily reflect the view and policies of the Agency, nor does mention of trade names or commercial products constitute endorsement or recommendation for use. Appendix A. Supplementary material Supplementary data to this article can be found online at https://doi.org/10.1016/j.wasman.2020.03.034. References Allred, B.M., Lang, J.R., Barlaz, M.A., Field, J.A., 2015. Physical and biological release of poly- and perfluoroalkyl substances (PFASs) from municipal solid waste in anaerobic model landfill reactors. Environ. Sci. Technol. 49 (13), 7648–7656. American Public Health Association (APHA), 2018. Standard Methods for the Analysis of Water and Wastewater, Method 5220 Chemical Oxygen Demand. American Public Health Association Inc, Washington, D.C.. Arvaniti, O.S., Stasinakis, A.S., 2015. Review on the occurrence, fate and removal of perfluorinated compounds during wastewater treatment. Sci. Total Environ. 524–525, 81–92. Association of State Drinking Water Administrators (ASDWA), (2019). Per- and polyfluoroalkyl substances (PFAS) state drinking water program challenges. https://www.asdwa.org/pfas/ [accessed January 18, 2019]. Backe, W.J., Field, J.A., 2012. Is SPE necessary for environmental analysis? A quantitative comparison of matrix effects from large-volume injection and solid-phase extraction based methods. Environ. Sci. Technol. 46, 6750–6758. Backe, W.J., Dat, T.C., Field, J.A., 2013. Zwitterionic, cationic, and anionic fluorinated chemicals in aqueous film forming foam formulations and groundwater from U. S. military bases by nonaqueous large-volume injection HPLC-MS/MS. Environ. Sci. Technol. 47 (10), 5526–15234. Barry, VWinquist, A.Steenland, K., 2013. Perfuorooctanoic acid (PFOA) exposures and incident cancers among adults living near a chemical plant. Environ. Health Perspect. Nov-Dec(11-12), 1313–1318. Benskin, J.P., Li, B., Ikonomou, M.G., Grace, J.R., Li, L.Y., 2012. Per- and polyfluoroalkyl substances in landfill leachate: patterns, time trends, and sources. Environ. Sci. Technol. 46, 11532–11540. Bossi, R., Strand, J., Sortkjær, O., Larsen, M.M., 2008. Perfluoroalkyl compounds in Danish wastewater treatment plants and aquatic environments. Environ. Int. 34 (4), 443–450. Bräunig, J., Baduel, C., Barnes, C.M., Mueller, J.F., 2019. Leaching and bioavailability of selected perfluoroalkyl acids (PFAAs) from soil contaminated by firefighting activities. Sci. Total Environ. 646, 471–479. Busch, J., Ahrens, L., Sturm, R., Ebinghaus, R., 2010. Polyfluoroalkyl compounds in landfill leachate. Environ. Pollut. 158 (5), 1467–1471. Calafat, A.M., Wong, L.Y., Kuklenyik, Z., Reidy, J.A., Needham, L.L., 2007. Polyfluoroalkyl chemicals in the U.S. population: data from the national health and nutrition examination survey (NHANES) 2003–2004 and comparisons with NHANES 1999–2000. Environ. Health Perspect. 115, 1596– 1602. California Water Boards (CWB), 2019. Perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS) accessed April 7, 2019 https://www. waterboards.ca.gov/drinking_water/certlic/drinkingwater/PFOA_PFOS.html. 199 Dauchy, X., Boiteux, V., Bach, C., Rosin, C., Munoz, J.F., 2017. Per- and polyfluoroalkyl substances in firefighting foam concentrates and water samples collected near sites impacted by the use of these foams. Chemosphere 183, 53–61. Ellis, D.A., Mabury, S.A., Martin, J.W., Muir, D.C.G., 2001. Thermolysis of fluoropolymers as a potential source of halogenated organic acids in the environment. Nature 412, 321–324. Favreau, P., Poncioni-Rothlisberger, C., Place, B.J., Bouchex-Bellomie, H., Weber, A., Tremp, J., Field, J.A., Kohler, M., 2017. Multianalyte profiling of per- and polyfluoroalkyl substances (PFAS) in liquid commercial products. Chemosphere 171, 491–501. Feng, M., Qu, R., Wei, Z., Wang, L., Sun, P., Wang, Z., (2015). Characterization of the thermolysis products of Nafion membrane: A potential source of perfluorinated compounds in the environment. Scientific Reports, 5: 9859. Florida Administrative Code (FAC), 2016. 62–701. Solid Waste Management Facilities, Florida Department of Environmental Protection, Tallahassee, FL. Fuertes, I., Gómez-Lavín, S., Elizalde, M.P., Urtiaga, A., 2017. Perfluorinated alkyl substances (PFAS) in northern Spain municipal solid waste landfill dfill leachates. Chemosphere 168, 399–407. Gallen, C., Gallen, M., Drage, D., Kaserzon, S., Baduel, C., Banks, A., Broomhall, S., Mueller, J.F., 2016. Occurrence and distribution of brominated flame retardants and perfluoroalkyl substances in Australian landfill leachate and biosolids. J. Hazard. Mater. 312, 55–64. Gallen, C.D., Drage, D., Eaglesham, G., Grant, S., Bowman, M., Mueller, J.F., 2017. Australia-wide assessment of perfluoralkyl substances (PFAS) in landfill leachates. J. Hazard. Mater. 331, 132–141. Garcia, A.N., Viciano, N., Font, R., 2007. Products obtained in the fuel-rich combustion of PTFE at high temperature. J. Anal. Appl. Pyrol. 80, 85–91. Hamid, H., Li, L.Y., Grace, J.R., 2018. Review of the fate and transformation of perand polyfluoroalkyl substances (PFAS) in landfills. Environ. Pollut. 235, 74–84. Houtz, E.F., Higgins, C.P., Field, J.A., Sedlak, D.L., 2013. Persistence of perfluoroalkyl acid precursors in AFFF-impacted groundwater and soil. Environ. Sci. Technol. 47 (15), 8187–8195. Huset, C.A., Barlaz, M.A., Barofsky, D.F., Field, J.A., 2011. Quantitative determination of fluorochemicals in municipal landfill leachates. Chemosphere 82 (10), 1380– 1386. Jin, C., Sun, Y., Islam, A., Qian, Y., Ducatman, A., 2011. Perfluoroalkyl acids including perfluorooctane sulfonate and perfluorohexane sulfonate in firefighters. J. Occup. Environ. Med. 53 (3), 324–328. Kjeldsen, P., Barlaz, M.A., Rooker, A.P., Baun, A., Ledin, A., Christensen, T.H., 2002. Present and long-term composition of MSW landfill leachate: a review. Crit. Rev. Environ. Sci. Technol. 32 (4), 297–336. Kotthoff, M., Müller, J., Jürling, H., Schlummer, M., Fiedler, D., 2015. Perfluoroalkyl and polyfluoroalkyl substances in consumer products. Environ. Sci. Pollut. Res. 22 (19), 14546–14559. Krusic, P.J., Marchione, A.A., Roe, D.C., 2005. Gas-phase NMR studies of the thermolysis of perfluorooctanoic acid. J. Fluorine Chem. 126, 1510. Kwon, H.-O., Kim, H.-Y., Park, Y.-M., Seok, K.-S., Oh, J.-E., Choi, S.-D., 2017. Updated national emission of perfluoroalkyl substances (PFASs) from wastewater treatment plants in South Korea. Environ. Pollut. 220, 298–306. Lang, J.R., Allred, B.M., Peaslee, G.F., Field, J.A., Barlaz, M.A., 2016. Release of per- and polyfluoroalkyl substances (PFAS) from carpet and clothing in model anaerobic landfill reactors. Environ. Sci. Technol. 50 (10), 5024–5032. Lang, J.R., Allred, B.M., Field, J.A., Levis, J.W., Barlaz, M.A., 2017. National estimate of per- and polyfluoroalkyl substance (PFAS) release to U.S. municipal landfill leachate”. Environ. Sci. Technol. 51 (4), 2197–2205. Lau, C., Anitole, K., Hodes, C., Lai, D., Pfahles- Hutchens, A., Seed, J., 2007. Perfluoroalkyl acids: a review of monitoring and toxicological findings. Toxicol. Sci. 99 (2), 366–394. Li, K., Gao, P., Xiang, P., Zhang, X., Cui, X., Ma, L.Q., 2017a. Molecular mechanisms of PFOA-induced toxicity in animals and humans: Implications for health risks. Environ. Int. 99, 43–54. Li, Yangjie, Cheng, Yating, Xie, Zhiyong, Zeng, Feng, 2017b. Perfluorinated alkyl substances in serum of the southern Chinese general population and potential impact on thyroid hormones. Sci. Rep. 7 (1). https://doi.org/10.1038/srep43380. Merino, N., Qu, Y., Deeb, R.A., Hawley, E.L., Hoffman, M.R., Mahendra, S., 2016. Degradation and removal methods for perfluoroalkyl and polyfluoroalkyl substances in water. Environ. Eng. Sci. 33 (9), 615–649. O’Hagan, D., 2008. Understanding organofluorine chemistry. An introduction to the C-F bond. Chem. Soc. Rev. 37, 308–319. Oliaei, F., Kriens, D., Weber, R., Watson, A., 2013. PFOS and PFC releases and associated pollution from a PFC production plant in Minnesota (USA). Environ. Sci. Pollut. Res. 20, 1977–1992. Organization for Economic Cooperation and Development (OECD) Environment Directorate, 2002. Hazard assessment of perfluorooctane sulfonate (PFOS) and its salts accessed January 21, 2019 www.oecd.org/chemicalsafety/riskassessment/2382880.pdf. Perkola, N., Sainio, P., 2013. Survey of perfluorinated alkyl acids in Finnish effluents, storm water, landfill leachate and sludge. Environ. Sci. Pollut. Res. 20, 7979–7987. Qin, X.Di., Qian, Z., Dharmage, S.C., Perret, J., Geiger, S.D., Rigdon, S.E., Howard, S., Zeng, X.-W., Hu, L.-W., Yang, B.-Y., Yang, Z., Li, M., Xu, S.-L., Bao, W.-W., Zhang, Y.-Z., Yuan, P., Wang, J., Zhang, C., Tian, Y.-P., Nian, M., Xiao, X., Chen, W., Lee, Y. L., Dong, G.-H., 2017. Association of perfluoroalkyl substances exposure with impaired lung function in children. Environ. Res. 155, 15–21. Schaider, L.A., Balan, S.A., Blum, A., Andrews, D.Q., Strynar, M.J., Dickinson, M.E., Lunderberg, D.M., Lang, J.R., Peaslee, G.F., 2017. Fluorinated compounds in U.S. Fast food packaging. Environ. Sci. Technol. Lett. 4 (3), 105–111. 200 H.M. Solo-Gabriele et al. / Waste Management 107 (2020) 191–200 Schultz, M.M., Barofsky, D.F., Field, J.A., 2003. Fluorinated alkyl surfactants. Environ. Eng. Sci. 20 (5), 487–501. Steenland, K., Woskie, S., 2012. Cohort mortality study of workers exposed to perfluorooctanoic acid. Am. J. Epidemiol. 176 (10), 909–917. Taylor, P.H., Yamada, T., Striebich, R.C., Graham, J.L., Giraud, R.J., 2014. Investigation of waste incineration of fluorotelomer-based polymers as a potential source of PFOA in the environment. Chemosphere 110, 17–22. United States Environmental Protection Agency (U.S. EPA), (2014). Emerging contaminants – perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA). EPA 505-F-14-001. Epa, U.S., 2016a. Lifetime health advisories and health effects support documents for perfluorooctanoic acid and perfluorooctane sulfonate. Fed. Reg. 81 (101), 33250–33251. Epa, U.S., 2016b. Standard operating procedure: improved methods for extraction and analysis of perfluorinated compounds (PFCs) from surface waters and well water by ultra-high performance liquid chromatography (UPLC)-tandem mass spectrometry (MS/MS). U.S. EPA, Office of Research and Development, National Exposure Research Laboratory, Exposure Methods and Measurements Division. Publ. Health Chem. Branch. Document D-EMMD-PHCB-043-SOP-03. U.S. EPA, (2018). Basic information on PFAS. https://www.epa.gov/pfas/basicinformation-pfas [accessed January 20, 2019]. Venkatesan, A., Halden, R., 2013. National inventory of perfluoroalkyl substances in archived U.S. biosolids from the 2001 EPA National Sewage Sludge Survey. J. Hazard. Mater. 252–253, 413–418. Wang, N., Buck, R.C., Szostek, B., Sulecki, L.M., Wolstenholme, B.W., 2012. 5:3 Polyfluorinated acid aerobic biotransformation in activated sludge via novel ‘‘one-carbon removal pathways”. Chemosphere 87 (5), 527–534. Wang, Z., DeWitt, J.C., Higgins, C.P., Cousins, I.T., 2017. A never-ending story of perand polyfluoroalkyl substances (PFASs)?. Environ. Sci. Technol. 51, 2508–2518. Xiao, F., Halbach, T.R., Simcik, M.F., Gulliver, J.S., 2012. Input characterization of perfluoroalkyl substances in wastewater treatment plants: Source discrimination by exploratory data analysis. Water Res. 4 (9), 3101–3109. Yamada, T., Taylor, P.H., Buck, R.C., Kaiser, M.A., Giraud, R.J., 2005. Thermal degradation of fluorotelomer treated articles and related materials. Chemosphere 61, 974–984. Yan, H., Cousins, I.T., Zhang, C., Zhou, Q., 2015. Perfluoroalkyl acids in municipal landfill leachates from China: Occurrence, fate during leachate treatment and potential impact on groundwater. Sci. Total Environ. 524–525, 23–31. Yang, Q., Abedi-Valugerdi, M., Xie, Y., Zhao, X.Y., Moller, G., Nelson, B.D., DePierre, J. W., 2002. Potent suppression of the adaptive immune response in mice upon dietary exposure to the potent peroxisome proliferator, perfluorooctanoic acid. Int. Immunopharmacol. 2 (2–3), 389–397. Ye, F., Zushi, Y., Masunaga, S., 2015. Survey of perfluoroalkyl acids (PFAAs) and their precursors present in Japanese consumer products. Chemosphere 127, 262– 268. Yin, T., Chen, H., Reinhard, M., Yi, X., He, Y., Gin, K.Y.-H., 2017. Perfluoroalkyl and polyfluoroalkyl substances removal in a full-scale tropical constructed wetland system treating landfill leachate. Water Res. 125, 418–426.