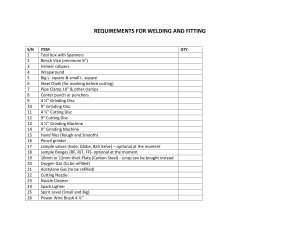

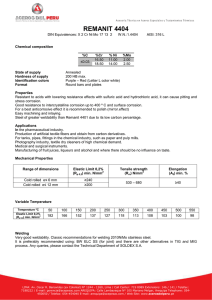

Available online at www.sciencedirect.com Available online at www.sciencedirect.com ScienceDirect ScienceDirect Available Availableonline onlineatatwww.sciencedirect.com www.sciencedirect.com Procedia Manufacturing 00 (2017) 000–000 Procedia Manufacturing 00 (2017) 000–000 ScienceDirect ScienceDirect www.elsevier.com/locate/procedia www.elsevier.com/locate/procedia Procedia Manufacturing 20 (2018) 517–522 Procedia Manufacturing 00 (2017) 000–000 www.elsevier.com/locate/procedia 2nd International Conference on Materials Manufacturing and Design Engineering 2nd International Conference on Materials Manufacturing and Design Engineering An Alternate Machining Method for Hardened Automotive Gears An Alternate Machining Method for Hardened Automotive Gears a c Manufacturing Engineering Society International Conference 28-30 June Debabrata Samantaraya , Sanjay Lakadebb, 2017, AshokMESIC Keche2017, a c 2017, Vigo (Pontevedra), Spain Debabrata Samantaraya , Sanjay Lakade , Ashok Keche a,b Pimpri Chinchwad College of Engineering, Sector-26, Pradhikaran, Nigdi, Pune-411044, Maharashtra, India c Maharashtra Institute of Technology, Aurangabad-431028, Pimpri Chinchwad College of Engineering, Sector-26, Pradhikaran, Nigdi,Maharashtra, Pune-411044,India. Maharashtra, India a,b,c c Corresponding authors’ E-mail addresses: sanjay.lakade@pccoepune.org, Maharashtra Instituted.samantaraya@yahoo.co.in, of Technology, Aurangabad-431028, Maharashtra, India. ashok.keche@mit.asia a,b,c Corresponding authors’ E-mail addresses: d.samantaraya@yahoo.co.in, sanjay.lakade@pccoepune.org, ashok.keche@mit.asia a,b Costing models for capacity optimization in Industry 4.0: Trade-off between used capacity and operational efficiency Abstract Abstract a a,* b b A. Santana , P. Afonso , A. Zanin , R.automotive Wernkegears This paper describes an experimental investigation on hard turning of disc type made of 20Mn5Cr5 steel hardened 60±2 HRC grinding are conducted by using PCBN tools on a CNC turning centre This papertodescribes an against experimental investigation on hard turning of disc type automotive gears made of 20Mn5Cr5 steel a process. Experiments University of Minho, 4800-058 Guimarães, Portugal b without using coolant. effectgrinding of machining parameters; cutting speed (v feed rate (f) and depth of cut (ap) on the surface hardened to 60±2 HRCThe against process. Experiments are conducted by using PCBN tools on a CNC turning centre Unochapecó, 89809-000 Chapecó, SC, c),Brazil roughness Ra (µm) is analyzed andofoptimized the help cutting of Taguchi design experiment (DOE), (S/N) ratio without using coolant. The effect machiningwith parameters; speed (vc), of feed rate (f) and depth signal of cut to(anoise surface p) on the and analysis variance (ANOVA) methods.with Thethe surface quality, process some economical and (S/N) ecological roughness Ra of (µm) is analyzed and optimized help of Taguchi designcharacteristics, of experiment (DOE), signal to noise ratio features of theofhard turning(ANOVA) are analyzed and compared with the grinding. and analysis variance methods. The surface quality, process characteristics, some economical and ecological Abstract features of the hard turning are analyzed and compared with the grinding. © 2017The Authors. Published by Elsevier B.V. Under concept of "Industry 4.0", production processes will be pushed to be increasingly interconnected, © 2018 the The Authors. Published by Elsevier B.V. Peer-review under responsibility the scientific © 2017The Authors. Published byofElsevier B.V. committee of the 2nd International Conference on Materials Peer-review under responsibility of the scientific committee of themuch 2nd International Conference oncontext, Materialscapacity Manufacturing and information based on a real time basis and, necessarily, efficient. In this optimization Manufacturing andresponsibility Design Engineering. Peer-review under of the scientific committee of more the 2nd International Conference on Materials Design Engineering. goes beyond the traditional aim of capacity maximization, contributing also for organization’s profitability and value. Manufacturing and Design Engineering. Indeed, leanPCBN; management and continuous approaches suggest capacity optimization instead of Keywords: Hard; Turning; Grinding; Taguchi;improvement ANOVA; Automotive; Gear maximization. The study of capacity optimization and costing models is an important research topic that deserves Keywords: PCBN; Hard; Turning; Grinding; Taguchi; ANOVA; Automotive; Gear contributions from both the practical and theoretical perspectives. This paper presents and discusses a mathematical model for capacity management based on different costing models (ABC and TDABC). A generic model has been 1. Introduction developed and it was used to analyze idle capacity and to design strategies towards the maximization of organization’s 1. Introduction value. The trade-off capacity vs operational efficiencyofis hardened highlighted andwith it ishardness shown that capacity Hard Turning is one of themaximization emerging technologies for machining steels values in the optimization might hide operational inefficiency. range of Turning 48 to 68 is HRC single point cutting tool.forThe popularity hard turning increasing day-by-day Hard oneusing of thea emerging technologies machining of of hardened steelsiswith hardness values in and the ©range The Published bya Elsevier B.V.process, it 2017 is becoming an important particularly in automotive bearing manufacturing industries. of 48Authors. to 68 HRC usingmanufacturing single point cutting tool. The popularity of hardand turning is increasing day-by-day and Peer-review under of theused scientific committee offinishing the Manufacturing Engineering Societymanufacturing International Traditionally, grinding has manufacturing been as aprocess, standard process for the of hardenedConference steels, but it is becoming anresponsibility important particularly in automotive andmachining bearing industries. 2017. technological advances fieldused of machine tools and cuttingprocess tool materials made hard turning possible on Traditionally, grinding in hasthe been as a standard finishing for the have machining of hardened steels, but modern lathesadvances as an attractive alternative to replace conventional grindinghave applications [1-5]. The possible factors that technological in the field of machine toolsmany and cutting tool materials made hard turning on Keywords: Cost Models; ABC; TDABC; Capacity Management; Idle Capacity; Operational Efficiency brought lathes the attention of industries towards turning are; substantial reduction of[1-5]. manufacturing modern as an attractive alternative to hard replace manyprocess conventional grinding applications The factorscosts, that reductionthe in attention production time, achievement of comparable or better finish and geometrical accuracies and brought of industries towards hard turning process are; surface substantial reduction of manufacturing costs, or complete elimination of environmentally harmful cooling media [6-8]. Davim and Figueira [9] reduction in production time, achievement of comparable or better surface finish and geometrical accuracies and 1. Introduction reported thatorit is possibleelimination to obtain a surface roughness of harmful Ra < 0.8µm in hard turning the suitable choice[9] of reduction complete of environmentally cooling media [6-8].with Davim and Figueira reported that it is possible to obtain a surface roughness of Ra < 0.8µm in hard turning with the suitable choice The cost of idle capacity is a fundamental information for companies and their management of extreme importanceof in modern production systems. In general, it is defined as unused capacity or production potential and can be measured 2351-9789© 2017 The Authors. Published by Elsevier B.V. in several ways: of production, available hours of manufacturing, etc.Conference The management of Manufacturing the idle capacity Peer-review under tons responsibility of the scientific committee of the 2nd International on Materials and 2351-9789© 2017 The Authors. Published by Elsevier B.V. * PauloEngineering. Afonso. Tel.:responsibility +351 253 510 of 761; +351 253 604 741 of the 2nd International Conference on Materials Manufacturing and Design Peer-review under thefax: scientific committee E-mail address: psafonso@dps.uminho.pt Design Engineering. 2351-9789 © 2017 The Authors. Published by Elsevier B.V. Peer-review under of the scientificbycommittee the Manufacturing Engineering Society International Conference 2017. 2351-9789 © 2018responsibility The Authors. Published Elsevier of B.V. Peer-review under responsibility of the scientific committee of the 2nd International Conference on Materials Manufacturing and Design Engineering. 10.1016/j.promfg.2018.02.077 Debabrata Samantaraya et al. / Procedia Manufacturing 20 (2018) 517–522 Author name / Procedia Manufacturing 00 (2017) 000–000 518 2 cutting parameters. Yallesea et al. [10] reported that grinding comparable surface finish can be achieved in hard turning of 100Cr6-tempered bearing steel with CBN tool. Kishawy and Elbestawi [11] investigated the surface integrity of AISI D2 steel of 62 HRC with cutting speeds in the range 140–500m/min, feeds 0.05–0.2mm/rev, depths of cut 0.2–0.6mm using the PCBN tools with edge preparations and reported that at the cutting speeds above 350m/min, the surface roughness increased with increase in tool wear due to material side flow. Therefore, an attempt has been made in the present research to find out the optimum combination of cutting parameters that would yield minimum surface roughness using PCBN tool. The majority of the researchers have carried out their researches on hard turning on the various steel material test pieces (round bars). However, in the present research, authors have chosen an actual part – an automotive disc type gear as the research object, hence the results obtained from this research can be used as a ready reference in the industries engaged in the manufacturing of similar parts. 2. Experimental Details 2.1. Workpiece material chemical composition and dimensional specification The chemical composition of workpice material 20Mn5Cr5 is given in Table 1, which is hardened to 60±2 HRc. The workpiece photo and drawing with dimensional specifications are shown in Fig. 1. Table 1: Chemical composition of 20Mn5Cr5 Steel (wt %) C Si Mn 0.17-0.22 0.15-0.35 1.0-1.4 a) b) c) Cr 1.0-1.3 P 0.035 S 0.035 d) Fig. 1. Workpiece & its dimensional specification: (a) RH side view, (b) Front view, (c) LH side view, (d) part drawing The experiments were conducted on Jyoti CNC Turning Centre (FM200 Model, spindle power 6.6KW and spindle speed 5500 RPM) with PCBN insert of ISO designation TNMA 160408 BN350 (Sumitomo make) in dry condition. The inserts were mounted on ISO tool holder PTFNL 16 S32S. The combination of the insert and the tool holder resulted an axial rake angle = -6° (negative), cutting edge inclination angle (radial rake) = -10° (negative) and cutting edge approach angle Kr = 91°. Mitutoyo make surface tester was used for measuring surface roughnessRa (µm). The surface roughness measurements were repeated three times at three different zones positioned at 120° apart for each turned workpiece and the average of three readings are given in Table 3. Klingelnberg P–40 gear measuring and inspection machine was used for measuring the cylindricity, circularity and straightness of the machined bore hole dia. 59.6H7. Three sets of cutting speeds (vc), feed rates (f) and depth of cut (ap) were chosen within the specified intervals recommended by the cutting tool manufacturer and arranged in three levels in Table 2. Table 2: Machining parameters and their levels for hard turning of bore hole dia.59.6H7 Level Cutting Speed Feed rate Depth of cut (m/min.) (mm/rev.) (mm) 1 110 0.05 0.08 2 130 0.07 0.10 3 150 0.09 0.12 Debabrata Samantaraya et al. / Procedia Manufacturing 20 (2018) 517–522 Author name / Procedia Manufacturing00 (2017) 000–000 519 3 3. Result and Discussion 3.1. Effect of machining parameters on surface roughness In this experiment, Taguchi L9 orthogonal array design of experiment and Signal-to-Noise (S/N) ratio methods were applied to find out optimal combination of cutting parameters for obtaining a minimal surface roughness (Ra). Nine experimental runs were conducted with three different combinations of cutting parameters and resulted surface roughnesses are arranged in Table 3. While analyzing S/N ratio, three categories of the quality characteristics were used, i.e. the-smaller-the-better, the-higher-the-better, and the nominal-the-better. A greater S/N ratio represents the optimal process parameter levels, regardless of the category of the quality characteristic selected. For obtaining a minimal surface roughness, the "the-smaller-the-better" quality characteristic was considered and the S/N ratio is calculated according to the following equation (1); S 1 n 2 = −10. lg y (1), Where n is the number of replication and yi is measured value of output variables. N n i=1 i The means of S/N ratios are calculated for each level of control parameters and shown in Table 4. The ranks are assigned to the values, which are the difference between maximum and minimum mean S/N ratio values. It can be seen from the Table 4, the feed rate has the highest rank followed by the depth of cut and cutting speed. This indicates that feed rate has the highest influence on the surface roughness followed by the depth of cut and cutting speed. The main effect plot (Fig. 2) shows that feed rate has the greatest significance on the surface roughness followed by the depth of cut and cutting speed. The S/N ratio response table and the main effect plots show that minimal surface roughness can be achieved with the cutting speed at level 2, feed rate and depth of cut at level 1, as these levels have the highest mean S/N ratios. Therefore, the optimal combination of machining parameters is A2-B1-C1, i.e. cutting speed (vc) 130m/min, feed rate (f) 0.05mm/rev. and depth of cut (ap) 0.08mm. Though the S/N ratio response table indicates the degree of influence of cutting parameters on the surface roughness, it does not specify the percentage of contribution of individual cutting parameters. Therefore, one-way analysis of variation (ANOVA) is conducted (Table 5). A low P-value indicates statistical significance of the corresponding parameter on the response factor. ANOVA shows that the feed rate (57%) has the highest statistical significant effect on surface roughness followed by the depth of cut (42.18%) and the cutting speed (0.46%) has the least significance on surface roughness. Table 3: Experimental results for surface roughness Test Run No. Cutting Speed (m/min.) Feed (mm/rev.) Depth of cut (mm) Surface Roughness Ra (m) S/N Ratio (dB) 1 110 0.05 0.08 0.299 10.487 2 110 0.07 0.10 0.618 4.180 3 110 0.09 0.12 0.959 0.364 4 130 0.05 0.10 0.373 8.566 5 130 0.07 0.12 0.765 2.327 6 130 0.09 0.08 0.516 5.747 7 150 0.05 0.12 0.486 6.267 8 150 0.07 0.08 0.425 7.432 9 150 0.09 0.10 0.760 2.384 Table 4: S/N ratio response table for surface roughness Symbol Cutting parameters Mean S/N ratio (dB) Rank Highest mean Level 1 Level 2 Level 3 Max-Min A Cutting speed 5.010 5.547 5.361 0.536 3 A2 B Feed rate 8.440 4.646 2.831 5.608 1 B1 C Depth of cut 7.889 5.043 2.986 4.903 2 C1 Table 5: Results of ANOVA for surface roughness Symbol Cutting parameters Degrees of freedom Sum of squares Mean squares F P Contribution (%) A Cutting speed 2 0.40 0.20 1.33 0.4292 0.46 B Feed rate 2 49.14 24.57 163.80 0.0061 57 C Depth of cut 2 36.37 18.185 121.23 0.0082 42.18 Error 2 0.30 0.15 Total 8 86.210 Debabrata Samantaraya al. / Procedia 00 Manufacturing 20 (2018) 517–522 Author name / Procedia et Manufacturing (2017) 000–000 4520 Fig. 2. Main effect plot for Surface roughness (Ra) 3.2. Process characteristics and economy analysis comparison: hard turning vs. grinding The surface roughness (Ra) and the geometrical accuracies – cylindricity, circularity and straightness are the major performance characteristics and represent the process capability of a machining process. For comparing these characteristics, a batch size of 250 numbers of gears was machined each in hard turning and grinding in a factory production line. Finish hard turning is carried out with the optimal combination of cutting parameters (vc=130m/min., f=0.05mm/rev., ap=0.08mm) that had resulted from Taguchi DOE and S/N ratio methods as discussed in preceding section 3.1. HMT cylindrical grinding machine was used for bore grinding. The machining parameters applied in hard turning and grinding are given in Table 6. Table 6: Machining parameters applied for the machining of bore hole in grinding and hard turning Grinding Hard turning Roughing Finishing vc = 150 m/min vc = 130 m/min Internal grinding: vc = 30 m/sec, Wheel RPM = 10,000, f L (roughing) =1.5 m/min., f L (finishing) =1 m/min., f = 0.15 mm/rev f = 0.05 mm/rev ap = 0.24 mm ap = 0.08 mm Workpiece RPM = 200, Stock allowance = 0.32mm 3.3. Surface roughness (Ra) and geometrical accuracy comparison Surface roughness achieved in both the processes (Fig. 4a) shows that though average surface roughness produced in hard turning (0.56µm) is little higher than that of grinding (0.37µm), but it was well within the prescribed requirement (0.8µm). Therefore, hard turning is capable of producing comparable surface roughness with grinding. The comparison of geometrical profiles and accuracies achieved in both the process are shown in Fig. 3 and Fig. 4b respectively. It is observed from the column diagrams (Fig. 4b) that circularity, cylindricity, and straightness obtained in hard turning are 3, 3, 4 microns respectively against 9 microns each in grinding. These results imply that hard turning is capable of producing better geometrical accuracies in comparison to grinding. Machining Process Circularity Cylindricity Straightness Grinding Hard turning Fig. 3. Comparison of geometrical accuracy profiles in hard turning and grinding Debabrata Samantaraya et al. / Procedia Manufacturing 20 (2018) 517–522 Author name / Procedia Manufacturing00 (2017) 000–000 0.8 1 0.56 Geometrical accuracies (µm) b) Surface roughness Ra(µm) a) 521 5 0.37 0 Specified requirement Hard turning 10 9 10 10 3 9 10 9 4 3 0 Circularity Cylindricity Straightness Specified requirement Grinding Hard turning Grinding Fig. 4. Comparison of process characteristics in hard turning and grinding (a) surface roughness; (b) geometrical accuracies 3.4. Economy Analysis: manufacturing nufacturing time and manufacturing cost 2 3.4 2.86 4 1.67 0.54 0.11 Time/piece (%) Time/piece (min) The objective to implement any newer machining process in a factory production line depends on few crucial parameters; its productivity, flexibility, impact on the environment and the most important parameter is its it overall cost impact. Therefore, a comparative economy analysis is required to examine the potential of implementation of hard turning in place of grinding in a factory production line. The manufacturing time of a part in a particular production process comprises of two components; namely setup preparation time and cycle time. Setup preparation time consists of time taken for setting up the fixture, fixture cutting tools, setting gauges and measuring ring instruments. instruments Cycle time includes the times consumed for workpiece loading and unloading, machining, measurement and inspection. Grinding process for bore holes is a time consuming process which requires roughing, finishing, spark out operations and wheel dressing at each cycle.. Whereas, hard turning can be accomplished by one rough and one finish depth of cut only. The setup preparation paration time in grinding was 135 minutes as against 25 minutes in hard turning. turning The setup preparation time (Ts) per piece is calculated by dividing the total time (Tt) with batch size (n). The various components of manufacturing time per piece is presented in column diagram (Fig. 5), time of hard turning were ), which shows that the setup preparation time and cycle c re 20% and 58% 58 of grinding rinding respectively. These results imply that total manufacturing time of hard turning is 52% of grinding which is significantly lower than that of grinding. b) a) 1.78 0 Set up prep. time Grinding Cycle Total time time Hard turning 100 100 100 58.4 100 20.4 50 52.4 0 Set up prep. Cycle Total time time time Grinding Hard turning Fig. 5. Comparison of manufacturing times in grinding and hard turning:: (a) times in minutes, (b) times in percentage 365.9 400 300 200 100 0 250 90.7 57.1 22.3 58.8 31.4 144.4 Operator Machining Production Total wages mfg.cost Grinding Hard turning Cost/piece ( %) Cost/piece (INR) Manufacturing cost comprises of three types of cost components namely operator wages, machining cost, and production cost. The manufacturing costt distribution in both the processes is presented in column diagram Fig. 6, which shows that the operator wage, machining time, and production cost of hard turning is 36%, 39%, and 53% of grinding respectively. Therefore, the total manufacturing cost of hard ha turning is 40% of grinding. a) b) 100 100 50 100 36.3 39.1 100 100 53.4 39.5 0 Operator MachiningProduction Total mfg. wages cost Grinding Hard turning Fig. 6. Comparison of manufacturing costs in grinding and hard turning:: (a) cost per piece in INR, (b) cost per piece in percentage 522 6 Debabrata Samantaraya et al. / Procedia Manufacturing 20 (2018) 517–522 Author name / Procedia Manufacturing 00 (2017) 000–000 3.5. Impact on environment Grinding as a machining process creates hazardous waste when the broken off abrasive particles and binding materials of grinding wheels mix with the coolant and create mud like residues [12]. These residues and used coolants are dangerous waste which cannot be reused and recycled and incurs additional expenditure for its handling and disposal. Therefore, grinding is not an environment-friendly machining process. In contrast to grinding, it is possible to machine a part using the PCBN tool without coolant in hard turning, making it a favorable green machining process by eliminating the harmful effect of coolant on the environment. 4. Conclusion Based on the experimental results and theoretical discussion, following conclusions can be drawn. • With the help of Taguchi method, process optimization can be possible with less number of experimental runs and the results can be extrapolated to a larger lot size in a factory production system. • The feed rate (57%) has the greatest influence on surface roughness followed by the depth of cut (42.18%). Cutting speed (0.46%) has insignificant influence on surface roughness. • It is observed that hard turning can provide a comparable and even better geometrical accuracies and surface roughness in comparison to grinding. • The manufacturing time and manufacturing cost of hard turning is 52% of grinding. This leads to 60% saving in manufacturing cost in hard turning in contrast to grinding. • Hard turning is possible to perform without coolant which makes it an environment-friendly process by eliminating the harmful effect of coolant on the environment. • Hard turning has a greater potential as an alternative machining method to traditional grinding process for the components such as automotive gears which have short machining lengths, different shapes and forms. References [1] Varaprasad. Bh, S. Rao.Ch, P.V. Vinay, Effect of Machining Parameters on Tool Wear in Hard Turning of AISI D3 Steel, GCMM Procedia Engineering, 97 ( 2014 ) 338–345. [2] G. Bartarya, S. K. Choudhury, Effect of cutting parameters on cutting force and surface roughness during finish hard turning AISI52100 grade steel, Procedia CIRP, 1 ( 2012 ) 651-656. [3] W. Zbala, J. Siwiec, Hard turning of cold work tool steel with CBN tools, Advances in Manufacturing Science and Technology, 36 (2012) 19-32. [4] S. Khamel, N. Ouelaa, K. Bouacha, Analysis and prediction of tool wear, surface roughness and cutting forces in hard turning with CBN tool, Journal of Mechanical Science and Technology, 26 (2012) 3605-3616. [5] H. K. Tönshoff, C. Arendt and R. Ben Amor, Cutting of hardened steel, CIRP Annals, 49 (2000) 547-566. [6] V. N. Gaitonde, S. R. Karnik, L. Figueira and J. P. Davim, Analysis of machinability during hard turning of cold work tool steel (type: AISI D2), Materials and Manufacturing Processes, 24 (2009) 1373-1382. [7] V. Molnar, J. Kundrak, Comparison of hard machining procedures on material removal rate, Hungarian Journal of Industrial Chemistry Veszprem, 39(2011) 219-224.-6 [8] J. Kundrák, A. G. Mamalis, K. Gyáni and A. Markopoulos, Environmentally Friendly Precision Machining, Materials and Manufacturing Processes, 21 (2006) 29–37. [9] J. P. Davim and L. Figueira, Machinability evaluation in hard turning of cold work tool steel (D2) with ceramic tools using statistical techniques, Materials and Design, 28 (2007) 1186-1191. [10]M. A. Yallesea, K. Chaoui, N. Zeghibb, L. Boulanouarb and J. F. Rigal, Hard machining of hardened bearing steel using cubic boron nitride tool, Journal of materials processing technology, 209 (2009) 1092-1104. [11]H. A. Kishawy, M. A. Elbestawi, Tool wear and surface integrity during high speed turning of hardened steel with PCBN tools, Journal of engineering manufacture, Proceeding Institution of Mechanical Engineering (Part B), 215 (2001) 755-767.-10 [12]J. Kundrak, A. G. Mamalis, A. P. Markopoulos, Finishing of Hardened Boreholes: Grinding or Hard Cutting, Materials and manufacturing processes, 19 (2004) 979-993.