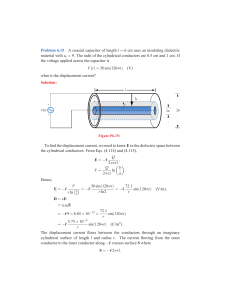

IEEE Guide for Application of Shunt Power Capacitors IEEE Power & Energy Society Sponsored by the Transmission and Distribution Committee IEEE 3 Park Avenue New York, NY 10016-5997 USA IEEE Std 1036™-2010 (Revision of IEEE Std 1036-1992) 17 January 2011 Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036™-2010 (Revision of IEEE Std 1036-1992) IEEE Guide for Application of Shunt Power Capacitors Sponsor Transmission and Distribution Committee of the IEEE Power & Energy Society Approved 30 September 2010 IEEE-SA Standards Board Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Abstract: This guide applies to the use of 50 Hz and 60 Hz shunt power capacitor units rated 2400 Vac and above, and assemblies of such capacitors. Included are guidelines for the application, protection, and ratings of equipment for the safe and reliable utilization of shunt power capacitors. The guide is general and intended to be basic and supplemental to specific recommendations of the manufacturer. The guide covers applications that range from simple capacitor unit utilization to complex capacitor bank situations. Keywords: capacitor, capacitor banks, externally fused, fuseless, internally fused, power factor correction, shunt power capacitors • The Institute of Electrical and Electronics Engineers, Inc. 3 Park Avenue, New York, NY 10016-5997, USA Copyright © 2011 by the Institute of Electrical and Electronics Engineers, Inc. All rights reserved. Published 17 January 2011. Printed in the United States of America. IEEE is a registered trademark in the U.S. Patent & Trademark Office, owned by the Institute of Electrical and Electronics Engineers, Incorporated. National Electrical Code and NEC are both registered trademarks of the National Fire Protection Association, Inc. National Electrical Safety Code and NESC are both registered trademarks and service marks of the Institute of Electrical and Electronics Engineers, Incorporated. PDF: Print: ISBN 978-0-7381-6491-5 ISBN 978-0-7381-6492-2 STD97034 STDPD97034 IEEE prohibits discrimination, harassment and bullying. For more information, visit http://www.ieee.org/web/aboutus/whatis/policies/p9-26.html. No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission of the publisher. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Standards documents are developed within the IEEE Societies and the Standards Coordinating Committees of the IEEE Standards Association (IEEE-SA) Standards Board. The IEEE develops its standards through a consensus development process, approved by the American National Standards Institute, which brings together volunteers representing varied viewpoints and interests to achieve the final product. Volunteers are not necessarily members of the Institute and serve without compensation. While the IEEE administers the process and establishes rules to promote fairness in the consensus development process, the IEEE does not independently evaluate, test, or verify the accuracy of any of the information or the soundness of any judgments contained in its standards. Use of an IEEE Standard is wholly voluntary. The IEEE disclaims liability for any personal injury, property or other damage, of any nature whatsoever, whether special, indirect, consequential, or compensatory, directly or indirectly resulting from the publication, use of, or reliance upon this, or any other IEEE Standard document. The IEEE does not warrant or represent the accuracy or content of the material contained herein, and expressly disclaims any express or implied warranty, including any implied warranty of merchantability or fitness for a specific purpose, or that the use of the material contained herein is free from patent infringement. IEEE Standards documents are supplied “AS IS.” The existence of an IEEE Standard does not imply that there are no other ways to produce, test, measure, purchase, market, or provide other goods and services related to the scope of the IEEE Standard. Furthermore, the viewpoint expressed at the time a standard is approved and issued is subject to change brought about through developments in the state of the art and comments received from users of the standard. Every IEEE Standard is subjected to review at least every five years for revision or reaffirmation, or every ten years for stabilization. When a document is more than five years old and has not been reaffirmed, or more than ten years old and has not been stabilized, it is reasonable to conclude that its contents, although still of some value, do not wholly reflect the present state of the art. Users are cautioned to check to determine that they have the latest edition of any IEEE Standard. In publishing and making this document available, the IEEE is not suggesting or rendering professional or other services for, or on behalf of, any person or entity. Nor is the IEEE undertaking to perform any duty owed by any other person or entity to another. Any person utilizing this, and any other IEEE Standards document, should rely upon his or her independent judgment in the exercise of reasonable care in any given circumstances or, as appropriate, seek the advice of a competent professional in determining the appropriateness of a given IEEE standard. Interpretations: Occasionally questions may arise regarding the meaning of portions of standards as they relate to specific applications. When the need for interpretations is brought to the attention of IEEE, the Institute will initiate action to prepare appropriate responses. Since IEEE Standards represent a consensus of concerned interests, it is important to ensure that any interpretation has also received the concurrence of a balance of interests. For this reason, IEEE and the members of its societies and Standards Coordinating Committees are not able to provide an instant response to interpretation requests except in those cases where the matter has previously received formal consideration. A statement, written or oral, that is not processed in accordance with the IEEE-SA Standards Board Operations Manual shall not be considered the official position of IEEE or any of its committees and shall not be considered to be, nor be relied upon as, a formal interpretation of the IEEE. At lectures, symposia, seminars, or educational courses, an individual presenting information on IEEE standards shall make it clear that his or her views should be considered the personal views of that individual rather than the formal position, explanation, or interpretation of the IEEE. Comments for revision of IEEE Standards are welcome from any interested party, regardless of membership affiliation with IEEE. Suggestions for changes in documents should be in the form of a proposed change of text, together with appropriate supporting comments. Recommendations to change the status of a stabilized standard should include a rationale as to why a revision or withdrawal is required. Comments and recommendations on standards, and requests for interpretations should be addressed to: Secretary, IEEE-SA Standards Board 445 Hoes Lane Piscataway, NJ 08854 USA Authorization to photocopy portions of any individual standard for internal or personal use is granted by The Institute of Electrical and Electronics Engineers, Inc., provided that the appropriate fee is paid to Copyright Clearance Center. To arrange for payment of licensing fee, please contact Copyright Clearance Center, Customer Service, 222 Rosewood Drive, Danvers, MA 01923 USA; +1 978 750 8400. Permission to photocopy portions of any individual standard for educational classroom use can also be obtained through the Copyright Clearance Center. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Introduction This introduction is not part of IEEE Std 1036-2010, IEEE Guide for Application of Shunt Power Capacitors. This standard was revised in response to a need created by changes in capacitor technology, primarily in the areas of internally fused and fuseless capacitors. In addition, capacitor application information previously contained in IEEE Std 18-2002 a was moved to this application guide. It was also the aim of this revision to coordinate the information contained in this standard, whenever possible, with other pertinent national and international standards. Notice to users Laws and regulations Users of these documents should consult all applicable laws and regulations. Compliance with the provisions of this standard does not imply compliance to any applicable regulatory requirements. Implementers of the standard are responsible for observing or referring to the applicable regulatory requirements. IEEE does not, by the publication of its standards, intend to urge action that is not in compliance with applicable laws, and these documents may not be construed as doing so. Copyrights This document is copyrighted by the IEEE. It is made available for a wide variety of both public and private uses. These include both use, by reference, in laws and regulations, and use in private selfregulation, standardization, and the promotion of engineering practices and methods. By making this document available for use and adoption by public authorities and private users, the IEEE does not waive any rights in copyright to this document. Updating of IEEE documents Users of IEEE standards should be aware that these documents may be superseded at any time by the issuance of new editions or may be amended from time to time through the issuance of amendments, corrigenda, or errata. An official IEEE document at any point in time consists of the current edition of the document together with any amendments, corrigenda, or errata then in effect. In order to determine whether a given document is the current edition and whether it has been amended through the issuance of amendments, corrigenda, or errata, visit the IEEE Standards Association web site at http://ieeexplore.ieee.org/xpl/standards.jsp, or contact the IEEE at the address listed previously. For more information about the IEEE Standards Association or the IEEE standards development process, visit the IEEE-SA web site at http://standards.ieee.org. a Information on references can be found in Clause 2. iv Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Errata Errata, if any, for this and all other standards can be accessed at the following URL: http://standards.ieee.org/reading/ieee/updates/errata/index.html. Users are encouraged to check this URL for errata periodically. Interpretations Current interpretations can be accessed at the following URL: http://standards.ieee.org/reading/ieee/interp/ index.html. Patents Attention is called to the possibility that implementation of this guide may require use of subject matter covered by patent rights. By publication of this guide, no position is taken with respect to the existence or validity of any patent rights in connection therewith. The IEEE is not responsible for identifying Essential Patent Claims for which a license may be required, for conducting inquiries into the legal validity or scope of Patents Claims or determining whether any licensing terms or conditions provided in connection with submission of a Letter of Assurance, if any, or in any licensing agreements are reasonable or nondiscriminatory. Users of this guide are expressly advised that determination of the validity of any patent rights, and the risk of infringement of such rights, is entirely their own responsibility. Further information may be obtained from the IEEE Standards Association. v Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Participants This standard was revised by a working group sponsored by the Capacitor Subcommittee of The Transmission and Distribution Committee of the IEEE Power Engineering Society. At the time this guide was submitted to the IEEE-SA Standards Board for approval, the Capacitor Subcommittee had the following membership: Mark McVey, Chair Clay L. Fellers, Vice Chair Roy Alexander Ignacio Ares Steve Ashmore Bharat Bhargava J. Antone Bonner S. Cesari Bill Chai Simon Chano Stephen Colvin Stuart Edmondson Cliff Erven Karl Fender Chuck Gougler Tom Grebe Paul Griesmer John E. Harder Luther Holloman Ivan Horvat Steve B. Ladd John Maneatis Jeff H. Nelson Ben Mehraban Stan A. Miske, Jr. Jim Osborne Pier Rancourt W. Edward Reid S. Rios-Marcuello Tom Rozek Don R. Ruthman Jan Samuelsson Eugene Sanchez Richard Sevigny Paul Steciuk Rao S. Thallam Alan Van Leuven The working group that developed this standard consisted of the following membership: Antone Bonner, Chair Roy Alexander Ignacio Ares Jim Barcus Ernst Camm Bill Chai Simon Chano Stephen Colvin Rory Dwyer Stuart Edmonson Cliff Erven Clay L. Fellers Karl Fender Chuck Gougler Tom Grebe John E. Harder Ivan Horvat Luther Holloman Gerald Lee Allan Ludbrook Mark McVey Stan Miske, Jr. Jeff Nelson George Newcomb Pier-Andre Rancourt Ed Reid Kurt Reim Don R. Ruthman Richard Sevigny Rao S. Thallam The following members of the individual balloting committee voted on this guide. Balloters may have voted for approval, disapproval, or abstention. William J. Ackerman Roy Alexander Steven Alexanderson Gregory Ardrey Gary Arntson Carlo Arpino Ali Awazi Thomas Barnes G. Bartok Kenneth Behrendt Gabriel Benmouyal Bill Bergman Enrique Betancourt Wallace Binder William Bloethe Stuart Bouchey Harvey Bowles Steven Brockschink Chris Brooks Gustavo Brunello Jim Cai Thomas Carpenter James Case Tommy Cooper James Cornelison Luis Coronado Randall Crellin John Crouse Russ Dantzler Stephen Dare Matthew Davis J. Doering Kevin Donahoe Carlo Donati Randall Dotson Paul Drum Paul Elkin Ahmed Elneweihi Bruce English Gary Engmann C. Erven Dan Evans Thomas Field Marcel Fortin James Gardner vi Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. David Garrett Frank Gerleve James Graham Thomas Grebe Charles Grose Randall Groves Kenneth Hanus John Harder Adrienne Hendrickson Gary Heuston Dennis Horwitz John Houdek Jose Jarque Lars Juhlin Peter Kemp Mark J. Kempker Gael Kennedy Joseph L. Koepfinger Boris Kogan Jim Kulchisky Scott Lacy Chung-Yiu Lam Stephen Lambert Gerald Lee Solomon Lee Blane Leuschner Maurice Linker Albert Livshitz William Lowe Thomas Lundquist G. Luri Keith Malmedal John Martin Kenneth McClenahan Mark McVey Charles Morse Daniel Mulkey Jerry Murphy Pratap Mysore Jeffrey Nelson Arthur Neubauer Michael S. Newman Joe Nims T. Olsen Lorraine Padden Donald Parker David Peelo Robert Pettigrew David Phillips Anthony Picagli Percy Pool Paulette Payne Powell Iulian Profir Michael Roberts Charles Rogers Joseph R. Rostron Thomas Rozek M. Sachdev Steven Sano Bartien Sayogo Richard Sevigny Lubomir Sevov Devki Sharma Cameron Smallwood Jerry Smith Joshua Smith R. Kirkland Smith Devendra Soni John Spare Allan St. Peter David Stone John Sullivan Paul Sullivan Richard Taylor Malcolm Thaden Demetrios Tziouvaras Waldemar Von Miller Reigh Walling Daniel Ward Lee Welch William Wessman Thomas Wiedman James Wilson Roland Youngberg Luis Zambrano Theodore Zeiss Ahmed Zobaa v Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. When the IEEE-SA Standards Board approved this guide on 30 September 2010, it had the following membership: Robert M. Grow, Chair Richard H. Hulett, Vice Chair Steve M. Mills, Past Chair Judith Gorman, Secretary Karen Bartleson Victor Berman Ted Burse Clint Chaplin Andy Drozd Alexander Gelman Jim Hughes Young Kyun Kim Joseph L. Koepfinger* John Kulick David J. Law Hung Ling Oleg Logvinov Ted Olsen Ronald C. Petersen Thomas Prevost Jon Walter Rosdahl Sam Sciacca Mike Seavey Curtis Siller Don Wright *Member Emeritus Also included are the following nonvoting IEEE-SA Standards Board liaisons: Satish Aggarwal, NRC Representative Richard DeBlasio, DOE Representative Michael Janezic, NIST Representative Catherine Berger IEEE Standards Project Editor Matthew J. Ceglia IEEE Standards Program Manager, Technical Program Development vi Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Contents 1. Scope .......................................................................................................................................................... 1 2. Normative references.................................................................................................................................. 1 3. Definitions .................................................................................................................................................. 3 4. Power system considerations...................................................................................................................... 4 4.1 Capacitor benefits ................................................................................................................................ 4 4.2 Size and number of capacitor banks .................................................................................................. 10 4.3 Control considerations ....................................................................................................................... 11 5. Capacitor ratings, capabilities, and service conditions ............................................................................. 12 5.1 Standard ratings ................................................................................................................................. 13 5.2 Related capabilities............................................................................................................................ 15 5.3 Service conditions.............................................................................................................................. 20 6. Switching and switchgear considerations................................................................................................. 21 6.1 Switching of capacitors...................................................................................................................... 21 6.2 Switching transients........................................................................................................................... 22 6.3 Outrush current .................................................................................................................................. 40 6.4 Switchgear ......................................................................................................................................... 44 7. Harmonics ................................................................................................................................................ 46 7.1 Capacitor limitations.......................................................................................................................... 46 7.2 Distortion limits................................................................................................................................. 47 7.3 Operating and application considerations.......................................................................................... 47 7.4 Harmonic “problems”........................................................................................................................ 48 8. Surge arresters .......................................................................................................................................... 48 8.1 Substation applications ...................................................................................................................... 48 8.2 Distribution applications.................................................................................................................... 49 9. Substation shunt power capacitor bank applications ................................................................................ 50 9.1 Capacitor bank connections and grounding....................................................................................... 50 9.2 Capacitor bank types ......................................................................................................................... 54 9.3 Protection........................................................................................................................................... 59 10. Capacitor applications on distribution lines............................................................................................ 66 10.1 Protection......................................................................................................................................... 67 10.2 Sizing and locating capacitors ......................................................................................................... 69 11. Special capacitor applications ................................................................................................................ 70 11.1 Harmonic filters............................................................................................................................... 70 11.2 Motor applications........................................................................................................................... 70 11.3 Surge capacitors............................................................................................................................... 72 vii Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. 12. Inspection and maintenance.................................................................................................................... 74 12.1 General ............................................................................................................................................ 74 12.2 Safety and personnel protection....................................................................................................... 74 12.3 Initial inspection, measurements, and energization ......................................................................... 75 12.4 Periodic inspection, measurements, and maintenance ..................................................................... 76 12.5 Field testing ..................................................................................................................................... 81 Annex A (informative) Bibliography ........................................................................................................... 84 viii Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Guide for Application of Shunt Power Capacitors IMPORTANT NOTICE: This standard is not intended to ensure safety, security, health, or environmental protection. Implementers of the standard are responsible for determining appropriate safety, security, environmental, and health practices or regulatory requirements. This IEEE document is made available for use subject to important notices and legal disclaimers. These notices and disclaimers appear in all publications containing this document and may be found under the heading “Important Notice” or “Important Notices and Disclaimers Concerning IEEE Documents.” They can also be obtained on request from IEEE or viewed at http://standards.ieee.org/IPR/disclaimers.html. 1. Scope This guide applies to the use of 50 Hz and 60 Hz shunt power capacitors rated 2400 Vac and above, and assemblies of such capacitors. Included are guidelines for the application, protection, and ratings of equipment for the improved safety and reliability in the utilization of shunt power capacitors. The guide is general and intended to be basic and supplemental to specific recommendations of the manufacturer. The guide covers applications that range from simple capacitor unit utilization to complex capacitor bank situations. 2. Normative references The following referenced documents are indispensable for the application of this document (i.e., they must be understood and used, so each referenced document is cited in text and its relationship to this document is explained). For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments or corrigenda) applies. 1 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors ANSI C2-2007, National Electrical Safety Code, American National Standards Institute.1 ANSI C37.06-2009, American National Standard for AC High-Voltage Circuit Breakers Rated on a Symmetrical Current Basis—Preferred Ratings and Related Required Capabilities.2 ANSI C37.66-2005, American National Standard Requirements for Oil-Filled Capacitor Switches for Alternating-Current Systems. IEEE Std 18™-2002, IEEE Standard for Shunt Power Capacitors. 3, 4 IEEE Std C37.04™-1999, IEEE Standard Rating Structure for AC High-Voltage Circuit Breakers. IEEE Std C37.012™-2005, IEEE Application Guide for Capacitance Current Switching for AC HighVoltage Circuit Breakers Rated on a Symmetrical Current Basis. IEEE Std C37.48™-2005, IEEE Guide for Application, Operation, and Maintenance of High-Voltage Fuses, Distribution Enclosed Single-Pole Air Switches, Fuse Disconnecting Switches, and Accessories. IEEE Std C37.99-2000, IEEE Guide for Protection of Shunt Capacitor Banks. IEEE Std C62.2-1987, IEEE Guide for the Application of Gapped Silicon-Carbide Surge Arresters for Alternating-Current Systems. IEEE Std C62.22™-2009, IEEE Guide for the Application of Metal Oxide Surge Arresters for AlternatingCurrent Systems. IEEE Std 141™-1993 (Reaff 1999), IEEE Recommended Practice for Electric Power Distribution for Industrial Plants (IEEE Red Book™). IEEE Std 262B-1977, IEEE Trial-Use Standard Dielectric Test Requirements for Power Transformers for Operation on Effectively Grounded Systems 345 kV and Above (Trial-Use Supplement to IEEE Std 2621973, ANSI C57.12.90-1973).5 IEEE Std 519-2004, IEEE Recommended Practices and Requirements for Harmonic Control in Electric Power Systems. IEEE Std 1247™-2005, IEEE Standard for Interrupter Switches for Alternating Current, Rated Above 1,000 Volts. IEEE Std 1531™-2003, IEEE Guide for Application and Specification of Harmonic Filters. ® ® NFPA 70-2008, National Electrical Code (NEC ).6 1 The National Electrical Safety Code is available from the Institute of Electrical and Electronics Engineers, Service Center, 445 Hoes Lane, Piscataway, NJ 08854, USA; and from the Sales Department, American National Standards Institute, 11 West 42nd Street, 13th Floor, New York, NY 10036, USA. 2 ANSI publications are available from the Sales Department, American National Standards Institute, 11 West 42nd Street, 13th Floor, New York, NY 10036, USA. 3 IEEE publications are available from the Institute of Electrical and Electronics Engineers, Service Center, 445 Hoes Lane, Piscataway, NJ 08854, USA (http://standards.ieee.org/). 4 The IEEE standards or products referred to in this clause are trademarks of the Institute of Electrical and Electronics Engineers, Inc. IEEE Std 262B-1 has been withdrawn; however, copies can be obtained from Global Engineering, 15 Inverness Way East, Englewood, CO 80112-5704, USA, tel. (303) 792-2181 (http://global.ihs.com/). 5 6 The NESC is available from the Institute of Electrical and Electronics Engineers, Inc., 445 Hoes Lane, Piscataway, NJ 08854, USA (http://standards.ieee.org/). 2 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 3. Definitions For the purposes of this document, the following terms and definitions apply. The IEEE Standards Dictionary: Glossary of Terms & Definitions should be referenced for terms not defined in this clause. 7 3.1 ambient temperature: The temperature of the medium, such as air, water, or earth, into which the heat of the equipment is dissipated. NOTE 1—For self-ventilated equipment, the ambient temperature is the average temperature of the air in the immediate vicinity of the equipment. NOTE 2—For air- or gas-cooled equipment with forced ventilation or secondary water cooling, the ambient temperature is taken as that of the ingoing air or cooling gas. NOTE 3—For self-ventilated enclosed (including oil-immersed) equipment considered as a complete unit, the ambient temperature is the average temperature of the air outside of the enclosure in the immediate vicinity of the equipment. See 5.7 and Table 1 of IEEE Std 18-2002. 3.2 back-to-back capacitor bank switching (back-to-back switching, back-to-back capacitor switching): Switching a capacitor bank in close enough electrical proximity to one or more other energized capacitor banks and/or cables to significantly influence the inrush current. 3.3 capacitor bank: An assembly at one location of capacitor(s) and all necessary accessories, such as switching equipment, protective equipment, controls, et cetera, required for a complete operating installation. It may be a collection of components assembled at the operating site or may include one or more pieces of factory-assembled equipment. 3.4 capacitor control: The device required to automatically operate the switching device(s) to energize and de-energize shunt power capacitor banks. 3.5 capacitor element: The basic component of a capacitor unit consisting of two electrodes separated by a dielectric. 3.6 capacitor equipment: A complete assembly of capacitors, including accessories such as buses, connectors, dischargers, and fuses suitable for connection to a power system. 3.7 capacitor line fuse (capacitor group fuse): A fuse applied to disconnect a faulted phase of a capacitor bank from the power system. 3.8 externally fused capacitor bank: A capacitor equipment with fuses external to the (power) capacitor units. 3.9 filter capacitor: Capacitor(s) utilized with inductors and/or resistors for controlling harmonic voltages and currents in the power system. 3.10 fixed capacitor bank: A capacitor bank not designed for automatic operation or frequent switching. 3.11 fused capacitor: A capacitor having fuses mounted on its terminals, or inside a terminal enclosure, or inside the capacitor case, for the purpose of interrupting a failed capacitor element, unit or group. 3.12 fuseless capacitor bank: A capacitor bank without any fuses, internal or external, that is constructed of (parallel) strings of capacitor units. Each string consists of capacitor units connected in series. 7 The IEEE Standards Dictionary: Glossary of Terms & Definitions is available at http://shop.ieee.org/. 3 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 3.13 indoor (prefix): Not suitable for exposure to the weather. NOTE—For example, an indoor capacitor unit is designed for indoor service or for use in a weatherproof housing. 3.14 inrush current: The transient charging current that flows in a capacitor when a capacitor bank is initially connected to a voltage source. 3.15 internal fuse: A fuse connected inside a capacitor unit, in series with an element or a group of elements. 3.16 internally fused capacitor (unit): A capacitor unit that includes internal fuses. 3.17 internally fused capacitor bank: A capacitor bank equipment with internally fused capacitor units. 3.18 isolated capacitor bank: A capacitor bank whose inrush current is limited by the inductance of the source and its own capacitance. Other capacitor banks and cables are not sufficiently coupled to the bank to significantly influence the inrush current. 3.19 metal-enclosed (prefix): A capacitor equipment assembly enclosed in a metal enclosure or metal house, usually grounded, to prevent accidental contact with live parts. Syn: metal-housed. 3.20 metal-housed (prefix): See: metal-enclosed. 3.21 outrush current: The transient discharge current that flows when an energized capacitor bank is initially connected to a short circuit. 3.22 power capacitor (shunt capacitor, capacitor unit): An assembly of dielectric and electrodes in a container (case), with terminals brought out, that is intended to introduce capacitance into an electric power circuit. NOTE—The abbreviated term “capacitor” or “capacitor unit” is used interchangeably with “power capacitor” throughout this standard. 3.23 string (string of capacitors) (string of capacitor elements): Capacitors connected in series between two terminals without parallel connection(s). 3.24 switched capacitor (switched capacitor bank): A capacitor bank designed for controlled operation and/or frequent switching. 3.25 weatherproof: An apparatus is designated as weatherproof, when so constructed, protected, or treated that its successful operation is not interfered with when subjected to adverse weather. 4. Power system considerations 4.1 Capacitor benefits As power systems become heavily loaded (above surge impedance loading), shunt power capacitors become essential to the reliable operation of the power system. The capacitors support the system voltage and reduce the reactive current flow through the power system. Acceptable system voltages generally 4 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors cannot be maintained by the generators and transmission system alone. Shunt power capacitors are required. During system contingencies, when parts of the transmission system are unavailable, increased loading on the remaining system causes additional voltage drop. Shunt capacitors are required to support the system voltage during these contingencies. The lack of available shunt capacitors can (and has) lead to system voltage collapse. Most power system loads and delivery apparatus (e.g., motors, lines and transformers) are inductive in nature and therefore operate at a lagging power factor. When operating at a lagging power factor, power system loads require reactive current from the system, which results in reduced system capacity, increased system losses, and reduced system voltage. Figure 1 illustrates how the application of shunt power capacitors increases system capacity and reduces system losses by reducing reactive power needs from Qr1 to Qr2 through the addition of Qc. As a result, the system load is reduced from S1 to S2 as shown in Figure 1. Table 1 gives a summary of benefits derived from shunt power capacitors as they apply to transmission and distribution systems. Var support and voltage control are the primary benefits for a transmission system while the distribution system benefits may be more varied depending upon whether the system belongs to a generating utility, a nongenerating utility, or an industrial power user. The following subclauses describe each of these benefits in more detail. P φ2 Qr2 φ1 S2 Qr1 S1 Qc Figure 1 — Effect of adding shunt capacitors Table 1 —Summary of benefits of applying shunt power capacitors Benefits Transmission system Distribution system Voltage support * * Var support * † 5 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Benefits Transmission system Distribution system Increase system capacity † * Reduce system power loss † * Reduce billing charges † * *This is generally a primary benefit † This is generally a secondary benefit 4.1.1 Voltage support Applying shunt capacitors to a system results in a voltage rise. This voltage rise is caused by the flow of capacitor current (or the reduction of inductive current) through the inductive reactance of the system from the point of installation back to the generation. The voltage rise at the capacitor location is approximately equal to the capacitor current IC times the inductive reactance of the system to the capacitor location XL. There is a voltage rise all the way back to the voltage source, the magnitude depending on the inductive reactance between the source and the location. In a radial system, there is also an increase in the voltage beyond the capacitor location resulting from the increase at the capacitor location. There are a number of formulas that can be used to estimate the voltage rise that capacitors will produce. Based on the capacitor current and the inductive reactance of the system to the capacitor location: ΔV ≈ IC X L (1) For systems with a reasonably high X/R ratio, where the short-circuit impedance to the capacitor location is about the same as the inductive reactance, the XL of Equation (1) is the impedance that determines the system short-circuit current available at the capacitor location. This short-circuit current is useful in estimating the voltage rise. A commonly used estimate is as follows in Equation (2). ΔV ≈ where ΔV IC ISC QC SSC I C QC kvar = I SC SSC kva (2) is the per unit voltage rise at the point of the capacitor installation is the capacitor current in amps is the system short-circuit current at the capacitor location is the capacitor three-phase kvar at system voltage is the system three phase short-circuit kva at the capacitor location Capacitor banks are typically installed on the transmission system at major buses to provide voltage support for a large area. They are also installed at distribution buses and directly on customer delivery buses to provide voltage support to smaller areas and to individual customers. Capacitor banks installed on distribution lines support voltage along the entire length of line. Capacitor banks that are installed for voltage support are generally switched on during the peak loading periods or low-voltage conditions and switched off during light loading periods or high-voltage conditions. Capacitors have also been used on distribution feeders to keep the feeder voltage constant (acceptable, but low) during substation voltage reduction contingencies. Voltage reduction can decrease feeder power and current during peak load conditions. 6 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 4.1.2 Var support Reactive power (var) support encompasses many of the different benefits of shunt power capacitors, such as improved voltage control and power factor; reduced system losses and reactive power requirements at generators; and increased steady-state stability limits. Capacitors are sized and located at transmission and distribution substations to supply reactive power close to the loads or to provide midway support across heavily loaded transmission circuits. 4.1.3 Increased system capacity Increased system capacity may justify the addition of shunt power capacitors on a distribution system. This is particularly significant when loads supplied by the system are increasing rapidly. The addition of shunt power capacitors reduces the kilovoltampere loading on the system, thereby releasing capacity that can then be used to supply future load increases. The optimum economical power factor for a system, with regard to released capacity only, can be estimated by use of Equation (3). ⎛C ⎞ PF = 1−⎜ ⎟ ⎝S⎠ 2 (3) where C S PF is the cost per kilovar of capacitor bank is the cost per kilovoltamperes of system equipment is optimum power factor Equation (3) compares the cost of capacitor banks to the cost of transformers, regulators, and/or other system equipment, as an alternative means of providing increased system capacity. The graph of the formula, the optimum power factor as a function of the cost ratio of the capacitor bank versus other system equipment, is illustrated in Figure 2. ECONOMICAL SYSTEM POW ER FACTOR (%) 100 90 80 ECONOMICAL SYSTEM POWER FACTOR BASED ON THERMAL CAPACITY USAGE BY KILOVAR FROM FORMULA 70 ⎛ C⎞ PF = 1 − ⎜ ⎟ ⎝ S⎠ 60 2 50 0 0.1 0.2 0.3 0.4 CAPACITOR COST SYSTEM COST 0.5 = 0.6 0.7 0.8 0.9 $ / kvar $ / kVA Figure 2 — Economical system power factor 7 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors The power factor required to release a desired amount of system kilovoltamperes can be determined by Equation (4). PFold PF new = 1 − S release (4) kva where PFnew PFold Srelease is the corrected power factor is the existing power factor is the amount of kilovoltamperes to be released (in per unit of existing kilovoltamperes) To calculate the capacitive kilovar necessary to correct to a new, higher power factor, one must subtract the inductive kvar of the new (corrected) power factor from the old (existing) power factor. The difference is the amount of capacitive kilovar to be added to the system. Equation (5) is a convenient way of doing this. QC kvar = PS kW[tan(cos −1 PFold ) − tan(cos −1 PFnew )] (5) where PS QC is the system kilowatt load is the amount of capacitive kilovar to be added Table 2 is a chart that may be used in place of this formula. Simply find the row corresponding to the existing system power factor and the column corresponding to the corrected new power factor. The number located where these intersect should be multiplied by the system kilowatt load to arrive at the total capacitive kilovar necessary to correct to the new power factor. 8 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Table 2—Power factor correction kilowatt multipliers Existing power factor 0.80 0.50 0.51 0.52 0.53 0.54 0.55 0.56 0.57 0.58 0.59 0.60 0.61 0.62 0.63 0.64 0.65 0.66 0.67 0.68 0.69 0.70 0.71 0.72 0.73 0.74 0.75 0.76 0.77 0.78 0.79 0.80 0.81 0.82 0.83 0.84 0.85 0.86 0.87 0.88 0.89 0.90 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 0.99 0.982 0.937 0.893 0.850 0.809 0.769 0.730 0.692 0.655 0.619 0.583 0.549 0.516 0.483 0.451 0.419 0.388 0.358 0.328 0.299 0.270 0.242 0.214 0.186 0.159 0.132 0.105 0.079 0.052 0.026 0.000 0.81 1.008 0.962 0.919 0.876 0.835 0.795 0.756 0.718 0.681 0.645 0.609 0.575 0.542 0.509 0.477 0.445 0.414 0.384 0.354 0.325 0.296 0.268 0.240 0.212 0.185 0.158 0.131 0.105 0.078 0.052 0.026 0.000 0.82 1.034 0.989 0.945 0.902 0.861 0.821 0.782 0.744 0.707 0.671 0.635 0.601 0.568 0.535 0.503 0.471 0.440 0.410 0.380 0.351 0.322 0.294 0.266 0.238 0.211 0.184 0.157 0.131 0.104 0.078 0.052 0.026 0.000 0.83 1.060 1.015 0.971 0.928 0.887 0.847 0.808 0.770 0.733 0.697 0.661 0.627 0.594 0.561 0.529 0.497 0.466 0.436 0.406 0.377 0.348 0.320 0.292 0.264 0.237 0.210 0.183 0.157 0.130 0.104 0.078 0.052 0.026 0.000 0.84 1.086 1.041 0.997 0.954 0.913 0.873 0.834 0.796 0.759 0.723 0.687 0.653 0.620 0.587 0.555 0.523 0.492 0.462 0.432 0.403 0.374 0.346 0.318 0.290 0.263 0.236 0.209 0.183 0.156 0.130 0.104 0.078 0.052 0.026 0.000 0.85 1.112 1.067 1.023 0.980 0.939 0.899 0.860 0.822 0.785 0.749 0.713 0.679 0.646 0.613 0.581 0.549 0.518 0.488 0.458 0.429 0.400 0.372 0.344 0.316 0.289 0.262 0.235 0.209 0.182 0.156 0.130 0.104 0.078 0.052 0.026 0.000 0.86 1.139 1.094 1.050 1.007 0.966 0.926 0.887 0.849 0.812 0.776 0.740 0.706 0.673 0.640 0.608 0.576 0.545 0.515 0.485 0.456 0.427 0.399 0.371 0.343 0.316 0.289 0.262 0.236 0.209 0.183 0.157 0.131 0.105 0.079 0.053 0.027 0.000 0.87 1.165 1.120 1.076 1.033 0.992 0.952 0.913 0.875 0.838 0.802 0.766 0.732 0.699 0.666 0.634 0.602 0.571 0.541 0.511 0.482 0.453 0.425 0.397 0.369 0.342 0.315 0.288 0.262 0.235 0.209 0.183 0.157 0.131 0.105 0.079 0.053 0.026 0.000 Corrected power factor 0.88 0.89 0.90 0.91 1.192 1.147 1.103 1.060 1.019 0.979 0.940 0.902 0.865 0.829 0.793 0.759 0.726 0.693 0.661 0.629 0.598 0.568 0.538 0.509 0.480 0.452 0.424 0.396 0.369 0.342 0.315 0.289 0.262 0.236 0.210 0.184 0.158 0.132 0.106 0.080 0.053 0.027 0.000 1.220 1.175 1.131 1.088 1.047 1.007 0.968 0.930 0.893 0.857 0.821 0.787 0.754 0.721 0.689 0.657 0.626 0.596 0.566 0.537 0.508 0.480 0.452 0.424 0.397 0.370 0.343 0.317 0.290 0.264 0.238 0.212 0.186 0.160 0.134 0.108 0.081 0.055 0.028 0.000 1.248 1.203 1.159 1.116 1.075 1.035 0.996 0.958 0.921 0.885 0.849 0.815 0.782 0.749 0.717 0.685 0.654 0.624 0.594 0.565 0.536 0.508 0.480 0.452 0.425 0.398 0.371 0.345 0.318 0.292 0.266 0.240 0.214 0.188 0.162 0.136 0.109 0.083 0.056 0.028 0.000 1.276 1.231 1.187 1.144 1.103 1.063 1.024 0.986 0.949 0.913 0.877 0.843 0.810 0.777 0.745 0.713 0.682 0.652 0.622 0.593 0.564 0.536 0.508 0.480 0.453 0.426 0.399 0.373 0.346 0.320 0.294 0.268 0.242 0.216 0.190 0.164 0.137 0.111 0.084 0.056 0.028 0.000 0.92 1.306 1.261 1.217 1.174 1.133 1.093 1.054 1.016 0.979 0.943 0.907 0.873 0.840 0.807 0.775 0.743 0.712 0.682 0.652 0.623 0.594 0.566 0.538 0.510 0.483 0.456 0.429 0.403 0.376 0.350 0.324 0.298 0.272 0.246 0.220 0.194 0.167 0.141 0.114 0.086 0.058 0.30 0.000 0.93 1.337 1.292 1.248 1.205 1.164 1.124 1.085 1.047 1.010 0.974 0.938 0.904 0.871 0.838 0.806 0.774 0.743 0.713 0.683 0.654 0.625 0.597 0.569 0.541 0.514 0.487 0.460 0.434 0.407 0.381 0.355 0.329 0.303 0.277 0.251 0.225 0.198 0.172 0.145 0.117 0.089 0.061 0.031 0.000 0.94 1.369 1.324 1.280 1.237 1.196 1.156 1.117 1.079 1.042 1.006 0.970 0.936 0.903 0.870 0.838 0.806 0.775 0.745 0.715 0.686 0.657 0.629 0.601 0.573 0.546 0.519 0.492 0.466 0.439 0.413 0.387 0.361 0.335 0.309 0.283 0.257 0.230 0.204 0.177 0.149 0.121 0.093 0.063 0.032 0.000 0.95 1.403 1.358 1.314 1.271 1.230 1.190 1.151 1.113 1.076 1.040 1.004 0.970 0.937 0.904 0.872 0.840 0.809 0.779 0.749 0.720 0.691 0.663 0.635 0.607 0.580 0.553 0.526 0.500 0.473 0.447 0.421 0.395 0.369 0.343 0.317 0.291 0.264 0.238 0.211 0.183 0.155 0.127 0.097 0.066 0.034 0.000 0.96 1.440 1.395 1.351 1.308 1.267 1.227 1.188 1.150 1.113 1.077 1.041 1.007 0.974 0.941 0.909 0.877 0.846 0.816 0.786 0.757 0.728 0.700 0.672 0.644 0.617 0.590 0.563 0.537 0.510 0.484 0.458 0.432 0.406 0.380 0.354 0.328 0.301 0.275 0.248 0.220 0.192 0.164 0.134 0.103 0.071 0.037 0.000 0.97 1.481 1.436 1.392 1.349 1.308 1.268 1.229 1.191 1.154 1.118 1.082 1.048 1.015 0.982 0.950 0.918 0.887 0.857 0.827 0.798 0.769 0.741 0.713 0.685 0.658 0.631 0.604 0.578 0.551 0.525 0.499 0.473 0.447 0.421 0.395 0.369 0.342 0.316 0.289 0.261 0.233 0.205 0.175 0.144 0.112 0.079 0.041 0.000 0.98 1.529 1.484 1.440 1.397 1.356 1.316 1.277 1.239 1.202 1.166 1.130 1.096 1.063 1.030 0.998 0.966 0.935 0.905 0.875 0.846 0.817 0.789 0.761 0.733 0.706 0.679 0.652 0.626 0.599 0.573 0.547 0.521 0.495 0.469 0.443 0.417 0.390 0.364 0.337 0.309 0.281 0.253 0.223 0.192 0.160 0.126 0.089 0.048 0.000 0.99 1.589 1.544 1.500 1.457 1.416 1.376 1.337 1.299 1.262 1.226 1.190 1.156 1.123 1.090 1.068 1.026 0.995 0.965 0.935 0.906 0.877 0.849 0.821 0.793 0.766 0.739 0.712 0.685 0.659 0.633 0.609 0.581 0.555 0.529 0.503 0.477 0.450 0.424 0.397 0.369 0.341 0.313 0.283 0.252 0.220 0.186 0.149 0.108 0.060 0.000 1.0 1.732 1.687 1.643 1.600 1.559 1.519 1.480 1.442 1.405 1.369 1.333 1.299 1.266 1.233 1.201 1.169 1.138 1.108 1.078 1.049 1.020 0.992 0.964 0.936 0.909 0.882 0.855 0.829 0.802 0.776 0.750 0.724 0.698 0.672 0.646 0.620 0.593 0.567 0.540 0.512 0.484 0.456 0.426 0.395 0.363 0.329 0.292 0.251 0.203 0.143 0.000 4.1.4 Reduced system power losses On some distribution and transmission systems, a significant reduction in losses may be achieved by the installation of shunt power capacitors. The installation of shunt power capacitors reduces current flow through the system from the point of the capacitor installation back to the generation. Since power losses are directly proportional to the square of the current, a reduction of current flow results in a much greater reduction of power losses. Capacitors are often installed as close to the load as possible for this reason. The ratio of the system losses associated with the local load, with and without capacitors installed, can be estimated with Equation (6), which assumes constant kilowatt and constant voltage at the load with no harmonics present (the effect of harmonics is addressed in Clause 7). 9 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors loss ratio = loss with capacitors loss without capacitors ⎛ PF ⎞ = ⎜⎜ old ⎟⎟ ⎝ PFnew ⎠ (6) 2 where PFold PFnew is the existing power factor is the corrected power factor This reduction in losses will reduce the generation fuel requirement to supply these losses as well as the system equipment costs to supply the losses at peak load. 4.1.5 Reduced billing charges A number of utilities use some form of kilovoltampere billing for their large customers (e.g., municipal utilities and large industrial customers). Since the application of shunt power capacitors beyond the meter can result in a reduced kilovolt-ampere loading, this can result in reduced billing charges. The kilovoltampere billing charge may be calculated in many different ways, including the following: a) b) c) d) A fixed charge for each kilowatt plus a fixed charge for each kilovar. A certain amount for each kilowatt at or above a certain power factor, with additional charges made for each kilovar in excess of that required by a minimum power factor. A charge per kilowatt demand multiplied by a factor that increases with decreasing power factor. A fixed charge per peak kilovoltampere. 4.2 Size and number of capacitor banks The shunt capacitance requirements are determined for a power system by modeling the system for various contingencies and determining the capacitors required to maintain acceptable system voltage. For specific applications, capacitors are applied to optimize the benefits described in 4.1 for a given set of system requirements. Distribution capacitors are often sized to supply the reactive power requirements of the load plus the reactive requirements of the transformer bank(s) at peak load. This provides for power factor correction to unity at the high side of the transformers and effective operation of the transmission or subtransmission system. Transmission substation capacitors are often sized and located based on load flow and stability studies of the transmission network. The capacitors minimize system losses, increase the system voltage, and increase stability margins. After the capacitor requirements are known, the individual capacitor bank megavar sizes and number of steps are determined. To take advantage of the economies associated with standardized equipment, other limitations may influence the maximum and minimum capacitor bank sizes used. 4.2.1 Maximum size The maximum capacitor bank size is influenced by the following factors: 10 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors a) b) Change in system voltage upon capacitor bank switching. Switchgear continuous current limitations. When a capacitor bank is energized or de-energized, the fundamental system voltage increases or decreases, respectively. In order to have a minimal effect upon customer loads, this voltage change is often limited to a value in the range of 2% to 3%. This voltage change (ΔV) can be estimated by Equation (7). ⎛ Q Mvar ⎞ ⎟⎟ × 100% ΔV = ⎜⎜ C Mva S sc ⎝ ⎠ (7) where ΔV is the voltage change as a percentage of the fundamental frequency rms system voltage QC Mvar is the Mvar size of the capacitor bank S sc Mva is the available three-phase short-circuit MVA at the capacitor bank location The continuous-current rating of switchgear used for capacitor bank switching may be a factor in choosing the capacitor bank size. The rating is usually determined by multiplying the nominal capacitor current by 1.25 for ungrounded capacitor banks and by 1.35 for grounded-wye capacitor banks. Where currents with substantial harmonic components are likely to be encountered, provision should be made for additional current-carrying capacity in the circuit breakers, fuses, and other auxiliary devices. More detailed information is available in IEEE Std C37.04-1999, ANSI C37.06-2009, IEEE Std C37.012-2005, ANSI C37.66-2005, and IEEE Std 1247-2005. 4.2.2 Minimum size While there is no absolute minimum capacitor bank size, the practical minimum capacitor bank size may be influenced by the following factors: a) b) c) d) e) The type of capacitor bank used: externally fused, internally fused, fuseless, etc. The easily available ratings of capacitor units Capacitor bank unbalance considerations Fuse performance and/or coordination The cost of the required switchgear and protection The principal concerns when installing a small capacitor bank are the proper performance of the proposed capacitor bank (including the protection) and the cost of the installation. Under some circumstances, the cost of the installation may be reduced by installing the capacitor on a lower voltage bus in the same substation. 4.3 Control considerations Capacitor banks are either switched or fixed, i.e., not switched. Generally, in determining the type of capacitor bank required, consider the following guidelines: a) b) Fixed capacitor banks are sized for minimum load conditions. Switched capacitor banks are designed for load levels above the minimum condition up to peak load. 11 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors The curve shown in Figure 3, which can be determined by a recording kilovar meter or calculated using kilowatt and power factor measurements, illustrates a typical kilovar demand over a 24 hour period. In this figure, the fixed capacitor banks satisfy the base load requirements, and the switched capacitor banks compensate for the inductive kilovar peak during the heavier load periods. In the operation of a power system, however, it is often desirable to use existing loads to hold down the system voltage during periods of light load (compensate for the excess capacitance of the transmission system). In this case, some of the “fixed capacitors” of this figure should actually be switched to allow the load to hold down the system voltage. In other cases, where excess capacitance can be tolerated during periods of light load, it may be less expensive to leave some of the “switched capacitors” unswitched. In more general terms, the “fixed capacitors” are those that can be left on the system all of the time, and the “switched capacitors” are those that are switched to meet system operating requirements or a billing tariff. 1800 1600 1400 Kilovars 1200 1000 800 Switched capacitors 600 400 Fixed capacitors 200 0 0 2 4 6 8 10 12 14 16 18 20 22 24 Time of day Figure 3 — Switching capacitors 5. Capacitor ratings, capabilities, and service conditions Capacitor ratings and service conditions are specified in IEEE Std 18-2002. Application guidelines for transient, short time and contingency capacitor overvoltages and overcurrents are given in this document. Key aspects of the ratings and service conditions are provided in this clause for easy reference. Short time “momentary” capabilities of capacitors are also explained in this clause. The life of a capacitor is shortened by overstressing, overheating, chemical change, physical damage, or repeated temperature changes. Life to 90% survival might exceed 20 years when capacitors are applied according to the guidelines of this application guide. 12 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Shunt capacitors cause a voltage rise at the point where they are located and are therefore more likely to operate at overvoltages than other types of equipment. Recognizing this factor, the nameplate voltage ratings of capacitors and permissible overvoltage operation are generally higher than those established for motors and most other equipment. 5.1 Standard ratings The standard ratings established in IEEE Std 18-2002 are as follows: a) b) c) d) e) Voltage, rms (terminal-to-terminal) Terminal(s)-to-case (or ground) insulation class Reactive power Number of phases Frequency 5.1.1 Tolerances in ratings Older capacitors may have tolerances as high as –0% to +15% for capacitance of individual capacitor units at 25 °C uniform case and internal temperature. Beginning with the 2002 edition, capacitors built to IEEE Std 18 have a tolerance of –0% to +10% at 25 °C. Temperature will affect capacitance measurements. Therefore, the capacitance of capacitor units that are much colder or much warmer than 25°C may measure outside the rated tolerance without having failed elements. 5.1.2 Voltage and reactive power ratings Typical voltage and reactive power ratings are summarized in Table 3. The reactive power output can be calculated as shown in Equation (8). Q OP = (2π fC )V 2A (8) 1000 where QOP VA f C is the operating reactive power of the capacitor in kilovoltamperes reactive is the applied voltage in volts is the supply frequency in Hertz is the capacitance of the capacitor in farads The reactive power output will vary according to the actual applied voltage, which may be different than the rated voltage. The operating kvar can also be calculated as shown in Equation (9). Q OP ⎛V kvar = Q R kvar ⎜⎜ A ⎝ VR ⎞ ⎟⎟ ⎠ 2 (9) 13 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors where QOP QR VA VR is the operating reactive power of the capacitor in kilovoltamperes reactive is the rated reactive power of the capacitor is the applied voltage is the rated voltage 5.1.3 Insulation classes The standard basic impulse insulation levels (BIL) of capacitor units are given in Table 3. Capacitors may be used on circuits of higher voltage than the terminal-to-case insulation class, provided the cases are supported on external insulation suitable for the circuit voltage and provided the terminal-toterminal voltage limits are not exceeded. Table 3—Typical voltage and reactive power ratings Volts, rms (terminal-to-terminal) kvar Number of phases BIL kVa 2400 2770 4160, 4800 50, 100, 150, 200, 300 and 400 50, 100, 150, 200, 300, 400 and 500 50, 100, 150 200,300, 400, 500, 600, 700 and 800 50, 100, 150, 200, 300, 400, 500, 600, 700 and 800 1 and 3 1 and 3 1 and 3 75, 95, 125, 150 and 200 75, 95, 125, 150 and 200 75, 95, 125, 150 and 200 1 95, 125, 150 and 200 50, 100, 150, 200, 300, 400, 500, 600, 700 and 800 100, 150, 200, 300, 400, 500, 600, 700 and 800 100, 150, 200, 300, 400, 500, 600, 700 and 800 1 125, 150 and 200 1 125, 150 and 200 1 150 and 200 6640,7200,7620,7960, 8320, 9540, 9960, 11 400, 12 470, 13 280, 13 800, 14 400 15 125 19 920 20 800, 21 600, 22 800, 23 800, 24940 a See IEEE Std 18-2002 for impulse test specifications. 5.1.4 Frequency Power capacitors are designed for operation at the device’s rated nominal frequency of either 50 Hz or 60 Hz. When capacitors are operated at frequencies lower than rated, both the reactive power and the capacitive current are reduced in direct proportion to the operating frequency as shown in Equation (10) and Equation (11). ⎛ f QOP kvar = ⎜⎜ OP ⎝ fR ⎞ ⎟⎟QR kvar ⎠ ⎛f I OP = I NOM ⎜⎜ OP ⎝ fR where QOP QR IOP INOM fOP fR (10) ⎞ ⎟⎟ ⎠ (11) is the operating reactive power of the capacitor, kvar is the rated reactive power of the capacitor, kvar is the capacitive current at the applied frequency and rated voltage is the capacitive current at the rated frequency and rated voltage is the frequency at which the capacitor unit is to be applied is the rated frequency of the capacitor unit 14 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 5.2 Related capabilities 5.2.1 Operating and ambient temperatures Capacitors are designed for switched or continuous operation in outdoor locations with unrestricted ventilation and direct sunlight under the maximum ambient temperatures for each mounting arrangement shown in Table 4. 5.2.1.1 Minimum ambient Capacitors are designed for continuous operation and switching operations at temperatures not lower than –40° C. The capacitor manufacturer should be consulted for operation below –40° C. 5.2.1.2 Effect of temperature It is essential that consideration be given to the arrangement of capacitors and complete equipment as an installation to provide adequate ventilation and dissipation of heat. Capacitors are designed to operate at a lower temperature rise than most other types of apparatus for the following specific reasons: a) Unlike most other power apparatus, shunt capacitors (whether unswitched or switched) normally operate for relatively long periods of time at full load and, therefore, do not benefit from the lower average temperature rise characteristic of typical daily load cycles. b) Capacitors are designed to operate at comparatively high dielectric stresses. The combination of these stresses with operation at high temperature for extensive periods of time will result in gradual deterioration and shortened life. 5.2.1.3 Design considerations Capacitor ratings are based on maximum ambient temperatures with an allowance for heat dissipation by radiation and convection. The arrangement and mounting of capacitors and the conditions of installations will affect the heat dissipation and thereby limit the ambient temperature in which capacitors may be operated. Capacitors and capacitor equipment operating outdoors in direct sunlight and with unrestricted ventilation will normally operate with lower temperature rise than those operating indoors in still air. The following points are important in relating the operating temperature of a capacitor to the conditions of installation: a) An individual non-enclosed capacitor, such as is mounted on an outdoor pole, will dissipate heat with the least temperature rise (the heat dissipation being approximately 45% by radiation and 55% by convection). b) The mounting of capacitors in rows side by side or in tiers, or both, increases the temperature rise because of heating of the air stream and because of reduced radiation. c) The enclosing of capacitors in a housing or room without forced air ventilation increases the temperature rise because of reduced radiation and restriction of the natural circulation of air. d) Capacitors subjected to radiation from the sun or from any surface, the temperature of which is above the ambient, show a higher temperature rise. 15 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Table 4—Maximum ambient Mounting arrangement Maximum ambient air temperature, °Ca Isolated capacitor 46 Single row of capacitors 46 Multiple rows and tiers of capacitors 40 Metal-enclosed or housed equipment 40 a The arithmetic average of the four highest hourly readings during the hottest day expected at the capacitor location For applications at temperatures higher than indicated in Table 4, consult the capacitor manufacturer. 5.2.2 Continuous operation Capacitors are suitable for continuous operation at 135% of rated reactive power. This maximum reactive power includes the following factors, the combined effects not exceeding 135%. a) b) c) Reactive power due to voltage in excess of nameplate rating at fundamental frequency but within the permissible voltage limitations described in 5.2.2.1. Reactive power due to harmonic voltages superimposed on the fundamental frequency. Reactive power in excess of nameplate rating due to manufacturing tolerance within the limits specified in 5.1.1. 5.2.2.1 Limitations on continuous operation Capacitors are intended to be operated at or below their rated voltage and frequency. Capacitors are capable of continuous operation under contingency system and capacitor bank conditions provided that none of the following limitations are exceeded: a) b) c) d) 110% of rated rms voltage. 120% of rated crest voltage, i.e., crest voltage not exceeding 1.2 × 2 × rated rms voltage, including harmonics but excluding transients (see Clause 7 for more on harmonics). 135% of nominal rms current based on rated kvar and rated voltage, including fundamental and harmonic currents (see Clause 7 for more on harmonics). 135% of rated kvar (see 5.2.2). The continuous and short-time overvoltage capabilities (without loss of life) of any series element of a capacitor unit shall be considered to be its share of the total capacitor unit voltage capability. (In internally fused capacitor units, capacitor elements in parallel with blown fuses sometimes are operated beyond their normal capability, accepting the possibility of shortened life. Similarly, in some externally fused capacitor banks and in some capacitor banks without capacitor unit fuses, capacitor units with failed elements are allowed to remain in service with the remaining healthy capacitor elements in those capacitor units 16 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors operating above their normal capability, accepting the possibility of shortened life.) Capacitor units without failed elements are intended to be operated within the guidelines a) through d) shown previously. 5.2.3 Momentary capabilities Capacitors are capable of withstanding with full-life expectancy switching transients having peak voltages up to 2 × 2 times rated voltage rms and other transient disturbances inherent in the operation of power systems. Capacitors may be subjected to both high voltage and high current under certain conditions associated with switching. The magnitude of the permissible current and voltage peaks depends on the frequency of occurrence. In the case of a frequently switched capacitor, current and voltage peaks must be held to relatively low values. Comparatively high values may be tolerated on a capacitor bank switched infrequently. Figure 4 through Figure 6 provide a guide for the evaluation of service conditions from the standpoint of peak currents and voltage. The capabilities indicated in these figures may be increased, upon recommendation by the manufacturer, when fewer overvoltages are expected or when less severe temperature conditions exist. 5.2.3.1 Momentary power frequency overvoltage A capacitor, tested in accordance with IEEE Std 18-2002 may reasonably be expected to withstand, during normal service life, a combined total of 300 applications of power frequency terminal-to-terminal overvoltages without superimposed transients or harmonic content, of the magnitudes and durations shown in Figure 4. 17 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Sh o rt T ime O ve rvo lta g e Po we r fre q ue n cy ca pa b ility o f ca pa cito r un its Volta ge (p er un it of rated rms volta 2 .6 2 .2 1 .8 1 .4 1 0 .6 0 .0 1 0 .1 1 10 100 1 0 00 10000 T ime (seco n d s) Figure 4 — Maximum contingency power frequency overvoltage capability of capacitor units NOTE—Figure 4 is based on straight line segments between the following points on semi-log coordinates: (0.01, 2.2), (0.1, 2.2), (0.25, 2.0), (1.0, 1.7), (15.0, 1.4), (60, 1.3), and (1800, 1.25). In using Figure 4, the overvoltage capability is for the capacitor unit, not the capacitor bank. Evaluation of capacitor unit overvoltage exposure should include allowance for any voltage unbalance in the capacitor bank. Overvoltages may cause localized damaging discharges (partial discharge) in a capacitor unit. Trapped charges and gas generated in the first half cycle make the discharge more severe in the second half cycle. The accumulation of damage makes the severity of the overvoltage event increase with the time of the event. When the overvoltage is eliminated, the trapped charges and accumulated gas tend to dissipate and be absorbed. This improves the dielectric capability of the capacitor from what it was at the end of the overvoltage event. The time axis of Figure 4 indicates the maximum time for a single event. Capacitor unit damage tends to escalate during an event, so that damage is happening more rapidly at the end of the event than at the beginning. Two continuous seconds at 1.73 per unit is much more severe than two separate events of 1 s each, with a time in between to allow for localized cooling, absorption of corona gasses accumulated gas, etc. The curve should not be used to estimate the effect of contingency overvoltage events exceeding the maximum time indicated by the curve. For event times shorter than those indicated by the curve, the times of the individual events can be accumulated to estimate the effect of the shorter events. For example, ten 1.73 per unit events of 0.1 s each (shorter than the allowable one second limit of the curve) would create equal or less damage to the capacitor unit than one 1.73 per unit event of 1 s duration. 18 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 5.2.3.2 Transient overcurrent A capacitor unit may reasonably be expected to withstand transient currents inherent in the operation of power systems. These include infrequent high lightning currents and discharge currents to nearby faults. For frequent back-to-back capacitor bank switching, peak capacitor unit current should be held to a lower value as indicated in Figure 5. (The capacitor bank current is the capacitor unit current times the number of capacitor units or strings in parallel.) Other equipment such as fuses, circuit breakers, and protection and control circuits may require limitation to a lower peak current. Maximumpeak capacitor unit current (kA) 14 12 10 4 Operations per year 8 6 1 Operation per day 4 10 Operations per day 2 0 0 20 40 60 80 100 Capacitor unit nominal current (Amperes) Figure 5 — Transient current capability of capacitor units for regularly occurring transients NOTE—In Figure 5 these curves are based on straight lines from the origin to 12 kA. The slopes are 1500 times the nominal current for 4 operations per year, 800 times the nominal current for 1 operation per day, and 400 times nominal current for 10 operations per day. 5.2.3.3 Transient overvoltage A capacitor may reasonably be expected to withstand the transient overvoltages indicated in Figure 6. 19 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Peak voltage (Per unit of crest of rated voltage) 4.0 3.5 3.0 2.5 2.0 1.5 1 10 100 1000 10000 Number of transients per year Figure 6 — Transient peak overvoltage capability of capacitor units NOTE—In Figure 6, the curve is based on straight line segments between the following points on semi-log coordinates: (1.0, 5/√2), (4.0, 5/√2), (40, 4/√2), (400, 3.4/√2) and (4000, 2.9/√2). 5.3 Service conditions 5.3.1 Normal service conditions Capacitors are suitable for operation at their specified rating when a) b) c) d) e) f) The ambient temperature is within the limits specified in 5.2.1. (Capacitors may be exposed to the direct rays of the sun.) The altitude does not exceed 1800 m above sea level. 8 The voltage applied to a capacitor bank does not exceed the rated voltage of the capacitor bank. The impulse voltage applied between each terminal and the case does not exceed BIL of that terminal as specified in 5.1.3. The applied voltage does not contain harmonics in excess of the limits specified in 5.2.2.1. The nominal operating frequency is equal to the rated frequency. 5.3.2 Abnormal service conditions If capacitors are required to operate under abnormal service conditions, such as the following, the application should be brought to the attention of the manufacturer: 8 6000 feet above sea level. 20 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors a) b) c) d) e) f) g) h) i) j) k) Exposure to damaging fumes or vapors Exposure to conducting or explosive dust Exposure to abnormal mechanical shock or vibration, including earthquakes Exposure to radiated heat from surfaces (other than the sun) that are hotter than the ambient temperature limits for capacitors given in 5.2.1 Mounting and/or arrangement that prevents adequate ventilation (see 5.2.1.3) Operation in ambient temperatures outside the range specified in 5.2.1 Altitude higher than 1800 m above sea level Momentary power frequency overvoltage that exceeds that listed in 5.2.3.1 Transient currents that exceed those listed in 5.2.3.2 Transient overvoltages that exceed those listed in 5.2.3.3 Service conditions other than those listed in 5.3.1 6. Switching and switchgear considerations 6.1 Switching of capacitors Switched capacitors give added flexibility in the control of system voltage, power factor, and losses. Switched capacitors are usually applied with some type of automatic switch control. The control senses a particular condition. If the condition is within a preset level, the control’s output level will initiate a close or trip signal to the switches that will either connect or disconnect the capacitor bank from the power system. Typical automatic capacitor controls are listed below with a description of why they may be chosen. a) b) c) d) e) Voltage. Improvement or control of voltage regulation is a major consideration. Current. Current magnitude is directly related to var demand. Var or reactive current controls. Var demand is a major consideration. Time switch. Var demand has a high degree of regularity with respect to time. Temperature. Increase in var demand is closely related to temperature change. Power factor is generally not a good basis for controlling capacitor switching. Low power factor at very low load requires very little capacitance, and the addition of capacitors may result in a leading power factor and immediate switching off of the capacitors—a “pumping” condition. High power factor at very high load may still benefit from the addition of capacitors, and the addition of some capacitors may not result in enough change in power factor to result in switching off of the capacitors. Var or reactive current controllers are more appropriate controllers where a power factor penalty is to be avoided. Fixed capacitor banks (i.e., not automatically switched) are usually left energized on a continuing basis. However, in areas with significant seasonal demand changes, fixed capacitor banks may be manually switched on a seasonal basis. Remote switching of capacitor banks is being used in some areas (Clinard [B3]). 9 This requires a specific capacitor bank or group of capacitor banks to have controls capable of receiving a signal and initiating a close or open operation on the capacitor switches. The computer algorithm or manually entered command originates at a remote location. Capacitor banks located in substations are most commonly controlled via the same system supervisory control automated and data acquisition (SCADA) used to control other equipment in the station. Typical 9 The numbers in brackets preceded by the letter B correspond to those of the bibliography in Annex A. 21 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors communications methods for remote switching of capacitor banks, mostly distribution, include the following: ⎯ Radio. When the area allows appropriate radio frequency to be transmitted without much interference. ⎯ Power line carrier. Appropriate line coupling equipment is required, usually at the substation. ⎯ Telephone. Over leased or private telephone lines. 6.2 Switching transients When a capacitor bank is energized or de-energized, current and voltage transients are produced that affect both the capacitor bank and the connected system (Greenwood [B4]). (Switchgear rating considerations are discussed in 6.4.) This clause starts with a description of the transients that result from switching followed by a summary of the devices most commonly used for switching capacitor banks. 6.2.1 Energization 6.2.1.1 Energizing an isolated capacitor bank Figure 7 shows an equivalent circuit for energizing an isolated capacitor bank from a predominantly inductive source. When the switch is closed, a high-frequency, high-magnitude current flows into the capacitor, attempting to equalize the system voltage and the capacitor voltage. If the switch is closed at a voltage peak, the voltage on the capacitor attempts to immediately increase from the zero-voltage, deenergized condition to the peak voltage. In the process of achieving this voltage change, an overshoot occurs, equal to the amount of the attempted voltage change. This voltage surge is also of the same high frequency as the inrush current, and rapidly decays to the system voltage. The magnitude of the voltage surge, for an isolated grounded-wye capacitor bank, is a maximum of about 2.0 per unit. Equivalent system representation Vpk Ls Rs C Capacitor Bank Figure 7 — System diagram for energizing an isolated capacitor bank For a practical capacitor bank energization without trapped charge, the system losses, loads, and transmission system capacitances can cause the transient magnitude to be much less than the theoretical 2.0 per unit (peak phase-to-ground voltage). Typical levels range from 1.2 to 1.8 per unit for substation 22 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors capacitor banks (EPRI TR-106294-V2 [B11]). Figure 8 shows example capacitor energizing transient voltage and current waveforms. Transient frequencies due to isolated capacitor bank switching generally fall in the 300 Hz to 1000 Hz range. The characteristic frequency is related to the steady-state voltage rise (ΔV—refer to 4.2.1) using Equation (12). 2 80 Capacitor Voltage 60 1 Source Voltage 20 -1 0 -2 Current (per unit) Voltage (per unit) 40 0 -20 Capacitor current -3 -180 -90 0 90 180 -40 270 Voltage angle (degrees) Figure 8 — Typical bus voltage and capacitor current during capacitor energizing fs = 1 = f system × 2π LsC ⎛ S sc Mva ⎞ ⎛ 1 ⎞ ⎜⎜ ⎟⎟ ≈ f system × ⎜ ⎟ ⎝ ΔV ⎠ ⎝ QC Mvar ⎠ (12) where fs fsystem Ls C Ssc QC ΔV is the switching transient frequency is the system power frequency is the source inductance of the system is the capacitance of the capacitor bank is the short-circuit MVA at the capacitor bus is the Mvar of the capacitor bank at nominal system voltage is the steady state voltage rise as per unit of the nominal Therefore, for a 60 Hz system, a voltage rise design range of 1.0% to 2.5% would correspond to characteristic frequency range of 380 Hz to 600 Hz. Transient overvoltages that result are usually not of concern to the utility, since peak magnitudes are just below the level at which utility surge protection, such as arresters, begins to operate. Because of the relatively low frequency, however, these transients will pass through step-down transformers to lower voltage loads. 23 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Energizing grounded wye and ungrounded wye capacitor banks can both result in transient overvoltages— both on the system and on the capacitors. The details of the transients tend to be different and depend on many factors including system impedance (reactance and resistance), presence of other capacitor banks on the system, delay between closing of the phases of the switch, etc. Generally the effects are similar. Re-energizing a capacitor bank with voltage on its terminals will increase the severity of the energization transient. For example, a trapped voltage of 10% of the crest of the normal voltage will increase the inrush transient voltage and current by 10%. Internal discharge resistors in each capacitor unit will dissipate the stored energy, reducing the voltage. These resistors are designed, per IEEE Std 18-2002, to reduce the voltage across the individual capacitor units to less than 50 V within 5 min. Enough delay should be provided to assure that the voltage on the capacitors is low enough to assure acceptable inrush transients. While a 5 min delay for re-energizing capacitors has frequently been used to limit inrush transient problems, re-energizing the capacitors in less than 5 min after de-energization may be desirable. Allowing the voltage to decay to about 10% of its original value will only increase the inrush transients by 10% and is often acceptable. Normally reduction to 10% is on the order of 2 min to 3 min, depending upon the capacitor unit voltage rating. Calculation of the time for capacitors to decay to a specific voltage is covered in IEEE Std C37.99-2000. External discharge reactors to more quickly discharge the capacitors, properlysized insertion resistors or reactors, or controlled switching to control the inrush transient may also be used to reduce the time before re-energizing. The transient inrush/discharge capability of the capacitors and the switching device should be considered. 6.2.1.2 Phase-to-phase insulation The energization of a shunt power capacitor bank may subject other system equipment to excessive phaseto-phase overvoltages, especially delta-connected transformers (O’Leary and Harner [B14]). A potential problem is illustrated in Figure 9. Surges generated by the energization of the capacitor bank would travel down the line towards the transformer and double at that point. It would be possible to get a +2.0 per unit surge on one phase and a –2.0 per unit on another. This would result in 4.0 per unit phase-to-phase. (Voltages are given in per unit of the rated peak line-to-ground voltage.) This could be a potential problem for transformers that are applied in this configuration (see IEEE Std 262B). A typical example of this type of transient is shown in Figure 10. The actual severity of the transient is a function of the system configuration and can be significantly higher than the 4.0 per unit value mentioned above. In general, this transient can be reduced by any of a number of methods including closing resistors, pre-insertion inductors, controlled closing, staggered closing, capacitor bank reactors, and surge arresters (Bayless, et al. [B2]). 24 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 230 kV 69 kV 34.5 miles 50.4 Mvar Figure 9 — System diagram for transient shown in Figure 10 25 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Phase B 4 V o lt a g e ( p u ) 2 0 -2 -4 50 55 Electrotek Concepts® 60 Time (ms) 65 4 70 TOP, The Output Processor® Phase C V o lt a g e ( p u ) 2 0 -2 -4 50 55 Electrotek Concepts® 4 60 Time (ms) 65 70 TOP, The Output Processor® Phase B-C V o lt a g e ( p u ) 2 0 -2 -4 50 El t t k C 55 60 Time (ms) t® 65 70 TOP Th O t t P ® Figure 10 — Simulation of transformer transient due to capacitor switching 6.2.1.3 Prestrike Prestrike may occur during the energization of a capacitor bank. When the capacitor bank is energized, an arc is established within the interrupters before the contacts physically make contact. This phenomenon is called prestrike. When a prestrike occurs, normal high-frequency inrush current flows. Certain interrupters can interrupt this current at a high-frequency current zero. When the interrupter again strikes the arc, transient voltages and currents occur due to the trapped charge on the capacitor. The level of concern for this phenomenon is a function of the time delay before it strikes again and the number of times that it occurs (Pflanz and Lester [B8]). 26 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 6.2.1.4 Inrush current Capacitor switches must be capable of repeatedly withstanding inrush current, which, for an isolated capacitor bank, is as follows in Equation (13) through Equation (16): I max pk = 1000 × VLL × C eq 2 × 3 Leq (13) or I max pk = 2 × I SC × I 1 (14) or I max pk = 1000 2 × × S SC Mva × QC Mvar VLL 3 (15) or I max pk = 1000 × Q C kvar 2 × 3 1000 × 2π × f s × Leq (16) where fs Ceq is the system frequency, in Hertz is the effective capacitance of the capacitor bank (in farads). This value should take into account the effect of capacitance tolerance Leq is the effective inductance of the source (in henries) ISC is the symmetrical rms three-phase short-circuit current at the capacitor bank location (in amperes) I1 is the rms capacitor bank current (in amperes). The current used should include the effect of operating the capacitor bank at a voltage above nominal rating of the capacitors and the effect of a positive tolerance of capacitance. In the absence of specific information, a multiplier or 1.15 times nominal capacitor current would give conservative results Imax pk is the peak value of inrush current calculated without damping, in Amperes. In practical circuits, it will be about 90% of this value. VLL is the rated maximum line-to-line voltage, in kilovolts Ssc is the available three-phase short-circuit MVA at the capacitor bank location QC is the three-phase Mvar or kvar (units shown in equation) of the capacitor bank being switched at nominal system voltage. It should include the effect of positive capacitance tolerance 6.2.1.5 Energization of back-to-back capacitor banks When a capacitor bank is energized in close proximity to a previously energized capacitor bank, further considerations arise. A high-frequency inrush current flows when the capacitor bank is energized. However, the limiting inductance is the inductance between the capacitor banks rather than the system 27 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors inductance. The magnitude and frequency of this inrush current is, therefore, much higher than the inrush to an isolated capacitor bank (see IEEE Std C37.012-2005, ANSI C37.66-2005, IEEE Std 1247-2005). The inrush current magnitude and frequency can be calculated as follows in Equation (17) through Equation (21): I max pk = 1000 × VLL × C eq 2 × 3 Leq (17) or I max pk = 1000 × 2 × 3 3 × 1000 × VLL × (I1 × I 2 ) 2π × f s × Leq × (I1 + I 2 ) (18) or I max pk ⎛ Q1 kvar × Q2 kvar ⎞ ⎜⎜ ⎟ Q1 kvar + Q2 kvar ⎟⎠ 1000 ⎝ = × 3×π × fs Leq (19) and ft = 1000 2π × Leq × Ceq (20) or ft = 1 2π × 1000 × f s × VLL × (I 1 + I 2 ) (21) 3 × Leq × (I 1 × I 2 ) where fs ft Ceq Leq I1, I2 is the system frequency, in Hertz is the frequency of transient inrush current, in kilohertz is the equivalent capacitance of the two capacitor banks in series (in farads) is the total equivalent inductance per phase between capacitor banks (in henries) are the currents of the capacitor bank being switched and of the capacitor bank already energized, respectively, in amperes. The capacitor bank being switched is assumed uncharged, with closing at a voltage crest of the source voltage. The current used should include the effect of operating the capacitor bank at a voltage above nominal rating of the capacitors and the effect of a positive tolerance of capacitance. In the absence of specific information, a multiplier of 1.15 times nominal capacitor current would give conservative results Imax pk is the peak value of inrush current calculated without damping, in amperes 28 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors VLL is the rated maximum line-to-line voltage, in kilovolts Q1, Q2 are the three-phase kvars of the capacitor bank being switched and the capacitor bank already energized, respectively. The kvar used should include the effect of a positive tolerance of capacitance These equations can also be used for computing of inrush currents when more than two capacitor banks are switched back-to-back provided the equivalent inductance is calculated properly. For distribution systems, about a hundred meters between overhead capacitor banks is usually an adequate separation distance to limit the inrush current to an acceptable level. Configurations where the capacitor banks are very close together may require inrush current limiting reactors. This high-frequency inrush may exceed the transient frequency momentary capability or peak withstand capability of the switching device (see ANSI C37.06-2009 and IEEE Std C37.012-2005) as well as the I2t withstand of the capacitor fuses. It may also cause false operations of protective relays and excessive voltages for current transformers in the neutral or phase of grounded-wye capacitor banks. Back-to-back switching is typified by the circuit shown in Figure 11. The magnitude and frequency of the inrush current must be limited to ensure the proper operation of the switching device as well as relays, fuses, etc. Where inrush currents are excessive, one or a combination of the following steps is taken: a) b) c) d) e) Use current limiting reactors to decrease the peak current and frequency of the oscillatory inrush transients. Use switching devices with properly sized pre-insertion resistors. These resistors are designed to over-damp the circuit, preventing oscillations and allowing the capacitor to become essentially charged to line potential before the main contacts of the switch close. Use switching devices with pre-insertion inductors. These inductors provide a large impedance between the capacitor banks to limit the inrush current. High resistance pre-insertion inductors will further limit inrush current through damping as in the case of pre-insertion resistors. Switch the capacitor in smaller megavar increments. Control the switching device to close at the instant of zero voltage difference across the switch. Figure 11 — Back-to-back switching circuit To control the substation ground mat transients due to the high-frequency inrush currents, where two or more grounded wye capacitor banks are at the same location, the capacitor bank neutrals may be directly connected, with a single connection to ground. (See 9.1.2 of this standard and IEEE Std C37.99-2000 for more details.) 29 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 6.2.1.6 Methods for controlling system transients during capacitor energization The devices currently available for transient overvoltage control either attempt to minimize the transient overvoltage (or overcurrent) at the point of application, or limit (clip) the overvoltage at local and remote locations (Pflanz and Lester [B8]). These devices include the following: a) Pre-insertion resistors and inductors b) Synchronous closing c) Surge arresters Previous studies [digital simulation and Transient Network Analyzer (TNA])] have suggested that the effectiveness of these control methods is system dependent, and that detailed analysis is required to select the optimum control scheme. While often justifiable for large transmission applications, analysis of distribution system capacitor applications is rarely performed, and in general, capacitor banks are installed without transient overvoltage control. Each of these transient control methods has various advantages and disadvantages in terms of transient overvoltage reduction, cost, installation requirements, operating/maintenance requirements, and reliability. Some of these techniques may be useful in controlling the transients when re-energizing a capacitor bank before the voltage has decayed to near zero. Pre-insertion resistors and inductors: Using a pre-insertion resistor or inductor on the switching device provides a means for reducing the transient currents and voltages associated with the energization of a shunt capacitor bank. The impedance is “shorted-out” (bypassed) shortly after the initial transient dissipates, thereby producing a second transient event. The performance of pre-insertion impedance is evaluated using both insertion and bypass transient magnitudes, as well as the capability to dissipate the energy associated with the event, and repeat the event on a regular basis. Pre-insertion resistors are one means for controlling capacitor energizing transients. The optimum resistor value for controlling capacitor energizing transient depends primarily on the capacitor bank size and the source strength including any back-to-back capacitor switching. The resistor size is normally based on equalizing the initial transient of resistor closing with the subsequent transient of resistor bypass (shorting). Pre-insertion inductors, which were traditionally used primarily for overcurrent control for back-to-back capacitor switching applications also provide transient overvoltage magnitude reduction. The degree of overvoltage reduction achieved is largely determined by the relative size of the source inductance and the resistance and inductance of the pre-insertion inductor. Pre-insertion inductors are generally very effective for overvoltage reduction if the inductance is equal to or greater than the source inductance. Pre-insertion inductors with high resistance further increase reduction in overvoltages by increased damping of the oscillatory transient portion of the capacitor-switching voltage transient. Synchronous closing control: Synchronous closing is independent contact closing of each phase near a voltage zero, as illustrated in Figure 12 for an ungrounded capacitor bank. To accomplish closing at or near a voltage zero (avoiding high prestrike voltages), it is necessary to apply a switching device that maintains a dielectric strength sufficient to withstand system voltages until the contacts touch. Because of variations from operation to operation, closing every operation at precisely voltage zero across the contacts is not possible. Previous studies have indicated that a closing consistency of 1.0 ms provides overvoltage control comparable to properly sized pre-insertion resistors. The success of a synchronous closing scheme is often determined by the ability to repeat the process under various system and climate conditions. 30 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Close third phase Close first two phases Per unit voltage 1.5 1 0.5 0 -0.5 -1 -1.5 0 360 720 Capacitor bank neutral voltage 1080 Electrical degrees Figure 12 — Concept of synchronous closing control for ungrounded wye banks Grounded banks are controlled by closing each phase as the phase-to-ground voltage goes through zero. Ungrounded capacitor banks are controlled by closing the first two phases at a phase-to-phase voltage zero and then delaying the third phase by 90 degrees (capacitor bank neutral to third phase voltage zero). Surge arresters: Surge arresters can limit the transient voltages to the arrester’s protective level (maximum switching surge protective level, typically 1.8–2.5 pu) at the point of application. Surge arresters are often used to protect equipment affected by capacitor bank switching such as radially-fed transformer terminals (6.2.1.2) and lower voltage capacitors where voltage magnification may occur (6.2.1.7.1). Care should be taken in arrester selection to ensure that arrester energy duty is not exceeded during restriking in the capacitorswitching device or due to voltage magnification. (See also Clause 8.) 6.2.1.7 Power quality considerations Capacitors may affect power quality in several ways, the two predominant ways being harmonic resonances and switching surges. Harmonic concerns are discussed in Clause 7. Switching surge power quality issues involve voltage magnification, motor drive trips, temporary overvoltages, and ferroresonance. These aspects are discussed in this clause. 31 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 6.2.1.7.1 Voltage magnification Voltage magnification occurs when the transient caused by energizing a capacitor bank excites a resonant oscillation in a capacitor bank or cable circuit at a lower voltage (Shultz, Johnson, and Shultz [B9]). Figure 13 illustrates a system on which this phenomenon might occur. 230kV Bus (ignore line impedance) 10 MVA Ztx = 10.0% 3000 MVAsc 97 MVAsc 50MVAr 13.2kV Bus 1.8MVAr 1000 kVA Ztx = 5.5% 15 MVAsc fs230 kV = fsystem * M VA sc 3000 = 60 * = 465Hz M VA r 50 480V Bus 450kVAr 10 HP ASD Figure 13 — System diagram for magnification condition Figure 14 shows the equivalent circuit. There are two coupled inductive-capacitive circuits. If the resonant frequencies of these two loops are approximately the same, voltage magnification can occur. The frequencies of the two loops can be compared by comparing (L1 × C1) to (L2 × C2) (see 6.2.1.1). The worst magnified transients occur when the following conditions are met: ⎯ The vars of the switched capacitor bank are significantly greater than (>10 times) the vars of the lower voltage capacitor bank (i.e., 50 Mvar versus 1.8 Mvar is a ratio of approximately 28). ⎯ The switching transient frequency (resonant frequency of the first loop) is close to the resonant frequency of the lower voltage loop. These frequencies can be calculated by Equation (22). S sc Mva f transient = f supply Qc Mvar (22) where ftransient is the switching transient frequency fsupply Ssc Qc is the nominal frequency of the source is the short-circuit MVA at the location of the capacitor bank is the rated Mvar of the capacitor bank For example, the calculation indicates that the transient frequency will be 465 Hz at the 230 kV bus vs. 440 Hz at the 13.2 kV bus in the power system of Figure 13. ⎯ There is relatively little damping (resistive) provided by the low voltage load (i.e., a primarily inductive motor load) 32 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors L1 L2 C1 C2 Figure 14 — Equivalent circuit for magnification condition Figure 15 illustrates a representative simulation of this phenomenon. These voltage magnitudes may be high enough to sparkover gap type silicon carbide surge arresters at the lower voltage capacitor or cable. Surge arresters should be capable of withstanding the event; however, this should be verified by appropriate analysis and simulations. The magnified surge at the lower voltage can be from 2.0 to 4.0 per unit and may occur for a wide range of capacitor sizes. Energizing Transient 2.5 2.0 1.5 Voltage (pu) 1.0 0.5 0.0 -0.5 -1.0 -1.5 -2.0 -2.5 60 80 Time (ms) 100 120 Low Voltage Transient 2.5 2.0 1.5 Voltage (pu) 1.0 0.5 0.0 -0.5 -1.0 -1.5 -2.0 -2.5 60 80 Time (ms) 100 120 Figure 15 — Magnification of transient at remote capacitor bank 33 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors The magnified surges can be a significant problem because capacitor switching is often a daily event. Repetitive surges of high magnitude may eventually damage equipment and may result in severe arrester duty. The damage is generally confined to surge protective devices or nuisance tripping of a power electronic device. Occasionally, other sensitive equipment is damaged. The problem can usually be remedied as follows: a) b) c) d) e) Detuning the circuit by changing capacitor bank sizes or moving or removing capacitor banks from service. Equipping the switching device with a transient reduction scheme such as pre-insertion resistors, pre-insertion reactors or synchronized closing control to limit voltage surge magnitudes (see 6.2.1.6). Applying surge arresters at the lower voltage capacitor. Adding a reactor to the lower voltage capacitor for detuning. Switching large capacitor banks in more than one step (Shultz, Johnson, and Shultz [B9]). For example, switch 50 Mvar in two steps of 25 Mvar each. 6.2.1.7.2 Tripping of adjacent motor drives due to capacitor switching Capacitor switching can result in unplanned shutdown of adjustable speed motor drives because of either transient overvoltages or multiple zero-crossings of the voltage waveform. Overvoltage tripping can occur in adjustable-speed drives when capacitor-switching transients result in a surge in internal voltages. Drives of the voltage source type with an uncontrolled source converter (using rectifier diode elements without source line reactors) can allow network transient voltage swings to result in a higher than normal voltage on the dc link capacitor. Figure 16 shows the power circuit schematic for such an adjustable-speed drive. The drive trips because an overvoltage is detected on the dc bus. Typically for the protection of the dc capacitor and inverter components, the dc bus voltage is monitored and the drive tripped when this voltage exceeds a preset level. This level may be as low as 760 V pk (for a 480 V rms application), which is only 117% of the nominal dc voltage. dc Link ac Choke AC Motor Diode Bridge Converter PWM Inverter Figure 16 — Adjustable speed motor drive—voltage source inverter type with uncontrolled source converter Figure 17 shows an energizing event where the drive overvoltage protection initiates a trip signal shutting down the drive. Although the overvoltage protection correctly initiated a trip signal, it is generally preferable that the drive and motor remain in service. The simplest method for avoiding the tripping event 34 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors is the addition of a reactor in series with the individual drive. Typically, a value of 3%–5% (on the drive kVA base) is sufficient to reduce the dc voltage below the trip level. Although this solution is simple, it may require many reactors in plants with a large number of drives to protect. An alternative solution is to apply a transient reducing technique to the capacitor-switching device (6.2.1.6) (Bellei, O’Leary, and Camm [B13] and Hensley et al. [B15] [B16]). Utility Distribution Bus Voltage 2.5 2.0 1.5 V o lt a g e ( p u ) 1.0 0.5 0.0 -0.5 -1.0 -1.5 -2.0 -2.5 60 80 100 120 Time (ms) Customer Low Voltage Bus Voltage (phase-to-phase) 2.5 2.0 1.5 V o lta g e ( p u ) 1.0 0.5 0.0 -0.5 -1.0 -1.5 -2.0 -2.5 60 80 100 120 Time (ms) Customer Adjustable-Speed Drive dc Bus Voltage 1100 V o lta g e ( V ) 1000 900 800 700 600 500 60 70 80 90 Time (ms) 100 110 120 Figure 17 — Transient voltage during capacitor switching 35 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Any electronic device using the power system voltage waveform for timing purposes may be confused by multiple zero-crossings of the ac source waveform. Some adjustable-speed drives use this voltage waveform as a reference to initiate firing pulses for the power electronics. One technique commonly used to avoid this problem is to develop a synthetic voltage reference that is tied to the actual waveform by a phase-locked loop. 6.2.1.7.3 Temporary overvoltages Energizing a lightly loaded transformer and a capacitor bank together (Figure 18a and Figure 18b) can cause excessive dynamic overvoltages that affect the transformer, the capacitors, the fuses, and the arresters. These overvoltages may be evidenced by capacitor failures and/or spurious fuse operations. Even when a capacitor bank is not switched with the transformer, energizing a lightly loaded transformer with nearby capacitor banks in service may also excite a harmonic resonance (Figure 18c). a. b. c. Figure 18 — System diagrams for dynamic overvoltage conditions The nature of the problem involves generation of high voltages due to the transformer inrush currents that are rich in harmonics by a system whose natural frequency is near one of these harmonics. Transformer inrush current includes significant magnitudes of harmonics of the fundamental frequency, i.e., second, third, fourth, fifth, etc. The highest magnitudes tend to occur for the lowest order harmonics. If the system equivalent impedance at one or more of those frequencies is high, then the voltage at the point will also be high (V = IZ). This tends to happen when a shunt power capacitor bank is applied, causing a parallel resonance with the system. The problem exhibits itself in the form of a long-term overvoltage, which has a high harmonic content, lasting for many cycles—even seconds (see Figure 19). 36 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Phase A 2 V o lta g e ( p u ) 1 0 -1 -2 0 50 100 Time (ms) 150 200 250 150 200 250 150 200 250 Phase B 2 V o lta g e (p u ) 1 0 -1 -2 0 50 100 Time (ms) Phase C 2 V o lta g e (p u ) 1 0 -1 -2 0 50 100 Time (ms) Figure 19 — Dynamic overvoltage on capacitors Because arresters cannot effectively protect against steady-state or dynamic overvoltages, switching transformers and capacitor banks together is not recommended unless detailed studies show that the resulting overvoltages will not be excessive. This type of switching usually does not cause dynamic overvoltages on distribution circuits because the resistive component of the connected load effectively dampens this type of transient. 6.2.1.7.4 Ferroresonance Grounded-wye, ungrounded-wye, and delta-connected capacitors may be subject to ferroresonant overvoltages if they are switched together with transformer banks of certain winding connections with single-pole switching devices or if a stuck pole should occur on a three-phase device. For the ungrounded 37 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors capacitor, if the transformer has a grounded neutral or even if it consists of many single-phase transformers applied about equally along the feeder, a potentially ferroresonant circuit exists if single-phase switching devices are operated upstream. Both transformers and surge arresters have failed under these conditions. If the transformer is three-phase ungrounded, then the grounded capacitor bank should be avoided for the same reason. Although ferroresonance can and does occur on these circuits, it occurs only rarely because resistive load on the transformers can prevent its occurrence. 6.2.2 De-energization 6.2.2.1 Interruption One-half cycle after current interruption, the voltage across the switch contacts is twice the crest value of the fundamental (for a grounded-wye capacitor bank) since the capacitor has retained its charge and the supply voltage has reached its crest of the opposite value, as shown in Figure 20a. The switch recovery voltage (instantaneous voltage across the open switch) expressed in per unit of the crest phase-to-ground voltage, 2 3 × V LL , is a) 2.0 per unit for a grounded wye bank and system For an ungrounded wye or delta connected bank, the switch recovery voltage is normally 2.5 per unit but can be higher as explained in items c) and d). b) 2.5 per unit on the first phase to clear when the other two phases clear at the next current zero c) 3.0 per unit on the first phase to clear when the other two phases delay clearing d) 4.1 per unit on the first phase to clear when one of the other two phases delays clearing NOTE—Even higher recovery voltages occur in some cases with capacitor bank insulator leakage. -0.6 -0.7 1 System voltage Capacitor Current Voltage (per unit) Voltage, Current (per unit) 2 0 Voltage between switch contacts (2 per unit) -0.8 -0.9 -1 -1 Capacitor voltage -2 -180 -90 0 90 System voltage without capacitors System voltage with capacitors -1.1 -180 180 Voltage angle (degrees) Fast transient following interruption -90 Capacitor voltage 0 Voltage angle (degrees) a) System frequency component of voltage b) System frequency and high-frequency component of voltage Figure 20 — Capacitor and bus voltage during deenergizing 38 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors The initial fast transient portion of the recovery voltage is less than twice the crest value of the regulation voltage ΔV (Figure 20b). Since ΔV is usually less than 3%, the fast portion of the switch recovery voltage is less than 0.1 per unit and places little stress on the switch interrupting capability. The low initial recovery voltage and the relatively low current being interrupted allows for capacitor current interruption to occur much earlier than interruption of system load and fault current. Initial interruption with very small, almost zero contact separation. Successful interruption is dependent on developing sufficient dielectric strength across the opening switch contacts to withstand the increasing recovery voltage. If a breakdown occurs across the contacts before 90 electrical degrees following the interruption, this attempt is called a reignition and another attempt will occur at the next current zero. This process may repeat several times until a successful interruption is complete. 6.2.2.2 Restrike A dielectric breakdown in the gap between the switch contacts, 90 or more electrical degrees after current interruption, results in a restrike. A breakdown that occurs at the peak of the recovery voltage usually results in a worst-case restrike. Figure 21 illustrates this phenomenon for one phase of a grounded-wye capacitor bank. 3 Voltage (per unit) 2 1 System voltage 0 Voltage between switch contacts -1 Capacitor voltage -2 -180 -90 0 90 180 Voltage angle (degrees) Figure 21 — De-energizing capacitor bank with restriking switching device One-half cycle after interruption on a grounded-wye capacitor bank, two times peak system line to ground voltage (2 per unit) appears across the contacts. If a restrike occurs at this point, the capacitor attempts to recover to crest voltage of the opposite polarity and, in doing so, over-shoots by the amount of the attempted correction. The current waveform has the same frequency but will be twice the magnitude of the normal oscillatory inrush current when closing at voltage peak. If this inrush is interrupted at a highfrequency current zero, as much as 3 per unit voltage may be trapped on the capacitor, and the restriking process may continue with the subsequent buildup of even higher voltages. 39 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Even without a restrike, ungrounded-wye capacitor banks subject the capacitor switching device to higher recovery voltages than the 2.0 per unit observed for grounded-wye capacitor banks: a) b) c) 2.5 per unit on the first phase to open when the other two phases open on the next current zero 3.0 per unit on the first phase to open when the other two phases delay opening 4.1 per unit on the first phase to open when one of the other two phases delays opening NOTE—Even higher recovery voltages will occur in some cases with capacitor bank insulator leakage. If the interrupter is not able to withstand these recovery voltages, a restrike will occur. Restriking capacitor bank switching devices can result in high system voltage surges that may result in severe arrester energy duty or equipment damage if not protected adequately. Therefore, it is desirable to choose a switching device that will minimize the possibility of restrike. A class “A” (IEEE Std 1247-2005) or Class “C2” (IEEE Std C37.04-1999, IEEE Std C36.016, and IEC 62271-100) switching device will have a reasonably low probability of restrike. Since all switching devices have some probability of restrike, the effects of restrikes should be considered. It may be desirable to protect the equipment with the appropriately sized arresters (McGranaghan, et al. [B7]). The arrester may be analyzed based upon the energy associated with a restrike. If the standard arrester energy capability could be exceeded, a highenergy-capability arrester with a lower overvoltage protective level may be applied at the capacitor bank. (See Clause 8 for additional surge arrester application information.) 6.2.2.3 Fault clearing Faults within a capacitor bank may be cleared either by the dedicated switch for the capacitor bank or by another switching device in the substation. In either case, the switch must be able to handle the recovery voltage and the capacitive switching current that will occur on the unfaulted phases during a fault clearing event. This is of special concern for circuit breakers that may be used to clear fault currents, but that may not be rated for capacitance switching duty. (See IEEE Std C37.012-2005, ANSI C37.66-2005, and IEEE Std 1247-2005 for additional details.) 6.3 Outrush current The outrush current from large capacitor banks is a concern for any switching device that may close into a nearby fault (McCauley, et al. [B6]). The result is that a high-frequency, high-magnitude current may flow in a circuit breaker that is not rated for that duty. In ANSI C37.06-2009, circuit breaker inrush current limitations are defined. These inrush limitations are also applied to the outrush considerations. The circuit of concern for the outrush calculations is illustrated in Figure 22. The limiting criterion may be as follows: ⎯ The circuit breakers or switches in the discharge path (ANSI C2, IEEE Std C37.012-2005, ANSI C37.66-2005, IEEE Std 1247-2005, McCauley , et al. [B6]) ⎯ Current transformers and/or relays ⎯ Induced voltages into control or secondary wiring ⎯ Sparking across fence gates, loose connections, etc. 40 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors C1 SYSTEM FAULT Figure 22 — System diagram for outrush current condition The limiting criterion from ANSI C37.06-2009 is sometimes the Ipk × f product. (See notes for Tables 1A, 2A, and 3A in ANSI C37.06-2009.) In many cases the Ipk × f product criterion is unnecessarily restrictive, particularly with non-oil circuit breakers and small capacitor banks. Many installations have been made with smaller reactors than required to meet the Ipk × f limitation of ANSI C37.06-2009, simply limiting the outrush current into a fault to something less that the peak current capability of the switching devices or 12 kA (where oil circuit breakers or older substations may be involved) or 20 kA (where there are no oil circuit breakers involved and the substation grounding can withstand the higher transient currents), whichever is smaller (Harder [B12]). It is interesting to note that this Ipk × f product is independent of capacitor size. In other words, the required series inductance is dependent only on the peak voltage when the circuit breaker closes into the fault (see the equations following Figure 23). Outrush is currently under study since the above treatment is likely to cause problems with oil breaker ratings. Refer to ANSI C37.06-2009 for guidance. 41 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors L2 L1 C1 I V0 f = 1 2π Leq C1 i pk = V0 C1 Leq i pk × f = V0 2πLeq where f C1 V0 L1 L2 Leq = frequency of outrush transient current = total capacitance of the discharging capacitor banks = initial voltage on C1 = self-inductance of C1 = inductance between capacitor and fault = L1 + L2 Figure 23 — Equivalent circuit for outrush current calculation For three-phase capacitor banks, a reasonably conservative estimate of the peak outrush current is i pk = QC kvar 1000 × 3πf L where ipk f QC L = peak current, kiloamperes = power system frequency, Hertz = Capacitor bank rating, three phase kvar = Inductance per phase between capacitor bank and fault (microhenries) For 60 Hertz systems this is approximately: i pk ≈ For 50 Hertz systems this is approximately: 4 QC kvar 3 L i pk ≈ 3 QC kvar 2 L 42 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors These formulas give a reasonable estimate of the transient peak current for phase-to-ground faults for grounded wye capacitor banks and for phase-to-phase faults for all capacitor banks. Transient reduction techniques discussed previously (closing resistors, synchronous closing, etc.) do not affect the outrush current magnitude or frequency. The full outrush current occurs when the resistors are bypassed. With a parallel capacitor bank, there are a number of different ways to configure the capacitors and required series reactors. A few of the options are indicated in Figure 24. Each option has advantages and disadvantages. Reactor to limit outrush Reactor to limit outrush Smaller reactor to limit inrush Single reactor to limit inrush Option 1(a) Option 1(b) Reactor to limit outrush Closing resistors, reactors, and/or closing control to limit inrush (does not work in case of restrike) Series reactor sized for inrush and outrush requirements Option 2 Option 3 Figure 24 — Current limiting reactor options with parallel capacitor banks Option 1: Separate reactors for inrush and outrush requirements. When a larger reactor is needed for outrush, a common reactor for limiting outrush current, in addition to smaller reactors for inrush current limiting, may be the optimum configuration. An alternate configuration for this scheme is shown in Option 1(b) of Figure 24. This alternate configuration has the advantage of only requiring two reactors while still accomplishing the objectives of controlling both inrush and outrush currents. Option 2: Reactor for outrush only, switching device limit inrush. If inrush current for back-to-back switching can be limited to acceptable levels without current-limiting reactors, this is probably the most economical configuration. Closing resistors, pre-insertion inductors or a closing control to close the contacts near voltage zeros are common alternate methods to limit the inrush current. The single reactor is used to limit outrush currents to acceptable levels. A disadvantage of this option is the high-current magnitude and frequency that can occur in the event of a restrike on opening. 43 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Option 3: Series reactors sized for inrush and outrush in series with each capacitor bank. If the reactor cost is not significantly dependent on its millihenry size, then this option may be more economical than Option 1. However, with two equal capacitor banks in parallel, the reactor millihenry value required to control outrush may be more than double the single capacitor bank size. 6.4 Switchgear 6.4.1 Switchgear ratings Switchgear applied to a capacitor bank should be rated for that specific duty. The key considerations include the following: ⎯ Maximum service voltage ⎯ Available short-circuit current ⎯ Maximum continuous capacitive current ⎯ Transient inrush current during energization ⎯ Nominal system voltage ⎯ Transient recovery voltage during de-energization ⎯ Differential capacitance voltage (IEEE Std 1247-2005 and ANSI C37.66-2005) ⎯ Switching endurance (IEEE Std 1247-2005 and ANSI C37.66-2005) ⎯ Restrike performance classification Table 5—Restrike performance classifications Expected maximum probability of restrike per three-phase operation IEEE 1247 classification IEC 62271-100 and IEEE C37.04 classification A C2 .002 B C1 .02 (Roughly equivalent to the old “Definite Purpose” circuit breaker as defined in IEEE Std C37.04-1999) C — Unspecified These parameters are defined in more detail for circuit breakers in ANSI C37.06-2009, IEEE Std C37.09, and IEEE Std C37.012-2005. These parameters are defined for Circuit Switchers in IEEE Std C37.016. IEEE Std 1247-2005 covers capacitor switching requirements for interrupter switches and circuit switchers. ANSI C37.66-2005 covers capacitor switches. IEC 62271-100 addresses capacitance current switching for circuit breakers. These standards suggest using a continuous current rating for the circuit breaker that is 1.25 times the nominal capacitor current at rated capacitor voltage for ungrounded neutral operation and 1.35 times the nominal current for grounded neutral operation. Inrush current duties are defined in terms of peak magnitude and frequency. 44 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 6.4.2 Switchgear types Shunt capacitor banks are typically switched by one of the following three types of switchgear: a) Circuit breakers: Circuit breakers have high fault interrupting capabilities. The interrupting media most commonly used are vacuum and SF6. Other media used, especially in older installations, are oil and air. In addition to switching the relatively low magnitude capacitor bank current on a frequent basis, circuit breakers also provide short-circuit interruption for major faults within the capacitor bank. Some circuit breakers may also be equipped with preinsertion resistors or synchronous closing control for reduction of closing transients (refer to 6.2.1.6). Circuit breakers for switching capacitors must be rated for capacitor switching (IEEE Std C37.012-2005). b) Circuit switchers: Circuit switchers have lower fault interrupting capabilities than circuit breakers. The interrupting media is typically SF6 although the circuit may be energized via contacts in SF6 or in air. The close-in-air style of circuit switcher can also be equipped with pre-insertion impedance (inductor or resistor) for reduction of switching transients (refer to 6.2.1.6). Synchronous closing may also be available on some circuit switchers. c) Vacuum and oil switches and vacuum fault interrupters: Capacitor switches are not required to have fault interrupting capability although they must be able to close in to a fault and latch closed. Fault interrupters have limited interrupting fault capability. Vacuum switches are used for switching medium voltage and high voltage capacitor banks. Oil switches are generally limited to distribution banks. Synchronous closing control is sometimes used with vacuum switches for transient reduction (refer to 6.2.1.6). For circuit switchers, interrupter switches, and capacitor switches, IEEE Std 1247-2005 provides for three classes of capacitive current switching: classes A, B, and C. Class C does not require any additional testing to prove the restrike performance of the switching device. Class B requires moderate testing to prove the restrike performance. Class A requires extensive testing of restrike performance. In general, class A devices have a very low probability of restriking; class B devices have a low probability of restriking; and class C devices have an unknown probability of restriking. For circuit breakers, IEEE Std C37.04-1999 and IEC 62271-100 provide for two classes of capacitive current switching: class C1 and class C2. Class C1 requires moderate testing to prove the restrike performance, which is roughly equivalent to the old “definite purpose” circuit breakers as defined in IEEE Std C37.04-1999. Class C2 requires extensive testing of restrike performance. In general, class C2 circuit breakers have a very low probability of restriking; and class C1 circuit breakers have a low probability of restriking. The selection of a particular type of switchgear will be influenced by protection philosophy, short-circuit and transient current capability of the available devices, frequency of operation, effectiveness of transient reduction technique, reliability, and cost. 45 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 7. Harmonics The levels of harmonic voltage and current on power systems are increasing. One important reason is the proliferation of devices that produce harmonics; solid-state power conversion devices are prime examples. These devices find uses at wide ranges of power levels industrially, commercially, and in the home for voltage control, speed control, frequency changing, and power conversion, generally at a lower cost, with increased efficiency and reduced maintenance as compared to the devices they replace. The use of shunt power capacitors to improve system operating efficiencies also has a significant influence on harmonic levels. Capacitors do not generate harmonics, but provide network loops for possible local or general resonance conditions. Even though capacitors do not generate harmonics, they can influence the magnitudes of harmonic voltages and currents that occur on the utility system as well as the customer loads (Arrillaga, et al. [B1]). The proper application of capacitors in a harmonic environment is determined by the following factors: a) b) c) Capacitor unit limitations as defined in IEEE Std 18-2002. System distortion limits as recommended in IEEE Std 519-2004. Other operating and application considerations of the shunt power capacitor bank. Harmonic conditions may require the capacitor to be designed as a harmonic filter. IEEE Std 1531-2003 provides guidance on the proper application and specification of harmonic filter components. 7.1 Capacitor limitations The effect of the harmonic components on the capacitor bank is to cause additional heating and higher dielectric stress. IEEE Std 18-2002 gives limitations on voltage, current, and reactive power for capacitor banks, which can be used to determine the maximum allowable harmonic levels. Capacitors are intended to be operated at or below their rated voltage and frequency. IEEE Std 18-2002 indicates that capacitors are capable of continuous operation under contingency system and capacitor bank conditions provided that none of the limitations given in 5.2.2.1 are exceeded Despite this attempt to overrate the capacitors for unusual conditions, such as harmonics, many harmonic problems show up first at shunt power capacitor banks, either in the form of blown fuses or capacitor unit failures. The reason for this is that capacitor banks are in many cases part of a resonant loop, resulting in magnification of specific harmonic components. The resulting harmonic voltages and currents are highest at the capacitor bank. If harmonic currents are above the allowable limits, one or more of the following remedies should be undertaken: a) Relocation of the capacitors to other parts of the circuit may reduce overcurrent due to partial resonance. b) Capacitors may be switched off the circuit during periods in which overcurrents are likely to occur. Automatic control actuated by change in current, change in voltages, change in reactive power, or by time switch may be used. c) Removal of capacitor bank neutral ground, if present. 46 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors CAUTION Capacitor bank insulation and switch load interrupting rating may be inadequate if the neutral is disconnected. Make sure the switch is rated for the increased transient over voltage d) If these remedies fail, it may be necessary to resort to the use of a harmonic filter. This guide does not cover harmonic filters, which may have significant harmonic current and/or harmonic overloads. Higher frequency harmonic currents will generate significantly more heating than power frequency currents of the same rms magnitude and may cause fuse operations and connection overheating and failure. Applications with significant harmonic loading represent unusual service conditions not covered by this guide and should be referred to the manufacturer. 7.2 Distortion limits The recommended voltage distortion limits from IEEE Std 519-2004 are summarized in Table 6. In general, waveform distortion is usually described by its total harmonic distortion (THD). Voltage THD is defined as follows: ∞ ∑VH2 THD = n=2 V1 × 100% where THD is the total harmonic distortion VH is the magnitude of the voltage at harmonic H V1 is the magnitude of the voltage at the fundamental frequency Table 6—Voltage distortion limits for medium- and high-voltage power systems Power system voltage level (kV) Total voltage THD (%) 69 and below 5.0 Greater than 69 through 161 2.5 Greater than 161 1.5 7.3 Operating and application considerations Other operating and application conditions that should be included in evaluating the harmonic condition are given as follows: a) The system operating voltage at a capacitor location may exceed the nominal rating, often approaching 105%. b) Unbalances within a capacitor bank, due to capacitor element failures and/or individual fuse operations result in overvoltages on some capacitor units. Typically individual capacitor unit 47 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors voltages are allowed to increase by 10% before unbalance protection removes the capacitor bank from service. c) If a system has been analyzed to ensure that the THD is less than the levels defined by IEEE Std 519-2004 under normal conditions, it is possible that the distortion will increase significantly during capacitor bank unbalance conditions, since the change of capacitance will change the system tuning. d) Fuse ratings, on externally fused banks, are typically chosen based on currents anywhere in the range of 125% to 165% of capacitor nominal current. (Note that some fuses and fuse links may have continuous current capability substantially higher than their current rating, in which case the fuse rated current may actually be less than the nominal capacitor current.) e) Capacitors are allowed a capacitance tolerance of –0 to +10% by IEEE Std 18-2002. Older capacitors may have a tolerance as high as –0 to +15%. 7.4 Harmonic “problems” Harmonic problems may result in blown fuses, failed capacitor units, damaged control transformers, and misoperating relays. Although transformers can be a major harmonic producer on distribution systems, devices that utilize arcs (arc furnaces, arc welders) or electronic power converters (e.g., computers, variable speed motors, dc motors, chemical processes, uninterruptible power supplies) have become significant harmonic sources on some feeders. With the rise of distributed resources (generation and storage) on distribution systems, as well as the widespread use of electronic power converters for other uses, a harmonic problem should be considered—and investigated—in the event of unexplained capacitor bank equipment failure or malfunction. IEEE Std 519-2004 recommends voltage THD limits as stated in Table 6. The usage of shunt power capacitors to improve system operating efficiencies also has a significant influence on harmonic levels. Capacitors do not generate harmonics, but provide a network path for possible local or general resonance conditions. Even though capacitors do not generate harmonics, they can influence the magnitudes of harmonic voltages and currents that occur on the utility system as well as the customer loads. If harmonic problems are discovered through measurement, analysis, or experience, possible solutions include the following: a) b) c) d) e) Ungrounding grounded-wye capacitors. Changing capacitor bank sizes and/or locations. Adding a reactor to an existing capacitor bank. Adding a filter capacitor. Controlling the capacitor switching scheme to avoid resonance. 8. Surge arresters 8.1 Substation applications Surge arresters may be applied at the capacitor bank to limit transient overvoltages on the capacitor as well as on other system equipment (see also 6.2.1.6). Due to the low surge impedance of large high-voltage shunt capacitor banks, it may not be necessary to add arrester protection against lightning beyond that which already exists in the substation. However, additional protection may be needed at the station and in 48 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors the vicinity to protect equipment from overvoltages caused by capacitor switching. Severe duty can be imposed on arresters adjacent to shunt capacitor banks during switching, particularly due to restriking in the capacitor-switching device, as noted in 6.2.2.2. This may require arresters with higher than normal energy dissipation capability. Some existing surge arresters, in particular gapped silicon-carbide, may have to be replaced with surge arresters of higher energy capability because of the higher duty imposed by the addition of shunt capacitors. Applying surge arresters on the capacitor side of the switch can help to reduce switch recovery voltages for an ungrounded-wye capacitor bank. Surge arresters on the neutrals of ungrounded shunt capacitor banks can reduce switch recovery voltages and neutral overvoltages. See McGranaghan, et al. [B7] for a detailed discussion. Capacitors connected to exposed bus may require surge protection by surge arresters located close to the capacitor bank. If capacitors are located indoors, the arresters may be located at the line entrance to the building. Installation should be made in accordance with the latest industry standards for surge arresters. Capacitors connected between the line and grounded neutral are effective in reducing the slope of a traveling wave front. However, the available energy will sometimes be sufficient to damage unprotected capacitors. When determining the protective margin for capacitor units, there are two considerations. (1) The protective level of the surge arrester is compared with the BIL of the capacitor unit or bank, applying the usual margins found in IEEE Std C62.2-1987 and IEEE Std C62.22-2009. This determines the protection of the capacitor bushings and major insulation (case wrapper). (2) When considering the voltage between the capacitor unit terminals, the maximum allowable voltage is given in 5.2.3.3. (Capacitor units are not capable of withstanding BIL between the terminals.) The capacitance of the capacitor unit slows the rate of rise of high-frequency transient voltage across its terminals to much slower rates than a BIL wave, more comparable with a switching surge. Thus the transient overvoltage capability of the capacitor unit, as given in 5.2.3.3, is compared with the arrester’s switching surge protective level (rather than 8/20 μs discharge voltage) at the maximum expected discharge current. If the switching surge protective level at maximum discharge current is not available, an approximation may be made by using 95% to 97% of the manufacturer’s published protective levels for 8/20 μs discharge current waves. Published values usually range from 1.5 kA to 40 kA. The 8/20 μs protective levels tend to be 3% to 5% higher than the voltages produced by switching surges (45 μs to 60 μs rise time) at the same current magnitudes. Since the overvoltage capability of 5.2.3.3 already includes a margin, no additional margin is normally applied for surge arrester application. This method applies to metal oxide arresters without series gaps. For arresters with series gaps, consult the manufacturer for switching surge protective levels. 8.2 Distribution applications Lightning surges and the switching of capacitors can result in significant system overvoltages. Surge arresters may be applied at the capacitor bank to limit these transient overvoltages (see IEEE Std C62.222009 and IEEE Std C62.2-1987). Restrikes in the switching device can cause the highest transients. Significant transient overvoltages can also occur at the capacitor bank due to surge magnification of resonant circuits on the power system associated with switching of a remote capacitor bank, cable, or transmission line (Shultz, Johnson, and Shultz [B9]) (see 6.2.1.7.1 for more detailed information). Generally, arresters are installed on the system side of the capacitor fuse, and as close as possible to the capacitor bank. The connections should be kept as short as possible, in order that the voltage stress upon capacitor unit insulation is minimized. Placing the arrester on the source side of the fuse protects the fuse support and reduces the surge current through the fuse. This is most important for small capacitor banks on high-voltage systems where fuse sizes of less than 15 amperes are common. 49 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors When determining the protective margin for capacitor units, there are two considerations. (1) The protective level of the surge arrester is compared with the BIL of the capacitor unit, applying the usual margins found in IEEE Std C62.2-1987 and IEEE Std C62.22-2009. This determines the protection of the capacitor bushings and major insulation (case wrapper). (2) When considering the voltage between the capacitor unit terminals, the maximum allowable voltage is given in 5.2.3.3. (Capacitor units are not capable of withstanding BIL between the terminals.) The capacitance of the capacitor unit slows the rate of rise of high-frequency transient voltage across its terminals to much slower rates than a BIL wave, more comparable with a switching surge. Thus the transient overvoltage capability of the capacitor unit, as given in 5.2.3.3, is compared with the arrester’s switching surge protective level (rather than 8/20 μs discharge voltage) at the maximum expected discharge current. If the switching surge protective level at maximum discharge current is not available, an approximation may be made by using 95% to 97% of the manufacturer’s published protective levels for 8/20 μs discharge current waves. Published values usually range from 1.5 kA to 40 kA. The 8/20 μs protective levels tend to be 3% to 5% higher than the voltages produced by switching surges (45 to 60 μs rise time) at the same current magnitudes. Since the overvoltage capability of 5.2.3.3 already includes a margin, no additional margin is normally applied for surge arrester application. This method applies to metal oxide arresters without series gaps. For arresters with series gaps, consult the manufacturer for switching surge protective levels. 9. Substation shunt power capacitor bank applications This clause describes the considerations for applying shunt power capacitor banks in a substation environment. It includes both distribution and transmission system applications. It does not include distribution line applications, which are discussed in Clause 10. 9.1 Capacitor bank connections and grounding 9.1.1 Connection and grounding considerations There are three basic capacitor bank configurations: grounded wye, ungrounded wye, and delta. Deltaconnected capacitors are generally only used at low voltages, e.g., 2400 V, where a standard capacitor rating is not available for a wye connection. Usually, wye-connected capacitor installations are less complicated to construct and more economical. On ungrounded, impedance grounded, or uni-grounded (grounded only at the source transformer, which is not at the capacitor location) systems, only ungrounded-wye and delta capacitor bank configurations should be used. On effectively grounded systems, grounded-wye, ungrounded-wye, and delta configurations may be used. There are certain advantages and disadvantages associated with grounded-versus-ungrounded-wye capacitor banks. The advantages of the grounded-wye arrangement compared to the ungrounded wye are as follows: ⎯ Initial cost of the capacitor bank may be lower since the neutral does not have to be insulated from ground at full system BIL, as in the case with floating neutral arrangements. ⎯ Capacitor switch recovery voltages are reduced. ⎯ Mechanical duties (e.g., seismic) may be less severe for the structure. 50 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors The disadvantages of the grounded-wye arrangement compared to the ungrounded wye are as follows: ⎯ High inrush currents may occur in station grounds and structures, which may cause instrumentation problems. ⎯ Grounded neutral may draw zero-sequence harmonic currents and cause telephone interference. ⎯ A fault short circuiting one phase of the capacitor bank results in a system line to ground fault. ⎯ Limiting fuses necessary because of the line-to-ground fault magnitudes. Ungrounded wye banks do not permit zero sequence currents, third harmonic currents, or large capacitor discharge currents during system ground faults. (Phase-to-phase faults may still occur resulting in large discharge currents.) The neutral, however, should be insulated for full-line voltage, since it is momentarily at phase potential when the bank is switched or when one capacitor unit fails in a bank configured with a single group of capacitor units. Delta-connected banks are generally used only at distribution voltages and are configured with a single series group of capacitor units rated at line-to-line voltage. Delta-connected banks require two-bushing capacitor units or single-bushing capacitor units with insulated racks. Delta-connected banks are frequently used at 2400 V, since capacitor units for wye connection at 2400 V are not readily available. 9.1.2 Substation ground grids The design of the substation ground grid and the connections of the respective bank neutrals to the substation grid are of prime importance. Improper grounding can result in neutral current transformer, voltage transformer, or control cable failures. Two methods of neutral grounding have been successfully used: single point grounding and peninsula type grounding. See Figure 25 and Figure 26. 51 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Substation bus Switch Switch Switch Schematic Substation ground mat Substation view Figure 25 — Single point grounding With single point grounding, the neutrals of all capacitor banks of a given voltage are connected together with insulated cable, or an isolated bus, and tied to the substation ground grid at only one point. This arrangement prevents high-frequency currents that flow between banks during back-to-back switching from flowing in the ground grid. In the event of a nearby ground fault, however, this arrangement does not eliminate those high frequency currents that flow back into the power system via the substation ground grid. 52 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors The peninsula ground grid connects to main station ground grid under buswork at the edge of the capacitor area Switch Switch Switch The shaded area shows the location of the peninsula ground grid Capacitor bank grounds (for grounded capacitor banks) Substation view Figure 26 — Peninsula grounding With peninsula grounding, the ground grid in the capacitor area is built under the capacitor banks and buswork, in a form resembling a series of peninsulas. One or more ground grid conductor(s) is carried underneath the capacitor rack of each phase of each group and tied to the main station ground grid at one point at the edge of the capacitor area. All capacitor bank neutral connections are made to this isolated peninsula ground grid conductor(s) only (Arrillaga, et al. [B1]). Although this arrangement allows the capacitor bank neutral potential (and associated current transformers and voltage transformers) to rise during capacitor bank switching, it does help reduce these transients in the rest of the substation. See Figure 25 and Figure 26. 53 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors If single point grounding is used, there will be substantial voltage (tens of kV) between the ends of the neutral bus and the single point ground during switching. (The use of shielded cable between the capacitor bank neutral and the single point ground, with the shield grounded to the local ground at both ends, will help reduce the voltage stress on measuring equipment at the neutral end of the capacitor bank.) As a result, the primary to secondary insulation of neutral current transformers, or voltage transformers, will be subjected to a high voltage, increasing the possibility of failure. A voltage transformer with two bushings should be used with the primary connected to the capacitor bank neutral and to the station ground grid. This does not occur with peninsula grounding, since all equipment at the neutral tends to rise to the same potential. Therefore, peninsula grounding coordinated with control cable shielding and grounding produces safer levels of common-mode voltages appearing on control cables in the control house. Single point grounding and peninsula grounding may be used together. It is desirable for all capacitor banks of the same system voltage to use the same grounding scheme in the same substation. 9.2 Capacitor bank types This guide covers the following three types of capacitor bank designs: ⎯ Externally fused ⎯ Internally fused ⎯ Fuseless 9.2.1 Externally fused An externally fused capacitor bank uses capacitor units that are individually fused by expulsion and or current limiting type fuses mounted external to the capacitor unit. The capacitor unit is made of groups of parallel elements connected in series. The current through a failed capacitor increases with subsequent element failures until the Time Current Curve of the applied fuse is exceeded and the fuse operates to isolate the failed capacitor. The BIL of the capacitor bushing and the internal insulation of the capacitor unit are typically determined by the rated voltage of the capacitor units. This is the case in most externally fused capacitor banks where the voltage between the fuse bus and the rack is equal to the voltage across one capacitor unit. An externally fused capacitor bank of a given size and voltage rating may be made up of a number of series and parallel groups. Use of capacitor units with the highest possible voltage rating will result in a capacitor bank with the fewest number of series groups. This generally provides the simplest rack structure and the greatest sensitivity for unbalance detection schemes. The number of capacitor units in parallel per series group is governed by both a minimum and maximum limitation. The minimum number of capacitor units per group is determined by the overvoltage considerations upon isolation of one capacitor unit in the group and also having sufficient overcurrent through a fuse on a faulted capacitor unit to blow the fuse in a reasonably short time (so that the unbalance protection does not require a long time delay). SeeFigure 27. 54 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Capacitor racks A B C Figure 27 — Schematic of an externally fused capacitor bank, single wye, 11 capacitors per series group, 4 series groups per phase The maximum number of capacitor units that may be placed in parallel per series group of an expulsion fused bank is governed by a different consideration. When a capacitor unit fails, other capacitors in the same parallel group will contain some amount of charge. This charge will drain off as a high-frequency transient current that flows through the failed capacitor unit and its expulsion fuse. The fuse holder and the failed capacitor unit should withstand this discharge transient without rupturing the failed capacitor or its fuse. To minimize the probability of failure of the expulsion fuse holder or rupture of the capacitor unit case, the total energy stored in a parallel connected group of capacitor units at maximum peak voltage should not exceed the discharge energy capability of the fuse or the faulted capacitor unit. If a capacitor bank having the minimum number of series groups exceeds the discharge energy limitt per series group, capacitors units of a lower voltage rating requiring more series groups and fewer capacitor units in parallel per group may be a suitable solution. Another possible solution is to split the bank into two sections (as a double wye). Current limiting fuses may be used in place of expulsion fuses to allow higher levels of parallel stored energy with less risk of capacitor unit or fuse rupture. 55 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 9.2.2 Internally fused capacitor banks An internally fused capacitor bank may be built up from a number of series and/or parallel connected capacitor units. The interior of a capacitor unit consists of a number of parallel and series connected groups of elements to meet the electrical requirements (voltage and capacitance). One fuse is connected in series with each capacitor element. When a puncture or a short-circuit occurs in a capacitor element, the current through the fuse increases in proportion to the number of elements connected in parallel. This increase is sufficient to melt the fuse within a very short time. If the puncture occurs at an instant when the voltage lies close to its peak value, which is the most likely event, the energy in the charged parallel elements will make an extra contribution to the melting. This interruption takes place extremely rapidly in a correctly applied fuse, generally within a few milliseconds. The capacitor units are designed with a large enough number of elements in parallel so that the operation of one fuse does not result in too much increase in voltage on the remaining parallel elements. Note that the operation of a fuse on an element results in a decrease in the capacitance of the capacitor unit. Figure 28 illustrates a typical capacitor bank utilizing internally fused capacitor units. In general, banks employing internally fused capacitor units are configured with fewer capacitor units in parallel and more series groups of capacitor units than are used in banks with externally fused capacitor units. Capacitor racks A B C Figure 28 — Schematic of an internally fused capacitor bank, wye-wye configuration with 24 capacitor units per phase It is usually desirable to have at least two capacitor units in parallel in each series group. In the event of a large number of internal fuse operations in one capacitor unit, the other capacitor helps keep the terminal voltage of the affected capacitor down. The maximum number of capacitor units that may be placed in parallel per series group is governed by the parallel energy capability of the capacitor unit. The manufacturer of the capacitor units should recommend the maximum number of capacitor units to be connected directly in parallel. 56 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Internally fused capacitors usually have two bushings in order to keep the parallel groups of capacitor units in one string isolated from the parallel groups of capacitor units in the adjacent string. The BIL of the bushings and the internal insulation of the capacitor unit are determined by the maximum voltage to the rack. The rack potential is established by connecting the racks to one series string of capacitor units. 9.2.3 Fuseless capacitor banks A fuseless capacitor bank is not created by simply removing the fuses from a conventional fused capacitor bank, but is a completely different capacitor bank arrangement that does not use fuses. When an all film capacitor has a dielectric short, the film burns away, resulting in a weld between the foils. This type of short creates a low resistance short, which should not generate large amounts of heat or gas, as long as the current is limited through the short, allowing the capacitor to continue in operation indefinitely. Fuseless capacitor bank designs were not commonly used with paper/film or all paper capacitors because dielectric shorts were more likely to have localized heating and gassing with an increased probability of case rupture. A fuseless capacitor bank is arranged with individual capacitors in series (called a “series string”) connected between the phase terminals and ground or neutral. The sum of the individual capacitor unit voltages in a string should equal or exceed the normal phase to ground or phase to neutral voltage of the capacitor bank. The desired three-phase kvar of the capacitor bank is accomplished by putting series strings of capacitor units in parallel as shown in Figure 29. Once the desired phase to ground or phase to neutral rating of the capacitor bank is determined then a capacitor unit voltage rating can be chosen to determine the number of capacitor units in the series string. In determining the kvar rating of the capacitor units keep in mind the continuous current capability of the available capacitor units. The string current should be limited to this value, as well as the value that is not likely to create gassing through the fault (consult the manufacturer). A good starting point in the design of a capacitor bank is to divide the total phase current, calculated from the desired three-phase kvar rating of the capacitor bank, by the continuous current capability of the capacitor unit to find the minimum number of strings required. Small fuseless capacitor banks may employ only a single series string per phase. In a fuseless capacitor bank the number of parallel paths for inrush and outrush currents might be significantly lower than a fused capacitor bank. This will subject the capacitor units to higher currents than a fused capacitor bank. Once the number of strings is determined, calculate the magnitude of inrush current each series string will be subjected to during isolated capacitor bank switching or back-to-back switching. Divide this magnitude by the number of series strings to determine the magnitude of inrush current each series string will be subjected to. Verify that the capacitor unit will handle this magnitude of current by checking the transient current capability of the capacitor units (5.2.3.2) and/or consulting with the manufacturer. It may be required to install some type of device to limit the inrush currents, such as series reactors, pre-insertion inductors, or a switching device that has synchronous closing capability. Fuseless capacitors usually have two bushings in order to keep the individual strings isolated from each other. A standard externally fused capacitor unit may not have adequate bushings or internal case insulation for a fuseless application. The BIL of the bushings and the internal insulation of the capacitor unit are determined by the maximum voltage to the rack. All of the capacitor units in a series string will probably not be in the same rack, but will be connected together in different racks as shown in Figure 29. These things should be considered in determining the stacking arrangement of the capacitor bank. 57 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Capacitor racks A B C Figure 29 — Schematic of a fuseless capacitor bank with 2 strings per phase, 12 capacitor units per string The rack potential is established by connecting the racks to one series string of capacitor units. The bushings and internal case insulation must withstand the voltage from the rack to the outside bushings of the capacitor units, in the same string, in that rack. For example, if four, 9.96 kV capacitor units in the same series string are mounted in the same rack, the rack potential would be tied to the midpoint of those four capacitor units. The voltage from the rack to the outside bushings of these four capacitor units will be 19.92 kV. Therefore, the bushings and the internal insulation of the capacitor units must be rated a minimum of 19.92 kV, 125 kV BIL. This requirement would be a higher insulation level than is required for normal 9.96 kV capacitor units. The higher external and internal insulation requirements for the capacitor units in the example above might not be preferred, therefore requiring consideration of another capacitor unit voltage rating or a different stacking arrangement. Changing the voltage rating on the capacitor unit could require a change in the kvar 58 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors rating of the capacitor unit or the number of series strings in the capacitor bank. Changing the stacking arrangement to only have two capacitor units from the same series string in the same rack would make the voltage from the rack to the outside bushings only 9.96 kV, equal to the rating of the capacitor units, and would allow use of 9.96 kV capacitor units with bushings and internal insulation rated for 9.96 kV and 95 kV BIL. For system voltages less than 34.5 kV, the failure of a single element (where there are 10 elements or less in a series string) may result in excessive voltage on the remaining elements requiring immediate removal of the bank from service. The voltage across the remaining elements would increase by a factor of about E/(E – 1), where E is the number of elements in the string. All the variables discussed above should be considered to find the optimum design for the installation. 9.3 Protection The following discussion is intended to complement IEEE Std C37.99-2000 (capacitor bank protection) and IEEE Std C37.48-2005 (external capacitor fuses), in which the protection of shunt power capacitor banks is considered in detail. Occasional failures should be anticipated and a protective scheme should be provided that will reliably detect and clear a faulted capacitor before a) A major fault develops that jeopardizes the circuit. b) Gas pressure inside the faulted capacitor increases to the point where case rupture may occur, affecting other equipment in the vicinity. c) The remaining capacitors are damaged by overvoltage (in ungrounded wye capacitor banks or in capacitor banks with more than one series group per phase). The protection of substation capacitor banks may include the following: ⎯ Capacitor fusing (see also fuseless capacitor banks, 9.2.3) ⎯ Unbalance relaying ⎯ Overcurrent relaying ⎯ Surge arresters ⎯ Phase voltage relays ⎯ Periodic visual inspections Capacitor bank protection works best if all capacitor units have the same rating. Mixing capacitors of different ratings in a capacitor bank will usually result in more complex considerations in setting the unbalance protection. 9.3.1 Capacitor fusing 9.3.1.1 External capacitor unit fusing The function of the capacitor fuse is to sense and indicate the failure of a single capacitor unit and remove the capacitor unit from service fast enough to prevent case rupture and damage to other capacitor units. At 59 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors the same time, it is desirable that the fuse withstand the normal capacitor bank conditions without spurious operations. To withstand normal conditions, it is desirable that the fuse be sized to withstand the following conditions: a) b) c) d) e) Maximum continuous current. This includes allowances for harmonics, capacitor unit tolerance, and overvoltage. Switching inrush current. This is a concern for back-to-back capacitor switching. Current-limiting reactors or switching device pre-insertion inductors may be used to change the magnitude and frequency of the inrush current to an acceptable level. Alternately, switching device pre-insertion resistors may be used to reduce the current magnitudes to acceptable levels. Restriking current. Significant fuse I2t duty may be produced by restriking of the switching device during opening. Synchronous closing or pre-insertion inductors and resistors usually are not in the circuit at the time of the restrike to limit the I2t. Lightning surge currents. This is more of a concern for pole-mounted racks and is seldom a problem for substation capacitor banks. Discharge current into a failing capacitor unit. When a capacitor unit fails, i.e., shorts, the adjacent capacitors discharge into it. The fuses on the good capacitors should withstand this high-frequency outrush current into the failed capacitor units. To ensure that the fuse will clear properly and prevent case rupture of the failed capacitor unit and damage to other capacitor units, the fuse should be sized to ⎯ Withstand the maximum power frequency current expected. ⎯ Remove the failed capacitor unit without resulting in excessive overvoltages on good capacitor units. ⎯ Coordinate with the capacitor case rupture curve for the failed capacitor unit (typical curves indicating regions of high and low probabilities of case ruptures for capacitors with paper, paperfilm, or all-film dielectrics are illustrated in Figure 33). ⎯ Withstand the energy discharge from parallel good capacitor units to the failed capacitor unit. In some applications, it may be difficult to meet all of these objectives. In such cases, trade-offs among the criteria are necessary. For more information or detail on fuse application for protection of capacitor banks please refer to IEEE Std C37-99 for application details. In general, the operation of the individual fuses in capacitor banks involving more than one series group per phase and in all ungrounded wye capacitor banks, irrespective of the number of series groups per phase, will increase the voltage on the capacitors remaining in service. Figure 30 through Figure 32 show the magnitude of overvoltages resulting from removal of various numbers of capacitors from the more common capacitor bank connections. The protective scheme should include provision for disconnecting the entire capacitor bank before the voltage on the remaining capacitors exceeds the values recommended in 5.2.3.1. 60 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Percent of nominal voltage on remaining capacitor units in affected series group (% V) IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 116.0 Series groups (S) 16 6 4 3 2 114.0 112.0 110.0 %V = 108.0 100 S ⎛ %R ⎞ 1 + ⎜1 − ⎟(S − 1) ⎝ 100 ⎠ 106.0 104.0 102.0 100.0 0 4 8 12 16 20 24 28 Percent of capacitor units removed from one series group (% R) Figure 30 — Grounded wye-connected, Δ, or grounded double wye-connected capacitor bank: Voltage on remaining capacitor units in series group vs. percentage of capacitor units removed from series group 61 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Percent of nominal voltage on remaining capacitor units in affected series group (% V) IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 116.0 Series groups (S) 16 6 3 2 114.0 112.0 110.0 %V = 108.0 100 S ⎛ % R ⎞ ⎛ 5 ⎞⎛ % R ⎞ S ⎜1 − ⎟ + ⎜ ⎟⎜ ⎟ ⎝ 100 ⎠ ⎝ 6 ⎠⎝ 100 ⎠ 106.0 1 104.0 102.0 100.0 0 4 8 12 16 20 24 28 Percent of capacitor units removed from one series group (% R) Figure 31 — Ungrounded double wye-connected (neutrals tied together) capacitor bank: Voltage on remaining capacitor units in series group vs. percentage of capacitor units removed from series group 62 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. Percent of nominal voltage on remaining capacitor units in affected series group (% V) IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 116.0 Series groups (S) 16 6 3 2 114.0 112.0 1 110.0 %V = 108.0 100 S ⎛ % R ⎞ ⎛ 2 ⎞⎛ % R ⎞ S ⎜1 − ⎟ ⎟ + ⎜ ⎟⎜ ⎝ 100 ⎠ ⎝ 3 ⎠⎝ 100 ⎠ 106.0 104.0 102.0 100.0 0 4 8 12 16 20 24 28 Percent of capacitor units removed from one series group (% R) Figure 32 —Ungrounded wye-connected or ungrounded double wye-connected (neutrals isolated) capacitor bank: Voltage on remaining capacitor units in series group vs. percentage of capacitor units removed from series group Certain contingencies can result in blowing all fuses in a series group. On multiple series group and ungrounded wye capacitor banks, the last fuse(s) to blow may not clear. The resulting arc even though short lived can damage otherwise healthy capacitors etc. On capacitor banks 230 kV and above, switched with multicontact devices employing grading capacitors, even when the switching device is open, the grading current can keep these arcs burning indefinitely. This has caused damage to fuse tubes and is generally undesirable. 9.3.1.2 Internal capacitor element fusing The function of an element fuse is to disconnect a faulty element before any damage has been caused to the remaining parts of the capacitor unit that will remain in service. Due to parallel stored energy the fuse operates instantaneously after a puncture in its series connected element. No spurious fuse operations are 63 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors allowed to occur under normal capacitor bank service conditions. In the protection of internally fused capacitors it is important to trip the capacitor bank for conditions that will result in excessive voltage on the individual element fuses or capacitor elements in the faulted capacitor unit, as well as protecting healthy capacitor units from excessive overvoltages. When a low voltage system (less than 5 kV) requires a grounded capacitor bank, the end user should make sure that the capacitor unit has more than a single series group of fused elements. To withstand normal conditions, it is desirable that the fuse be sized to withstand the following conditions: a) b) c) d) e) Maximum continuous current. This includes allowances for harmonics, capacitor unit tolerance, and overvoltage. Switching inrush current. This is a concern for back-to-back capacitor switching. Current-limiting reactors or switching device pre-insertion inductors may be used to change the magnitude and frequency of the inrush current to an acceptable level. Alternately, switching device pre-insertion resistors may be used to reduce the current to acceptable levels. Restriking current. Significant fuse I2t duty may be produced by restriking of the switching device during opening. Synchronous closing or pre-insertion inductors and resistors usually are not in the circuit at the time of the restrike to limit the I2t. Lightning surge currents. This is more of a concern for pole-mounted racks and is seldom a problem for substation capacitor banks. Discharge current into a failing capacitor element. When a capacitor element fails, i.e., shorts, the adjacent capacitor elements discharge into it. The fuses on the good capacitor elements should withstand this high-frequency outrush current into the failed capacitor elements. To ensure that the fuse will clear properly and prevent case rupture of the failed capacitor unit and damage to other capacitor units, the fuse should be sized to ⎯ Withstand the maximum power frequency current expected. ⎯ Remove the failed capacitor element without resulting in excessive overvoltages on good capacitor elements. ⎯ Withstand the energy discharge from parallel good capacitor elements into the failed capacitor element. 9.3.2 Overcurrent relaying In setting relays for fault current protection, the magnitude and time duration of inrush and outrush currents should be considered so that false trips do not occur. 9.3.3 Unbalance relaying 9.3.3.1 External capacitor unit fusing When a fuse blows in a capacitor bank, an increase in the fundamental frequency voltage occurs on the remaining capacitor units in that series group. An unbalance detection scheme is employed to monitor such conditions and to take action as required. This scheme usually includes two levels of action (see IEEE Std C37.99-2000): a) Promptly trip the capacitor bank switching device for 1) A level of unbalance that indicates a fault in the capacitor bank, 2) Overvoltage on good capacitor units greater than 110%, or 3) Excessive voltage on capacitor elements or fuses. 64 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors This setting should be as fast as possible and coordinated with the maximum fuse clearing time. The trip time delay is frequently as short as 0.1 s. Longer delay is sometimes required for protection systems affected by system line to ground faults. b) Alarm for low level of unbalance. Overvoltage on good capacitor units is less than 110%. The delay is usually 4 s or greater. 9.3.3.2 Internal capacitor element fusing When a fuse operates, a voltage increase occurs across the remaining elements in that series group of elements inside the capacitor unit and to a lower magnitude also across the capacitor units in parallel with the capacitor containing the operated fuse. An unbalance detection scheme is employed to monitor such conditions and to take action as required. This scheme may include the following levels of action: a) Promptly trip the capacitor bank switching device for 1) A level of unbalance that indicates a fault in the capacitor bank, 2) Overvoltage on good capacitor units greater than 110%, or 3) More than the maximum allowable number of internal fuses blown (provided by the manufacturer of the capacitor units). This setting should be as fast as possible and coordinated with the maximum fuse clearing time. The trip time delay is frequently as short as 0.1 s. Protection systems affected by system line to ground faults are generally not good practice with internally fused capacitors. Note that before tripping, the voltage on the healthy elements in parallel with failed elements following operations may be of the order of 150% of normal. This group of elements is expected to withstand normal switching without cascading failures. The acceptable value may be affected by the capacitor bank design, system application, and the capability of the capacitor unit. See the capacitor unit manufacturer for the acceptable value. b) Alarm for low level of unbalance. The alarm set point is typically halfway between the unbalance signal associated with the trip level and the unbalance signal associated with all the fuses being intact. The delay is usually 4 s or greater. 9.3.3.3 Fuseless capacitor bank protection Each individual capacitor unit consists of many elements connected in series and parallel within the capacitor unit to give the proper voltage and kvar rating. If one of these capacitor elements fails, the capacitor bank may normally stay in service. Since there are many individual elements in series between phase and neutral, there is very little increase in the voltage on the remaining elements in that string. Therefore, the failure of an individual element does not usually lead to the failure of additional elements in that string. An unbalance protection scheme may include the following levels of action: a) Promptly trip the capacitor bank switching device for a level of unbalance, which indicates that 1) There is a fault in the capacitor bank, 2) The voltage on the remaining elements exceeds 110% of rated voltage, or 3) The number of series sections that make up one capacitor have shorted (consult the manufacturer for this information). (Tripping the capacitor bank upon the equivalent of one 65 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors shorted capacitor unit will also trip the capacitor bank for a capacitor unit terminal-to-case insulation fault, which could result in case rupture.) Use the lower of the two values, item 2) or item 3) for tripping. This setting should be as fast as possible. The trip time delay is frequently as short as 0.1 s. b) Alarm for low level of unbalance. Overvoltage on good capacitor units is less than 110%. The delay is usually 4 s or greater. An alarm from the unbalance protection on the capacitor bank can provide indication of the failure of one or two individual elements, to allow the affected capacitor units to be replaced at a convenient time. 9.3.4 Phase voltage relays The application of capacitors inherently results in a voltage rise at that point in the system. To protect the capacitors and other station equipment against long-term overvoltage conditions, phase overvoltage relays are sometimes applied on one or more phases at the bus to trip the capacitor bank. 10. Capacitor applications on distribution lines Shunt power capacitors applied to distribution systems are generally located on the distribution lines or in the substations. This clause deals with those capacitors located on the distribution lines, which may be in pole-mounted racks, pad-mounted capacitor banks, or submersible installations. (Substation applications are discussed in Clause 9.) The distribution capacitor banks often include three to nine capacitor units connected in three-phase grounded-wye, ungrounded-wye, or delta configurations. Since they are closer to the load, capacitors located on the distribution lines represent a more effective means for supplying the reactive power requirements while minimizing system losses. On ungrounded, impedance grounded, or uni-grounded (grounded only at the source transformer) systems, only ungrounded-wye and delta capacitor bank configurations should be used. On effectively grounded systems, grounded-wye, ungrounded-wye, and delta configurations may be used. There are certain advantages and disadvantages associated with grounded-versus-ungrounded-wye capacitor banks. The advantages of the grounded-wye arrangement compared to the ungrounded wye are as follows: a) b) c) d) Phases are isolated from each other. When single-phase sectionalizing (fusing or reclosing) is used on a multigrounded system, grounding the neutral of the capacitor bank avoids problems associated with disconnected phases being energized through an ungrounded capacitor bank. Initial cost of the capacitor bank may be lower since the neutral does not have to be insulated from ground at full system BIL, as in the case with floating neutral arrangements. Capacitor switch recovery voltages are reduced. When compared to ungrounded wye, no overvoltage on the unfaulted capacitor units during fuse operation for a faulted capacitor on another phase will occur. (The same advantage exists for delta connected capacitor banks.) The disadvantages of the grounded-wye arrangement compared to the ungrounded wye are as follows: ⎯ Grounded neutral may draw zero-sequence harmonic currents and cause telephone interference. ⎯ Transient ground currents caused by capacitor switching or nearby faults may induce undesirable voltages into other circuits sharing the same ground as the grounded capacitor. 66 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Grounded-wye, ungrounded-wye, and delta-connected capacitors may be subject to ferroresonant overvoltages if they are switched together with transformer banks of certain winding connections with single-pole switching devices or if a stuck pole should occur on a three-phase device. For the ungrounded capacitor, if the transformer has a grounded neutral or even if it consists of many single-phase transformers applied about equally along the feeder, a potentially ferroresonant circuit exists if single-phase switching devices are operated upstream. Both transformers and surge arresters have failed under these conditions. If the transformer is three-phase ungrounded, then the grounded capacitor bank should be avoided for the same reason. Although ferroresonance can and does occur on these circuits, it occurs only rarely because resistive load on the transformers can prevent its occurrence. 10.1 Protection For small capacitor banks without unbalance protection used in distribution feeder applications, the protection includes external capacitor fusing and surge arresters. For internally fused capacitors with unbalance protection, the guidelines for the unbalance protection settings are the same as for substation capacitor banks. 10.1.1 Fusing Guidelines for capacitor fusing are given in IEEE Std C37.48-2005. In distribution capacitor banks, group (line) fusing, individual capacitor unit fusing, internal fusing, or a combination may be used. Group fusing involves the use of a single fuse in series with all of the capacitors in that phase. For individual fusing, each capacitor unit is fused separately (see 9.2.1). Group fusing with externally fused capacitors is the most commonly used method in distribution line application. Internally fused capacitor units require unbalance protection and are not normally used for distribution line capacitor banks. Individual capacitor unit fusing is generally not used on small ungrounded-wye capacitor banks due to overvoltage stress on capacitor units in parallel with a capacitor unit isolated by a fuse operation. The function of the capacitor line fuse (group fuse) is to detect the escalating failure of a single capacitor and remove the capacitor group from service fast enough to prevent case rupture and damage to other capacitor units. At the same time, it is desirable that the capacitor line fuse (group fuse) withstand the normal capacitor bank operating conditions without spurious fuse operations. To withstand normal conditions, it is necessary that the capacitor line fuse (group fuse) be sized to withstand the following conditions: a) b) c) Continuous current. This includes consideration for a harmonic component, capacitance tolerance (maximum of +10% to +15%), and overvoltage (+10%). Historically, the continuous current capability of the fuse has been a minimum of 125% to 135% of the capacitor nominal current. Switching inrush current. Although this is seldom a concern for pole-mounted capacitor banks (except in cases where they are very close together), the “minimum-melting” curve of the fuse should be coordinated with the capacitor bank inrush current to minimize the possibility of nuisance fuse operations. Surge current. The surge current due to a lightning stroke or a nearby arcing fault can be a significant concern for pole-mounted capacitor banks especially if lower amperage rated fuses are used. In high lightning incidence areas, slower fuse speeds with higher surge withstand capabilities (e.g., T-speed) are often used rather than faster fuse speeds (e.g., K-speed) for the lower amperage rated fuses. 67 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors d) Rated fuse voltage. The capacitor line fuse (group fuse) is rated for phase-to-phase voltage for ungrounded-wye capacitor banks and for phase-to-ground voltage for grounded-wye capacitor banks applied on solidly grounded neutral (multi-grounded) systems, provided that BIL rating and leakage distance to ground of the fuse mounting are sufficient for the application. The higher voltage is needed for ungrounded-wye capacitor banks due to the higher recovery voltage across the fuse when clearing a failed capacitor unit. To minimize the possibility of case rupture of the failed capacitor unit and damage to other capacitor units, the fuse should be selected to ⎯ Interrupt the maximum power frequency fault current expected. ⎯ Coordinate with the capacitor case rupture curve for each capacitor unit. The “maximum total clearing” curve of the fuse to be used should lie to the left of the case rupture curve from the capacitor manufacturer. A typical capacitor case rupture curve is given in Figure 33. 102 x 1000 = 100 000 1000 All film Dielectric Time (Seconds) 100 High probability of case rupture Constant I2t = 100 000 10 Paper or Paper / Film Dielectric 1 Minimum I2t = 4422 x 1 = 195 000 Amp2 Sec. 0.1 Low probability of case rupture 0.01 1 10 100 1000 RMS Current (Amperes) 10000 31622 x .01 = 100 000 Figure 33 — Typical case rupture curves for approximately 30 liters case volume 68 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors The withstand capability of each capacitor varies with design and size, so the available fault current at each location should be compared with the capacitor case rupture curve. If the short-circuit current is excessive, options available include the utilization of current-limiting fuses to limit the fault current or moving the capacitor bank to another location with an acceptably lower available fault current. It should be noted that if the capacitor bank is connected in an ungrounded-wye configuration, a phase-to-ground fault may still occur since the capacitor tank is normally grounded. For ungrounded or poorly grounded systems where the line-to-ground fault current is much lower than phase-to-phase fault current, connecting the capacitor bank in ungrounded wye may allow the use of non-current limiting fuses in a high fault current location, since the probability of a faulted capacitor unit in two phases at the same time is very low. The fuse should be sized to promptly clear a faulted capacitor unit in one phase. ⎯ Remove the failed capacitor unit without impressing excessive overvoltages on good capacitor units. In ungrounded-wye applications, line-to-line voltage will be impressed on the good phases during the shorting of a capacitor unit. The permissible overvoltages are summarized in 5.2.3.1. Figure 4 indicates a desired clearing time of less than 1 s. This is generally difficult to achieve in a group-fused ungrounded-wye application since the available fault current is only three times the normal capacitor bank phase current. Good performance has generally been achieved by selecting the fastest clearing fuse that meets the continuous current, switching inrush current, and lightning surge current requirements discussed previously. Generally, clearing times on the order of 15 s to 2 min can be achieved for a completely failed capacitor unit with three times the normal phase current flowing. In some applications, it may be difficult to meet all of these objectives. In such cases, trade-offs among the criteria are necessary. 10.2 Sizing and locating capacitors To obtain the optimum benefit of shunt power capacitor applications on the distribution system, the capacitor banks should be located where they produce the maximum loss reduction, provide the maximum voltage benefits, and are as close to the load as possible. When this is not practical, several “rules of thumb” have been utilized for locating capacitors. These include the following: a) b) c) For uniformly distributed loads, the capacitor should be placed two-thirds of the distance from the substation. For uniformly decreasing distributed loads, the capacitor should be placed one-half of the distance from the substation. For maximum voltage rise, the capacitor should be placed near the end of the line. More specifically, capacitor banks are required at locations where field measurements indicate a lowvoltage or low-power factor problem. This information can be obtained as follows: ⎯ By making voltage measurements during full-load and light-load conditions at various points on the feeder; and ⎯ By making kilowatt and kilovoltampere measurements on the feeder at minimum and maximum daily loads, and during a typical 24 hour period. Once these measurements have been obtained, the equations given in 4.1 can be used to determine voltage rise and kilovar parameters. The capacitor banks may be connected grounded wye, ungrounded wye, or delta. These configurations are discussed in 9.1.1. 69 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 11. Special capacitor applications This clause describes the considerations for applying shunt power capacitors in the following special applications: a) b) c) Harmonic filters Motors Surge protection These special capacitor applications also require consideration of the previous clauses of this guide relating to purpose and ratings of capacitors, limitations, capacitor bank size, etc. 11.1 Harmonic filters The levels of harmonic voltages and currents on power systems have generally increased as more nonlinear devices, such as solid-state power conversion equipment, are applied. When the levels of harmonic voltage or current become excessive, shunt power capacitors are often used in harmonic filters to control the harmonic performance of the power system. The recommendations of this application guide should not be used for capacitors applied in harmonic filters. Refer to IEEE Std 1531-2003. 11.2 Motor applications 11.2.1 Capacitors and motors Shunt power capacitors are frequently used to improve the power factor of circuits or industrial power systems with a large induction motor load since the power factor of large motors running at full load ranges from 0.60 to 0.95 lagging depending upon motor design. Under-loaded or lightly loaded motors operate at significantly lower power factors. Several safeguards should be considered when applying capacitors in conjunction with motors (IEEE 79 EHO 144-6 PWR [B5], Shula [B10]). Capacitors permanently connected in parallel and switched with medium voltage induction motors should be limited in size to prevent overvoltage due to self-excitation when the motor and capacitor combination is disconnected from the electrical supply and the rotor continues to rotate due to mechanical inertia. IEEE Std 141-1993 contains a table of maximum recommended capacitor ratings to be applied with induction motors when the capacitors are switched with motors. When special application motors are involved or questions arise, the recommendation should be checked with the motor manufacturer. When capacitors larger than the rating permitted above are used, they should either be connected ahead of the motor switch or have a separate switch that automatically disconnects the capacitor when the motor is disconnected. Capacitors switched with motors prolong the duration of residual voltage in the motor as it slows down after de-energization. High transient torques that can damage motor and equipment are possible if open transition transfer is used or the motor is re-energized before the residual voltage has decayed to a safe level (20–25%). 70 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 11.2.2 Motor starting An undesired characteristic of large induction motors and industrial synchronous motors is that they draw several times their full-load current from their supply when starting. The starting current flowing through the system impedances can result in an unacceptable voltage drop that may be large enough to cause contactors to drop out and influence the ability of the motor to start. A typical starting curve is illustrated in Figure 34. The actual shape and magnitude of the starting current curve depends on the motor design, the voltage at the motor terminals during starting, and the speed-torque characteristic of the mechanical load connected to the motor. Since the power factor during starting is usually in the range of 0.15 to 0.30 lagging, shunt power capacitors are sometimes used to reduce the voltage dip when starting a large motor. Their effect is to reduce the reactive component of the input kilovoltamperes. With this method, the high inductive component of the normal starting current is compensated, at least partially, by the addition of capacitors to the motor bus during the starting period. The capacitor size needed for this purpose is usually 2 to 3 times the motor full-load kilovoltampere rating. Motor Starting Current, per unit of full load 8 6 4 2 0 0 20 40 60 80 100 Time, percent of total starting time Figure 34 — Typical motor starting curve The typical reactive current requirement of a motor running at rated speed following start-up is 30% of its full-load current (0.95 lagging power factor). Therefore, in order to control the voltage properly during start-up, the capacitor is usually switched out in steps as the motor accelerates. (See Figure 35.) Due to the large kilovar size of these capacitors, they are usually in the circuit for only a few seconds during motor starting. 71 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors In determining the voltage rating of the capacitors, they should be within the overvoltage capability defined in Figure 4 and limited to a combined total of 300 applications of overvoltage during the service life (see 5.2.3.1). The capacitor manufacturer should be contacted for more severe duties. MOTOR SWITCHED CAPACITORS Figure 35 — Motor starting capacitor application 11.3 Surge capacitors Capacitors may be used to reduce the rate of rise of voltage (and in some cases the magnitude of the surge voltage) to protect insulation. Some manufacturers provide specially designed “surge capacitors” for this application. The design and manufacturing requirements for these “surge capacitors” are not covered by IEEE Std 18-2002. These “surge capacitors” generally have greater design margins than the capacitors manufactured in compliance with IEEE Std 18-2002. They are intended to be applied directly in parallel with the protected apparatus, with no separate protection. Surge capacitors are most often used to protect rotating machinery, dry type transformers, arc furnace transformers, and sensitive electronic equipment. See Figure 36 for a typical installation. The stress on the major insulation of a rotating machine—the insulation between winding and frame—is determined mainly by the magnitude of the surge voltage to ground. However, the stress on the insulation between the turns of the winding is more a function of the rate-of-rise of the surge voltage as it penetrates the winding. Proper protection of rotating machines requires not only limiting the surge voltage magnitude at the machine terminals, but also reducing the slope of the wavefront of the incoming surge. The function of the surge capacitor is to reduce the slope of the wavefront of an incoming surge (IEEE 79 EHO 144-6 PWR [B5]). 72 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors MOTOR (OR TRANSFORMER) SURGE ARRESTER SURGE CAPACITOR Figure 36 — Surge capacitor application Surge capacitors are also used to protect equipment, especially transformers, from transient overvoltages due to current chopping. Current chopping is the action of interrupting low levels of currents prior to a natural current zero. When this happens, energy is trapped in the transformer inductance, which is subsequently interchanged with circuit capacitance producing a voltage surge. The magnitude of the voltage surge is conservatively calculated by Equation (23). V = IC Lm C (23) where Ic Lm C is the chopped current level is the transformer magnetizing inductance is the capacitance on the transformer side of the switch As can be seen in Equation (23), the voltage surge produced is independent of the system voltage level; therefore, this phenomenon is most troublesome on low-voltage, low-BIL systems. The addition of a surge capacitor will act to reduce this transient. Surge capacitors may see transient voltage duties in excess of those defined in 5.2.3.3 (Figure 6). Consequently, these capacitors are specially designed for the duties required in these applications. Typical values of surge capacitors are given in Table 7. Table 7—Typical capacitance values for line-to-ground surge capacitors Rated system voltage (kV) Capacitance (µf) 2.4–6.9 0.5 13.8 0.25 24.0 0.125 34.5 0.0833a a One 0.25 µf, 13.8 kV in series with one 0.125 µf, 24 kV (one capacitor unit must be insulated from ground). 73 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 12. Inspection and maintenance 12.1 General This clause describes the general considerations for maintenance and inspection of shunt power capacitor banks for substation and distribution (pad-mounted and pole-mounted) applications. All capacitor banks should be inspected and electrical characteristics measured upon initial installation and periodically, or as required, throughout their service life. Since capacitors are “closed systems,” a visual inspection alone cannot determine the condition of all individual capacitors. 12.2 Safety and personnel protection Normal good safety practices should be followed during installation, inspection, and maintenance of capacitors. In addition, there are procedures that are unique to capacitors that should be followed for the protection of personnel and equipment as given in the National Electrical Safety Code® (NESC®) (ANSI C2). Several precautions that should be observed are listed in 12.2.1 through 12.2.5. 12.2.1 Clearance and grounding After a capacitor bank has been de-energized, wait at least 5 min before approaching it. This is to allow enough time for the internal discharge resistors in each capacitor unit to dissipate the stored energy. These resistors are designed to reduce the voltage across the individual capacitor units to less than 50 V within 5 min; however, one should always apply grounding leads to all three phases to short out and ground the capacitor bank. On larger substation capacitor banks, permanent grounding switches may be installed to accomplish this. Even after the capacitor bank has been grounded, it is recommended that individual capacitor units be shorted and grounded before personnel contact them to assure that no stored energy is present. (In some circumstances, failure of the internal resistor could leave a stored charge on an individual capacitor unit.) 12.2.2 Bulged capacitor units Excessively bulged capacitor units indicate excessive internal pressure caused by overheating and/or creation of gasses during a probable arcing condition. These capacitor units should be handled carefully. The manufacturer should be consulted if there are questions regarding special handling of these capacitor units. 12.2.3 Leaking capacitor units When handling capacitors with leaking fluid, avoid fluid contact with skin and prevent entry into sensitive areas, such as eyes. Handling and disposal of capacitor insulating fluid should follow the methods required by applicable government regulations. 74 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 12.2.4 Combustible fluid Some capacitor units contain combustible liquid and their location should be chosen with consideration given to the possibility of fire and its containment in the event of capacitor failure. See the National Electrical Code® (NEC®) (NFPA Std 70) for location limitations. 12.2.5 Re-energizing When returning a capacitor to service, verify that all shorts and grounds that were installed for maintenance have been removed. Allow a minimum of 5 min between de-energization of a capacitor bank and reenergization of the capacitor bank to allow enough time for the stored energy to dissipate. (For applications where quicker re-energizing is required, allowing the voltage to decay to about 10% of its original value will only increase the inrush transients by 10%, and is often acceptable. This may be of the order of 2 min to 3 min, depending upon the capacitor unit voltage rating. External discharge reactors to more quickly discharge the capacitors or properly sized insertion resistors or reactors to control the inrush transient may also be used to reduce the time before re-energizing.) 12.3 Initial inspection, measurements, and energization The initial inspection should include the following items: a) b) c) d) e) f) g) h) i) j) k) Verify mechanical assembly of the capacitor equipment for proper electrical clearances and structural soundness. Some utilities have found it useful to measure the capacitance of new capacitor units to verify proper markings and establish a benchmark for future comparison. Ensure flipper devices on fuses are properly installed for successful operation of the fuse. Check electrical connections for proper installation and good electrical contact. Verify that capacitor unit terminal nuts are torqued properly. Check individual fuse connections to ensure that they are tight and make good contact, as listed: 1) The fuse tube cap-to-bus connection for proper torque. 2) The fuse tube-to-cap connection for proper torque. 3) On expulsion fuses, ensure that the “button heads” make good contact with the tube cap; on those fuse links with removable “button heads,” ensure that the button heads are properly assembled on the fuse link. Clean all insulators, fuses, and bushings to prevent the possibility of dirty insulation creating a flashover danger. Inspect insulators and bushings for cracks or breaks. Inspect for damaged bushings and cases to identify any source of leaks. Test the operation of all controls and load break, disconnect, and grounding switches prior to energizing the capacitor. Prior to energization, verify that the capacitance values of each of the phases are sufficiently close to allow coordination with any relay scheme utilized. At a minimum, this capacitance unbalance should not result in a voltage higher than the alarm overvoltage level setting on any one capacitor. For capacitor bank without relay protection, this capacitance unbalance should be limited to 2% On those capacitor units with capacitance unbalance protection equipment, verify that such equipment operates properly. (See IEEE Std C37.99-2000.) Immediately after energization, verify that the voltage boost obtained is sufficiently close to the expected value. Verify that impressed voltage, capacitor current, and kilovar are within the limits of capacitor ratings. 75 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors l) m) An infrared scan of the installation may be desirable to check the integrity of the many electrical connections within a capacitor assembly. Within 8 h to 24 h after the capacitor is put in service, it is highly desirable to recheck the capacitor bank for any blown fuses, bulged capacitor units, and proper phase current balance. 12.4 Periodic inspection, measurements, and maintenance Substation and distribution capacitor banks should be inspected and electrical measurements made periodically, or as required, throughout their service life. The frequency of inspections should be determined by local conditions and requirements (i.e., environmental conditions, percent of time the capacitor bank is switched “on,” and number of “on” and “off” switching operations). 12.4.1 Visual inspections Visual inspections should include the following items: a) b) c) d) e) f) g) Check for blown capacitor fuses, capacitor case leaks, bulged cases, discolored cases, and ruptured cases. Check the ground for spilled dielectric fluid. Check for dirty insulating surfaces and cracked bushings. Check for signs of overheated electrical joints. Check for open switches and “tripped” protective devices. Check for vandalism. On metal-housed and pad-mounted capacitor banks, verify that locking devices are in place and functioning properly; inspect the exterior for corrosion and oil leaks around the structure; check for proper functioning of forced cooling equipment and associated intakes, vents, and filters; and ensure that any required safety or warning signs (e.g., “High Voltage”) are properly installed and legible. 12.4.2 Physical inspection and measurements Physical inspections and measurements should include the following items: a) b) c) d) e) f) Check for loose connections, frayed leads, faulty fuse tubes, and faulty ejector spring assemblies. Fuses should be inspected for evidence of overheating or other damage. Verify proper settings and operation of protective and/or control devices, switches, and potential and/or current transformers. Equipment exposed to weathering should be repainted, if necessary, to prevent corrosion. The capacitance of the individual capacitor units or groups of capacitor units should be measured and compared with their previous reading (see 12.5). Any other maintenance operations suggested in the manufacturer’s instructions. 12.4.3 Capacitor banks with excessive failures Capacitor banks with excessive capacitor unit failures and/or blown fuses should be inspected on a more frequent basis. In addition to the items in 12.4.1 and 12.4.2, the inspections may also include measurements of transient and/or harmonic voltages and currents impressed upon the capacitor bank to ensure that they are within the limits of the capacitor ratings. The manufacturer should be consulted for assistance. 76 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 12.4.4 Locating a defective capacitor unit in a fuseless capacitor bank A dielectrically defective capacitor unit can be located in a fuseless capacitor bank without disconnecting any of the capacitor units. The failure of a capacitor section in an all-film capacitor unit causes the capacitance of the capacitor unit to increase. The increase in capacitance for a capacitor unit with failed elements is n ΔC (per unit) = S-n where n is the number of failed series elements and S is the total number of series elements in the capacitor unit. For instance, for a capacitor unit with one failed series element out of 10, the capacitance would increase by 1/9, more than 10%. This increase in capacitance can be used to quickly determine whether there is a dielectrically failed capacitor element in a string, and to locate the faulty capacitor unit. CAUTION Immediately prior to making any capacitance measurements, simultaneously ground the terminals to be measured for about a second. This will discharge any trapped charge which might damage the meter. First, the three capacitor bank phase connections and the neutral are connected to ground (Figure 37). This safety grounding provides a convenient capacitor bank configuration for locating a capacitor unit with a failed element. The capacitor bank grounding illustrated in Figure 37, results in each string of capacitor units being grounded at both ends as illustrated in Figure 38. A B C Figure 37 — Capacitor bank grounded in preparation for testing By measuring the midpoint to ground capacitance of each of the strings in the capacitor bank, those strings that contain defective elements (Figure 38) are identified. For strings that have an odd number of capacitor units, measure from either bushing of the middle capacitor unit to ground. The strings having defective elements will have a slightly higher capacitance than those strings without defective elements. For those strings without indication of failed elements, there is no need for any further measurement. 77 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors CM Figure 38 — Measurement of midpoint to ground capacitance for one string with capacitor bank phase and neutral grounded CM Figure 39 — Midpoint to ground measurement with one failed capacitor unit If any string has an indication of failed elements, the next step is to determine which rack contains the failed elements. Measure the capacitance across each rack (Figure 40). The rack containing the failed elements will have a higher capacitance than the rest of the racks. If the racks do not have equal numbers of capacitor units, the capacitance of one rack may be compared with the capacitance of the same number of capacitor units in another rack (Figure 41). 78 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors CR CR Figure 40 — Capacitance measurements across racks without and with a failed capacitor unit CR CR Figure 41 — Comparing capacitances with different numbers of capacitor units in various racks Once the rack(s) containing the failed elements is identified, each of the capacitor units in that rack is measured to determine which capacitor unit has the failed elements (Figure 42). 79 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors CU CU CU CU Figure 42 — Measuring individual capacitor units in a rack with an indicated failure 12.4.5 Locating a defective capacitor unit in an internally fused capacitor bank A dielectrically defective capacitor unit can be located in an internally fused capacitor bank without disconnecting any of the capacitor units. The operation of an internal fuse in a capacitor unit causes the capacitance of the capacitor unit to decrease. This decrease in capacitance can be used to determine whether there is a failed element in the capacitor unit, and to locate the faulty capacitor unit. 12.4.5.1 Capacitor bank comprised of capacitor units in series/parallel arrangement First, the three capacitor bank phase connections and the neutral are connected to ground (similar to Figure 37, except that the capacitor bank may be comprised of capacitor units in a series/parallel arrangement instead of parallel strings of capacitor units). This safety grounding provides a convenient capacitor bank configuration for locating a capacitor unit with a failed element. The capacitor bank grounding illustrated in Figure 38, results in each phase being grounded at both ends, similar to Figure 39. By measuring the midpoint to ground capacitance of each wye in the capacitor bank, those wyes that contain capacitor units with defective elements (Figure 38) are identified. For wyes having an odd number of series groups, measure from either bushing of one of the middle group of capacitor units to ground. The wyes having capacitor units with defective elements will have a slightly lower capacitance than those wyes having capacitor units without defective elements. For those wyes without indication of failed elements, there is no need for any further measurement. The capacitance change of a failed capacitor unit with a single element will normally range from 2% to 3% of the original value. The capacitance change of a wye will depend on the number of capacitor units in the wye and the number of failed elements in the same wye. Since the operator is usually trying to detect a defective capacitor unit(s) that has generated at least an alarm signal, it is usually possible to find the defective capacitor units(s). 80 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors 12.4.5.2 Capacitor bank comprised of capacitor units connected directly in parallel Using a low-voltage power source (110–125 Vac) to energize a parallel group of capacitor units, current flow through each capacitor unit can be measured using a clip on meter. The measured current is then compared with the calculated value previously established for a healthy capacitor unit at this reduced voltage. Any current measurement that is lower than the calculated value is an indication that the particular capacitor unit has defective elements. Once a capacitor unit has been identified as potentially defective, a capacitance check can be performed with a capacitance meter, after the suspect capacitor unit has been disconnected from the others. Alternatively, by using a modified Schering bridge, it is possible to locate a defective capacitor unit without disconnecting any of the capacitor units within the bank. This portable device measures capacitance. The current through the capacitance to be measured is coupled inductively to the bridge via a high performance current clamp. Each capacitor unit is measured individually by moving the clip-on transformer from one capacitor unit to the next. See Figure 43. Clamp Power Supply Figure 43 — Capacitance measurement using a modified Shering bridge 12.5 Field testing Field tests on capacitors may include capacitance or current tests, insulation resistance tests, and a seal test for liquid tightness. WARNING Capacitor units may rupture during high voltage tests. Adequate safeguards should be provided to prevent injury to personnel or damage to adjacent equipment in the event of violent failure of a capacitor unit during test. Testing should be done at or near room temperature to avoid damage to the dielectric. The capacitor unit may be damaged if discharged by short-circuiting its terminals before five minutes after the test potential is removed. Before any tests are initiated, the manufacturer’s instructions should be carefully studied and followed. 12.5.1 Tests to check the condition of a capacitor unit after it has been in service Field tests may be made to ascertain the operating condition of a capacitor unit. Such tests are necessary only in case of indication of trouble or after exposure to possible damage. 81 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Several electrical devices are available in the market to measure capacitance, power factor, impedance, resistance, and voltage withstand. While all of these instruments can detect an open or shorted capacitor unit, some can detect a partially shorted capacitor unit as well. The service ability of a capacitor unit may be determined by one or more of the following simple tests. 12.5.1.1 Capacitance Capacitance can be measured with a digital capacitance meter, which generally gives reliable, accurate readings. However, the low-voltage meter may fail to detect some internal failures that require high breakdown voltage, such as failures to the capacitor unit case. Capacitance may also be satisfactorily determined by measuring the current while applying a known voltage and frequency of a good waveshape undistorted by voltage control devices. The applied current and voltage should be proportional to the rating of the capacitor unit and be within IEEE Std 18-2002 tolerances. This test will also indicate short-circuited or open-circuited capacitor units. Since capacitor units are usually made up of series groups of parallel capacitor elements, the measurement of the capacitance of a capacitor unit can be a direct indication of the internal condition of the capacitor unit. Capacitor standards specify that capacitor units shall give not less than the rated reactive power at rated sinusoidal voltage and frequency, and not more than 110% of this value, measured at 25 °C uniform case and internal temperature. Based on this tolerance, capacitor units with capacitance readings outside the tolerance, of –0% to +10% should be replaced. However, when capacitance readings are made at temperatures much colder than 25 °C, the capacitance could read slightly above the +10% value and readings at temperatures much warmer than 25 °C could read slightly below the –0% value. Since design and manufacturing tolerances vary, the manufacturer should be consulted concerning the capacitance value for partially failed capacitor units. Some utilities have found it very useful to record initial capacitance values for each capacitor unit in the capacitor bank on the capacitor units or in a test report. Significant changes in capacitance readings from one inspection to the next may indicate capacitor element failures and may require replacement of the capacitor unit. 12.5.1.2 Terminal-to-terminal resistance Terminal-to-terminal insulation resistance measurements may be made on capacitor units with suitable bridge, or calculated from the direct-current voltage and current readings. When internal discharge resistors are included, as indicated on the nameplate, the terminal-to-terminal resistance reading obtained will be the value of the discharge resistor that is much lower than the normal insulation resistance of the dielectric. Refer to IEEE Std 18-2002 for the basis on which nominal resistance values are selected. When values of insulation resistance of the dielectric are needed, they should be obtained from the manufacturer. 12.5.1.3 Terminal-to-case resistance Terminal-to-case insulation resistance measurements may be made on two-bushing capacitor units to determine the condition of the line insulating terminals and dielectric insulation to case. (If the capacitor unit has a single bushing and internal discharge resistors, the resistance reading obtained will be the value of the discharge resistors that is much lower than the normal insulation resistance.) This test is normally 82 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors made by connecting the bushing terminals together and measuring the resistance to the case. When values of insulation resistance of the case insulation are needed, they should be obtained from the manufacturer. Measuring the terminal-to-case power factor or dielectric loss is another means of determining the condition of the line insulating terminals and insulation to case. This measurement is more difficult and has no advantage over the resistance test described. 12.5.1.4 Leak test Liquid tightness of a capacitor unit may be checked by increasing the internal pressure and inspecting for leaks at elevated pressure. This may be done effectively by thoroughly cleaning the case, heating the capacitor unit a minimum of 4 h in an oven, and then placing it horizontally on clean paper with suspected point of leakage on the bottom. NOTE—The temperature of the capacitor unit case should not be allowed to exceed the manufacturer’s recommendations. 83 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors Annex A (informative) Bibliography [B1] Arrillaga, J., Bradley, D. A., and Bodger, P. S., Power System Harmonics. New York: John Wiley & Sons, 1985. [B2] Bayless, R. S., Selman, J. D., Truax, D. E., and Reid, W. E., “Capacitor Switching and Transformer Transients,” IEEE Transactions on Power Delivery, vol. 3, no. 1, Jan. 1988, pp. 349–57. [B3] Clinard, Kay N., “Distribution Automation: Research and the Emergence of Reality, IEEE Transactions on Power Apparatus and Systems, vol. PAS-103, no. 8, Aug. 1984, pp. 2071–75. [B4] Greenwood, Alan. Electrical Transients in Power Systems. New York: John Wiley & Sons, 1971. [B5] IEEE 79 EHO 144-6 PWR, Chapter 8: D.W. Jackson, “Surge Protection of Rotating Machines,” Surge Protection in Power Systems, Power Engineering Society, 1979. [B6] McCauley, T. M., Pelfrey, D. C., Roettger, W. C., and Wood, C. E., “The Impact of Shunt Capacitor Installations on Power Circuit Breaker Applications,” IEEE Transactions on Power Apparatus and Systems, vol. 99, no. 6, Nov./Dec. 1980, pp. 2210–22. [B7] McGranaghan, M. F., Reid, W. E., Law, S. W., and Graham, D. W., “Overvoltage Protection of Shunt Capacitor Banks Using MOV Arresters,” IEEE Transactions on Power Apparatus and Systems, vol. 104, no. 8, Aug. 1984, pp. 2326–36. [B8] Pflanz, H. M. and Lester, G. N., “Control of Overvoltages on Energizing Capacitor Banks,” IEEE Transactions on Power Apparatus and Systems, vol. PAS-92, no. 3, May/June 1973, pp. 907–15. [B9] Schultz, A. J., Johnson, J. B., and Schultz, N. R., “Magnification of Switching Surges,” AIEE Transactions on Power Apparatus and Systems, Feb. 1959, pp. 1418–26. [B10] Shula, W. E., “Capacitors Help Start Large Motors,” Electrical World, Nov. 1, 1974. [B11] “An Assessment of Distribution System Power Quality - Volume 2: Statistical Summary Report”, Final Report, EPRI TR-106294-V2, EPRI RP 3098-01, May 1996. [B12] Harder, J. E., “Transient Current Limiting Reactors for Capacitor Installations,” November 1996, published by John E. Harder, 97 North Hartstrait Road, Bloomington, IN 47404-9700, USA [B13] Bellei, T. A., O’Leary, R. P., Camm, E. H., “Evaluating Capacitor Switching Devices for Preventing Nuisance Tripping of Adjustable-Speed Drives Due to Voltage Magnification”, IEEE Transactions on Power Delivery, Vol. 11, No. 3, July 1996. [B14] O’Leary, R. P., Harner, R. H., “Evaluation of Methods for Controlling the Over-voltages produced by the Energization of a Shunt Power Capacitor, CIGRE 13-05, 1988 Paris meeting. 84 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply. IEEE Std 1036-2010 IEEE Guide for Application of Shunt Power Capacitors [B15] G. Hensley, T. Singh, M. Samotyj, M. McGranahan, and T Grebe, “Impact of Utility Switched Capacitors on Customer Systems Part II – Adjustable Speed Drive Concerns”, IEEE Transactions PWRD pp. 1623–1628, October 1991. [B16] G. Hensley, T. Singh, M. Samotyj, M. McGranahan, and R. Zavadil, “Impact of Utility Switched Capacitors on Customer Systems – Magnification at Low Voltage Capacitors”, IEEE Transactions PWRD pp. 862–868, April 1992. [B17] Impact of Shunt Capacitor Banks on Substation Surge Environment and Surge Arrester Applications, Report by Working Group 3.4.17 of the IEEE Surge Protective Devices Committee, IEEE Transactions on Power Delivery, Vol. 11, No.4, October 1996. [B18] C.C. Erven and A. Narang, “Switching of Large Ungrounded Shunt Capacitor Banks on the Ontario Hydro System”, Canadian Electrical Association, 1985 Transactions of Engineering and Operations, Vol. 24, Part 1, Paper No.85-A-65. 85 Copyright © 2011 IEEE. All rights reserved. Authorized licensed use limited to: University of Virginia Libraries. Downloaded on October 10,2012 at 16:21:47 UTC from IEEE Xplore. Restrictions apply.