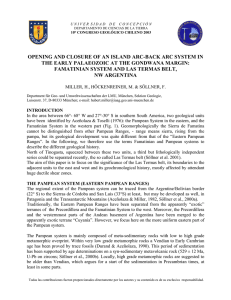

HOSTED BY Available online at www.sciencedirect.com ScienceDirect Soils and Foundations 57 (2017) 384–396 www.elsevier.com/locate/sandf A new prediction method for the rheological behavior of grout with bottom ash for jet grouting columns Hamza Güllü ⇑ Department of Civil Engineering, University of Gaziantep, 27310 Gaziantep, Turkey Received 18 December 2015; received in revised form 4 October 2016; accepted 4 February 2017 Available online 16 May 2017 Abstract Among the many variables involved in jet grout technology, dealing with the complex phenomena of grout flow, specifically related to the pumping pressure (shear stress), the pumping rate (shear rate) and the viscosity, mostly becomes a difficult task for grouting in practice. Thus, this study presents the capability of a new methodology in soft computing techniques, called gene expression programming (GEP), to predict the rheological behavior (i.e., the shear stress versus the shear rate and the viscosity versus the shear rate) of grout with bottom ash for jet grouting columns, as an alternative approach to traditional methods. For this purpose, shear stress and viscosity formulas, including the main input variables of the shear rate and bottom ash proportion, are derived using GEP modeling through the stages of production and testing. Then, the performances of the GEP formulas are compared with the measured data and the regression and conventional rheological models (De Kee and Robertson-Stiff) for use in practice. The results indicate that the GEP formulas are able to yield estimations with good precision resulting in better predictions (R 0.96) compared to the regression model. A successful description of the pseudoplastic response of rheological behavior is given, and a response consistent with conventional rheological models is obtained. Moreover, the measured data (shear stress and viscosity) generally follow the GEP modeling well, but the level of satisfaction is more favorable at high proportions of bottom ash. In conclusion, the study reveals that the derived GEP formulas are relatively promising for estimating the pumping pressure, the viscosity and the pumping rate of grout with bottom ash for jet grouting columns, at least in assisting conventional methods for preliminary designs. Ó 2017 Production and hosting by Elsevier B.V. on behalf of The Japanese Geotechnical Society. This is an open access article under the CC BYNC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). Keywords: Jet grouting column; Grout; Bottom ash; Rheological behavior; Gene expression programming 1. Introduction The jet grouting technique is one of the most popular ground-improvement methods that offers relatively good soil quality for the engineering characteristics (i.e., bearing capacity, settlement, permeability, etc.) in a variety of applications (i.e., foundation reinforcement, retaining structures, impermeable barriers, etc.) for solving possible ground problems. The resulting product is a cemented- Peer review under responsibility of The Japanese Geotechnical Society. ⇑ Fax: +90 342 360 1107. E-mail address: hgullu@gantep.edu.tr soil body called the jet column appropriately arranged in the subsoil (Croce and Flora, 2000). In brief, in this technique (Fig. 1), the grout (cement-based fluid mixture) is injected into the ground at the treatment depth at a very high flow (200–400 L/min) with a very high velocity of energy through small-diameter injection nozzles (1– 10 mm) placed on a grout pipe or rod. The jet grout propagates radially with respect to the treatment axis from the borehole at a constant rate of rotation due to the road speed by separating the soil particles. The particles are then mixed and cemented with the jet grout. Then, the rod is slowly withdrawn toward the ground surface resulting in a homogeneous mass of a high-strength soil-cement body http://dx.doi.org/10.1016/j.sandf.2017.05.006 0038-0806/Ó 2017 Production and hosting by Elsevier B.V. on behalf of The Japanese Geotechnical Society. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). H. Güllü / Soils and Foundations 57 (2017) 384–396 Fig. 1. Brief representation of jet grouting (Shen et al., 2013). (jet column) due to the solidification of the injected cementbased grout (Croce and Flora, 2000; Modoni et al., 2006; Nikbakhtan et al., 2010). Most jet grouting applications have been based on the subjective rules of thumb firstly by means of trial and error at the site for jet grouting. The grout is ejected from the small nozzles with at very high speeds, but the experimental determination of the velocity mechanism is very difficult. Thus, at the design stage of the jet grout columns, there still appears a relative degree of uncertainty coming from the grout variables (the grout composition, binder content, particle size, particle shape, particle distribution, temperature, mixing, etc.) that play a significant role in grout rheology. The uncertainty during the injection process is also a major problem. Thus, it is necessary to adjust the operational injection parameters (Croce and Flora, 2000; Modoni et al., 2006, 2016; Ochmański et al., 2015; Ribeiro and Cardoso, 2016). Relevant to the velocity considerations of grout are the uncertainty related to the pumping pressure (shear stress), the pumping rate (shear rate) and the viscosity of the grout involved with rheological behavior (i.e., flow behavior) that significantly affect the hardened properties of the grout (Warner, 2004). This issue encourages engineers to develop more satisfactory design methods from the viewpoint of the prediction of rheological behavior in jet grouting. In terms of jet-soil interaction, the jet-grout column can be reasonably considered through the typical features of the seepage and erosion. These features can be useful for modeling gravelly soils, and sandy and clayey soils, respectively (Modoni et al., 2006; Shen et al., 2013), where the rheology plays a significant role in their modeling. Through the mechanisms of jet grouting (Dabbagh et al., 2002) a bellshaped crater is formed at the soil-jet interface with a cutting front advancing at a progressively slower rate with the increased rate from the nozzle. For jet grouting of very pervious soils (gravels and sandy gravels), the seepage 385 velocity is very large near the nozzle. However, it decreases sharply as the grout penetrates further into the soil (Modoni et al., 2006). From the viewpoint of grout rheology, it may be inferred that the injected flow propagates in the jet column under turbulent conditions in the inner region and under laminar conditions in the outer region. The diameter of jet grout column increases considerably with the soil permeability through the mechanism of seepage in the case of very pervious materials (i.e., gravelly soils). On the other hand, decreases in the column diameter obtained for sands and clays depends upon the shear strength of the soil. When the injected grout impacts the soils with lower permeability compared to gravel, the grout seepage is largely inhibited. Then, it turns back dragging the soil aside from its initial position through the erosion mechanism. This erosion mechanism of the flow results in the growth of the jet columns together with the replacement of the soil particles by the grout. The column diameter, involved with the flow behavior, can be simulated on the basis of the erosive action of the injected flow which depends upon the resistive action of the soil (Modoni et al., 2006, 2016). The extension of jet erosion for the jet grouting column results from the balance between the soil resistance and the jet cutting energy (Flora et al., 2013). It has been reported that the dependence of the column diameters for all soil types during the grouting process can generally be attributed to the parameters that include the diameter of the distance from the nozzle, the number of nozzles, the lifting speed of the monitor, the velocity along the cross-sectional profile, the kinematic viscosity of the grout and the flow rate of the grout or the fluid velocity (Modoni et al., 2006; Flora et al., 2013). Regarding clayey soils, jet grouting is found effective only when the performance is improved by high flow rates and low monitor withdrawal speeds. However, the increase in volume of the injected fluid for an appropriate flow rate could increase the amount of spoil. This results in a reduction in the economical efficiency of the ground improvement (Modoni et al., 2006). One of the existing methods for estimating the column diameter through the design stage of jet grouting is the empirical approach (Shen et al., 2013). In the proposed formulations for the empirical approach (Shibazaki, 2003; Mihalis et al., 2004), it is observed that the variables of jetting pressure and the flow rate of the grout play primary roles compared to the other variables (the number of passes of the jet, the velocity of the nozzle, the withdrawal rate of the rod) (Shen et al., 2013). It has been reported that any adverse effect due to the interactions with the variables during the jet grouting process may cause detrimental effects to the foundations of buildings or utilities as well as to the anticipated displacements in the subsoil and ground surface (Wang et al., 2013). When the jet grouting involves the injection of large volumes of grout that could need high pumping pressure, a considerable lateral movement of the soil with significant ground improvement can be expected. This could have a possible impact involving the hydraulic fracturing of the ground 386 H. Güllü / Soils and Foundations 57 (2017) 384–396 (Shen et al., 2008; Wang et al., 2013). Regarding the composition of the injected grout, a recent study (Modoni et al., 2016) has shown that denser and less viscous grouts allow columns with larger dimensions to be reached. In practice, most of the operational parameters for jet grouting are assigned based on previous experiences with experimentally verified field trials for their effectiveness (Flora et al., 2013; Shen et al., 2013). Nonetheless, more reliable estimations of the shear stress (pumping pressure), the shear rate (pumping rate) and the grout viscosity at the design stage of jet grouting columns are of utmost importance. This is due to the rheology of these grout variables that significantly interacts with other variables, such as the rate of penetration of the fluid jet in the soil, the rotation speed, the duration of jetting action and the withdrawal rate for the final desired quality (i.e., the hardened state of the grout). The rheology of grout (i.e., cement-based mixtures) can be represented by the flow behavior of the shear stress versus the shear rate. Depending upon the mixture proportions and the considered range of shear rates, the flow behavior due to the cement-based grout for jet grouting mostly results in the nonlinear responses of the pseudoplastic (shear thinning) or dilatant (shear thickening). While the pseudoplastic response exhibits viscosity (apparent viscosity) that decreases with the increasing shear rate, the dilatant response exhibits viscosity that increases with the increasing shear rate (Roussel et al., 2010; Kazemian et al., 2012; Güllü, 2015, 2016) (Fig. 2). While the pseudoplastic response could provide some interesting effects for fresh grout, it has been reported (Ma et al., 2016) that the dilatant response is strongly undesired for grout mixtures in the process of mixing or pumping. The dilatant response may even lead to the damaging of the grouting equipment, even though it is hard to avoid for grout. It is important to note that the grouting process during the production, mixing, transportation and pumping could result in changes in the shear rate that causes an obvious change in the rheological behavior. Thus, the grouting pressure, the flow rate, the viscosity and the time become the main focus in the design of grouting. To ensure an adequate flow of the grout for jet grouting, it is essential to assure good fresh grout properties from the viewpoint of rheology (Yahia, 2011; Ma et al., 2016). It should be noted that the pumping pressure due to the grout behavior during pumping will depend on the pumping rate and the mixture proportion of the binder composition (Roussel et al., 2010). The fundamental parameter, known as the viscosity due to the rheological behavior of grout, depends not only on the shear rate applied to the mixture, but also on the duration under which the grout mixture has been subjected to shearing during pumping. The yield stress (i.e., shear stress at a zero shear rate) is also of importance such that elastic deformation occurs when shear stress is applied that is lower than the yield value. A continuous flow is obtained when the shear stress exceeds the yield stress or the internal network force resists structural breakage (Bras et al., 2013). Fig. 2. Typical nonlinear rheological behaviors of cement-based grout for jet grouting (modified from Kazemian et al., 2012). In other words, the yield stress of the grout mixture during grouting should be overcome to initiate the flow from rest. The grout flow stops during casting below the yield stress (Roussel et al., 2010). All these concerns can clearly be overcome by referring to the impact of the rheological behavior of the grout that needs to be investigated for obtaining reliable prediction methods. The rheological behavior of grout is closely associated with its fresh properties that should be understood and controlled well in order for the correct pumping and flowing of the grout inside the ground soil to be injected for improvement. The rheological behavior of grout mixtures (Fig. 2) could be described by rheological models (Bingham, modified Bingham, Casson, De Kee, Herschel-Bulkley, and Robertson-Stiff, etc.) that offer mathematical equations for the shear stress versus the shear rate, reported in many past studies (Yahia and Khayat, 2001, 2003; Nehdi and Rahman, 2004; Banfill, 2006; Kazemian et al., 2012; Güllü, 2016). It has been observed that the mathematical equations for the rheological models are mostly based on a derivation using the curve fitting method that gives the empirical relationships for the shear stress versus the shear rate curves. It was proposed in the previous study (Güllü, 2016) that while the Casson model is unfavorable for the case of jet grouting, the Bingham, modified Bingham, Herschel-Bulkley, De Kee and Robertson-Stiff models could be acceptable through the ranking from low to high H. Güllü / Soils and Foundations 57 (2017) 384–396 levels, respectively. It can be said that the time-dependent behavior of the rheological models limitedly allows for the fitting of the shear stress, the shear rate and the viscosity data to their empirical equations, since none of them is free from statistical errors (Nehdi and Rahman, 2004). Thus, as well as the need to choose an appropriate model, the rheology of the mathematically derived model deserves to be investigated by more attempts that depend upon on the power for precise predictions with the fewest errors. If relationships could be established on the basis of more reliable methods alternatively, the rheological behavior of grout mixtures mostly involved with the interactions of the shear stress, the shear rate and the viscosity could be understood well in practice for jet grouting applications. Through the development of soft computing techniques in recent decades (Tinoco et al., 2014; Ochmański et al., 2015), a new prediction approach to artificial intelligence, called gene expression programming (GEP), has been proposed for function finding (i.e., mathematical equations) for more precise estimations of desired models, compared to the conventional curve-fitting methods. GEP is as an extended algorithm of the biological evolutionary-based-c omputational technique that was first proposed by Ferreira (2001). As for a comparison with previous genetic-based-methods (i.e., genetic algorithm (Goldberg, 1989) and genetic programming (Koza, 1992)), it has been reported (Ferreira, 2001; Baykasoglu et al., 2008; Güllü, 2012) that the GEP technique offers superior algorithms for solving the complex relationships between model parameters. Its algorithms have the ability to produce relationships between the data of input variables (i.e., independent variables) and the corresponding output variables (i.e., dependent variables) resulting in the derivation of mathematical formulations through an efficient evolutionary process in a wide range of flexible operations applicable to experimental data. This facility of flexible operations provides the derivation of formulations that considerably reduce the errors between predicted and measured outputs. Moreover, this GEP facility has been found to be relatively beneficial particularly for the most complex behaviors (such as the rheological behavior of grout addressed in this study) between input and output parameters. Using the GEP for the field of civil engineering has been found successful for solving several issues and for the derivation of predictive models for a wide range of applications (Baykasoglu et al., 2008; Cevik and Sonebi, 2008; Sonebi and Cevik, 2009; Saridemir, 2010; Alkroosh and Nikraz, 2011; Güllü, 2012). However, as attempts to use GEP for the prediction of the rheological behavior of grout mixtures for jet grouting are insufficient, they still need to be extensively studied. More importantly, according to the author’s knowledge of surveying and predictions of rheological behavior for jet grouting purposes via the GEP method, cement-based-grout mixtures that specifically include waste material (i.e., bottom ash in this study) have not been researched up to now. Bottom ash (an industrial waste material or byproduct) is a pozzolanic material 387 that could be useful for improving the flow properties of grout mixtures (Güllü, 2015), most likely due to the interparticle repulsive forces developed through pozzolanic reactions from the viewpoint of physicochemical effects (Roussel et al., 2010; Yahia, 2011). The reuse of bottom ash in grout mixtures as a recyclable material would bring about economical and environmental benefits. Consequently, an attempt has been made in this paper to model the flow phenomena due to the rheology of grout mixtures with bottom ash via the GEP approach for jet grouting columns. Considering the complexity of the flow characteristics, the prediction has been restricted to approximations of the shear stress (i.e., pumping pressure) versus the shear rate (i.e., pumping velocity) and the viscosity (apparent viscosity) versus the shear rate. 2. GEP methodology The GEP algorithm simply presented in Fig. 3 has been employed in this study for the derivation of the mathematical formulations due to the generation of models through the evolutionary process. In this process, the GEP modeling starts with the random generation of chromosomes of the initial population (see Ferreira (2001) for algorithm details). The GEP methodology is based on the evolution of computer programs (chromosomes or individuals) that are encoded linearly in the chromosomes of a fixed length. Fig. 3. Flow chart of GEP algorithm used for this study (modified from Ferreira (2001)). 388 H. Güllü / Soils and Foundations 57 (2017) 384–396 Expression tree (ETs) (Fig. 4), which are the main power of GEP for the formula derivation, have been used to represent the chromosomes of different sizes and shapes. During the expressions of the GEP models, the gene (one-ormultiple) encoded in a smaller sub-program has been constructed by the chromosomes. Linking functions are used to connect multiple genes. The computations of the GEP algorithm (Fig. 3) for the model generations and the function finding use biologically evolutionary operators, which include mutation, inversion, transposition and recombination (crossover) operators (Ferreira, 2001; Baykasoglu et al., 2008; Alkroosh and Nikraz, 2011). The mathematical derivations of the models, by means of the GEP algorithm (Fig. 3), are obtained through a procedure that generally includes the following main components: (i) the terminal set (i.e., the model variables, such as a, b, c and d, and the constants, such as 1, 2, 3 and 4), (ii) the function set (i.e., the arithmetical and mathematical operators used in the model, such as +, , *, /, Sqrt, Exp, Ln, Sin, Cos, etc., or Boolean functions, such as AND, OR, IF, etc.), (iii) the fitness function (i.e., the function used for the GEP modeling to provide an optimal solution for the expression of the formulation (i.e., the derivation of the mathematical equation) within an accepted error or correlation coefficient), (iv) the stop condition (i.e., a stopping criterion met for the developmental process and repeated due to the individuals of the new generation based on an error tolerance on the fitness or a predefined number of generations) (Ferreira, 2001; Saridemir, 2010). The fitness function of the GEP algorithm (Fig. 3) is mathematically expressed by the error Eq. (1), principally the absolute error (Eq. (1a)) or the relative error (Eq. (1b)), as follows (Ferreira, 2001): Fitnessi ¼ Ct X ðM jC ði;jÞ T ðjÞ jÞ j¼1 ð1aÞ Ct X C ði;jÞ T ðjÞ M 100 Fitnessi ¼ T ðjÞ j¼1 ð1bÞ where ‘‘M” is the range of selection, ‘‘C(i, j)” is the value returned by the individual chromosome ‘‘i” for fitness case ‘‘j”, ‘‘Ct” is the total number of fitness cases and ‘‘Tj” is the target value for fitness case ‘‘j”. It is noted that the GEP system in this form of fitness function is able to find the optimal solution for itself. The GEP running for the model generations could be stopped when the fitness values vary within the tolerable limits required for the model derivation. Through the fitness evaluations Eq. (1) of the GEP algorithm (Fig. 3), the three statistical measures given by Eq. 2 were employed for a performance assessment of the generated GEP models in this study, namely, the mean absolute error (MAE), the root-mean-squared error (RMSE) and the correlation coefficient (R), as follows: MAE ¼ N 1X jX m X p j N i¼1 PN RMSE ¼ R¼ i¼1 ðX m X p Þ N ð2aÞ 2 !1=2 PN 2 N X ðX m X p Þ 2 ðX m Þ i¼1 PN 2 i¼1 i¼1 ðX m Þ ð2bÞ !0:5 ð2cÞ where N is the number of samples, and Xm and Xp are the measured and predicted output values, respectively. The aim is to produce GEP models that are capable of fewer errors with a higher correlation using the performance measures. For the derivation of GEP-based empirical models of the rheological behavior (i.e., Fig. 2), by means of the grout mixture for jet grouting in this study, a free evaluation of the GEP software, called GeneXproTools (www.gepsoft.com) and developed by Ferreira (2001), has been run for the employed GEP algorithm (Fig. 3). This tool has been employed successfully in the past works (Alkroosh and Nikraz, 2011; Güllü, 2012) for engineering problems. 3. Data used and development of GEP model Fig. 4. Typical example of expression tree with one gene. The data (i.e., the shear stress versus the shear rate due to the cement-based grout mixture with bottom ash additions) used for the GEP modeling in this study was obtained from the experimental study conducted in the previous work (Güllü, 2015). The viscosity used for the modeling in this study is the apparent viscosity (i.e., the ratio between instantaneous shear stress and shear rate) that was calculated from the data. Readers interested in a detailed description of the experimental study are asked to refer to the corresponding work. In summary, the experimental study consists of conducting rheometer (or viscometer) tests for obtaining the shear stress-shear rate data due to the cement-based grout mixtures with added H. Güllü / Soils and Foundations 57 (2017) 384–396 bottom ash for jet grouting purposes. The grout mixtures include the binders of cement (PC)+bottom ash (BA), where the bottom ash additions are at the stabilizer proportions of 0%, 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90% and 100%, by dry weight of the binder, employing the water/binder ratio of 1/1. The experimental apparatus of the rheometer used for the testing is a rotational rheometer with a smooth-walled concentric cylinder (Brookfield DV-II + Pro). The shear stresses are measured at the shear rates of 0.17, 0.34, 0.85, 1.70, 3.40, 6.8, 17 and 34 s1. The principal of the operation by the DV-II + Pro type rheometer is to drive a spindle (immersed in the test fluid) through a calibrated spring. The spring deflection, measured with a rotary transducer, is used to measure the viscous drag of the fluid against the spindle. The measurement range of the rheometer is determined by the rotational speed, the size and the shape of the spindle, the container and the calibrated spring. The data used for the GEP modeling in this study have been illustrated in Fig. 5. Table 1 summarizes the variables included in the GEP models, the number of samples and the range of variables. As for the development of the GEP models, their input and output variables for the derivation of the mathematical formulas due the rheological behavior have been presented in Table 2. The GEP models are produced in terms of function formulations that include the terminal set (i.e., variables) given by Eq. 3, as follows: s ¼ f ð_c; BAÞ ð3aÞ s ¼ f ð_c; g; BAÞ ð3bÞ g ¼ f ð_c; BAÞ ð3cÞ g ¼ f ðs; c_ ; BAÞ ð3dÞ In order for the data division to generate the GEP models in this study, the data are randomly divided into two subsets (i) a training set for model calibration and (ii) a testing test for model generalization or verification, following the recommendations in the previous studies (Baykasoglu et al., 2008; Alkroosh and Nikraz, 2011; Güllü, 2012). As a result, 56 data samples (71%) of the available 79 data samples are used for the training set, 389 Table 1 Data used in the study: the variables, the number of samples and the range. Variables Number of samples Range Shear stress (s), Pa Viscosity (g), Pa s Shear rate (_c), 1/s Bottom Ash (BA) addition, % 79 79 79 79 0.09–21.4 0.03–13.5 0.17–34 0–100 s = shear stress (Pa), g = viscosity (Pa s), c_ = shear rate (1/s), BA = Bottom Ash (%). Table 2 Inputs and outputs of the GEP models. Model name Model input Model output s s g g c_ , c_ , c_ , s, s s g g BA g, BA BA c_ Z, BA and 23 data samples (29%) are used for the testing set. Here, it should be noted that the GEP models are mostly able to predict within the ranges of data used, since the GEP performs best in interpolation rather than extrapolation, like all empirical models. For building the formulations, the settings (i.e., the fitness function, the number of chromosomes, the head size, the linking functions, the GEP operators, the function set and the number of generations) used for the GEP models are presented in Table 3. As shown in this table, the fitness function of the error type (MAE) is used for the fitness of the models through the performance measures (Eq. 2) given earlier. The sizes of the general GEP settings (i.e., the number of chromosomes, the head size, the number of genes and the linking functions of the genes) were fixed after many trials to obtain high fitness. The settings of the biologically evolutionary GEP operators (i.e., mutation, inversion, transposition and recombination) for the model generations were selected from the values suggested in past studies (Ferreira, 2001; Baykasoglu et al., 2008; Güllü, 2012). The function set includes some arithmetical and Fig. 5. Data used for the GEP modeling in the study. BA: Bottom Ash. 390 H. Güllü / Soils and Foundations 57 (2017) 384–396 0 Table 3 Parameter settings for the GEP models. B s ¼ f ð_c; g; BAÞ ¼ @ Parameter Setting Fitness function error type Number of chromosomes Head size Number of genes Linking function Mutation rate Inversion rate IS transposition rate RIS transposition rate One-point recombination rate Two-point recombination rate Gene recombination rate Gene transposition rate Function set MAE 30 6 and 7 2 and 3 Addition, Multiplication 0.044 0.1 0.1 0.1 0.3 0.3 0.1 0.1 +, , *, /, Pow10, Sqrt, Exp, Ln, x2, x3, x4, 3Rt, 4Rt 6177, 3882, 10628, 2943 Number of generations mathematical operators, such as ‘‘+, , *, /, power (Pow10), square root (Sqrt), exponential (Exp), natural logarithm (Ln), x2 (x2), x3 (x3), x4 (x4), x5 and cube root (3Rt) and quartic root (4Rt)”. The number of model generations falls in the range of 2943–10,628. Usually, several runs (or many trials) are required for best fitness. The formulations due to the GEP modeling that propose the best responses in the performances of MAE, RMSE and R are presented and discussed next. 4. Results and discussions In this study, the GEP approach was employed to derive the mathematical formulas due to the GEP modeling to predict the flow behavior (rheological behavior) of the grout mixture with bottom ash for jet grouting. The obtained models that result in the best performances in MAE, RMSE and R are first illustrated by the expression trees of the GEP approach, given in Fig. 6. Then, from the expression trees of GEP (Fig. 6), the rheological formulas are derived for discussion. From the ETs of the GEP models (Fig. 6), it is seen that two genes (Fig. 6a and c) and three genes (Fig. 6b and d) were used for the derivation. The genes were linked by the linking functions of ‘‘multiplication” (Fig. 6a–c) or ‘‘addition” (Fig. 6d), mentioned in Table 3. The derived GEP formulations from the expression trees (Fig. 6), in accordance with the terminal set (Eq. 3) with (i) s dependent upon c_ and BA (Eq. (3a) and Fig. 6a), (ii) s dependent upon c_ , g and BA (Eq. (3b) and Fig. 6b), (iii) g dependent upon c_ and BA (Eq. (3c) and Fig. 6c) and (iv) g dependent upon s, c_ and BA (Eq. (3d) and Fig. 6d), are given through Eq. 4, as follows: s ¼ f ð_c;BAÞ ¼ ð6:945099ð_c0:5 BAÞ 0:67 10:333 Þ þ ðBA2 þ 10ð4:923218BAÞ Þ ð4aÞ c_ 9:998017 c_ 8:051544 C 0:5 A 2 0:333 ðBA3 Þ ð9:324859 þ ðg þ ðln gÞ Þ Þ 3:585449 g ¼ f ð_c; BAÞ ¼ ð2BA4 Þ 0:25 10lnðð0:036þ_cÞ Þ ðs2 Þ s g ¼ f ðs; c_ ; BAÞ ¼ ð105:185699ðe sþBAÞ Þ þ c_ þ ð105:185699ðlnðs 2 Þþ5:185699þBAÞ Þ ð4bÞ ð4cÞ ð4dÞ Predictions using the GEP formulas (Eq. 4) are compared with the measured experimental data by the graphical representation of the perfect fit (i.e., y = x) in the scattering plot, for the results of the testing phases of the GEP models (Fig. 7). It is seen from the scattering of data in Fig. 7 that the predictions are relatively precise in view of their deviations. As shown in Fig. 7, despite the highly nonlinear responses (i.e., shear stress and viscosity) due to the rheological behavior of grout mixtures, the GEP approach employed in this study is clearly able to derive formulations for s and g that appear to have good prediction potential with the measured data and with high accuracy. Performances (MAE, RMSE and R) of the derived formulations using the GEP models (Eq. 4 and Fig. 6) from the results of the training and testing phases are presented in Table 4 and compared to the performances from the conventional prediction method of nonlinear regression. For the regression analysis, the SPSS statistical analysis software program (Ver.15.0, 2006) was run in this study. It can be noted that the nonlinear regression has the ability to produce nonlinear models with arbitrary relationships between the dependent and the independent parameters using the iterative estimation algorithms, in comparison with the linear models estimated by the ordinary linear regression (Walpole et al., 2007). Thus, within the conventional regressions of curve-fitting methods, a comparison with the nonlinear regression is considered plausible specifically for the rheological behavior of jet grout mixtures that highly represent nonlinear behavior. The model performances (Table 4) due to the GEP and the regression methods could be evaluated using a previous guide (Smith, 1986), where it is suggested that the correlation (R) between the predicted and the measured values: (i) become weak if jRj < 0.2, (ii) exist (likely to be moderate) if 0.2 < jRj < 0.8 and (iii) become strong if jRj 0.8. Since a verification of the training performances is conducted during the testing phase, the testing performances (i.e., testing MAE, RMSE and R) have been taken into consideration for the predictive ability of the GEP models. It is shown in Table 4 that the performances of the GEP models are obtained in a more superior way than those of the regression. It can be said that the formulations from the GEP models become more satisfactory for all responses (s and g) resulting in an acceptable degree of accuracy in errors (MAE and H. Güllü / Soils and Foundations 57 (2017) 384–396 391 Fig. 6. Expression trees for the formulas: (a) d0 = c_ , d1 = BA, c0 = 6.945099 (Gene 1), c0 = 3.923218 (Gene 2): (Eq. (3a)) (b) d0 = c_ , d1 = g, d2 = BA, c0 = 9.998017 (Gene 1), c1 = 8.051544 (Gene 1), c0 = 9.324859 (Gene 3): (Eq. (3b)); (c) d0 = c_ , d1 = BA, c1 = 0.00177 (Gene 1), c0 = 3.585449 (Gene 2), c1 = -3.327789 (Gene 2): (Eq. (3c)) (d) d0 = s, d1 = c_ , d2 = BA, c1 = 5.185699 (Gene 1), c1 = -5.185699 (Gene 3): (Eq. (3d)). RMSE) and relatively strong correlations (R 0.96). As for the regression, while it produces a moderate level of correlations for g (R = 0.65 and R = 0.68), the performances for s are obtained in the strong level (R = 0.81 392 H. Güllü / Soils and Foundations 57 (2017) 384–396 Fig. 7. Comparison of the predictions due to the GEP formulas with the measured data. Table 4 Performances of GEP models compared to regression. Formula or model GEP Regression Train s-Eq. (4a)-Fig. 6a s-Eq. (4b)-Fig. 6b g-Eq. (4c)-Fig. 6c g-Eq. (4d)-Fig. 6d Test MAE RMSE R MAE RMSE R MAE RMSE R 0.642 0.687 0.567 0.0002 0.854 0.939 0.319 0.0002 0.98 0.98 0.98 0.99 0.763 0.766 0.489 0.0001 1 1.047 0.843 0.0002 0.97 0.96 0.96 0.99 2.233 2.201 1.411 1.414 2.783 2.686 2.001 1.934 0.81 0.83 0.65 0.68 and R = 0.83), but still less than GEP. However, it is obvious that the accuracy of the performances in the errors (MAE and RMSE) due to the regression could be considered far from the adequate for the predictions of s and g in both, despite the existence of correlations. As a consequence of the performance results (Table 4), it is found that the performances are less improved by the regression method than by the GEP. Thus, it is concluded that in predicting the rheological behavior of grout mixtures, the use of the GEP approach is thought to be more favorable than the regression method. The GEP technique can be applied by comparing it to some common conventional rheological models particularly for the GEP formulation of s versus c_ (Eq. (4a)) regarding the inclusion rates. The conventional models (Table 5) that are found more favorable for a description of the nonlinear behavior of grout for jet grouting than others (i.e., Casson, Bingham, modified Bingham and Herschel-Bulkley) in the previous study (Güllü, 2016) have been used for the comparison. The applicability of GEP was primarily tested for Eq. (4a), because the conventional rheological models in current practice are mostly modeled in the functional form s versus c_ , as presented in Table 5. Readers are recommended to check elsewhere (Yahia and Khayat, 2001, 2003) for more information on rheological models (Table 5 and the others), as these details are out of the scope of the present work. Comparisons are shown in Fig. 8 in the s versus c_ plots. It is seen in Fig. 8 that the GEP formulation is relatively consistent with the conventional rheological models for the usual representation of the shear stress versus shear rate curve due to the pseudoplastic (shear-thinning) response (see Fig. 2a). It generally seems to have a good modeling potential for all dosage rates (except for native cement) due to the high level of correlations (R 0.96). However, the GEP formulation appears to favorably follow well the measured data with mostly high dosage rates (i.e., >40%BA) compared to the conventional models (R 0.89). Thus, it can be said that the prediction trend of the GEP is better with increased BA proportions. This finding for GEP modeling could be H. Güllü / Soils and Foundations 57 (2017) 384–396 Table 5 Some conventional rheological models employed for comparison (Yahia and Khayat, 2001, 2003; Güllü, 2016). Model name Mathematical formulation De Kee (DK) Robertson-Stiff (RS) 1 s ¼ s0 þ l_c ea_ c n s ¼ Að_c þ BÞ s: shear stress (Pa), c_ : shear rate (s1), s0: yield stress (Pa), l: viscosity (plastic viscosity) (Pa s), a: time-dependent parameter, A and B: adjustable parameters, n: flow behavior index or rate index. useful for understanding the nonlinearity of rheology specifically due to the high BA rates for jet grouting. Here, it should be emphasized that for the native cement only 393 (i.e., 0%BA), the GEP modeling was not able to fit the prediction of s, since in the GEP formulation (Eq. (4a)) a zero inclusion rate of BA unfortunately causes zero shear stress. This issue most likely needs to be fixed by using a large dataset that includes a sufficient number of samples of native cement (i.e., 0% rate of stabilizer) for the model calibration during the training phase and the model generalization during the testing phase. However, this is a separate investigation for future study. As a result of the comparisons (Fig. 8), it can be concluded that the GEP technique used in this study is potentially considered a good candidate for modeling the rheological curves (shear stress-shear rate) due to the grout with bottom ash for jet grouting. Fig. 8. Comparison of GEP model (Eq. (4a)) with the conventional rheological models (DK = De Kee = ; RS = Robertson-Stiff). 394 H. Güllü / Soils and Foundations 57 (2017) 384–396 The GEP technique has also been performed through comparisons using the GEP formulation of g versus c_ (Eq. (4c)) particularly for high inclusion rates (Fig. 9). It is observed from the comparisons (Fig. 9) that the GEP formulation (Eq. (4c)) becomes relatively satisfactory for the usual description of the viscosity versus shear rate curve due to the pseudoplastic behavior (see Fig. 2a). This GEP formulation also follows the measured data and conventional rheological models well resulting in a fitting trend with strong correlations (R 0.93). Thus, it can be concluded (Fig. 9) that the GEP technique can also be a good candidate for offering viscosity versus shear rate predictions. Overall, from the successful comparisons (Figs. 8 and 9) using the GEP formulations (Eqs. (4a) and (4c)), it can be said that the GEP technique could be beneficial for predicting rheology due to the grout with bottom ash as an alternative to the conventional rheological models. Based on the effort given to the ability of the GEP technique presented in this paper, it is understood that the GEP modelings (Fig. 6) are able to derive the mathematical formulas (Eq. 4) for the rheological behavior. They are not only capable of producing the mathematical formulas (Eq. 4) during the training stage, but they can also general- ize the formulas during the testing stage for the potential use in practice through a verification of their precision (Fig. 7 and Table 4). Compared to the nonlinear regressions, the GEP formulations are found to achieve better predictions in strong correlations and fewer errors resulting in high accuracy (Table 4). For their applicability in practice, as compared to the measured data (s, g) and the conventional rheological models (Table 5), it is shown that the GEP modeling could be assessed as a powerful tool for describing the rheological behavior (i.e., shear stress versus shear rate and viscosity versus shear rate) due to the grout with bottom ash in good quality predictions (Figs. 8 and 9). Hence, all the findings obtained in this study are relatively promising for the application of the GEP technique for prediction of the flow behavior or the rheological behavior of grout with bottom ash for jet grouting, as an alternative to curve-fitting methods (the nonlinear regression or conventional rheological models). Even though the mathematical functions evolved from the GEP technique are complex, the successful results offer significant advantages over the conventional solutions. Consequently, the derived GEP formulas (Eq. 4) could be proposed to estimate the pumping pressure (shear stress s) and the viscosity (g) of grout with bottom ash under an Fig. 9. Comparison of GEP model due to the GEP formulation of g versus c_ (Eq. (4c)) with the conventional rheological models. H. Güllü / Soils and Foundations 57 (2017) 384–396 applied pumping rate (shear rate c_ ) for jet grouting columns, at least to assist with the conventional rheological models resulting in even more satisfactory predictions. Moreover, the GEP formulations could present some contributions for querying the interactions between the pumping pressure and the pumping rate of grout. However, it should be emphasized that the proposed GEP formulations are more able to predict within the range of data used in this study. Thus, supplying more data that covers new ranges in future experimental works will extend the current limitation of the proposed GEP models. The attempt to use GEP to predict the rheological behavior of grout, specifically including bottom ash, is newly proposed in this study. Hence, the findings obtained due to the GEP could be better offered for a preliminary design of jet grouting in practice. As a final remark, the benefits of including GEP predictions in engineering judgments should not be underestimated for final decisions made during the design stage. 5. Conclusions For the prediction of rheological behavior (i.e., the shear stress versus the shear rate and the viscosity versus the shear rate), using grout with bottom ash for jet grouting has been investigated and the ability of a new prediction technique called GEP has been presented in this research as an alternative method. Based on the findings obtained from the GEP modeling in the study, the following conclusive remarks can be drawn for the prediction of the rheological behavior of grout with bottom ash for jet grouting: (1) The rheological formulations (Eq. 4) due to the GEP models (Fig. 6) are relatively able to produce estimations with good precision (Fig. 7). (2) Compared to the nonlinear regression (R 0.65), the GEP obtains better predictions with fewer errors and strong correlations (R 0.96) for accurate predictions. (3) The rheological formulas due the GEP (Eqs. (4a) and (4c)) are found consistent with the conventional rheological models (De Kee and Robertson-Stiff) for a successful description of the pseudoplastic behavior (i.e., the shear stress-shear rate and the viscosity versus shear rate) of grout with bottom ash (Figs. 8 and 9). The estimations due to the GEP formulations (Eqs. (4a) and (4c)) generally follow the measured data well. However, they are obtained better specifically at high BA proportions. (4) The GEP technique is relatively promising for predictions of the rheological behavior of grout with bottom ash as an alternative to the conventional rheological models. Thus, the derived GEP formulas could be beneficial for adjusting the pumping pressure, the viscosity and the pumping rate of grout mixtures with bottom ash for jet grouting columns, at least to assist the conventional solutions. 395 Acknowledgements The author would like to express his gratitude to the anonymous reviewers for their valuable comments and suggestions on how to improve the quality of this article during the revision of the manuscript. References Alkroosh, H., Nikraz, H., 2011. Correlation of pile axial capacity and CPT data using gene expression programming. Geotech. Geol. Eng. 29, 725–748. Banfill, P.F.G., 2006. Rheology of fresh cement and concrete. Rheol. Rev., 61–130, ISBN 0-9547414-4-7, CD: 0-9547414-5-5 Baykasoglu, A., Güllü, H., Canakci, H., Özbakır, L., 2008. Prediction of compressive and tensile strength of limestone via genetic programming. Expert Syst. Appl. 35, 111–123. Bras, A., Henriques, F.M.A., Cidade, M.T., 2013. Rheological behaviour of hydraulic lime-based grouts. Shear-time and temperature dependence. Mech. Time-Depend. Mater. 17, 223–242. Cevik, A., Sonebi, M., 2008. Modelling the performance of self-compacting SIFCON of cement slurries using genetic programming technique. Comput. Concr. 5 (5), 475–490. Croce, P., Flora, A., 2000. Analysis of single-fluid jet grouting. Geotechnique 50 (6), 739–748. Dabbagh, A.A., Gonzalez, A.S., Pen, A.S., 2002. Soil erosion by a continuous water jet. Soils Found. 42 (5), 1–13. Ferreira, C., 2001. Gene expression programming: a new adaptive algorithm for solving problems. Complex Syst. 13 (2), 87–129. Flora, A., Modoni, G., Lirer, S., Croce, P., 2013. The diameter of single, double and triple fluid jet grouting columns: prediction method and field trial results. Geotechnique 63 (11), 934–945. GeneXproTools, 2016. <http://www.gepsoft.com/> (access 21.11.16). Goldberg, D., 1989. Genetic Algorithms in Search, Optimization and Machine Learning. Addison-Wesley, Boston. Güllü, H., 2012. Prediction of peak ground acceleration by genetic expression programming and regression: a comparison using likelihood-based measure. Eng. Geol. 141–142, 92–113. Güllü, H., 2015. On the viscous behavior of cement mixtures with clay, sand, lime and bottom ash for jet grouting. Constr. Build. Mater. 93, 891–910. Güllü, H., 2016. Comparison of rheological models for jet grout cement mixtures with various stabilizers. Constr. Build. Mater. 127, 220–236. Kazemian, S., Prasad, A., Huat, B.K., 2012. Review of Newtonian and non-Newtonian fluids behaviour in the context of grouts. In: Viggiani, G. (Ed.), Geotechnical Aspects of Underground Construction in Soft Ground. Taylor & Francis Group, London, ISBN 978-0-415-68367-8, pp. 321–326. Koza, J.R., 1992. Genetic Programming: On the Programming of Computers by Means of Natural Selection. MIT Press, Cambridge. Ma, K., Feng, J., Long, G., Xie, Y., 2016. Effects of mineral admixtures on shear thickening of cement paste. Constr. Build. Mater. 126, 609– 616. Mihalis, I.K., Tsiambaos, G., Anagnostopoulos, A., 2004. Jet grouting applications in soft rocks: The Athens Metro case. Proc. Instit. Civ. Eng. Geotech. Eng. 157 (4), 219–228. Modoni, G., Croce, P., Mongiovi, L., 2006. Theoretical modelling of jet grouting. Geotechnique 56 (5), 335–347. Modoni, G., Wanik, L., Giovinco, G., Bzowka, J., Leopardi, A., 2016. Numerical analysis of submerged flows for jet grouting. Ground Improvement 169 (1), 42–53. Nehdi, M., Rahman, M.A., 2004. Estimating rheological properties of cement pastes using various rheological models for different test geometry, gap and surface friction. Cem. Concr. Res. 34, 1993–2007. Nikbakhtan, B., Ahangari, K., Rahmani, N., 2010. Estimation of jet grouting parameters in Shahriar dam, Iran. Min. Sci. Technol. 20, 472–477. 396 H. Güllü / Soils and Foundations 57 (2017) 384–396 Ochmański, M., Modoni, G., Bzówka, J., 2015. Prediction of the diameter of jet grouting columns with artificial neural networks. Soils Found. 55 (2), 425–436. Ribeiro, D., Cardoso, R., 2016. A review on models for the prediction of the diameter of jet grouting columns. Eur. J. Environ. Civ. Eng. http:// dx.doi.org/10.1080/19648189.2016.1144538. Roussel, N., Lemaı̂tre, A., Flatt, R.J., Coussot, P., 2010. Steady state flow of cement suspensions: A micromechanical state of the art. Cem. Concr. Res. 40, 77–84. Saridemir, M., 2010. Genetic programming approach for prediction of compressive strength of concretes containing rice husk ash. Constr. Build. Mater. 24, 1911–1919. Shibazaki, M., 2003. State of Practice of Jet Grouting. Grouting and Ground Treatment. ASCE, Reston, VA, pp. 198–217. Shen, S.L., Han, J., Du, Y.J., 2008. Deep mixing induced property changes in surrounding sensitive marine clays. J. Geotech. Geoenviron. Eng. 134 (6), 845–854. Shen, S.L., Wang, Z.F., Yang, J., Ho, C.E., 2013. Generalized approach for prediction of jet grout column diameter. J. Geotech. Geoenviron. Eng. 139 (12), 2060–2069. Smith, G.N., 1986. Probability and Statistics in Civil Engineering: An Introduction. Collins, London. Sonebi, M., Cevik, A., 2009. Genetic programming based formulation for fresh and hardened properties of self-compacting concrete containing pulverised fuel ash. Constr. Build. Mater. 23, 2614–2622. Tinoco, J., Correia, A.G., Cortez, P., 2014. Support vector machines applied to uniaxial compressive strength prediction of jet grouting columns. Comput. Geotech. 55, 132–140. Walpole, R.E., Myers, R.H., Myers, S.L., Ye, K., 2007. Probability & Statistics for Engineers & Scientists, eight ed. Prentice Hall, NJ. Wang, Z.F., Shen, S.L., Ho, C.E., Kim, Y.H., 2013. Investigation of fieldinstallation effects of horizontal twin-jet grouting in Shanghai soft soil deposits. Can. Geotech. J. 50, 288–297. Warner, J., 2004. Practical Handbook of Grouting: Soil, Rock and Structures. Wiley, Hoboken. Yahia, A., Khayat, K.H., 2001. Analytical models for estimating yield stress of high performance pseudoplastic grout. Cem. Concr. Res. 31, 731–738. Yahia, A., Khayat, K.H., 2003. Applicability of rheological models to high-performance grouts containing supplementary cementitious materials and viscosity enhancing admixture. Mater. Struct. 36, 402– 412. Yahia, A., 2011. Shear-thickening behavior of high-performance cement grouts influencing mix design parameters. Cem. Concr. Res. 41, 230–235.