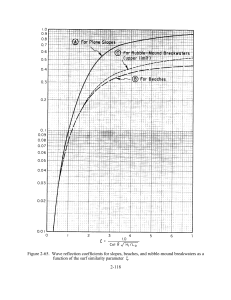

Journal of Marine Science and Engineering Article Numerical Investigation into Freak Wave Effects on Deepwater Pipeline Installation Pu Xu 1, *, Zhixin Du 1 1 2 * and Shunfeng Gong 2 College of Civil Engineering, Fuzhou University, Fuzhou 350116, China; 15259143923@163.com Institute of Structural Engineering, Zhejiang University, Hangzhou 310058, China; sfgong@zju.edu.cn Correspondence: puxu@fzu.edu.cn Received: 18 January 2020; Accepted: 3 February 2020; Published: 14 February 2020 Abstract: Freak waves are an extreme marine environment factor in offshore structure design and become a potential risk, particularly for laying oil-gas pipelines in deep waters. The objective of this study was to reveal the freak wave effects on dynamic behaviors of offshore pipelines for deepwater installation. Thus, a dedicated finite element model (FEM) for deepwater pipeline installation by the S-lay method was developed with special consideration of freak waves. The FEM also took pipelay vessel motions, pipe–stinger roller interactions, and the cyclic contacts between the pipeline and seabed soil into account. Real vessel and stinger data from an actual engineering project in the South China Sea were collected to obtain an accurate simulation. Moreover, an effective superposition approach of combined transient wave trains and random wave trains was introduced, and various types of freak wave trains were simulated. Extensive numerical analyses of a 12 inch gas pipeline being installed into a water depth of 1500 m were implemented under various freak wave conditions. The noticeable influences of freak waves on the pipeline and seabed responses were identified, which provides significant awareness of offshore pipelines for deepwater installation design and field operation monitoring. Keywords: offshore pipeline; installation simulation; deepwater; freak wave; S-lay method 1. Introduction Freak waves occur unexpectedly far out at sea with remarkably large wave heights and are deemed to be an extreme marine environment condition. The irregular distribution of freak wave heights does not comply with the basic law of Rayleigh distribution for normal ocean waves, especially in deep waters. The unique feature of freak waves makes it difficult for marine structural engineers to sufficiently consider the huge wave loads in the design stage. In the past, plenty of tremendous accidents, including shipwrecks and massive destruction of offshore structures, have been caused by the great impact of freak waves [1,2]. These accidents have produced a striking warning on the potential risk of freak waves for lay barge and offshore structures and have attracted wide attention on the investigation into freak-wave-induced structural responses. The offshore pipeline is a representative type of marine structure that is widely utilized for crude oil and natural gas transportation from subsea well sites to surface processing facilities. In recent years, the great demand for energy resources has facilitated the expansion of oil-gas exploitation into deepwater areas. The S-lay approach is one of most common methods of deepwater pipeline installation to the sea floor owing to its excellent adaptability and workability [3]. In this pipelay technique, numerous section pipes with designed lengths are welded and inspected on the operating lines of the vessel. The qualified pipeline is drawn by the tensioners and slides over the stinger to arrive at the seabed. The overall pipeline is characterized as an S-shaped curve and divided into two regions, as displayed in Figure 1. The upper curved section of the pipeline from the tensioner to the J. Mar. Sci. Eng. 2020, 8, 119; doi:10.3390/jmse8020119 www.mdpi.com/journal/jmse J. Mar. Sci. Eng. 2020, 8, 119 2 of 22 J. Mar. Sci. Eng.(LOP) 2020, 8,is 119 2 of 22 lift-off point denoted as the overbend, and the suspended section from the LOP to the seabed is known as the sagbend. The whole process of laying the pipeline generally takes months or even is known as the sagbend. The whole process of laying the pipeline generally takes months or even longer periods, and is more likely to encounter the occurrence of freak waves. Therefore, to assess longer periods, and is more likely to encounter the occurrence of freak waves. Therefore, to assess the influences of freak waves on the dynamic behaviors of S-laying pipelines in deep waters is highly the influences of freak waves on the dynamic behaviors of S-laying pipelines in deep waters is highly significant for the purpose of pipelay design and operation safety. significant for the purpose of pipelay design and operation safety. z Sea level Heave Sway Yaw y Freak wave Pitch Surge x o Vessel Tensioner Roll Overbend Stinger Current LOP Pipelin Sagbend TDZ TDP Seabed Figure 1. Deepwater pipeline installation by the S-lay method under exposure to freak waves. Figure 1. Deepwater pipeline installation by the S-lay method under exposure to freak waves. A reasonable wave generation method is necessary to simulate freak waves and explore their impact marine structures. A numerical is extensively due and to itsexplore convenient A on reasonable wave generation methodtechnique is necessary to simulateemployed freak waves their simulation and good repeatability. Davis and Zarnick [4] initially proposed a wave focusing method impact on marine structures. A numerical technique is extensively employed due to its convenient to simulate and freakgood waves by controlling theand focalized time space. Subsequently, al. [5] simulation repeatability. Davis Zarnick [4] and initially proposed a wave Baldock focusinget method applied the technique to accumulate numerous water waves and produce a huge transient wave group. to simulate freak waves by controlling the focalized time and space. Subsequently, Baldock et al. [5] Fochesato et technique al. [6] superposed wave trains of different to generate (3D) applied the to accumulate numerous waterdirections waves and produce three-dimensional a huge transient wave freak waves. Zhao et four focusing to generate the freak trainsthreeand group. Fochesato et al. al.[7,8] [6] presented superposed wave trainsmodels of different directions to wave generate numerically simulated the wave effect on a floating structure. Liu et al. [9] developed a modified dimensional (3D) freak waves. Zhao et al. [7,8] presented four focusing models to generate the freak phase modulation approach to focus wave trainseffect with on thea specified phase and obtained precise wave trains and numerically simulated the wave floating structure. Liu et al. [9]the developed wave spectrum that coincided well with the target results. Hu et al. [10] employed a probability-based a modified phase modulation approach to focus wave trains with the specified phase and obtained superposition method to calculate the generation of a freak wave. Tang et al. [11]a the precise wave spectrum that coincided well probability with the target results. HuRecently, et al. [10] employed improved the phase modulation model a freak wave and probability investigatedofitsa effect the probability-based superposition methodtotogenerate calculate the generation freak on wave. dynamic responses of the Floating Production Storage and Offloading (FPSO) and Single Point Mooring Recently, Tang et al. [11] improved the phase modulation model to generate a freak wave and (SPM) system. et on al. the [12]dynamic conducted extensive to observe the greatStorage differences cylinder investigated itsPan effect responses of tests the Floating Production and in Offloading motion under waves and freak waves obtained the important influencing factors. (FPSO)responses and Single Pointirregular Mooring (SPM) system. Pan etand al. [12] conducted extensive tests to observe The wave focusing and superposition techniques were demonstrated to effectively generate freak the great differences in cylinder motion responses under irregular waves and freak waveswave and trains, which a prior simulation of theThe wave impact on pipeline installation in techniques deepwater areas. obtained theprovided important influencing factors. wave focusing and superposition were Under theto excitation of surface vessel motions, laying apipelines usually exhibit demonstrated effectively generatewaves freak and wave trains, which the provided prior simulation of the sophisticated non-linear, dynamic responses. The complicated S-lay problems mainly result from large wave impact on pipeline installation in deepwater areas. pipeline deflections, pipe material plasticity, hydrodynamic loads,the and boundary interactions. These Under the excitation of surface waves and vessel motions, laying pipelines usually exhibit non-linear features could cause some difficulties for analytical approaches and experimental tests to sophisticated non-linear, dynamic responses. The complicated S-lay problems mainly result from obtain accuratedeflections, and comprehensive simulations. As ahydrodynamic consequence, numerical preferred large pipeline pipe material plasticity, loads, andtechniques boundaryare interactions. for modeling systematical of offshore pipelines for in the S-lay process [13–15]. Gong et al. [16] These non-linear features behaviors could cause some difficulties analytical approaches and experimental and Gong and Xu [17] developed a full FEM on the basis of OrcaFlex to simulate the structural behaviors tests to obtain accurate and comprehensive simulations. As a consequence, numerical techniques are of pipelinefor installation and explored the influence of normal sea states on the pipeline responses. preferred modeling systematical behaviors of offshore pipelines in the S-lay process [13–15]. Gong Ivić et [16] al. [18,19] established a pipeline laying model the on usethe of non-linear elastic beam elementsthe to et al. and Gong and Xu [17] developed a fullby FEM basis of OrcaFlex to simulate structural behaviors of pipeline installation and explored the influence of normal sea states on the pipeline responses. Ivić et al. [18,19] established a pipeline laying model by the use of non-linear elastic beam elements to analyze the static behaviors of the S-laying pipe and formulated a specialized J. Mar. Sci. Eng. 2020, 8, 119 3 of 22 analyze the static behaviors of the S-laying pipe and formulated a specialized optimization method for the pipeline laying operation. Xie et al. [20] investigated the dynamic loading history of laying pipelines in light of a test-verified FEM and confirmed obvious pipeline plastic deformations resulting from the S-lay operation. Cabrera-Miranda and Paik [21] quantified the probabilistic distribution of loads on a marine riser and observed the highly random characteristic of the loads to aid in the determination of nominal design values. Wang et al. [22] pointed out the probable underestimation of pipeline dynamic behaviors for practical engineering and built a real-time installation monitoring system to predict on-site pipeline responses. Recently, Liang et al. [23,24] presented a refined FEM to take account of the complex surface contact behaviors of overbend pipes and reproduced the pipe laying process of a deep S-lay case in the laboratory. Kim and Kim [25] employed the FEM-based linear beam element to present an efficient, linearized, dynamic analysis approach for pipeline installation design. The aforementioned studies usually adopted normal random waves as the input ocean conditions to calculate the dynamic responses of laying pipelines. The neglect of the freak wave effect could result in the inadequacy of pipeline installation design for field operation safety. The objective of this study was to thoroughly investigate the freak wave effects on the dynamic responses of offshore pipelines during deepwater S-lay installation. A new extended FEM with particular consideration of freak waves was developed on the basis of our previous model [16] for S-lay pipelines. This model took the induced vessel motions, pipe–stinger roller contacts, and pipe–seabed soil interactions into account. The real vessel, stinger roller, and seabed soil data from an actual engineering project in South China Sea were collected to obtain an accurate simulation. Furthermore, an effective superposition technique was employed to generate freak waves by combining transient wave trains and random wave trains. The insertion of various freak wave trains into the S-lay FEM was then implemented to carry out a large number of numerical analyses of a 12 inch gas pipeline being installed into a 1500 m water depth. Finally, the influences of the freak wave energy ratio coefficient, focusing location, phase range, and peak value were sufficiently assessed on the pipeline and seabed responses. The dynamic amplification factors (DAFs) of the axial tension, bending moment, von Mises stress, longitudinal strain, pipeline embedment, and seabed resistance are discussed in detail in relation to pipeline installation design and field operation safety. 2. Deepwater Pipeline Installation Simulation A reasonable FEM for S-lay system was presented by Gong et al. [16] to explore the random wave effects on the dynamic behaviors of deepwater pipeline installation. This model, developed within the framework of OrcaFlex [26], was validated with acceptable accuracy and effective applicability by an actual engineering case of S-laying pipelines. In this study, a new extension of the FEM was implemented to consider the freak waves with wave-induced pipeline behaviors, pipe–stinger roller contacts, pipe–seabed soil interaction, and pipelay vessel motions, as displayed in Figure 1. The following section presents a concise description of the main features of the deepwater pipeline installation model by the S-lay technique. 2.1. Pipeline Model In the FEM of the S-lay system, the entire pipeline, from the tensioner to the sea floor, was discretized into a sequence of mass nodes connected together by massless line segments, as displayed in Figure 2. The local xyz-frames of references for the node and line segment were established, and the mechanical properties of the pipe weight, buoyancy, drag force, and so on for each half-segment were concentrated on its adjacent node. At either side of the node, two rotational springs and dampers were employed to model the bending stiffness and damping of the line segment. At the center of the line segment, an axial spring with a damper was utilized to represent its axial stiffness and damping, and a torsional spring with a damper was applied to characterize its torsional stiffness and damping. For the detailed calculation derivation of the tension force, bending moment, and torque moment, one can refer to the literature [16], and their expressions are given by J. Mar. Sci. Eng. 2020, 8, 119 4 of 22 Te = Tw (ε) + (1 − 2ν) · (Po Ao − Pi Ai ) + EAnom · ξ · (dL/dt)/L0 J. Mar. Sci. Eng. 2020, 8, 119 (1) 4 of 22 M2 = Mb (κ2 ) + ς · (dκ2 /dt) (2) (2) (3) (3) where Te and Tw are the effective tension and wall tension relating to the axial strain; Pi and Po are the e and Tw and are the effective tension tension relatingand to the axial cross-section strain; Pi andareas; Po areνthe where Tpressure internal external pressure; Aiand andwall Ao are the internal external is internal pressure pressure; i andstiffness Ao are the internal and external areas; ν the Poisson’s ratio;and EAexternal nominalAaxial defined at zero strain; L cross-section is the instantaneous nom is the is the Poisson’s EAnom axiallength stiffness defined at zero strain; is the instantaneous length of the lineratio; segment; L0isisthe thenominal unstretched of the line segment; Mb isLthe bending moment length oftothe segment; 0 is unstretched lengthrelating of the line segment; Mb is the bending moment relating theline curvature κ2 ;LT is the torque moment to the twist angle ϕ; and the damping or the relating to the κ2; Tor isrepresent the torque moment relating to the twist angle and thedamping. damping coefficients ξ, ς curvature and ζ separately axial, bending, and torsional effects of φ; structural coefficients ξ, ς and ζ separately represent bending, andcarbon–manganese torsional effects of steel structural The oil-gas pipelines installed in deepaxial, waters comprise with adamping. distinct pipelines in deep waters comprise carbon–manganese a distinct yield The pointoil-gas and some plasticinstalled deformation capability. The pipeline material featuressteel werewith simulated by yield pointtheory and some plastic deformation The pipeline material features were simulated the J2 flow of plasticity performancecapability. with isotropic strain hardening. The Ramberg–Osgood by the [27] J2 flow of plasticity performance withstress isotropic The model wastheory applied to represent the non-linear andstrain strainhardening. relationship ofRamberg–Osgood the adoptive X65 model [27] was applied representasthe non-linear stress and strain relationship of the adoptive X65 line pipe, which could betoexpressed line pipe, which could be expressed as ε(σ) = σ/E + B(σ/σy )n n (4) ε (σ ) = σ / E + B(σ / σ y ) (4) where σy is the effective yield stress, E is the elastic modulus, and B and n are the coefficient and the where σ y is the effective yield stress, E is the elastic modulus, and B and n are the coefficient and power exponent of the constitutive model. the power exponent of the constitutive model. M 2 = M b (κ 2 ) + ς ⋅ (dκ 2 / dt ) Tt = Tor (φ/L0 ) + ζ · (dφ/dt) T t= Tor (ϕ / L0 ) + ζ ⋅ (dϕ / dt ) Segment Nx Nz α1 Sx1 Sx2 φ Sy2 Sy1 Ny Axial spring +damper Node α2 Node… Sz1 Sz2 Bending spring +damper Torsion spring + damper Segment… Figure Figure2.2. Node Node and and line line segment segment model modelof ofthe theS-lay S-laypipeline. pipeline. 2.2. Pipe–Stinger Roller Interaction 2.2. Pipe–Stinger Roller Interaction In the overbend, the sections of the pipeline were continuously supported by 10 roller boxes that In the overbend, the sections of the pipeline were continuously supported by 10 roller boxes that were regularly spaced and settled on the articulated stinger, which was 75 m in length, as illustrated were regularly spaced and settled on the articulated stinger, which was 75 m in length, as illustrated in Figure 3. The stinger with three sections of truss structure was collected from the actual design in Figure 3. The stinger with three sections of truss structure was collected from the actual design for for the Hai Yang Shi You (HYSY) 201 pipelay vessel [28]. A group of pipe segments was employed the Hai Yang Shi You (HYSY) 201 pipelay vessel [28]. A group of pipe segments was employed to to simulate the stinger’s geometrical and mechanical properties. The clashing contacts between the simulate the stinger’s geometrical and mechanical properties. The clashing contacts between the pipeline and stinger rollers would vary with the vessel motions. Before the calculation of pipe–stinger pipeline and stinger rollers would vary with the vessel motions. Before the calculation of pipe–stinger roller interactions, an inspection had to be implemented to confirm whether the pipeline was in contact roller interactions, an inspection had to be implemented to confirm whether the pipeline was in with the roller. If a mutual interaction was identified, the contact force was calculated and applied to contact with the roller. If a mutual interaction was identified, the contact force was calculated and the pipe and the roller, which was given by applied to the pipe and the roller, which was given by Fr = [1/(1/k1 + 1/k2 )] × [d − (r1 + r2 )] (5) Fr = [1 / (1 / k1 + 1 / k 2 )]× [d − (r1 + r2 )] (5) where k1 and k2 are the contact stiffness of the pipe and the roller, d is the shortest separation distance of the center lines between them, and r1 and r2 are the corresponding radii. Pipe Roller Roller box J. Mar. Sci. Eng. 2020, 8, 119 5 of 22 (a) where k1Eng. and2020, k2 are the J. Mar. Sci. 8, 119 contact stiffness of the pipe and the roller, d is the shortest separation distance 5 of 22 of the center lines between them, and r1 and r2 are the corresponding radii. (b) Pipe diagram of the deepwater S-lay stinger: (a) Pipe–roller interaction; (b) articulated Figure 3. Schematic stinger of the Hai Yang Shi You (HYSY) 201 vessel. Roller 2.3. Pipe–Seabed Soil Interaction Roller box At the touchdown zone (TDZ), the laying pipeline was freely supported by the seabed soil, (a) which was liable to be trenched and remolded under dynamic installation in deep waters. In the vertical plane, the dynamic features of the cyclic pipe–seabed interactions were simulated by a nonlinear hysteretic soil model with hyperbolic secant stiffness formulations [29], as shown in Figure 4. (b) In this model, four types of pipe–soil penetration modes were applied to characterize the cyclic variations of the pipeline periodic embedment into the seabed. For the not-in-contact pattern, the Figure 3. Schematic diagram of the deepwater S-lay stinger: (a) Pipe–roller interaction; (b) articulated seabed resistance P(z) is naturally zero. For other three patterns, including initial penetration, uplift, Figure 3. Schematic diagram of the deepwater S-lay stinger: (a) Pipe–roller interaction; (b) articulated stinger of the Hai Yang Shi You (HYSY) 201 vessel. and repenetration, the relationships between the seabed resistance P(z) and the penetration z nonstinger of the Hai Yang Shi You (HYSY) 201 vessel. linearly vary in hysteretic cycles with the incessant shift of the penetration modes. 2.3. Pipe–Seabed Soil Interaction In another Soil view of the horizontal plane, the lateral and axial pipe–seabed interactions were 2.3. Pipe–Seabed Interaction At theby touchdown zoneCoulomb (TDZ), the layingmodel, pipeline was freely supported by the seabed soil, simulated the modified friction which expressed the lateral resistance andwhich axial At thetotouchdown zoneremolded (TDZ), the laying pipeline was freely supported by thevertical seabedplane, soil, was liable be trenched and under dynamic installation in deep waters. In the friction force with the deflection as a bilinear equation, as illustrated in Figure 5. When the lateral which was liable to be trenched and remolded under dynamic installation in deep waters. In the the dynamic features of the cyclic pipe–seabed interactions were simulated by a non-linear hysteretic displacement y varies from −ybreakout to +ybreakout, the linear friction force is given by Fy = −ks Ay , in vertical plane, thehyperbolic dynamic features of the cyclic pipe–seabed simulated by model, a nonsoil model with secant stiffness formulations [29],interactions as shown inwere Figure 4. In this s refers to the seabed shear stiffness and A represents the contact area. When the lateral which k linear hysteretic soil model with hyperbolic secant stiffness [29],cyclic as shown in Figure 4. four types of pipe–soil penetration modes were applied to formulations characterize the variations of the displacement y four exceeds theof range between −ybreakout and +ybreakout , the frictiontoforce of the pipe is cyclic equal In this model, types pipe–soil penetration modes were applied characterize the pipeline periodic embedment into the seabed. For the not-in-contact pattern, the seabed resistance P(z) to μP(z) , where is the vertical seabed resistance andseabed. μ is the For soil the friction coefficient.pattern, This model variations the P(z) pipeline embedment into initial the not-in-contact is naturallyofzero. For otherperiodic three patterns, including penetration, uplift, and repenetration, the the could effectively avoid the discontinuous nature of the friction force at zero lateral displacement and seabed resistance P(z) is naturally zero. For other three including initial penetration, uplift, relationships between the seabed resistance P(z) and thepatterns, penetration z non-linearly vary in hysteretic was conveniently implemented the numerical program [30]. and repenetration, the relationships between themodes. seabed resistance P(z) and the penetration z noncycles with the incessant shift ofin the penetration linearly vary in hysteretic cycles with the incessant shift of the penetration modes. P(z) Ultimate In another view of the horizontal plane, thepenetration lateral and axial pipe–seabed interactions were resistance, Pu simulated by the modified Coulomb friction model, which expressed the lateral resistance and axial (1) Initial friction force with the deflectionpenetration as a bilinear equation, as illustrated in Figure 5. When the lateral displacement y varies from −ybreakout to +ybreakout, the linear friction force is given by Fy = −ks Ay , in stiffness and A represents the contact area. When the lateral which ks refers to the seabed shear (5) Repenetration (2) Uplift following lift-off displacement y exceeds the range between −ybreakout and +ybreakout, the friction force of the pipe is equal to μP(z) , where P(z) is the vertical seabed resistance and μ is the soil friction coefficient. This model O z (4) Suction releases could effectively avoid the discontinuous nature (3) Suction decays of the friction force at zero lateral displacement and with repentration was conveniently implemented in the numerical program [30]. P(z) Ultimate penetration Ultimate suction Pu resistance,resistance, Pu-suc (1) Initial penetration Figure Figure 4. 4. Non-linear Non-linear hysteretic hysteretic seabed seabed soil soil model model [29]. [29]. In another view of the horizontal plane, the lateral and axial pipe–seabed interactions were (5) Repenetration (2) Uplift simulated by the modified Coulombfollowing frictionlift-off model, which expressed the lateral resistance and axial friction force with the deflection as a bilinear equation, as illustrated in Figure 5. When the lateral z (4) Suction releases displacement y varies fromO−ybreakout to +ydecays breakout , the linear friction force is given by Fy = −ks Ay, (3) Suction with repentration in which ks refers to the seabed shear stiffness and A represents the contact area. When the lateral displacement y exceeds the range between −ybreakout and +ybreakout , the friction force of the pipe is equal Ultimate suction to µP(z), where P(z) is the vertical seabed resistance and µ is the soil friction coefficient. This model resistance, Pu-suc could effectively avoid the discontinuous nature of the friction force at zero lateral displacement and Figure in 4. Non-linear hysteretic seabed soil model [29]. was conveniently implemented the numerical program [30]. J. Mar. Mar. Sci. Sci. Eng. Eng. 2020, 2020, 8, 8, 119 119 J. J. Mar. Sci. Eng. 2020, 8, 119 of 22 22 66 of 6 of 22 Fy Fy μP(z) μP(z) -ybreakout -ybreakout o o ybreakout ybreakout y y -μP(z) -μP(z) Figure 5. Modified Coulomb friction model. Figure 5. Modified Modified Coulomb friction model. 5 5 5 5 4 4 4 4 Pitch ( deg Pitch ( deg ) ) Surge Surge ( m()m) 2.4. 2.4. Pipelay Pipelay Vessel Vessel Motions Motions 2.4. Pipelay Vessel Motions According According to to the the geometrical geometrical features features of of the the HYSY HYSY 201 201 vessel, vessel, aa pipelay pipelay vessel vessel model model was was built built According to the geometrical features of the HYSY 201 vessel, a pipelay vessel model was built with a length length of of 204.65 204.65 m m and and breadth breadth of of 39.2 39.2 m. m. The with a The wave wave frequency frequency motion motion of of the the vessel vessel was was with a length of 204.65 m and breadth of 39.2 m. The wave frequency motion of the vessel was simulated simulated by by use use of of the the displacement displacement response response amplitude amplitude operators operators (RAOs), (RAOs), which which define define the the vessel vessel simulated by use of the displacement response amplitude operators (RAOs), which define the vessel motion motion responses responses for for each each degree degree of of freedom freedom (DoF) (DoF) to to one one specified specified wave wave direction direction and and wave waveperiod. period. motion responses for each degree of freedom (DoF) to one specified wave direction and wave period. Considering heave, roll, pitch, and Considering the the six six DoFs DoFs of of vessel vessel motions motions (surge, (surge, sway, sway, heave, roll, pitch, and yaw), yaw), the the motion motion Considering the six DoFs of vessel motions (surge, sway, heave, roll, pitch, and yaw), the motion response response spectra spectra of of the the vessel vessel at at the the stinger stinger base base were were derived derived in in light light of of the the RAOs RAOs of of the the HYSY HYSY 201 201 response spectra of the vessel at the stinger base were derived in light of the RAOs of the HYSY 201 vessel, as illustrated in Figure 6. Almost all six DoFs of the vessel motion responses were vessel, as illustrated in Figure 6. Almost all six DoFs of the vessel motion responses were greatly greatly vessel, as illustrated in Figure 6. Almost all six DoFs of the vessel motion responses were greatly noticeable motion was was comparatively comparatively remarkable noticeable for for the the quartering quartering seas, seas, in in which which the the heave heave motion remarkable for for all all noticeable for the quartering seas, in which the heave motion was comparatively remarkable for all seas. It is noted that the slow drift motion of the vessel was restrained to be very small by the seas. It is noted that the slow drift motion of the vessel was restrained to be very small by the advanced seas. It is noted that the slow drift motion of the vessel was restrained to be very small by the advanced dynamic positioning [31], sotaken it was notconsideration taken into consideration in the following dynamic positioning system [31],system so it was not into in the following analyses due advanced dynamic positioning system [31], so it was not taken into consideration in the following analyses due to its small effect on the pipeline dynamic behaviors. to its small effect on the pipeline dynamic behaviors. analyses due to its small effect on the pipeline dynamic behaviors. 3 3 Quartering Quartering 2 2 1 1 5 5 Head/stern Head/stern 2 3 4 Wave 2 height(m) 3 4 Wave height(m) Head/stern Head/stern 1 1 5 5 2 3 2 height(m) 3 Wave Wave height(m) 4 4 5 5 4 4 Roll ( deg Roll ( deg ) ) Sway Sway ( m()m) 2 2 0 00 0 5 5 4 4 3 3 Quartering Quartering 2 2 1 1 0 00 0 Quartering Quartering 1 1 1 1 0 00 0 3 3 2 3 Wave 2 height(m) 3 Wave height(m) 4 4 2 2 1 1 Beam Beam 1 1 Beam Beam 3 3 5 5 0 00 0 Figure 6. Cont. 1 1 Quartering Quartering 2 3 4 2 height(m) 3 4 Wave Wave height(m) 5 5 J. Mar. Sci. Eng. 2020, 8, 119 J. Mar. Sci. Eng. 2020, 8, 119 7 of 22 7 of 22 5 10 4 8 Yaw( deg) Heave( m) Quartering 6 Beam 4 2 0 3 2 1 Head/stern 0 0 1 2 3 Wave height(m) Quartering 4 5 0 1 2 3 Wave height(m) 4 5 Figure 6. 6. Motion Motion response response spectra spectra of of the the HYSY HYSY 201 201 pipelay pipelay vessel vessel at at the the stinger stinger base. Figure base. 3. Freak Wave Generation 3. Freak Wave Generation Based on a large amount of ocean observations and laboratory tests, a great many generation Based on a large amount of ocean observations and laboratory tests, a great many generation models of freak waves have been developed to investigate the phenomenon of rogue wave impact [32,33]. models of freak waves have been developed to investigate the phenomenon of rogue wave impact In contrast with the non-linear model, the linear superposition model is simply understood by offshore [32,33]. In contrast with the non-linear model, the linear superposition model is simply understood structure engineers and can be rapidly simulated by researchers. It is also noted that during deepwater by offshore structure engineers and can be rapidly simulated by researchers. It is also noted that installation, the pipeline usually experiences large tension forces of the tensioners, and the influence during deepwater installation, the pipeline usually experiences large tension forces of the tensioners, of hydrodynamic forces induced by non-linear wave factors is very small. A time history train of and the influence of hydrodynamic forces induced by non-linear wave factors is very small. A time freak waves must be inserted into the developed installation FEM for the dynamic analysis of an S-lay history train of freak waves must be inserted into the developed installation FEM for the dynamic pipeline. Therefore, the linear superposition technique was employed to generate the freak wave trains. analysis of an S-lay pipeline. Therefore, the linear superposition technique was employed to generate the trains. Approach 3.1. freak Linearwave Superposition In theSuperposition linear superposition 3.1. Linear Approach method, freak waves are described as a combination of transient wave trains with random wave trains for different energy proportions. The transient waves were In the linear superposition method, freak waves are described as a combination of transient simulated by the wave focusing model which converges the wave energy of a certain number of wave wave trains with random wave trains for different energy proportions. The transient waves were components at a specified position at the assigned time. The random waves were deemed to be a simulated by the wave focusing model which converges the wave energy of a certain number of wave stationary stochastic process of dispersed energy. The standard JONSWAP spectrum was employed to components at a specified position at the assigned time. The random waves were deemed to be a represent the random sea states in the South China Sea. The generation formula of freak waves can be stationary stochastic process of dispersed energy. The standard JONSWAP spectrum was employed expressed as to represent the random sea states in the South China Sea. The generation formula of freak waves can 12 21 N Z N Z fi X be expressed asX fi η(x, t) = Ep1 2S( f )d f cos[ki (x − xp ) − ωi (t − tp )] + Ep2 2S( f )d f cos[ki x − ωi t + φi ] (6) i=1 fi−1 N 1 2 i= N 1 fi−1 1 2 η ( x, t ) = Ep1 2S ( f )df cos[k i ( x − xp ) − ωi (t − t p )] + Ep 2 2S ( f )df cos[k i x − ωi t + ϕ i ] fi fi (6) f f 1 i =1 where Ep1 and Ep2 are the energy ratio coefficients of transienti=waves and random waves; the spectral h i densityEfunction S(the f) = αg2 /(ratio 16π4coefficients f 5 ) exp −1.25 (transient f / fm )−4 waves γβ ; α isand the random spectralwaves; energythe coefficient; p1 and Ep2is are energy of spectral where h i 2 −4 2β 2 2 4 5 S ( f ) = α g /( 16 π f ) exp − 1 . 25 ( f / f ) γ ; α is the spectral energy coefficient; density function is ( ) and g is the gravitational constant. β = exp − f − fm m/ 2τ fm , in which τ is the spectral width 2 parameter; is the peak constant. frequency;βγ=isexp the− peak N is thethe number of width wave ( f − fenhancement 2τ 2 f m2 , factor; and g is thef m gravitational in which τ is spectral m) components; ki , ωi , and φi are the wave number, angular frequency, and phase lag of the ith wave parameter; fm is the peak frequency; γ is the peak enhancement factor; N is the number of wave component; and xp and tp are two constants separately representing the focusing position and time of components; ki , ωi , and ϕi are the wave number, angular frequency, and phase lag of the ith wave transient waves. component; and xp and tp are two constants separately representing the focusing position and time of waves. 3.2.transient Case Study i −1 i −1 [ [ ( ] )] Before the generation of freak waves, there should be a clear mathematical definition. The popularly 3.2. Case Study acceptable criterion for freak waves was adopted in this study, which defines the maximum wave Before generation freak waves, there should be Based a clearupon mathematical height to be the more than two of times its significant wave height. the ocean definition. statistics inThe the popularly acceptable criterion for freak waves was adopted in this study, which defines the South China Sea, the significant wave height, Hs = 2.0 m, and the peak period, Tp = 8.7 s, were maximum wave height to bespectrum, more thanastwo times itsinsignificant height. Based peak uponfrequency, the ocean specified for the JONSWAP illustrated Figure 7. wave The corresponding statistics in the South China Sea, the significant wave height, H s = 2.0 m, and the peak period, Tp peak = 8.7 fm = 0.115 Hz, and the spectral energy coefficient, α = 0.002, were calculated along with the s, were specified for the JONSWAP spectrum, as illustrated in Figure 7. The corresponding peak frequency, fm = 0.115 Hz, and the spectral energy coefficient, α = 0.002, were calculated along with the 2 S( f ) (m /Hz) trains were set as Ep1 = 0.4 and Ep2 = 0.6, and the distribution range φ of the phase lag was taken as 1.1π. The wave focusing time and position were set at tp = 1000 s and xp = 0 m. Figure 8 illustrates a part of the time history trains of generated freak waves, and the beginning simulation time point was shifted to 750 s with the duration of 500 s so as to cover the maximum wave height in the globe time J. Mar. Mar. Sci. Sci. Eng. Eng. 2020, 119 of 22 22 It can be8,8,observed that the freak wave amplitude suddenly surged to a great wave crest of J.domain. 2020, 119 88 of 5.1 m at the focusing time of 1000 s. The maximum wave height attained 7.8 m, which is 3.9 times peak factor, γ wave = 3.3. Besides, the spectral width parameter was varied with the largerenhancement than its significant height. The wave time history trainsσ properly reflect the value basic enhancement factor, γ = 3.3. Besides, the spectral width parameter σ was varied with the value of of wave frequency. If f ≤ f m , τ = 0.07; otherwise, f > f m , τ = 0.09. characteristic of freak waves in the ocean sea and satisfy the wave amplitude criterion for its wave frequency. If f ≤ fm , τ = 0.07; otherwise, f > fm , τ = 0.09. The selected wave spectrum was discretized into 900 components by use of the equal energy definition. approach. These wave components were then gathered in the numerical flume to constitute a 8 sequence of transient wave trains and random wave trains. The energy proportions for both wave Hs=2.0 m trains were set as Ep1 = 0.4 and Ep2 = 0.6, and the distribution range φ of the phase lag was taken as T = 8.7 s 6 1.1π. The wave focusing time and position were set at tp =p 1000 s and xp = 0 m. Figure 8 illustrates a part of the time history trains of generated freak waves, and the beginning simulation time point was 4 of 500 s so as to cover the maximum wave height in the globe time shifted to 750 s with the duration domain. It can be observed that the freak wave amplitude suddenly surged to a great wave crest of 5.1 m at the focusing time of 1000 2 s. The maximum wave height attained 7.8 m, which is 3.9 times larger than its significant wave height. The wave time history trains properly reflect the basic characteristic of freak waves in the ocean sea and satisfy the wave amplitude criterion for its 0 definition. 0.0 0.1 0.2 0.3 0.4 f (Hz) 8 Figure 7. JONSWAP spectrumHfor Hs = 2.0 m. s=2.0Hm Figure 7. JONSWAP spectrum for s = 2.0 m. T = 8.7 s η (m) 2 S( f ) (m /Hz) 6 p components by use of the equal energy The selected wave spectrum was discretized into 900 6 approach. These wave components were then gathered in the numerical flume to constitute a sequence 4 of transient wave trains and random wave trains. The energy proportions for both wave trains were set as Ep1 = 0.4 and Ep2 = 0.6, and the distribution range ϕ of the phase lag was taken as 1.1π. The wave 3 2 set at tp = 1000 s and xp = 0 m. Figure 8 illustrates a part of the time focusing time and position were history trains of generated freak waves, and the beginning simulation time point was shifted to 750 s with the duration of 500 s so as to cover the maximum wave height in the globe time domain. It can be 0 0.0 0.1 0.2 0.4 crest of 5.1 m at the focusing observed that the freak wave 0amplitude suddenly surged to a0.3great wave f (Hz) time of 1000 s. The maximum wave height attained 7.8 m, which is 3.9 times larger than its significant wave height. The wave time history trains properly reflect the basic characteristic of freak waves in the Figure 7. JONSWAP spectrum for Hs = 2.0 m. -3 amplitude criterion for its definition. ocean sea and satisfy the wave 750 800 900 1000 t (s) 1100 1200 1250 6 Figure 8. Time history trains of the freak wave. 3 η (m) 3.3. Sensitive Analysis The time history trains of freak waves are crucial for the investigation into their effects on the dynamic behaviors of S-laying pipelines. The sensitive analyses of generation factors for the freak 0 wave train must be conducted. Four input parameters, including the wave energy ratio coefficient, focusing position, phase range, and peak value, were selected for the wave simulation by the linear superposition technique. Plenty of freak wave trains were obtained, and a group of represented trains -3 800 900in Figure 1000 9. 1100 1200 differences 1250 750illustrated with the duration of 500 s are Significant in the wave crest and t (s) wave trough at the middle time were observed under different initial conditions. Figure 8. Time history trains of the freak wave. Figure 8. Time history trains of the freak wave. 3.3. Sensitive Analysis 3.3. Sensitive Analysis The time history trains of freak waves are crucial for the investigation into their effects on the The historyoftrains of freak wavesThe are sensitive crucial for the investigation intofactors their effects the dynamic time behaviors S-laying pipelines. analyses of generation for theonfreak dynamic behaviors of S-laying pipelines. The sensitive analyses of generation factors for the freak wave train must be conducted. Four input parameters, including the wave energy ratio coefficient, wave train must bephase conducted. inputvalue, parameters, including ratiobycoefficient, focusing position, range, Four and peak were selected for the the wave wave energy simulation the linear focusing position, phase range, and peak value, were selected for the wave simulation by the linear superposition technique. Plenty of freak wave trains were obtained, and a group of represented trains superposition technique. of freak in wave trains were obtained, and a group represented with the duration of 500 sPlenty are illustrated Figure 9. Significant differences in the of wave crest andtrains wave with the duration of 500 s are illustrated in Figure 9. Significant differences in the wave crest and trough at the middle time were observed under different initial conditions. wave trough at the middle time were observed under different initial conditions. J.J.Mar. Mar.Sci. Sci.Eng. Eng.2020, 2020,8, 8,119 119 J. Mar. Sci. Eng. 2020, 8, 119 9 9ofof2222 9 of 22 -6 6 0 Ep1=0.35 Ep1=0.35 η (m) η (m) 6 -6 6 0 0 -6 6 -6 6 0 0 -6 -6 6 6 0 0 -6 -6 0 Ep1=0.40 Ep1=0.40 ηη (m) (m) 0 6 60 0 -6 -66 60 Ep1=0.30 Ep1=0.30 6 Ep1=0.45 Ep1=0.45 0 100 100 200 300 200 t (s) 300 t (s) 400 400 500 500 0 -6 -66 6 0 0 -6 -66 6 0 0 -6 -66 6 0 0 -6 -6 0 0 xp=-200 m xp=-200 m xp=-100 m xp=-100 m xp=0 m m xp=0 xp=100 m m xp=100 xp=200 m xp=200 m 100 100 (a) (a) ϕϕ=1.0 =1.0ππ ϕϕ=1.2 =1.2ππ ηη (m) (m) ϕϕ=1.1 =1.1ππ ϕϕ=1.3 =1.3ππ =1.4ππ ϕϕ=1.4 100 100 400 400 500 500 (b) (b) η (m) η (m) 66 00 -6 -6 66 00 -6 -6 66 00 -6 -6 66 00 -6 -6 66 00 -6 -6 00 200 300 200 t (s) 300 t (s) 200 300 200 (s) 300 t t(s) 400 400 500 500 66 00 -6 -6 66 00 -6 -6 66 0 -6 6 0 -6 6 0 -6 =3.6mm ηη =3.6 p p =4.1mm ηη =4.1 pp =4.6mm ηη =4.6 pp =5.1mm ηη =5.1 pp ηη =5.6 =5.6mm pp 0 100 100 (c) (c) 200 200 t t(s) 300 (s) 300 400 400 500 500 (d) (d) Figure 9.Time Time history trains of freak freak waves under different input (a) energy ratio Figure 9.9.Time history trains of freak waveswaves underunder different input conditions: (a) energy coefficient; Figure history trains of different input conditions: conditions: (a)ratio energy ratio coefficient; (b) focusing position; (c) phase range; (d) wave peak value. (b) focusing (b) position; (c) position; phase range; (d) wave peak coefficient; focusing (c) phase range; (d) value. wave peak value. Figure displays the maximum wave heights of freak wave trains with ofofinitial the Figure 101010 displays the maximum wave heights of freak wave trains with the the variation of the Figure displays the maximum wave heights of freak wave trains with thevariation variation the initial input parameters. It can be seen that the maximum wave height linearly increases with the input parameters. It can be seen that the maximum wave height linearly increases with the increase initial input parameters. It can be seen that the maximum wave height linearly increases with theof increase theenergy energyratio ratio coefficientEEp1p1,, which which denotes energy of transient wave the energyofof ratio coefficient Ecoefficient thedenotes energy the proportion of the transient in the freak increase the the energyproportion proportion ofthe thewave transient wave p1 , which denotes in the freak wave trains. When the focusing location occurred from the distance x p = −200 m to xp = wave Whentrains. the focusing location occurred from the distance xp distance = −200 mxpto= x−200 in thetrains. freak wave When the focusing location occurred from the m tom,xpthe = p = 200 200 m, the maximum wave height firstly augmented and then reduced, and the attained crest value attained maximum heightwave firstlyheight augmented then reduced, and the crest value 7.86 m at the 200 m, thewave maximum firstly and augmented and then reduced, and the crest value attained 7.86 m at the point xp = 0 m. As the phase range added from 1.0π to 1.4π, the maximum wave height point xpat=the 0 m. As xthe added fromadded 1.0π to 1.4π, thetomaximum wave height gradually 7.86 m point p = phase 0 m. Asrange the phase range from 1.0π 1.4π, the maximum wave height gradually decreased. Oppositely, along with the augmentation of the wave peak value from 3.6 to 5.6 decreased. Oppositely, along with the augmentation of the wave peak value to 5.6 the gradually decreased. Oppositely, along with the augmentation of the wave peakfrom value3.6 from 3.6 m, to 5.6 m, the maximum wave height linearly magnified. maximum wave height magnified. m, the maximum wave linearly height linearly magnified. Hmax (m) Hmax (m) 10 (b) 10 8 (b) 86 64 4 -200 -200 -100 -100 Ep1 Ep1 0 x0p(m) xp(m) 0.40 0.40 0.45 0.45 100 100 200 200 Hmax (m) Hmax (m) 0.35 0.35 10 (c) 10 (c) 8 8 6 6 4 41.0 1.0 10 (d) 10 (d) 8 8 6 6 4 43.6 3.6 Hmax Hmax (m)(m) Hmax (m) Hmax (m) 10 (a) 10 (a) 8 8 6 6 4 4 0.30 0.30 1.1 1.1 4.0 4.0 1.2 1.2 ϕ (π) ϕ (π) 4.4 4.8 4.4η (m) 4.8 η (m) 1.3 1.3 5.2 5.2 1.4 1.4 5.6 5.6 Figure 10. Variation of the maximum freak wave height with different input conditions: (a) energy Figure the wave height with different input conditions: conditions:(a) (a)energy energy Figure 10. Variation Variation of the maximum maximum freak input ratio 10. coefficient; (b)of focusing position;freak (c) phase range; (d)with wavedifferent peak value. ratio value. ratiocoefficient; coefficient;(b) (b)focusing focusingposition; position; (c) (c) phase phase range; range; (d) wave peak value. J. Mar. Sci. Eng. 2020, 8, 119 J. Mar. Sci. Eng. 2020, 8, 119 J. Mar. Sci. Eng. 2020, 8, 119 10 of 22 10 of 22 10 of 22 4. Numerical Numerical Implementation Implementation of of Pipeline Pipeline Installation Installation under under Freak Freak Waves Waves 4. 4. Numerical Implementation of Pipeline Installation under Freak Waves 4.1. 4.1. Pipelay Pipelay Parameters Parameters 4.1. Pipelay Parameters According According to to aa practical practical engineering engineering case, case, aa 12 12 inch inch pipeline pipeline was was installed installed into into aa water water depth depth of of 1500 m in the Liwan3-1 (LW3-1) gas field in the South China Sea. The laying pipeline parameters listed According to a practical engineering case, a 12 inch pipeline was installed into a water depth of 1500 m in the Liwan3-1 (LW3-1) gas field in the South China Sea. The laying pipeline parameters in Table 1Table were adopted, which included thein outer diameter D, wall t’thickness steel pipe ρp , 1500 minin the Liwan3-1 (LW3-1) gas field the the South China Sea.thickness The laying p , pipeline listed 1 were adopted, which included outer diameter D, wall t’pparameters ,density steel pipe elastic modulus Poisson’s ratio v, effective yield stress σyyield , thickness density oft’the corrosion listed in 1E,were adopted, which included the outer diameter thickness p, steel pipe density ρTable p, elastic modulus E, Poisson’s ratio v, effective stresstD, σc yand , wall thickness tρc cand density ρc of coatings, weight per unit length in air w , and submerged weight per unit length w . density ρ p , elastic modulus E, Poisson’s ratio v, effective yield stress σ y , thickness t c and density ρ a the corrosion coatings, weight per unit length in air wa, and submerged weight pers unit length wsc. of the corrosion coatings, weight per unit length in air wa, and submerged weight per unit length ws. Table Table1.1. Laying Laying pipeline pipelineparameters. parameters. Table 1. Laying pipeline parameters. 3 D (MPa) ttcc (mm) (mm) ρρcc (kg/m (kg/m33)) w D(mm) (mm) t’t’p p(mm) (mm) ρpρp(kg/m (kg/m)3) EE(MPa) (MPa) vv σσyy (MPa) waa (N/m) (N/m) w wss (N/m) (N/m) 3 3 5 5 D323.9 (mm) t’p23.8 (mm) ρp 7850 (kg/m E (MPa) σy (MPa) tc (mm) ρc (kg/m (N/m) ws917.2 (N/m) v 323.9 23.8 7850 ) 2.07 2.07 0.3 448 3.0 950 ) wa1754.9 1754.9 917.2 448 3.0 950 ×× 1010 0.3 323.9 23.8 7850 2.07 × 105 0.3 448 3.0 950 1754.9 917.2 X65material materialgrade grade was used forsteel the pipe, steel whose pipe, stress–strain whose stress–strain relationship curve is X65 was used for the relationship curve is displayed X65 material grade was used for the steel pipe, whose stress–strain relationship curve is displayed in Figure 11 on the basis of the Ramberg–Osgood model. The non-linear relationship in Figure 11 on the basis of the Ramberg–Osgood model. The non-linear relationship between the displayed in bending Figure 11moment on the and basiscurvature of the Ramberg–Osgood model.inThe non-linear between the of the steel pipe shown Figure 12 was relationship obtained by bending moment and curvature of the steel pipe shown in Figure 12 was obtained by use of the between the bending moment and curvature of the steel pipe shown in Figure 12 was obtained by use of the hysteretic bending model, which gave a precise simulation of the bending state of the hysteretic bending model, which gave a precise simulation of the bending state of the overbend pipeline use of the pipeline hysteretic bending model, whichcontacts gave a precise simulation overbend under the cyclic clashing with stinger rollers.of the bending state of the under the cyclic clashing contacts with stinger rollers. overbend pipeline under the cyclic clashing contacts with stinger rollers. 500 500 400 σ (MPa ) ) σ (MPa 400 σy=448 MPa σB=0.0028 =448 MPa y 300 300 200 n=11.3 B=0.0028 200 n=11.3 100 100 0 0.0 0 0.0 0.2 0.4 0.6 0.4 ε (%) 0.6 ε (%) 0.2 0.8 0.8 1.0 1.0 Figure 11. Stress–strain curve for the Ramberg–Osgood model. Figure 11. Stress–strain curve for the Ramberg–Osgood model. Figure 11. Stress–strain curve for the Ramberg–Osgood model. M M O O κ κ Figure Figure 12. 12. Non-linear Non-linear hysteretic hysteretic moment–curvature moment–curvature relationship. relationship. Figure 12. Non-linear hysteretic moment–curvature relationship. The vertical distribution distributionofofthe the current speed among various water depths is illustrated in The vertical current speed among various water depths is illustrated in Figure ◦ Figure 13vertical inoflight of themeasurement. fieldofmeasurement. The current direction 0 with in line with the the current among various depths isline illustrated Figure 13 inThe light thedistribution field Thespeed current direction waswater set was as 0°set inas thein pipelay pipelay heading. The ocean current was considered as a two-dimensional steady flow in the vertical 13 in lightThe of the field measurement. The current direction was set as 0°flow in line with the pipelay heading. ocean current was considered as a two-dimensional steady in the vertical plane. plane. TheThe hydrodynamic calculated bytwo-dimensional means Morison’s equation [34] and are given given by heading. ocean current waswere considered as ameans steady flow[34] in the vertical plane. The hydrodynamic loadsloads were calculated by of of Morison’s equation and are by (∆ · aw + Ca · ∆loads Fd =hydrodynamic · ar ) +were 0.5 · Ccalculated · ρw · A · vby ∆ is the mass of fluid[34] displaced bygiven the pipe, |, in which r |vrmeans D The of Morison’s equation and are by Fd = (Δ ⋅ a w + C a ⋅ Δ ⋅ a r ) + 0.5 ⋅ C D ⋅ ρ w ⋅ A ⋅ vr vr , in which Δ is the mass of fluid displaced by the F ⋅ a + C ⋅ Δ ⋅ a r ) + 0.5 ⋅ C D ⋅ ρrelative vr the , in which Δ is the mass of fluid displaced by the d = (Δ w ⋅ A ⋅ v r to αw isw the afluid acceleration earth, Ca is the added mass factor, αr is the fluid pipe, pipe, αw is the fluid acceleration relative to the earth, Ca is the added mass factor, αr is the fluid J. Mar. Sci. Eng. 2020, 8, 119 11 of 22 J. Mar. Sci. Eng. 2020, 8, 119 11 of 22 αw is the fluid acceleration relative to the earth, Ca is the added mass factor, αr is the fluid acceleration acceleration relative the pipe, CD is the drag coefficient, ρw is the density of sea water, A is the drag relative to the pipe, Cto D is the drag coefficient, ρw is the density of sea water, A is the drag area, and νr area, and ν r is the fluid velocity relative to the pipe. For the hydrodynamic calculation, Ca was taken is the fluid velocity relative to the pipe. For the hydrodynamic calculation, Ca was taken as 1.0, and the as andaxial the and CD the for normal the axial and thewas normal directions wasand assumed to be 0.024 and 1.2, CD 1.0, for the directions assumed to be 0.024 1.2, respectively. respectively. 0 d (m) -300 -600 -900 -1200 -1500 0.0 0.2 0.4 0.6 vc (m/s) 0.8 1.0 Figure 13. Current speed distribution with various water depths. Figure 13. Current speed distribution with various water depths. With regard to the non-linear hysteretic soil model applied in this study, a group of seabed soil With regard to the non-linear hysteretic soil model applied in this study, a group of seabed soil parameters was selected to describe the basic features of soft clay in the deep water, as listed in parameters was selected to describe the basic features of soft clay in the deep water, as listed in Table Table 2. The ultimate penetration resistance Pu (z) and the nominal bearing capacity factor Nc (z/D) are 2. The ultimate penetration resistance Pu(z) and the nominal bearing capacity factor N c ( z D) are non-linearly related to the penetration z and are given by [29] non-linearly related to the penetration z and are given by [29] PuP(z()z)== N ·D Nc ((z/D z D))⋅·SSu( (zz) )⋅ D (7) (7) b NN c (cz/D ( z D))= = aa ⋅·((zz/D D) b) (8) (8) u c u where the in which which S isthe themudline mudline shear shear ugzz,, in ) =SSu0u 0 + + SSug Su0 u0 is where the soil soil undrained undrainedshear shearstrength strengthrefers referstotoSuS(zu )( z= strength and Sug is the shear strength gradient, and a and b are the non-dimensional penetration factors. strength and Sug is the shear strength gradient, and a and b are the non-dimensional penetration The saturated soil density ρsoil and normalized maximum stiffness Kmax were taken for the soft clay; factors. The saturated soil density ρsoil and normalized maximum stiffness Kmax were taken for the soft other soil model parameters for different penetration patterns were specified as the defaults, including clay; other soil model parameters for different penetration patterns were specified as the defaults, the suction ratio f suc and the decay factor λsuc , repenetration coefficient λrep and soil buoyancy factor f b . including the suction ratio fsuc and the decay factor λsuc, repenetration coefficient λrep and soil In addition, the seabed soil friction coefficient µ and shear stiffness ks were adopted for the simulation buoyancy factor fb. In addition, the seabed soil friction coefficient μ and shear stiffness ks were of axial and lateral pipe–seabed interactions [35]. adopted for the simulation of axial and lateral pipe–seabed interactions [35]. Table 2. Seabed soil model parameters. Table 2. Seabed soil model parameters. Su0 (kPa) Su0 (kPa) 1.51.5 Sug (kPa/m) Sug (kPa/m) 1.51.5 ρsoil (t/m3 ) 3 a b K f ρsoil (t/m ) Kmax suc fsuc a b max 1.51.5 6.06.0 0.25 200 0.25 200 0.6 0.6 λsuc λsuc 1.0 1.0 λ λrep rep 0.3 0.3 f µ k (kN/m3 ) s 3) fb b ks (kN/m μ 1.5 0.55 33.3 1.5 0.55 33.3 Calcultion Method Method 4.2. Calcultion calculation of of laying pipeline pipeline responses responses induced induced by freak waves contained two The dynamic calculation modules: one one was was the the S-lay S-lay model model and and another another was was the the freak freak wave wave train. train. Firstly, Firstly, a global global S-lay model atat a water depth of 1500 m. m. This model comprised the with the the framework frameworkof ofOrcaFlex OrcaFlexwas wasestablished established a water depth of 1500 This model comprised pipelay vessel, tensioner, stinger, pipeline, and seabed. UnderUnder the combined actionsactions of self-weight, the pipelay vessel, tensioner, stinger, pipeline, and seabed. the combined of selfbuoyancy, and internal the equilibrium positions of the laying pipeline from the tensioner on the weight, buoyancy, andforces, internal forces, the equilibrium positions of the laying pipeline from vessel via on thethe stinger to the weretoinitially determined by utilization of theby catenary technique. tensioner vessel via seabed the stinger the seabed were initially determined utilization of the Subsequently, the hysteretic bending stiffness and the clashing mutual contacts of pipe-stinger rollers catenary technique. Subsequently, the hysteretic bending stiffness and the clashing mutual contacts were further taken intowere account to obtain equilibrium configurations of the pipeline. The final of pipe-stinger rollers further taken the intofull account to obtain the full equilibrium configurations of static results The of the S-lay system were taken as the initial values of as thethe dynamic simulation. the pipeline. final static results of the S-lay system were taken initial values of the dynamic simulation. Based upon the linear superposition technique, a series of time history trains of freak waves were obtained from the MATLAB program. These freak wave trains were then inserted into the J. Mar. Sci. Eng. 2020, 8, 119 12 of 22 J. Mar.Based Sci. Eng.upon 2020, 8,the 119linear 12 of 22 superposition technique, a series of time history trains of freak waves were obtained from the MATLAB program. These freak wave trains were then inserted into the developed sea states. developed S-lay S-lay model model as as the the input input conditions conditions of of extreme extreme sea states. The The geometric geometric non-linearities non-linearities of of the the laying laying pipeline, pipeline, spatial spatial variations variations of of hydrodynamic hydrodynamic forces, forces, and and clashing clashing contacts contacts were were sufficiently sufficiently incorporated incorporated in in the the simulation. simulation. The The time time domain domain calculations calculations of of the the S-lay S-lay system system under under freak freak waves waves were conducted by use of the explicit dynamic integration approach. Besides, critical damping were conducted by use of the explicit dynamic integration approach. Besides, critical damping and and target target damping damping were were utilized utilized to to cut cut down down the the spurious spurious non-physical non-physical high high frequency frequency responses, responses, and and they were demonstrated to have little effect on the pipeline behaviors. Finally, the whole motion they were demonstrated to have little effect on the pipeline behaviors. Finally, the whole motion equations equations for for the the vessel vessel and and all all line line nodes nodes were were solved solved by by iterative iterative update update of of the the forces forces and and moments moments on time step. step. on the the nodes nodes and and segments segments at at each each time 4.3. Time Time History Response of Pipelay Vessel Motions The pipelay vessel motions are significant top excitation boundaries of the S-laying pipeline and cause dynamic responses. Under Under the the generated generated freak freak wave wave trains trains shown shown in in Figure Figure 8 for the extreme quartering quartering sea, sea, the time history responses responses of six DoFs of pipelay vessel motions were calculated calculated by use of displacement RAOs, as displayed in Figure 14. The heave motion among vessel translation responses responses was was more prominent than the surge and the sway motion, and the pitch motion among vessel rotation responses was larger than the roll and and the the yaw yaw motion. motion. These results validate the above-mentioned response spectra of the pipelay vessel. Moreover, Moreover, all six DoFs of the vessel motion response amplitudes amplitudesabruptly abruptlyrose rose and attained maximum values the middle time 250 s, and attained maximum values nearnear the middle time of 250of s, which which also reflects thetime basic time history characteristic freak waves. also reflects the basic history characteristic of freakofwaves. 2 3.4 Surge Sway Heave 1 θ (° ) Sxyz(m) 1.7 0.0 0 -1 -1.7 -3.4 Pitch Roll Yaw -2 0 100 200 t (s) 300 400 500 0 100 200 t (s) 300 400 500 Figure 14. 14. Time Time history history responses responses of pipelay vessel motions under freak waves. Figure 5. Results Analysis 5. Results Analysis 5.1. Effect of the Wave Energy Ratio Coefficient 5.1. Effect of the Wave Energy Ratio Coefficient In the simulation of freak wave trains, the energy ratio coefficient directly dominates the energy In the simulation of freak wave trains, the energy ratio coefficient directly dominates the energy proportion of transient waves and random waves. By selecting four energy ratio coefficients, Ep1 = 0.30, proportion of transient waves and random waves. By selecting four energy ratio coefficients, Ep1 = 0.35, 0.40 and 0.45, a group of freak wave trains in Figure 9a was utilized as the input marine 0.30, 0.35, 0.40 and 0.45, a group of freak wave trains in Figure 9a was utilized as the input marine environment conditions for the dynamic analyses of the S-laying pipeline. The pipeline and seabed environment conditions for the dynamic analyses of the S-laying pipeline. The pipeline and seabed response results, which includes the axial tension, bending moment, von Mises stress, longitudinal response results, which includes the axial tension, bending moment, von Mises stress, longitudinal strain, pipeline embedment, and seabed resistance, are illustrated in Figure 15. strain, pipeline embedment, and seabed resistance, are illustrated in Figure 15. As the energy ratio coefficient Ep1 increased from 0.30 to 0.45, the axial tension of the overall As the energy ratio coefficient Ep1 increased from 0.30 to 0.45, the axial tension of the overall pipeline noticeably rose, and its maximum value at the top end increased by 39.9% from 3512.57 to pipeline noticeably rose, and its maximum value at the top end increased by 39.9% from 3512.57 to 4915.02 kN. The bending moments of the pipeline had some differences between the overbend and the 4915.02 kN. The bending moments of the pipeline had some differences between the overbend and sagbend, and the maximum results appeared at the last contact roller location in the overbend with a the sagbend, and the maximum results appeared at the last contact roller location in the overbend minor increase of 12.1% from 585.86 to 656.95 kN·m. In the sagbend, the maximum bending moment with a minor increase of 12.1% from 585.86 to 656.95 kN·m. In the sagbend, the maximum bending occurring near the touchdown point (TDP) had a prominent augmentation of 202.3% from 151.97 to moment occurring near the touchdown point (TDP) had a prominent augmentation of 202.3% from 151.97 to 459.33 kN·m, and some bending moment crests along the touchdown pipeline formed as a result of pipe bending and soil softening. Under the combined axial tension, bending moment, and hydrostatic force, the von Mises stress of the pipeline increased to some extent and attained 20.8% of J. Mar. Sci. Eng. 2020, 8, 119 13 of 22 459.33 kN·m, and some bending moment crests along the touchdown pipeline formed as a result of pipe bending and soil softening. Under the combined axial tension, bending moment, and hydrostatic J. Mar. Sci. Eng. 2020, 8, 119 13 of 22 force, the von Mises stress of the pipeline increased to some extent and attained 20.8% of the maximum value from 461.27 to 557.10 MPa. Similarly, the maximum longitudinal strain of the pipeline rose the maximum value from 461.27 to 557.10 MPa. Similarly, the maximum longitudinal strain of the by 23.9% from tofrom 0.353%. Moreover, the maximum embedment had a remarkable pipeline rose0.285% by 23.9% 0.285% to 0.353%. Moreover, thepipeline maximum pipeline embedment had a enlargement 1139.5% from (0.130D) 0.533 m (1.616D), and maximum resistance remarkableofenlargement of 0.043 1139.5% from to 0.043 (0.130D) to 0.533 mthe (1.616D), and seabed the maximum grew by 199.8% fromgrew 1.837 ) to 5.507 (8.097w is demonstrated these results s ). ItkN/m seabed resistance by(2.701w 199.8%sfrom 1.837kN/m (2.701w s) to 5.507 (8.097ws). It isfrom demonstrated thatfrom the energy ratio coefficient has an obvious effecthas on an theobvious pipelineeffect dynamic and seabed these results that the energy ratio coefficient on thebehaviors pipeline dynamic resistance. Especially, when the Ep1Especially, reaches 0.45, the wave causes drastic dynamic responses behaviors and seabed resistance. when thefreak Ep1 reaches 0.45, the freak wave causes drastic of of the pipeline in and seabed the dynamic pipeline responses and seabed interaction the TDZ.interaction in the TDZ. 700 5000 Ep1=0.30 Te(kN) Ep1=0.40 Ep1=0.45 3000 M(kN⋅m) Ep1=0.35 4000 Ep1=0.30 600 Ep1=0.35 500 Ep1=0.40 400 Ep1=0.45 300 200 2000 100 1000 -2500 -2000 -1500 -1000 x(m) -500 0 0 -2500 500 -2000 -1500 (a) -1000 x(m) -500 0 500 (b) 600 0.4 Ep1=0.30 Ep1=0.30 Ep1=0.35 Ep1=0.40 ε (%) σ (MPa) Ep1=0.45 Ep1=0.35 0.3 Ep1=0.40 400 Ep1=0.45 0.2 200 0.1 -2000 -1500 -1000 x(m) -500 0 0.0 -2500 500 -2000 -1500 (c) -1000 x(m) -500 (d) 8 Ep1=0.30 0.6 0.2 Ep1=0.35 Ep1=0.35 6 Ep1=0.40 P(kN/m) 1.2 Ep1=0.30 z/D z(m) 4 0.6 500 6 0.0 0.0 0.4 0 Ep1=0.45 4 P/ws 0 -2500 2 1.8 Ep1=0.40 2 Ep1=0.45 0.8 -2400 -2200 -2000 x(m) (e) 2.4 -1800 0 -2400 -2200 -2000 0 -1800 x(m) (f) Figure 15. Dynamic responses the S-laying pipeline freakenergy wave ratio energy ratio Figure 15. Dynamic responses of theofS-laying pipeline under under variousvarious freak wave coefficients: coefficients: tension; (b) bending moment; stress; strain; (e) pipeline embedment; seabed (a) tension; (b) (a) bending moment; (c) stress; (d) (c) strain; (e)(d) pipeline embedment; (f) seabed(f) resistance. resistance. 5.2. Effect of the Wave Focusing Location 5.2. Effect of the Wave Focusing Location A noticeable characteristic of freak waves is the crest value appearing at the focusing position A noticeable characteristic of freak is the the influence crest valueofappearing the focusing position where the wave energy accumulates. To waves explore the waveatfocusing location on the where the wave energy accumulates. To explore the influence of the wave focusing location on the dynamic responses of the laying pipeline, five focusing locations, xp = −200, −100, 0, 100, 200 m, were dynamic responses of the laying pipeline, five focusing locations, xp = −200, −100, 0, 100, 200 m, were assumed to simulate the freak waves shown in Figure 9b, which were separately taken as the input surface wave conditions to perform a dynamic analysis of pipeline installation. The pipeline and seabed response results illustrated in Figure 16 are the axial tension, bending moment, von Mises stress, longitudinal strain, pipeline embedment, and seabed resistance. When the wave focusing location varied from −200 m to 200 m, the pipeline and seabed responses firstly rose and then dropped. The maximum responses occurred at the center position xp J. Mar. 8, 119 = 0Sci. m Eng. with2020, a peak axial tension of 4550.13 kN, bending moment of 654.13 kN·m, von Mises stress14ofof 22 536.49 MPa, longitudinal strain of 0.340%, pipeline embedment of 0.406 m (1.231D), and seabed resistance of 4.685 kN/m (6.889ws). The pipeline responses and seabed resistance at xp = 100 m and xp assumed towere simulate thelarger freakthan waves in Figure 9b, which weremseparately taken as the input = 200 m slightly the shown corresponding results at xp = −100 and xp = −200 m, for which surface wave conditions to perform a dynamic analysis of pipeline installation. The pipeline the freak waves produced by the forward focusing location led to more prominent motion responsesand seabed response resultsEvidently, illustrated Figure 16 are theof axial tension, bending von Mises of the pipelay vessel. theindynamic behaviors the laying pipeline andmoment, seabed resistance stress, strain, and seabed resistance. are longitudinal greatly influenced bypipeline the waveembedment, focusing location. 700 5000 xp=-200 m xp=0 m 4000 Te(kN) xp=100 m xp=200 m M( kN⋅m) xp=-100 m 3000 xp =-200 m 600 xp =-100 m 500 xp =0 m 400 xp =100 m xp =200 m 300 200 100 2000 -2500 -2000 -1500 -1000 x(m) -500 0 0 -2500 500 -2000 -1500 (a) -1000 x(m) -500 0 500 (b) 600 0.4 xp =-200 m xp =-200 m xp =-100 m xp =100 m xp =200 m ε (%% σ (MPa ) 400 xp =-100 m 0.3 xp =0 m xp =0 m xp =100 m 0.2 xp =200 m 200 0.1 0 -2500 -2000 -1500 -1000 x(m) -500 0 0.0 -2500 500 -2000 -1500 (c) -1000 x(m) -500 0 500 (d) 0.0 6 0.0 8 x p=-200 m x p=-100 m 1.2 x p=0 m 6 x p=0 m s x p=100 m 4 x p=200 m P/w x p=-100 m P(kN/m) z/D z(m) x p=-200 m 0.4 4 0.6 0.2 2 2 x p=100 m x p=200 m 0.6 -2400 -2200 -2000 1.8 -1800 0 -2400 -2200 -2000 x(m) x(m) (e) (f) 0 -1800 Figure Dynamic responsesofofthe theS-laying S-laying pipeline pipeline under wave focused positions: Figure 16. 16. Dynamic responses undervarious variousfreak freak wave focused positions: (a) tension; bending moment;(c) (c)stress; stress;(d) (d)strain; strain; (e) (e) pipeline seabed resistance. (a) tension; (b)(b) bending moment; pipelineembedment; embedment;(f)(f) seabed resistance. When the wave focusing location varied from −200 m to 200 m, the pipeline and seabed responses firstly rose and then dropped. The maximum responses occurred at the center position xp = 0 m with a peak axial tension of 4550.13 kN, bending moment of 654.13 kN·m, von Mises stress of 536.49 MPa, longitudinal strain of 0.340%, pipeline embedment of 0.406 m (1.231D), and seabed resistance of 4.685 kN/m (6.889ws ). The pipeline responses and seabed resistance at xp = 100 m and xp = 200 m were slightly larger than the corresponding results at xp = −100 m and xp = −200 m, for which the freak waves produced by the forward focusing location led to more prominent motion responses of the pipelay vessel. Evidently, the dynamic behaviors of the laying pipeline and seabed resistance are greatly influenced by the wave focusing location. J. Mar. Sci. Eng. 2020, 8, 119 15 of 22 J. Mar. Sci. Eng. 2020, 8, 119 15 of 22 5.3. Effect of the Wave Phase Range 5.3. Effect of the Wave Phase Range The wave phase range plays a significant role in generating freak waves and, to some degree, The wave phase range plays a significant role in generating freak waves and, to some degree, determines the wave height by controlling the phases of wave components in a specified region. determines the wave height by controlling the phases of wave components in a specified region. Five Five groups of the wave phase range, ϕ = 1.0π, 1.1π, 1.2π, 1.3π and 1.4π, were selected to produce groups of the wave phase range, φ = 1.0π, 1.1π, 1.2π, 1.3π and 1.4π, were selected to produce the the freak wave trains shown in Figure 9c, and the influence of the wave phase range on the pipeline freak wave trains shown in Figure 9c, and the influence of the wave phase range on the pipeline behaviors was explored wavetrains trainswith withthe the developed S-lay FEM behaviors was exploredbybythe thecombination combination of of these these wave developed S-lay FEM for for timetime domain dynamic analyses. seabedresponse responseresults results aspects of axial tension, domain dynamic analyses.The Thepipeline pipeline and and seabed onon aspects of axial tension, bending moment, von Mises stress, longitudinal strain, pipeline embedment, and seabed resistance bending moment, von Mises stress, longitudinal strain, pipeline embedment, and seabed resistance are displayed in Figure 17. 17. are displayed in Figure ϕ=1.0π ϕ=1.1π ϕ=1.2π ϕ=1.3π ϕ=1.4π Te(kN) 5000 4000 3000 700 ϕ=1.0π ϕ=1.1π ϕ=1.2π ϕ=1.3π ϕ=1.4π 600 M(kN⋅m) 6000 500 400 300 200 2000 100 1000 -2500 -2000 -1500 -1000 x(m) -500 0 0 -2500 500 -2000 -1500 (a) -1000 x(m) -500 0 500 (b) ϕ=1.0π ϕ=1.1π ϕ=1.2π ϕ=1.3π ϕ=1.4π σ (MPa ) 400 0.4 ϕ=1.0π ϕ=1.1π ϕ=1.2π ϕ=1.3π ϕ=1.4π 0.3 ε (%− 600 0.2 200 0.1 -1500 -1000 x(m) -500 0 0.0 -2500 500 -2000 -1500 (c) 6 0.0 0.2 0.6 0.8 -2400 1.2 P(kN/m) ϕ=1.0 π ϕ=1.1 π ϕ=1.2 π ϕ=1.3 π ϕ=1.4 π z/D z (m) 4 0.6 -500 0 500 (d) 0.0 0.4 -1000 x(m) ϕ=1.0π ϕ=1.1π ϕ=1.2π ϕ=1.3π ϕ=1.4π 8 6 s -2000 4 P/w 0 -2500 2 1.8 -2200 -2000 x(m) (e) 2.4 -1800 2 0 -2400 -2200 -2000 0 -1800 x(m) (f) Figure Dynamic responses responses of pipeline under various freakfreak wave wave phase phase ranges:ranges: (a) Figure 17.17.Dynamic of the theS-laying S-laying pipeline under various tension; (b) stress; (d)(d) strain; (e) (e) pipeline embedment; (f) seabed resistance. (a) tension; (b) bending bendingmoment; moment;(c)(c) stress; strain; pipeline embedment; (f) seabed resistance. With increase of wave the wave phase 1.0π to all 1.4π, the pipeline and seabed With the the increase of the phase rangerange from from 1.0π to 1.4π, theall pipeline and seabed responses haddecreases. prominentThe decreases. The reductions in the maximum values45.0% were 45.0% the axial hadresponses prominent reductions in the maximum values were for thefor axial tension, tension, from 5034.62 kN; to 2769.11 for the moment, bending moment, fromto661.99 to kN·m; 506.08 29.0% kN·m; for from 5034.62 to 2769.11 23.6%kN; for 23.6% the bending from 661.99 506.08 the von Mises stress, from 565.67 to 401.41 MPa; and 32.4% for the longitudinal strain, from 0.361% J. Mar. Sci. Eng. 2020, 8, 119 16 of 22 J. Mar. Sci. Eng. 2020, 8, 119 16 of 22 29.0% for the von Mises stress, from 565.67 to 401.41 MPa; and 32.4% for the longitudinal strain, from 0.361% to 0.244%. Moreover, the maximum pipeline embedment reduced by 97.2%, from 0.649 (1.967D) 0.018 m (0.055D), and the maximum seabed resistance by 81.1%, from 5.793 to 0.244%.toMoreover, the maximum pipeline embedment reduced bydropped 97.2%, from 0.649 (1.967D) to (8.518w to 1.097 kN/m (1.613w s). When the wave phasedropped range was thefrom bending 0.018 ms)(0.055D), and the maximum seabed resistance by 1.0π, 81.1%, 5.793moment (8.518wsand ) to von Mises ofs the pipeline in thephase TDZ range tremendously to form some and crests, illustrated 1.097 kN/mstress (1.613w ). When the wave was 1.0π,jumped the bending moment vonasMises stress in Figure 17b,c. in This can be explained peakcrests, curvesasofillustrated pipeline embedment and of the pipeline thephenomenon TDZ tremendously jumped tofrom formthe some in Figure 17b,c. seabed resistance can shown in Figurefrom 17e,fthe as peak the cyclic of the pipeline and penetrating into and This phenomenon be explained curvesmotions of pipeline embedment seabed resistance uplifting from the seabed, resulting in the softening trenching ofand seabed soil, from and the drastic shown in Figure 17e,f as the cyclic motions of the pipelineand penetrating into uplifting the seabed, pipe–seabed interactions induced by freak waves causing pipeline flexural deflections. These resulting in the softening and trenching of seabed soil, and thegreat drastic pipe–seabed interactions induced results adequately demonstrate that the phase range of freak waves greatly influences the dynamic by freak waves causing great pipeline flexural deflections. These results adequately demonstrate behaviors of the pipeline the greatly seabed,influences particularly the entire axialoftension and pipeline that the phase range of freakand waves the for dynamic behaviors the pipeline and the embedment as well for as seabed resistance in theand TDZ. seabed, particularly the entire axial tension pipeline embedment as well as seabed resistance in the TDZ. 5.4. Effect of Wave Peak Value 5.4. Effect of Wave Peak Value Another noteworthy feature of freak waves is the peak value which generally represents the impact levels on offshore structures. order to better understand wavegenerally peak value effect on the Another noteworthy feature of In freak waves is the peak valuethe which represents dynamiclevels behaviors of the S-laying pipeline, the five representative freak Figure impact on offshore structures. In order to better understand thewave wavetrains peakshown value in effect on 9d were generated withof their wave of 3.6, 4.1, 4.6, wave 5.1, and 5.6 m. A time the dynamic behaviors the corresponding S-laying pipeline, thepeak fivevalues representative freak trains shown in domain9d analysis of pipelinewith installation under these freak conducted to obtain pipeline Figure were generated their corresponding wavewaves peak was values of 3.6, 4.1, 4.6, 5.1,the and 5.6 m. and seabed response results, as shown in Figureunder 18. these freak waves was conducted to obtain the A time domain analysis of pipeline installation Since theseabed wave peak valueresults, gradually became pipeline and response as shown in larger Figurefrom 18. 3.6 to 5.6 m, all the pipeline and seabed responses obvious The axial tension of the pipeline and Since showed the wavean peak valueincrease. gradually became larger from 3.6overall to 5.6 m, all the became pipelinegreater, and seabed the maximum tension enlargedincrease. by 32.6%,The fromaxial 3647.71 to 4838.41 Thepipeline bendingbecame momentgreater, of the responses showed an obvious tension of the kN. overall pipeline mildly increased byenlarged 9.7% for its value, from to 602.24 to 660.69 MPa, in the overbend. and the maximum tension bymaximum 32.6%, from 3647.71 4838.41 kN. The bending moment Meanwhile, themildly bending moment thefor sagbend had a great withtothe increment of the its of the pipeline increased byin 9.7% its maximum value,increase from 602.24 660.69 MPa, in maximum Meanwhile, value, attaining 103.2%, moment from 197.25 tosagbend 400.83 kN·m. the maximum von Mises overbend. the bending in the had a Likewise, great increase with the increment of stress of the pipeline rose by 17.1%, from 471.98 toto 552.47 MPa, andLikewise, the maximum longitudinal strain its maximum value, attaining 103.2%, from 197.25 400.83 kN·m. the maximum von Mises of theofpipeline roserose by by 19.5%, 0.350%. the maximum pipeline stress the pipeline 17.1%,from from 0.293% 471.98 toto552.47 MPa,Additionally, and the maximum longitudinal strain embedment and seabed resistance remarkably enlarged by 507.0% 127.3%,pipeline respectively, from of the pipeline rose by 19.5%, from 0.293% to 0.350%. Additionally, the and maximum embedment 0.086seabed (0.261D) to 0.522remarkably m (1.582D)enlarged and from (3.510w s) to 5.426 kN/m (7.978w ). Therefore, and resistance by2.387 507.0% and 127.3%, respectively, from s0.086 (0.261D)the to increase in the freak peak (3.510w value would result in great augmentation of the pipeline behaviors and 0.522 m (1.582D) and wave from 2.387 kN/m (7.978w increase in the freak s ) to 5.426 s ). Therefore, seabedpeak resistance. wave value would result in great augmentation of pipeline behaviors and seabed resistance. 4000 η p=3.6 m 700 ηp=3.6 m η p=4.1 m 600 ηp=4.1 m η p=4.6 m 500 ηp=4.6 m 400 ηp=5.1 m 300 ηp=5.6 m Te(kN) η p=5.1 m η p=5.6 m 3000 M (kN⋅m) 5000 200 100 2000 -2500 -2000 -1500 -1000 x(m) -500 0 500 0 -2500 (a) -2000 -1500 -1000 x(m) (b) Figure 18. Cont. -500 0 500 J. Mar. Sci. Eng. 2020, 8, 119 J. Mar. Sci. Eng. 2020, 8, 119 17 of 22 17 of 22 600 0.4 ηp=3.6 m ηp=4.1 m σ (MPa ) ηp=5.1 m ηp=5.6 m 200 ηp=4.1 m 0.3 ε ( %% ηp=4.6 m 400 ηp=3.6 m ηp=4.6 m ηp=5.1 m 0.2 ηp=5.6 m 0.1 0 -2500 -2000 -1500 -1000 x(m) -500 0 0.0 -2500 500 -2000 -1500 (c) -1000 x(m) -500 0 500 (d) 0.0 6 0.0 ηp=3.6 m 8 ηp=4.1 m ηp=4.6 m 1.2 ηp=5.1 m 6 ηp=4.6 m 2 s ηp=5.1 m 4 ηp=5.6 m P/w P( kN/m) ηp=4.1 m 0.4 4 0.6 ηp=3.6 m z/D z (m) 0.2 2 ηp=5.6 m 0.6 -2400 -2200 -2000 1.8 -1800 0 -2400 -2200 -2000 x(m) x(m) (e) (f) 0 -1800 Figure 18. Dynamic Dynamicresponses responsesofof S-laying pipeline under various freak peak wavevalues: peak values: (a) Figure 18. thethe S-laying pipeline under various freak wave (a) tension; tension; (b) bending stress; (d)(e)strain; (e) pipeline embedment; (f)resistance. seabed resistance. (b) bending moment;moment; (c) stress;(c)(d) strain; pipeline embedment; (f) seabed 6. Discussion Discussion and and Implications Implications 6. The deepwater deepwater S-lay S-lay FEM FEM is is aa complicated, complicated, non-linear non-linear structural structural system, system, and and dynamic dynamic response response The analysis of of the the laying laying pipeline pipeline under under freak freak waves waves is isdifficult difficult and andtime-consuming time-consuming for for marine marine structure structure analysis engineers. A simplified technique was presented to estimate the pipeline dynamic response amplitudes engineers. A simplified technique was presented to estimate the pipeline dynamic response by means of by the means dynamic (DAFs), which defined which by the maximum responses amplitudes ofamplification the dynamicfactors amplification factorsare(DAFs), are defined by the relative to the corresponding static results. As a consequence, the dynamic response amplitudes of the maximum responses relative to the corresponding static results. As a consequence, the dynamic laying pipeline can be easily determined if the static responses and DAFs are given. response amplitudes of the laying pipeline can be easily determined if the static responses and DAFs As shown in Figure 19a, the pipeline and seabed DAFs in the parametric analyses were obtained are given. with As theshown variation of the energy coefficient. AlongDAFs with in thethe increase of theanalyses energy ratio in Figure 19a, theratio pipeline and seabed parametric werecoefficient obtained E , the DAFs of axial tension, bending moment, stress, and strain gradually increased, in which the p1 the variation of the energy ratio coefficient. Along with the increase of the energy with ratio tension DAF prominent from 1.69 to 2.37. The pipeline DAFincreased, largely rose coefficient Ep1was , the relatively DAFs of axial tension, bending moment, stress, and embedment strain gradually in from 3.75 to 46.41, and the seabed resistance DAF increased from 2.35 to 7.04. Figure 19b shows the which the tension DAF was relatively prominent from 1.69 to 2.37. The pipeline embedment DAF variation in from pipeline seabed DAFs with the wave focused position, from and all thetoDAFs firstly rose largely rose 3.75and to 46.41, and the seabed resistance DAF increased 2.35 7.04. Figure 19b up and then dropped down. The maximum tension DAF reached 2.19, and the maximum pipeline shows the variation in pipeline and seabed DAFs with the wave focused position, and all the DAFs embedment and resistance DAFsThe reached 35.35 tension and 5.99, respectively. Moreover, pipeline firstly rose up andseabed then dropped down. maximum DAF reached 2.19, and thethe maximum and seabed DAFs with theseabed variation in the wave range are and illustrated in Figure 19c. As the wave pipeline embedment and resistance DAFsphase reached 35.35 5.99, respectively. Moreover, the phase range increased, all of the DAFs reduced step by step. The DAF reductions were from 2.43 to pipeline and seabed DAFs with the variation in the wave phase range are illustrated in Figure 19c. 1.34 for axial tension, from 56.50 to 1.57 for pipeline embedment, and from 7.40 to 1.40 for seabed As the wave phase range increased, all of the DAFs reduced step by step. The DAF reductions were resistance. thetension, pipelinefrom and seabed enlarged stage by stage with augmentation from 2.43 toOppositely, 1.34 for axial 56.50 toDAFs 1.57 for pipeline embedment, andthe from 7.40 to 1.40 of the wave peak value, as displayed in Figure 19d, the DAF increment in axial tension was from for seabed resistance. Oppositely, the pipeline and seabed DAFs enlarged stage by stage with 1.42 the to 1.56, and theofDAF increments in pipeline embedment and seabed resistance were from 7.49 tension to 45.44 augmentation the wave peak value, as displayed in Figure 19d, the DAF increment in axial and from obtained DAFs of thein pipeline and seabed behaviors couldresistance offer intuitional was from 3.05 1.42toto6.93. 1.56,These and the DAF increments pipeline embedment and seabed were knowledge for offshore pipeline engineers, which could be used to consider the freak wavebehaviors effects in from 7.49 to 45.44 and from 3.05 to 6.93. These obtained DAFs of the pipeline and seabed the initial stage.knowledge for offshore pipeline engineers, which could be used to consider could offerdesign intuitional the freak wave effects in the initial design stage. J. Mar. Sci. Eng. 2020, 8, 119 J. Mar. Sci. Eng. 2020, 8, 119 3.0 18 of 22 18 of 22 50 Te M 30 DAF DAF 40 σ ε 2.5 z (z/D) P (P/ws) 2.0 1.5 20 10 1.0 0.30 0.35 Ep1 0.40 0 0.30 0.45 0.35 Ep1 0.40 0.45 (a) 2.5 50 Te M 40 σ ε DAF DAF 2.0 z (z/D) P (P/ws) 30 20 1.5 10 1.0 -200 -100 0 x p(m) 100 0 -200 200 -100 0 x p(m) 100 200 (b) 60 2.5 z (z/D) Te P (P/ws) M σ ε 40 DAF DAF 2.0 20 1.5 1.0 1.0 1.1 1.2 ϕ (π) 1.3 0 1.0 1.4 1.1 1.2 1.3 ϕ (π) 1.4 (c) 2.5 T 60 e M σ ε 40 DAF DAF 2.0 z (z/D) P (P/ws) 1.5 1.0 3.6 20 4.0 4.4 4.8 ηp(m) 5.2 0 3.6 5.6 4.0 4.4 η p(m) 4.8 5.2 (d) Figure 19. Effect Effect of freak wave conditions on dynamic amplification factors of pipeline behaviors and position; (c) (c) phase phase range; range; (d) (d) peak peak value. value. seabed resistance: (a) energy ratio coefficients; (b) focused position; 5.6 J. Mar. Sci. Eng. 2020, 8, 119 19 of 22 7. Conclusions This paper presented a profound investigation of freak wave effects on the dynamic responses of offshore pipelines for deepwater installation. For this purpose, an extended FEM of the S-lay system was developed in OrcaFlex with the particular consideration of freak waves. The linear superposition method of combined transient wave trains and random wave trains was applied to generate a series of freak wave trains. The wave induced pipelay vessel motions, pipe–stinger roller interactions in the overbend, as well as the cyclic contacts between the pipeline and seabed in the TDZ were also taken into account in the dynamic analysis of laying pipelines. The influences of the freak wave energy ratio coefficient, focusing location, phase range, and peak value on the pipeline and seabed behaviors were estimated in detail, and the DAFs of the axial tension, bending moment, von Mises stress, longitudinal strain, pipeline embedment, and seabed resistance were derived. Some significant conclusions were obtained as follows: (1) (2) (3) (4) The reasonable selection of wave parameters can effectively generate a variety of freak wave trains by the linear superposition model. The maximum heights of freak wave trains are obviously different with variations in the energy ratio coefficient, focusing position, phase range, and peak value. The freak wave trains could be steadily incorporated into the developed S-lay FEM to implement the dynamic analysis of deepwater pipeline installation. The energy ratio coefficient has a great influence on the generation of freak waves and the induced pipeline dynamic responses. With an increase in the energy ratio coefficient for transient waves, all the pipeline behaviors and seabed resistance remarkably increase. Especially, when the Ep1 reaches 0.45, the interaction responses of the touchdown pipeline and seabed soil are drastically noticeable, which causes tremendous variation in the bending moment, von Mises stress, and pipeline embedment in the TDZ. The dynamic behaviors of the laying pipeline and seabed resistance are also strongly influenced by the wave focusing location. When the focusing wave is located at the center position xp = 0 m, the responses of the offshore pipeline and seabed resistance are the most significant. Besides, the axial tension, pipeline embedment, and seabed resistance for the forward wave focusing location are slightly larger than the corresponding results for the negative wave focusing location. The phase range and peak value of freak waves were proven to be important influencing factors in the pipeline and seabed responses. As the wave phase range increases, the axial tension, bending moment, von-Mises stress, longitudinal strain, pipeline embedment, and seabed resistance as well as their DAFs remarkably decrease. On the contrary, when the wave peak value becomes larger, the pipeline behaviors and seabed resistance obviously augment. Author Contributions: Conceptualization, P.X. and S.G.; methodology, P.X. and S.G.; software, P.X.; validation, P.X.; formal analysis, P.X. and Z.D.; investigation, P.X. and Z.D.; resources, P.X. and S.G.; data curation, Z.D.; writing—original draft preparation, P.X. and Z.D.; supervision, S.G.; funding acquisition, P.X. and S.G. All authors have read and agreed to the published version of the manuscript. Funding: This research was funded by the National Natural Science Foundation of China (grant numbers 51809048, 51779223) and the Natural Science Foundation of Fujian Province, China (grant number 2018J05081). Acknowledgments: The authors would like to thank the anonymous reviewers for their constructive comments and suggestions. Conflicts of Interest: The authors declare no conflict of interest. Nomenclature Ai Ao B Ca CD internal cross-section area external cross-section area coefficient of the Ramberg–Osgood model added mass coefficient drag coefficient J. Mar. Sci. Eng. 2020, 8, 119 d D E Ep1 Ep2 EAnom fm g k1 k2 ki Kmax ks L L0 Mb n N Nc Pi Po Pu (z) r1 r2 S(f ) Su0 Sug tc tp t’p Te Tw Tor wa ws xp α γ κ2 µ ν ρc ρp ρsoil ρw ωi φi σy ϕ τ ξ ς ζ shortest separation distance of the center lines between the pipe and roller pipe outer diameter elastic modulus energy ratio coefficient of a transient wave energy ratio coefficient of a random wave nominal axial stiffness peak frequency gravitational constant pipe contact stiffness roller contact stiffness wave number of the ith wave component soil normalized maximum stiffness soil shear stiffness instantaneous length of a line segment unstretched length of a line segment bending moment power exponent of the Ramberg–Osgood model number of wave components soil nominal bearing capacity factor internal pressure external pressure soil ultimate penetration resistance pipe radius roller radius spectral density function soil mudline shear strength soil shear strength gradient corrosion coating thickness wave focusing time pipe wall thickness effective tension wall tension torque moment pipe weight per unit length in air pipe submerged weight per unit length wave focusing position spectral energy coefficient peak enhancement factor curvature soil friction coefficient Poisson’s ratio pipe corrosion coating density pipe density saturated soil density sea water density angular frequency of the ith wave component phase lag of the ith wave component effective yield stress twist angle spectral width parameter axial damping coefficient bending damping coefficient torsional damping coefficient 20 of 22 J. Mar. Sci. Eng. 2020, 8, 119 21 of 22 References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. Kjeldsen, S.P. Measurements of freak waves in Norway and related ship accidents. In Proceedings of the Royal Institution of Naval Architects International Conference-Design and Operation for Abnormal Conditions III, London, UK, 29–30 April 2004. Slunyaev, A.; Didenkulova, I.; Pelinovsky, E. Rogue waves in 2006–2010. Nat. Hazards Earth Syst. Sci. 2011, 11, 2913–2924. Bruschi, R.; Vitali, L.; Marchionni, L.; Parrella, A.; Mancini, A. Pipe technology and installation equipment for frontier deep water projects. Ocean Eng. 2015, 108, 369–392. [CrossRef] Davis, M.C.; Zarnick, E.E. Testing ship models in transient waves. In Proceedings of the 5th International Symposium on Naval Hydrodynamics, Bergen, Norway, 10–12 September 1964; David Taylor Model Basin Hydromechanics Lab: Washington, DC, USA, 1964. Baldock, T.E.; Swan, C.; Taylor, P.H. A laboratory study of nonlinear surface wave in water. Philos. Trans. Math. Phys. Eng. Sci. 1996, 354, 649–676. Fochesato, C.; Grilli, S.; Dias, F. Numerical modeling of extreme rogue waves generated by directional energy focusing. Wave Motion 2007, 44, 395–416. [CrossRef] Zhao, X.Z.; Sun, Z.C.; Liang, S.X. Efficient focusing models for generation of freak waves. China Ocean Eng. 2009, 23, 429–440. Zhao, X.Z.; Ye, Z.T.; Fu, Y.N.; Cao, F.F. A CIP-based numerical simulation of freak wave impact on a floating body. Ocean Eng. 2014, 87, 50–63. [CrossRef] Liu, Z.Q.; Zhang, N.C.; Yu, Y.X. An efficient focusing model for generation of freak waves. Acta Oceanol. Sin. 2011, 30, 19–26. [CrossRef] Hu, Z.Q.; Tang, W.Y.; Xue, H.X. A probability-based superposition model of freak wave simulation. Appl. Ocean Res. 2014, 47, 284–290. [CrossRef] Tang, Y.G.; Li, Y.; Wang, B.; Liu, S.X.; Zhu, L.H. Dynamic analysis of turret-moored FPSO system in freak wave. China Ocean Eng. 2016, 30, 521–534. [CrossRef] Pan, W.B.; Zhang, N.C.; Huang, G.X.; Ma, X.Y. Experimental study on motion responses of a moored rectangular cylinder under freak waves (I: Time-domain study). Ocean Eng. 2018, 153, 268–281. [CrossRef] Gong, S.F.; Chen, K.; Chen, Y.; Jin, W.L.; Li, Z.G.; Zhao, D.Y. Configuration analysis of deepwater S-lay pipeline. China Ocean Eng. 2011, 25, 519–530. [CrossRef] Marchionni, L.; Alessandro, L.; Vitali, L. Offshore pipeline installation: 3-dimensional finite element modelling. In Proceedings of the 30th International Conference on Offshore Mechanics and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011. O’Grady, R.; Harte, A. Localised assessment of pipeline integrity during ultra-deep S-lay installation. Ocean Eng. 2013, 68, 27–37. [CrossRef] Gong, S.F.; Xu, P.; Bao, S.; Zhong, W.J.; He, N.; Yan, H. Numerical modelling on dynamic behaviour of deepwater S-lay pipeline. Ocean Eng. 2014, 88, 393–408. [CrossRef] Gong, S.F.; Xu, P. The influence of sea state on dynamic behaviour of offshore pipelines for deepwater S-lay. Ocean Eng. 2016, 111, 398–413. [CrossRef] Ivić, S.; Čanađija, M.; Družeta, S. Static structural analysis of S-lay pipe laying with a tensioner model based on the frictional contact. Eng. Rev. 2014, 34, 223–234. Ivić, S.; Družeta, S.; Hreljac, I. S-Lay pipe laying optimization using specialized PSO method. Struct. Multidiscip. Optim. 2017, 56, 297–313. [CrossRef] Xie, P.; Zhao, Y.; Yue, Q.J.; Palmer, A.C. Dynamic loading history and collapse analysis of the pipe during deepwater S-lay operation. Mar. Struct. 2015, 40, 183–192. [CrossRef] Cabrera-Miranda, J.M.; Paik, J.K. On the probabilistic distribution of loads on a marine riser. Ocean Eng. 2017, 134, 105–118. [CrossRef] Wang, F.C.; Chen, J.; Gao, S.; Tang, K.; Meng, X.W. Development and sea trial of real-time offshore pipeline installation monitoring system. Ocean Eng. 2017, 146, 468–476. [CrossRef] Liang, H.; Yue, Q.J.; Lim, G.; Palmer, A.C. Study on the contact behaviour of pipe and rollers in deep S-lay. Appl. Ocean Res. 2018, 72, 1–11. [CrossRef] Liang, H.; Zhao, Y.; Yue, Q.J. Experimental study on dynamic interaction between pipe and rollers in deep S-lay. Ocean Eng. 2019, 175, 188–196. [CrossRef] J. Mar. Sci. Eng. 2020, 8, 119 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 22 of 22 Kim, H.S.; Kim, B.W. An efficient linearised dynamic analysis method for structural safety design of J-lay and S-lay pipeline installation. Ships Offshore Struct. 2019, 14, 204–219. [CrossRef] Orcina. OrcaFlex User Manual, Version 9.7a; Orcina: Cumbria, UK, 2014. Ramberg, W.; Osgood, W.R. Description of Stress-Strain Curves by Three Parameters; Technical Note, No. 902; National Advisory Committee for Aeronautics (NACA): Washington, DC, USA, 1943. Wang, F.C.; Luo, Y.; Xie, Y.; Li, B.; Li, J.N. Practical and theoretical assessments of subsea installation capacity for HYSY 201 laybarge according to recent project performances in South China Sea. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014; pp. 2696–2704. Randolph, M.F.; Quiggin, P. Non-linear hysteretic seabed model for catenary pipeline contact. In Proceedings of the 28th International Conference on Ocean, Honolulu, HI, USA, 31 May–5 June 2009. Gong, S.F.; Xu, P. Influences of pipe–soil interaction on dynamic behaviour of deepwater S-lay pipeline under random sea states. Ships Offshore Struct. 2017, 12, 370–387. [CrossRef] Ai, S.M.; Sun, L.P.; Tao, L.B.; Yim, C.S. Modeling and simulation of deepwater pipeline S-lay with coupled dynamic positioning. J. Offshore Mech. Arct. Eng. 2018, 140, 051704. [CrossRef] Slunyaev, A.; Pelinovsky, E.; Sergeeva, A.; Chabchoub, A.; Hoffmann, N.; Onorato, M.; Akhmediev, N. Super-rogue Waves in Simulations Based on Weakly Nonlinear and Fully Nonlinear Hydrodynamic Equations. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2013, 88, 012909. [CrossRef] Lu, W.Y.; Yang, J.M.; Fu, S.X. Numerical Study of the Generation and Evolution of Breather-type Rogue Waves. Ships Offshore Struct. 2017, 12, 66–76. [CrossRef] Morison, J.R.; O’Brien, M.D.; Johnson, J.W.; Schaaf, S.A. The force exerted by surface waves on piles. J. Pet. Technol. 1950, 2, 149–154. [CrossRef] White, D.J.; Cheuk, C.Y. Modelling the soil resistance on seabed pipelines during large cycles of lateral movement. Mar. Struct. 2008, 21, 59–79. [CrossRef] © 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).