Engineering, Construction and Architectural Management

A comparative study of truck cycle time prediction methods in open-pit mining

Emmanuel K. Chanda Steven Gardiner

Article information:

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

To cite this document:

Emmanuel K. Chanda Steven Gardiner, (2010),"A comparative study of truck cycle time prediction methods

in open-pit mining", Engineering, Construction and Architectural Management, Vol. 17 Iss 5 pp. 446 - 460

Permanent link to this document:

http://dx.doi.org/10.1108/09699981011074556

Downloaded on: 10 March 2015, At: 11:28 (PT)

References: this document contains references to 13 other documents.

To copy this document: permissions@emeraldinsight.com

The fulltext of this document has been downloaded 928 times since 2010*

Access to this document was granted through an Emerald subscription provided by 121184 []

For Authors

If you would like to write for this, or any other Emerald publication, then please use our Emerald for

Authors service information about how to choose which publication to write for and submission guidelines

are available for all. Please visit www.emeraldinsight.com/authors for more information.

About Emerald www.emeraldinsight.com

Emerald is a global publisher linking research and practice to the benefit of society. The company

manages a portfolio of more than 290 journals and over 2,350 books and book series volumes, as well as

providing an extensive range of online products and additional customer resources and services.

Emerald is both COUNTER 4 and TRANSFER compliant. The organization is a partner of the Committee

on Publication Ethics (COPE) and also works with Portico and the LOCKSS initiative for digital archive

preservation.

*Related content and download information correct at time of download.

The current issue and full text archive of this journal is available at

www.emeraldinsight.com/0969-9988.htm

ECAM

17,5

A comparative study of truck

cycle time prediction methods

in open-pit mining

446

Emmanuel K. Chanda

School of Civil, Environmental and Mining Engineering,

The University of Adelaide, Adelaide, Australia, and

Received June 2009

Revised June 2009

Accepted April 2010

Steven Gardiner

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

Kalgoorlie Consolidated Gold Mines, Kalgoorlie, Australia

Abstract

Purpose – The purpose of this paper is to compare the predictive capability of three methods of truck

cycle time estimation in open-pit mining: computer simulation, artificial neural networks (NNs), and

multiple regressions (MRs). The aim is to determine the best method. The most common method

currently used is computer simulation.

Design/methodology/approach – Truck cycle times at a large open pit mine are estimated using

computer simulation, artificial NNs, and MRs. The estimated cycle times by each method are in turn

compared to the actual cycle times recorded by a computerized mine monitoring system at the same

mine. The errors associated with each method relative to the actual cycle times are documented and

form the basis for comparing the three methods.

Findings – The paper clearly indicates that computer simulation methods used in predicting truck

cycle times in open-pit mining underestimate and overestimate the results for short and long hauls,

respectively. It appears that both NN and regression models are superior in their predictive abilities

compared to computer simulations.

Research limitations/implications – The cycle time prediction models developed apply to a

specific mine site and one has to be careful not to directly apply these models to other operations.

Practical implications – The paper describes the implementation of regression and NN modelling.

An opportunity exists for mines to utilise the large volumes of data generated to predict truck haulage

cycle times more accurately and hence, improve the quality of mine planning.

Originality/value – The paper addresses an area of need in the mining industry. Accurate prediction

of cycle times is critical to mine planners as it impacts on production targets and hence, the budgets.

Keywords Production cycle, Simulation, Multiple regression analysis, Neural nets

Paper type Research paper

Engineering, Construction and

Architectural Management

Vol. 17 No. 5, 2010

pp. 446-460

q Emerald Group Publishing Limited

0969-9988

DOI 10.1108/09699981011074556

Introduction

There are a number of methods being used by the industry to predict load-haul cycle

times in open-pit mining. The most commonly used approach is computer simulation

using the so-called Monte-Carlo technique. This method aims to simulate by computer

the step-by-step operations of the entire truck and loader fleet, including the randomness

of the loader-truck cycle time, and the queuing of trucks at the loader and at the dump or

elsewhere. However, the accuracy of the truck and loader cycle times generated by these

simulations is questionable as evidenced by significant discrepancies between actual

and predicted cycle times (Blackwell, 1999; Hardy, 2007). Computer programs such as

truck and loader productivity and cost (TALPAC) and Caterpillar’s fleet production

and cost (FPC) analysis are currently used by mining engineers to estimate open-pit

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

haulage truck requirements. A perceived shortcoming of software such as TALPAC is

that it provides a best estimate based on manufacturers’ equipment performance

specifications and capabilities, such as rim-pull curves. This method incorporates

performance assumptions that are optimistic, as equipment is subjected to wear and tear

which reduces its operational efficiency (Hardy, 2007). Furthermore, no account is made

for random events that occur over the course of a truck haul cycle. Queuing to load and

unload, refuelling, operator breaks, and unloaded trucks giving way to loaded trucks on

narrow sections of road or intersections are examples of events that will impact on a

truck cycle time. Such events cannot be accounted for when a predicted cycle time is

based on theoretical equipment capabilities.

In this study, one of the analytical models developed is based on multiple regression

(MR), where factors in the load/haul cycle considered potentially significant are the

independent variables and the cycle time is the dependent variable. Edwards and Holt

(2000) developed an MR model for hydraulic excavator cycle time with satisfactory

results. Edwards and Griffiths (2000) and Tam et al. (2002) have subsequently shown

that a neural network (NN) model for hydraulic excavator cycle times has a predictive

performance that “is superior to the MR models.” However, this assertion may not be

true in every case.

The second analytical model developed for this project is based on NN technology.

To this end the MATLABw (MATrix LABoratory) software package developed by The

Mathworks (Demuth et al., 2005) is utilised to create an NN that is the core of an artificial

intelligence (AI) model. The same significant variables used in the MR models are used

to train the AI model. NN have found application in mining; for example, Alehossein

(2002) discusses an NN model for prediction of three Cartesian force components acting

at and on the cutter-head of a rock cutting machine, Tam et al. (2002) developed an

artificial NN model predict excavator performance, and Grayeli and Moosavi (2006)

used artificial NN modelling to predict the load distribution in mining cable bolts.

In this study, three methods of truck cycle time estimation are compared. These are:

(1) simulation using TALPAC;

(2) artificial NN; and

(3) multiple regression.

The objective is to determine the best method among the three based on comparison with

the actual cycle times for various truck haulage routes at a large open-pit gold mine in

Western Australia. A secondary objective of this study is to investigate whether the

predictive capabilities of the three methods used will increase from TALPAC to the MR

model and from this model to the AI model as previously believed.

The scope of this study is limited to predicting the truck travel time (loaded þ empty)

only; the reason being that these are the elements of truck cycle for which accurate data

were available for modelling. However, a base set of 12 independent variables is used

in both the regression and NN models (Table I).

TALPAC Software

TALPAC is one of the most widely used truck and loader simulation packages

in Australian mining, but most truck manufacturers have programs that calculate

results using similar algorithms, for example, FPC by Caterpillar, Inc. For mine

Truck cycle time

447

ECAM

17,5

Variable

Description

shift

wait

Is a Boolean type data field, 0 for day shift and 1 for night shift

Is a Boolean field equal to 1 where waiting at shovel is non-zero, and a 0 in all

other cases

Is a Boolean field equal to 1 where queuing at shovel is non-zero, and a 0 in all

other cases

Numeric field listing the loading time for each cycle

Numeric field listing distance of haul route

Numeric field listing the change in elevation over the haul route

Numeric filed representing the type of loading unit

Numeric field listing total rainfall for the day of the haul cycle in mm

Numeric field listing evaporation for the day of the haul cycle in mm

Numeric field listing speed of the maximum wind gust on the day of the haul

cycle in km/h

Numeric field representing direction of the maximum wind gust on the day of

the haul cycle

A numeric field averaging the 9 a.m. and 3 p.m. relative humidity values

que

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

448

Table I.

Base set of independent

variables

load

tot_dist

vert_dist

loading_unit

rain_amount

evap_amount

max_wind_gust

max_wind_direction

av_rel_humidity

planning purposes, the aim of computer simulation is to determine the truck-loader

fleet productivity expressed in bank cubic metres (BCM) per operating hour.

The first step in running a TALPAC simulation is to define the load and haul

equipment. Properties such as bucket/tray capacities, power ratings, and both capital

and operating costs are defined for the load and haul units used by the operation. Also

defined at this point are the expected spotting and loading times. The user is then able

to assign a statistical spread to the times that will be used in the simulation based on

the expected time.

The intended haul route then is defined as a series of sections. Each section is

allocated a length, grade, rolling resistance, and speed limitation. Indication is also

made as to whether the truck is loaded or empty for that section of the route. Truck

spotting and loading/dumping times also are included in the haul cycle as auto entries

of zero distance. The duration of these sections of the cycle are drawn from the

parameters defined for the loading and dumping units.

Material properties and shift rosters are defined before the simulation is run for the

extraction of the target BCM (or tonnes) of rock. A number of reports are generated by

the simulation relating to productivity, tyre and fuel consumption, haul cycle, and cash

flow. For this study, the haul cycle report is the key point of interest.

Artificial NNs

Artificial NNs have been utilised for a variety of applications as the processing power of

computers has improved since the late-1980s. The primary advantage of such networks is

their ability to “learn” non-linear relationships between input variables and target output

values. Artificial NNs are designed in such a way as to attempt to replicate biological NNs

that are part of an animal’s nervous system. The human brain does not use higher

mathematics to solve problems; instead hundreds of billions of neurons interactively put

their contributions (weights) together towards achieving the best and quickest possible

outcome (Mehrotra et al., 1997). This concept has been used in the NN technique to predict

the haulage cycle time from a combination of variables presented in Table I.

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

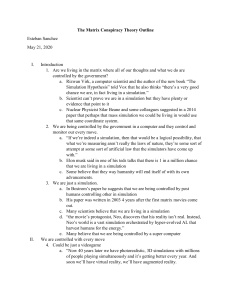

A simplified representation of feed-forward NN functionality is shown in Figure 1,

where R inputs are presented to a single neuron transfer function f. The elementary

neuron has R inputs and with each input there is an associated weight w. Before using

the NN for predictions, it is trained for a set of data to calculate the weights of each

neuron-to-neuron connection. This happens by continuous readjustment of the weights

through the redistribution of the feedback errors, which arise by comparing the

calculated output with the actual. A single layer neuron network is similar to a

multivariable linear regression model. The input to the transfer function f comprises the

sum of the weighted inputs and bias and the output from transfer function gives the

activation a of the neuron. Back propagation networks often use the hyperbolic tangent

sigmoid (tansig), ft, or log sigmoid (logsig), fl transfer function as given in equation (1):

ft ¼

2

21

1 þ e 22n

fl ¼

1

1 þ e 2n

Truck cycle time

449

ð1Þ

Each input is multiplied by its individual weighting, w1,1 to w1,R, where the subscripts

refer to (layer 1, input number). The bias, b, is applied to the sum of all weighted inputs

before presentation to the neuron function. Mathematical details of the process of

applying weights and biases in the training of the NN are discussed by Haykin (2008).

Multiple linear regression

Multiple linear regression analysis is a statistical method of determining a formula

with which to find the value of a dependent (unknown) variable by its relationship to a

set of independent (known) variables. Each of the independent variables is assigned

a weighting that reflects its impact on the value of the dependent variable. This

weighting is referred to as the coefficient of the variable in question. The formula is

developed based on a set of data where the values of both independent and dependant

variables are known. Then the formula is applied to a set of known independent

variables in an attempt to estimate the unknown dependent variable:

P1

W11

P2

n

Σ

a

f

P3

W1R

PR

b

l

Input

Source: Demuth et al. (2005)

General neuron

= f (Wp + b)

Figure 1.

Simplified neuron

functionality

ECAM

17,5

.

The general form of a linear regression model is shown in equation (2) (Neter et al.,

1985):

p21

X

bk X ik þ 1i where X i0 ¼ 1

ð2Þ

Yi ¼

k¼0

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

450

where:

.

there are ( p 2 1) independent variables;

.

the Yi term represents each instance of the dependent variable;

.

the bk term represents each of the coefficient values from 0 to ( p 2 1);

.

the Xik term represents each instance of all independent variables from 0 to

( p 2 1); and

.

1i is a random error term with a mean value of 0.

Assuming that the expected value of the random error term is zero, an expected value

for the dependent variable is shown by equation (3) (Neter et al., 1985):

EðY Þ ¼ b0 þ b1 X 1 þ b2 X 2 þ · · · þ bp21 X p21

ð3Þ

It is not expected that all independent variables will have a purely linear influence on the

cycle time. It has been shown, however, that a linear MR technique can be utilised by

manipulating the data before commencing the regression (Chanda, 1989). In developing

his model to estimate the probability of success in multiple seam room and pillar coal

mining, Chanda (1989) used the linear form of each of the identified independent

variables as well as cube root, square root, square, cubic, and logarithmic forms of each

variable to take into account the non-linear interactions among the variables. A similar

process is applied to the defined independent variables used in this project.

It is recognised that not all defined independent variables will prove significant in

determining the dependent variable. In such cases, forward stepwise regression is

considered to be the preferential regression method (Draper and Smith, 1966). Stepwise

regression is an iterative process where the correlation of each of the independent

variables to the dependent variable is assessed, and the independent variable with the

highest correlation is entered into the regression equation at each iteration. The process

is ended when all variables are included in the equation or the correlation between the

remaining independent variables and the dependent variable is considered insignificant.

Modelling applications

Truck cycle time data

Data recorded by a computerised fleet management system employed at the mine was

utilised for this project. The data were extracted from the onsite database via

specifically developed database queries. Two initial sample sets of data received from

the mine were in the form of Excel spreadsheet files. The datasets were filtered later to

include only truck cycles along a particular haul route. Haul route data were supplied

by the mine in the form of digitised strings from a mine design package. The “all bench

data” refer to data relating to a mining bench from which a loading unit loads broken

rock onto trucks for haulage to the surface. The data were stored in separate

spreadsheets representing 16 individual blasting blocks (block data). An additional

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

field of loading unit was added to allow filtering of the data in order to focus on a

particular loading unit (shovel) as the source of material for haulage.

The routes were created by starting in the approximate centre of the mine bench in

question and digitising points along the haul route by snapping points to the pit

topography triangulation along the centre of the haul route to the dumping point. The

specific blast blocks represented in the cycle data were selected to correspond with

the actual block where the haul route string originated. Analysis in Vulcan generated the

total length of the route and the total change in elevation along the length of each route –

intended variables in the NN and regression models. The digitised routes were used to

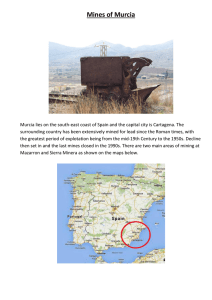

define the haul routes in the TALPAC simulation. Figure 2 shows a typical haul route from

a specific blast block in the pit to the stockpile. Five haul routes were used in the modelling.

Truck cycle time

451

TALPAC model

Haul route information is entered into TALPAC by importing route information in the

form of comma separated value (CSV) text files. The CSV files contain values of the

northing (Y), easting (X), and elevation (Z) at all points digitised along the haul route.

Such files are created by exporting string data from Vulcan Software. Speed limits

applicable to different sections of each haul route are entered with the haul route data.

Speed limits used for this project are the actual limits supplied by the mining company.

Rolling resistance working against trucks is also defined with the haul routes. The

rolling resistance defined for this project is the TALPAC default of 3 per cent. This is

not a measured variable and is often adjusted by TALPAC users as a way of forcing

the software to fit actual cycle times. Once the TALPAC variables are defined, one can

simulate the haulage system to determine cycle times, costs, and productivity.

In order to fully investigate the variation between TALPAC cycle time predictions,

25 simulations are conducted for each haul route in this project.

Artificial NN model

Spreadsheet data for network inputs and targets were imported into the Matlabw for

modelling. For this project, a total of 48 networks are developed. All networks are

two-layer networks where inputs are fed into a layer of tansig neuron/s. Outputs from

layer 1 subsequently report to a single purelin neuron, which in turn produces a single

Blast polygons

Haul road

Stockpile

Figure 2.

Plan of the open pit

showing a haul road

ECAM

17,5

452

output value. For each of the datasets, 12 networks are created with the number of tansig

neurons in layer 1 ranging from one to 12. Figure 3 is a graphical representation of a

network with six tansig neurons in the first layer. Using the tools in MATLAB the network

was trained based on the back-propagation algorithm (Edwards and Griffiths 2000).

Regression model

The regression model uses the same training and simulation matrices as created for the

NN modelling. However, it is necessary to transpose network-training data so that it is in

the correct format to utilise the regress command and obtain variable coefficients.

Equation (4) is an example of a regression model developed for all bench data. As the

same sets of data are used for regression as the NN modelling, regression results are also

filtered to contain only cycle times where trucks are loaded by one of the face shovels:

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

time ¼ 20:670783171ðshiftÞ2 2 0:407837745ðwaitÞ0:50 þ 0:295354166ðqyeÞ0:33

þ 1:39236775ðload Þ 2 0:029126259ðload Þ2 þ 0:000401797ðload Þ3

þ 0:030977804ðtot_distÞ 2 5:49535 £ 10206 ðtot_distÞ2

2 3:41946 £ 10211 ðtot_distÞ3 þ 0:001092995ðvert_distÞ2

þ 3:29469 £ 10206 ðvert_distÞ3 þ 0:010015433ðrain_amountÞ3

2 0:057618089ðevap_amountÞ2 þ 0:005808809ðevap_amountÞ3

ð4Þ

2 0:012901967ðmax _windgustÞ 2 0:002691516ðmax _windgustÞ2

þ 5:79927 £ 10205 ðmax _windgustÞ3

þ 0:642826831 log10 ðmax _wind_directionÞ

þ 0:136417323ðav_rel_humidityÞ 2 0:004912923ðav_rel_humidityÞ2

þ 5:13972 £ 10205 ðav_rel_humidityÞ3

12

Figure 3.

Network with six tansig

neurons in the first layer

12 Input variables

Input weights

Hidden layer weights

IW{1,1}

LW{2,1}

b{1}

b{2}

Layer 1 bias

6

Layer 2 bias

6 tansig neurons

O

u

t

p

u

t

1

1 purelin neuron

Truck cycle time

453

Artificial NN results

The mean time for each list of outputs is considered the simulated cycle time. As is

shown in Figure 4, the predicted cycle time varies between network structures.

In the majority of cases, the variance is minimal. Note that the outlier prediction for the

eight-neuron networks applied to the filtered bench dataset (Figure 5) has a negligible

effect on the mean cycle time for that network. A similar observation can be made

Time

Mean Minimum Maximum

Variation (%)

(minutes) (minutes) (minutes) ðmaximum 2 minimum=minimumÞ £ 100%

Route

Brownhill – TW4

Chaffers – Blendfinger

Chaffers – SW3

Stores – Blendfinger

Stores – TW4

24.83

23.23

24.97

44.00

48.31

24.70

23.09

24.86

43.78

48.11

24.95

23.34

25.20

44.21

48.57

1.0

1.1

1.4

1.0

1.0

Table II.

TALPAC results

Neural network results for all bench data

45

40

Brownhill to TW4

Chaffers to blendfinger

Chaffers to SW3

Stores to blendfinger

Stores to TW4

35

30

25

1

N

eu

ro

n

2

N

eu

ro

ns

3

N

eu

ro

ns

4

N

eu

ro

ns

5

N

eu

ro

ns

6

N

eu

ro

ns

7

N

eu

ro

ns

8

N

eu

ro

ns

9

N

eu

ro

ns

10

N

eu

ro

ns

11

N

eu

ro

ns

12

N

eu

ro

ns

20

A

ct

ua

l

Time (minutes)

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

Results

Variation in the predicted cycle time between simulations for each route in TALPAC is

limited. The most significant difference between minimum and maximum predicted

times is a 1.4 per cent variation for the “Chaffers to SW3” haul route. Table II

summarises the simulated times for relevant haul routes as determined by TALPAC.

Mean times listed in Table II are used for comparison with regression and NN cycle

time predictions.

Networks

Figure 4.

Comparative results for all

networks developed for all

bench simulation data

ECAM

17,5

Neural network results for filtered bench data

45

Brownhill to TW4

Chaffers to blendfinger

Chaffers to SW3

Stores to blendfinger

Stores to TW4

35

30

25

Figure 5.

Comparative results for all

networks developed

for filtered bench

simulation data

A

ct

ua

l

1

N

eu

ro

n

2

N

eu

ro

ns

3

N

eu

ro

ns

4

N

eu

ro

ns

5

N

eu

ro

ns

6

N

eu

ro

ns

7

N

eu

ro

ns

8

N

eu

ro

ns

9

N

eu

ro

ns

10

N

eu

ro

ns

11

N

eu

ro

ns

12

N

eu

ro

ns

20

Networks

regarding the outlier for the three-neuron network as shown in Figure 6 for all block

data. However, Figure 7 shows a large discrepancy for the network with 12 tansig

neurons. The filtered block dataset contain the lowest number of sample cycles, and it is

expected that the poor result for the 12-neuron network is an example of “over fitting”

Neural network results for all block data

45

40

Time (minutes)

Brownhill to TW4

Chaffers to blendfinger

Chaffers to SW3

Stores to blendfinger

Stores to TW4

35

30

25

ua

l

N

eu

ro

n

2

N

eu

ro

ns

3

N

eu

ro

ns

4

N

eu

ro

ns

5

N

eu

ro

ns

6

N

eu

ro

ns

7

N

eu

ro

ns

8

N

eu

ro

ns

9

N

eu

ro

ns

10

N

eu

ro

ns

11

N

eu

ro

ns

12

N

eu

ro

ns

20

1

ct

Figure 6.

Comparative results for all

networks developed for all

block simulation data

A

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

454

Time (minutes)

40

Networks

Neural network results for filtered block data

Truck cycle time

80

Brownhill to TW4

Chaffers to SW3

Stores to blendfinger

Stores to TW4

455

60

50

40

30

1

N

eu

ro

n

2

N

eu

ro

ns

3

N

eu

ro

ns

4

N

eu

ro

ns

5

N

eu

ro

ns

6

N

eu

ro

ns

7

N

eu

ro

ns

8

N

eu

ro

ns

9

N

eu

ro

ns

10

N

eu

ro

ns

11

N

eu

ro

ns

12

N

eu

ro

ns

20

A

ct

ua

l

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

Time (minutes)

70

Networks

of data due to an excess of neurons in the first layer of the network in relation to the

number of samples presented to the network.

In order to determine the optimal network structure for each dataset, an iterative

process was used in which the target time was subtracted from the simulated time for

each haul route. Results relating to the network with minimum variance were used for

comparison with the other methods.

Regression model results

As the same sets of data were used for regression modelling as the NN modelling,

regression results also were filtered to contain only cycles where trucks were loaded by

one of the face shovels.

Comparison of results

Predicted cycle times for all simulation methods are shown in Figures 8-11. Predicted

times in each graph are plotted against a line representing the mean actual cycle times

for each dataset. Where predicted times were close to the actual cycle times, points

were plotted in close proximity to this line.

Generally speaking, predicted times for both the regression and NN models were

significantly more accurate than the TALPAC predictions for all sets of data. There

appears to be a limited variation between the times predicted by regression and NN

models.

In order to quantify variations between predicted and actual cycle times, a

percentage error for each haul route was calculated using equation (5). Graphical

representations of calculated errors are shown in Figures 12-15:

Figure 7.

Comparative results for

all networks developed

for filtered block

simulation data

ECAM

17,5

Simulated times (minutes)

Regression simulation

Figure 8.

Compared results for all

bench simulation data

45

TALPAC simulation

Neural network simulation

Actual times

40

35

30

25

20

20

25

30

35

Actual time (minutes)

40

45

Filtered bench data

Simulated times (minutes)

50

Figure 9.

Compared results

for filtered bench

simulation data

Regression simulation

TALPAC simulation

45

Neural network simulation

Actual times

40

35

30

25

20

20

25

30

35

Actual time (minutes)

40

45

40

45

All block data

50

Simulated times (minutes)

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

456

All bench data

50

Figure 10.

Compared results for all

block simulation data

TALPAC simulation

Regression simulation

45

Neural network simulation

Actual times

40

35

30

25

20

20

25

30

35

Actual time (minutes)

Simulated times (minutes)

Regression simulation

TALPAC simulation

45

Neural network simulation

Actual times

40

457

35

30

25

20

20

25

30

35

40

45

Actual time (minutes)

Figure 11.

Compared results

for filtered block

simulation data

Percentage errors all bench data

20

15

10

5

Errors (%)

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

Truck cycle time

Filtered block data

50

0

–5

Regression

Neural network

TALPAC

–10

–15

–20

–25

Chaffers to blendfinger

Brownhill to TW4

Chaffers to SW3

Stores to blendfinger

Stores to TW4

Figure 12.

Comparative percentage

errors for all bench

simulation data

–30

Haul routes

Percentage error ¼

Mean predicted time 2 Mean actual time

£ 100%

Mean actual time

ð5Þ

Figures 12-15 show that both regression and NN models are more accurate than

TALPAC in all cases. TALPAC simulation consistently is most accurate for the

Chaffers to SW3 haul route through all datasets.

Conclusions

The results outlined above would appear to indicate that both NN and regression

models based on actual mine data are superior in their predictive abilities to TALPAC

simulations. TALPAC Software appears to have under predicted cycle times for

shorter haul routes and over predicted times for the longer haul routes. There appears

ECAM

17,5

Percentage errors filtered bench data

20

15

10

5

Errors (%)

458

0

–5

–20

–25

Neural network

Chaffers to blendfinger

Brownhill to TW4

Chaffers to SW3

Stores to blendfinger

Stores to TW4

TALPAC

–30

Haul routes

Percentage errors all block data

20

15

10

Errors (%)

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

–15

Figure 13.

Comparative percentage

errors for filtered bench

simulation data

Regression

–10

5

0

–5

Figure 14.

Comparative percentage

errors for all block

simulation data

Chaffers to blendfinger

Brownhill to TW4

Chaffers to SW3

Stores to blendfinger

Stores to TW4

Regression

Neural network

TALPAC

–10

–15

Haul routes

to be minimal quantifiable difference between predictions made by the regression and

NN models.

The data utilised for this project is limited to information made available from an

operating mine only. Therefore, the models developed apply to this specific mine site

and one has to be careful not to directly apply these models to other operations.

However, the regression and NN models similar to those developed in this project

easily can be developed for any open-pit operation providing that sufficient data is

available. In such a case, input data could be refined to include variables considered

significant by the operation itself.

Truck cycle time

Percentage errors filtered block data

25

20

15

Brownhill to TW4

Chaffers to SW3

Stores to blendfinger

Stores to TW4

Errors (%)

10

459

5

0

–5

Regression

Neural network

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

–10

–15

TALPAC

–20

Haul routes

The quantity, and quality, of data recorded by open-cut mining operations is ever

increasing, particularly with the implementation of computer-based monitoring

systems. An opportunity exists for mines to utilise the collected data to predict load

and haul cycle times more accurately. The benefits to be gained from increased

accuracy include the potential to assist in mine planning, scheduling and budgeting

decisions.

References

Alehossein, H. (2002), “Data mining for miners – the general mixed model (GMM)”, Exploration

and Mining Research News, Vol. 14, pp. 6-8.

Blackwell, G.H. (1999), “Estimation of large open pit haulage truck requirements”, CIM Bulletin,

Vol. 92 No. 1028, pp. 143-69.

Chanda, E.C.K. (1989), “Evaluation of success probability in multiple seam room-and-pillar

mining”, Mining Science and Technology, Vol. 9, pp. 57-73.

Demuth, H., Beale, M. and Hagan, M. (2005), Neural Network Toolbox for Use with MATLABw,

The Mathworks, Natick, MA.

Draper, N.R. and Smith, H. (1966), Applied Regression Analysis, Wiley, New York, NY.

Edwards, D.J. and Griffiths, I.J. (2000), “Artificial intelligence approach to calculation of

hydraulic excavator cycle time and output”, Mining Technology: Transactions of the

Institute of Mining and Metallurgy, Section A, Vol. 109 No. 1, pp. 23-9.

Edwards, D.J. and Holt, G.D. (2000), “ESTIVATE: a model for calculating excavator productivity

and output costs”, Engineering, Construction and Architectural Management, Vol. 7 No. 1,

pp. 52-62.

Grayeli, R. and Moosavi, M. (2006), “Using artificial neural network (ANN) for modelling of load

distribution along fully grouted cable bolts”, Mining Technology: IMM Transactions

Section A, Vol. 115 No. 1, pp. 24-33.

Hardy, R.H. (2007), “Selection criteria for loading and hauling equipment – open pit mining

applications”, PhD thesis, Curtin University of Technology, Sydney, 2 Volumes, 558 pp.

Figure 15.

Comparative percentage

errors for filtered block

simulation data

ECAM

17,5

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

460

Haykin, S. (2008), Neural Networks and Learning Machines, 3rd ed., Prentice-Hall, Upper Saddle

River, NJ, 938 pp.

Mehrotra, K., Mohan, C.K. and Ranka, S. (1997), Elements of Artificial Neural Networks, The MIT

Press, Cambridge, MA.

Neter, J., Wasserman, W. and Kutner, M.H. (1985), Applied Linear Statistical Models, 2nd ed.,

Richard D. Irwin, Homewood, IL.

Tam, C.M., Tong, T.K.L. and Tse, S.L. (2002), “Artificial neural networks model for predicting

excavator productivity”, Engineering Construction & Architectural Management, Vol. 9

Nos 5/6, pp. 446-52.

About the authors

Emmanuel K. Chanda is an Associate Professor and a Program Leader in School of Civil,

Environmental and Mining Engineering, University of Adelaide (Australia). His expertise is in

mine planning and design. He has over 25 years experience in mine operations, academia, and

consulting, mainly involving base and precious metal projects. His research interests are process

optimization in mining, new generation mine haulage and systems, novel mining techniques,

and measurement and sensing in mining. Chanda has been a recipient of the American Fulbright

Senior Research Scholarship. For ten years prior to joining the University of Adelaide, he worked

for Curtin University of Technology, WA School of Mines, as Senior Lecturer, Associate

Professor, and Head of the Mining Engineering Department and member of the Program Leaders

Committee of Mining Education Australia (MEA). Prior to joining Curtin University, Chanda

worked for Zambia Consolidated Copper Mines Limited where he held various positions

including that of Mine Planning Superintendent. Chanda has BMinSc (Mining Engineering) from

the University of Zambia, MEng (Engineer of Mines) from the Colorado School of Mines, USA,

and PhD (Mining Engineering) from the Technical University of Berlin, Germany. He is a

member of the Australasian Institute of Mining and Metallurgy (AusIMM) and the Society for

Mining, Metallurgy and Exploration (SME). Emmanuel K. Chanda is the corresponding author

and can be contacted at: echanda@civeng.adelaide.edu.au

Steven Gardiner is a Long-Term Planning Engineer at Kalgoorlie Consolidated Gold Mines’

Superpit Operation in Kalgoorlie, Western Australia. He graduated from Curtin University of

Technology, WA School of Mines in 2006 and commenced working as a graduate at BHP Billiton

Iron Ore’s Mt Whaleback mine in the Western Australian Pilbara region. He has returned to

Kalgoorlie to gain experience in a different type of operation and commodity, and to continue his

studies. Gardiner enjoyed a diverse career path before enrolling in university as a mature age

student. He successfully completed a BEng (Mining Engineering) with first class honours and

received a number of academic awards in the process. He is currently working at attaining a

Master of Engineering Science (Mining) and is a member of the Australasian Institute of Mining

and Metallurgy (AusIMM).

To purchase reprints of this article please e-mail: reprints@emeraldinsight.com

Or visit our web site for further details: www.emeraldinsight.com/reprints

Downloaded by University of Pittsburgh At 11:28 10 March 2015 (PT)

This article has been cited by:

1. Alireza S. Kaboli, David G. Carmichael. 2014. Optimum scraper load time and fleet size for minimum

emissions. International Journal of Construction Management 14, 209-226. [CrossRef]

2. Alireza S. Kaboli, David G. Carmichael. 2014. Truck dispatching and minimum emissions earthmoving.

Smart and Sustainable Built Environment 3:2, 170-186. [Abstract] [Full Text] [PDF]

3. Toly Chen. 2014. A PCA-FBPN Approach for Job Cycle Time Estimation in a Wafer Fabrication Factory.

International Journal of Fuzzy System Applications 2:10.4018/IJFSA.20120401, 50-67. [CrossRef]

4. David G. Carmichael, Beau J. Bartlett, Alireza S. Kaboli. 2014. Surface mining operations: coincident unit

cost and emissions. International Journal of Mining, Reclamation and Environment 28, 47-65. [CrossRef]

5. David G. Carmichael, Evan H. Williams, Alireza S. KaboliMinimum Operational Emissions in

Earthmoving 1869-1878. [CrossRef]

6. Toly Chen. 2011. Job cycle time estimation in a wafer fabrication factory with a bi-directional classifying

fuzzy-neural approach. The International Journal of Advanced Manufacturing Technology 56, 1007-1018.

[CrossRef]