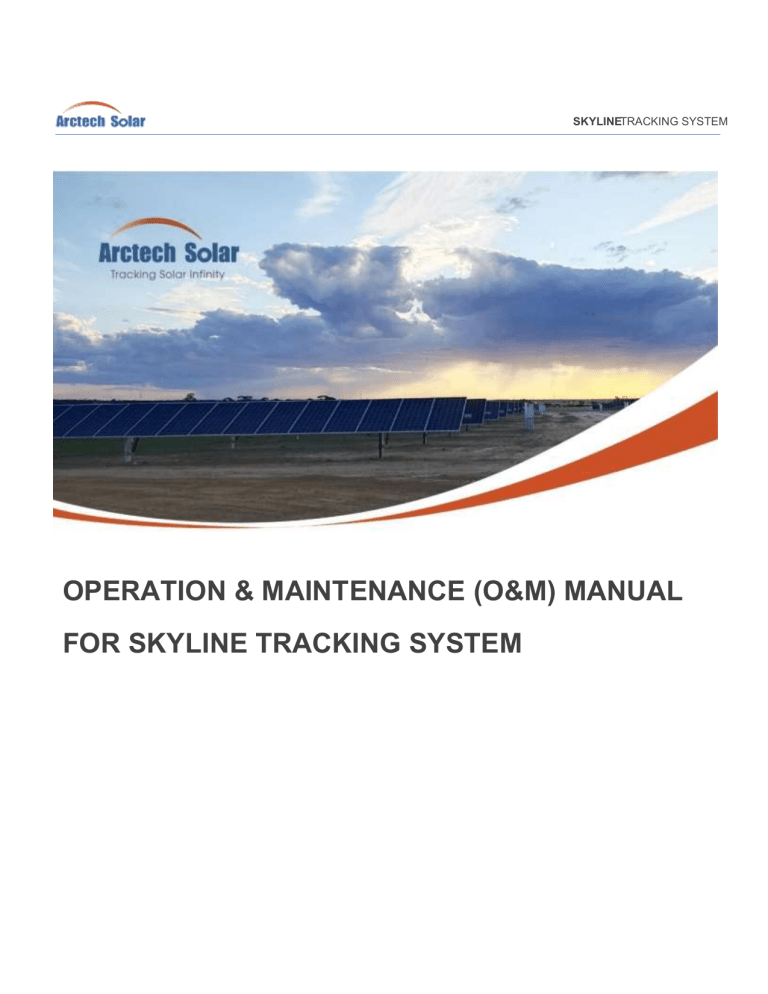

SKYLINETRACKING SYSTEM SKYLINE TRACKING SYSTEM OPERATION & MAINTENANCE (O&M) MANUAL FOR SKYLINE TRACKING SYSTEM Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL -China · Japan · India · U.S. · Spain · Mexico · Australia · UAE · Chile · Argentina · Vietnam- Log of the document Rev. Description Date Created 1.0 First release 2020/07/10 LYR & FSR 1.3 Some wording ana controller pic, lubricant type update. 2020/08/11 Pascal & Yisong 1.4 Wording updating in wind protection 2020/09/08 setting Checked Approved Pascal TABLE OF CONTENTS 1. FOREWORD ...................................................................................................... 4 1.1. ABOUT THIS MANUAL .................................................................................................................................... 4 1.2. SAFETY RECOMMENDATIONS AND SYMBOLS USED .......................................................................... 5 2. DATASHEET OF SKYLINE TRACKER ............................................................. 6 3. GENERAL TRACKER DESCRIPTION .............................................................. 8 4. LIST OF TOOLS REQUIRED .......................................................................... 11 2 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL 5. LIST OF RELATED DOCUMENTS .................................................................. 12 6. SOLAR TRACKER FUNCTIONALITY OVERVIEW ......................................... 12 6.1. HORIZONTAL SINGLE AXIS TRACKER (HSAT) ...................................................................................... 12 6.2. DAYTIME TRACKING .................................................................................................................................... 12 6.3. BACKTRACKING ............................................................................................................................................ 12 6.4. AI TECHNOLOGY(Optional) .......................................................................................................................... 13 7. WIND PROTECTION SKYLINE ....................................................................... 14 7.1. Wind Stow Strategy with Weather Warning ................................................................................................. 14 7.2. Wind Stow Strategy Without Weather Warning .......................................................................................... 15 7.3. Summary ........................................................................................................................................................... 15 8. POWER SUPPLY ............................................................................................ 16 9. AI CONTROLLER AND COMMUNICATIONS ................................................. 18 10. CONTROLLER INTERFACE AND WORKING MODES .................................. 23 11. GENERAL TROUBLESHOOTING ................................................................... 24 12. PREVENTIVE MAINTENANCE ....................................................................... 27 1. FOREWORD 1.1. ABOUT THIS MANUAL This O&M manual explains how to safely operate and maintain Artech’s SkyLine tracking system. Please pay special attention to the key warnings presented in this manual. It describes the proper operation and maintenance procedures and provides minimum standards required for product performance and reliability, as well as for warranty purposes. Failure to follow the guidelines set forth can result in property damage, bodily injury, or even death. 3 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL • Ensure that operation and maintenance is completed by a trained professional. • Comply with all applicable local or national codes, including any that may supersede this manual. • Use only SkyLine original parts or parts supplied or recommended by Arctech Solar. Replacements with parts from other sources may void any applicable warranty. • Comply with all applicable fire codes including, but not limited to, keeping walkways clear and avoiding obstacles. • Ensure provided information is accurate. Issues resulting from inaccurate information are the installer’s responsibility. • Ensure safe installation of all electrical parts. All electrical installation and procedures should be conducted by a trained professional. All work must comply with national, state and local installation procedures, product and safety standards. COPYRIGHT STATEMENT: All the contents of this manual, including the graphics contained herein, are intended for the use of the recipient to whom the document and all associated information are directed. Arctech Solar Holding Co., Ltd. owns the copyright of this document, which is supplied in confidence. It must not be used for any purpose other than that for which it is supplied and must not be reproduced, in whole or in part stored in a retrieval system or transmitted in any form or by any means without prior permission in writing from Arctech Solar Holding Co., Ltd. ARCTECH SOLAR® is a trademarked tracker and module mounting structure of Arctech Solar Holding Co. A patent covering the ARCTECH SOLAR® has been granted. DISCLAIMER: Information and data contained in this manual is exclusively for the purpose of assisting in the operation and maintenance of Arctech Solar Holding Co., Ltd.’s ARCTECH SOLAR®. No warranty is given nor can liability be accepted for use of this information for any other purpose. Arctech Solar Holding Co., Ltd. has a policy of continuous product development and reserves the right to amend specifications and parameters without notice. The parts and spare parts supplied by Arctech Solar have been specially designed by Arctech Solar for its trackers, non-original parts and spare parts and / or not validated by Arctech Solar will be considered invalid, however Arctech Solar may certify these elements and their safety. 1.2.SAFETY RECOMMENDATIONS AND SYMBOLS USED 1. Comply with all the applicable local or safety standards and laws, including those that may supersede this manual. 2. Use only original parts or parts supplied or recommended by Arctech Solar. Replacements with parts from other sources may avoid any applicable warranty. 3. Use only tools recommended by the manufacturer and which are certified, regulated and in good condition. These tools must only be used for the purpose they are made for. 4. The personal who is to perform these activities must wear certified personal protective equipment (PPE) associated for each task during installation, operation, service and maintenance of the tracking system and follow local regulations always. 4 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL In all tasks, it is mandatory to wear high visibility clothing, safety boots, protection gloves, googles, hearing protectors and a hard hat. 5. The working area and its environment must be clean and tidy with no elements that could obstruct visibility or works. 6. For works that may have electric shock risk, make sure the protections are designed for this purpose. 7. Do not perform any works while under the effects of alcohol or drugs. 8. Do not perform any works if feeling tired or sleepy. 9. Make sure that you adopt an appropriate posture while performing the tasks which will not cause pain or injuries. 10. Do not perform any works in case of doubt or if any of the above-mentioned instructions are not being implemented. 1.3 AFTER SALES SERVICE For any issue regarding after sales, please contact us by e-mail: services@arctechsolar.com 5 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL 2. DATASHEET OF SKYLINE TRACKER 6 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL 7 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL 8 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL 9 | Page Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL 3. GENERAL TRACKER DESCRIPTION Arctech’s Skyline is a string-powered tracking system which tracks the Sun’s position throughout the day and returns to stow during night-time. Different stow routines are also used in diverse weather conditions, such as high winds, heavy rainfall or snowfall. Once the trackers are installed and commissioned, the trackers continue to track the sun's trajectory in auto-mode Figure. Main functional groups of the Solar Tracker “SkyLine” 1 | Page 0 Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL MAIN ASSEMBLIES OF THE SKYLINE TRACKER Item 1 Description Qty. per Assy. Qty per tracker 1 DRIVE ASSEMBLY 1.1 Slew Drive Motor Assembly 1 1.2 Drive Seat Welding Assembly 2 1.4 Control Box 1 1.3 Bolts, nuts and Washers M20 - 1.4 Bolts, nuts and Washers M16 - 2 Normal post head ASSEMBLY Refer to installation manual 2.1 Pre-assembled bearing pedestal 1 2.2 Plastic Bearing 2 2.3 Bearing Baffles 2 2.4 Bolts and fasteners M16 - 3 Refer to installation manual TORQUE TUBE ASSEMBLY 3.1 Torque Tubes 8 3.2 Torque Tubes Connection 8 3.3 Bolts, nuts and Washers M20 - 4 Refer to installation manual PURLIN ASSEMBLY 4.1 Purlin 1 4.2 U-Bolt 1 4.3 Bolts, nuts and Washers M10 - 1 | Page 1 S kyLine O&M Manual 1 .4 PROJECT NAME Doc. Rev. Project OPERATION & MAINTENANCE 5 MANUAL Refer to installation manual SPRING ASSEMBLY 5.1 Spring 1 5.2 Spring Adjusting seat 1 5.3 Spring Upper Fixing plate 1 5.4 Bolts, nuts and Washers M12 - 6 DAMPER ASSEMBLY Refer to the GA drawing. 6.1 Damper 1 6.2 Damper Adjusting seat 1 6.3 Damper Upper Fixing plate 1 6.4 Bolts, nuts and Washers M12 - All fasteners should have been torqued according to the installation manual using the maximum allowable value. In this manual, when torque checks are required, they should be done using the appropriate required value. TORQUE VALUE TABLE Hex Bolt size Join description Torque, Nm Torque, ft-lb M4 Antenna bracket to antenna 1.5 1.1 M6 Modules to purlin (If applied) 8~11 5.9~8.1 M8 Controller brackets to torque tube, communication box bracket to wind sensor post 14~17 10.3~12.5 M10 Purlin to torque tube, Wind sensor post connection 35~40 25.8~25.9 1 | Page 2 Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL M12 Bearing baffle, torque tube connector, spring arm to torque tube, damper/spring lower bracket to pile 70~85 51.6~62.7 M16 Motor post head to pile, normal post head to pile, wind sensor post assemblies 180~210 132.8~154.9 M20 Slew drive to motor post head 380~440 280.3~324.5 4. LIST OF TOOLS REQUIRED The following list shows the recommended tools for Operation & Maintenance. However, other tools may be used according to the staff team experience: 1 | Page 3 Doc. Rev. Project OPERATION & MAINTENANCE S kyLine O&M Manual 1 .4 PROJECT NAME MANUAL 1 | Page 4 OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 5.LIST OF RELATED DOCUMENTS • • • • SkyLine Installation Manual Slew Drive O&M Manual Tracker layout and GA drawings Annex (included at the end of this document) OPERATION 6. SOLAR TRACKER FUNCTIONALITY OVERVIEW Automatic system which drives solar panels to receive solar irradiation. 6.1. HORIZONTAL SINGLE AXIS TRACKER (HSAT) The rotation axis is horizontal with respect to the ground. 6.2. DAYTIME TRACKING This tracking technology uses geographic latitude, longitude, and time as the main parameters, and astronomical algorithms (a general formula for the sun's position and horizontal coordinates) to calculate the sun's altitude α and azimuth γ. The mechanical system is then driven by the intermittent drive motor of the control system. At the same time, the rotation position of the real time photovoltaic power generation system is detected by the inclination sensor, to achieve the purpose of closed-loop control further optimizing the tracker accuracy. 6.3. BACKTRACKING During sunrise and sunset, shadow will be casted on consecutive PV arrays due to the low altitude of the Sun. Increasing row spacing can effectively reduce power caused by shadow occlusion, but it will increase investment costs such as land, cables, and construction. 15 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME Backtracking technology is a reverse-direction tracking routine. Its application in PV tracking systems can avoid shadow occlusion between PV arrays ensuring the optimisation of power generation of PV systems, and reducing the land area. In simple terms, the backtracking routine uses the control system to calculate whether there is a shadow between the PV arrays in the morning and afternoon according to the module pitch, the array size and the azimuth and altitude of the sun. If there is shadow, the tracker will turn in the opposite direction to avoid it and until the shadow is no longer there. The operation of the tracker throughout the day is: as the Sun's altitude increases after sunrise, the tracker gradually rotates from the flat or starting position to the maximum angle until the time when there is no shading between PV arrays. Then it goes into regular tracking, which is turning towards the sun. In the afternoon, there will be shadow occlusion between PV arrays and the tracker will be in the backtracking mode again, from the maximum tracking angle position gradually turning to flat position to ensure that there is no shadow occlusion in the PV array throughout the day. Figure. PV arrays in the morning or evening without backtracking Figure PV arrays in the morning or evening with backtracking 6.4. AI TECHNOLOGY(Optional) In addition, the AI tracking algorithm continually self-adapts to daily operating conditions including (but not limited to) slope etc, and optimizes the algorithm accordingly for enhanced productivity in varying conditions of operations. By using its own meteorological database and real-time weather data our system is able to identify if cloud shadows are being projected over the panels and make the trackers work individually in consequence. 16 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 7.WIND PROTECTION SKYLINE 7.1. Wind Stow Strategy with Weather Warning If the weather forecast signal indicates that tomorrow there will be a thunderstorm or hurricane whose wind speed ≥ 25m/s (3s gust, 10m), a gale warning information will be generated. By the warning information, the gale protection strategy will be initiated for the next day, despite the anemometer measurements. This gale mode can be categorized by wind directions. The most critical directions for the tracker are East and West (+- 30 degrees). Under gale mode and depending upon measured wind speed, the wind stow strategy can be categorized into two routines: i) gale protection and ii) stow. During i) gale routine, there are three possible positions: East Stow Position: East wind condition, system stays on east stow position. Flat position: System remains flat. West Stow Position: West wind condition, system stays on west stow position. The field wind speed is acquired by the anemometers. The anemometers take the wind speed data in the frequency of one acquisition per second, and the anemometer outputs wind data in a frequency of every three seconds (the output data is the average value of the closest 3 second). The tracker communication system processes the received wind speed data every 30 seconds (calculate the average output value 30 seconds’). Both East and West have two modes that depend on real-time wind speed measured by the field anemometer. If we are in gale mode, the system acquires wind direction and one of the following three will occur: Wind coming from the EAST: Normal Tracking to Flat Position – Stay in Flat position Wind coming from the WEST: Move to Flat position – Normal Tacking to West Wind Position Wind coming from the NORTH or SOUTH: Normal Tacking to the closest stow position at the time anemometers detect wind above threshold. If real-time wind speed is higher than 12 m/s (30s gust), the system will enter Stow Mode directly: East Wind: East Stow Position – East Stow Position – East Stow Position West Wind: West Stow Position – West Stow Position – West Stow Position North/South Wind: Move to the closest East or West position, depending on time of the day anemometer detects wind speeds above the stow threshold Stow mode means the tracker is always nose down, which is the most stable position. The different modes are shown in the following diagram: 17 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 7.2. Wind Stow Strategy Without Weather Warning Regardless the warning routine, field anemometers keep acquiring real-time wind speed data at all times during normal operation mode (no gale warning received). This protects the trackers from large instantaneous wind gusts that had not been forecasted and are higher than 12m/s (30s average). If the instantaneous speed is larger than 12m/s (30s average), the trackers will rotate into stow position 7.3. Summary There are two routines operating simultaneously for added protection. a) b) c) d) e) Stow angle: 30 degree from horizontal. At this tilt tracker is very stable. Wind stow mode gets triggered at 12 m/s (30s interval, detected at 4 m height).This is equivalent to 15 m/s, 3 sec gust measured at 10 m height. Consider the speed of motor is about 5 second per degree, the rapid stowing time from 0deg to 30deg, or 60deg to 30deg will be less than 2.5min. Tracking mode gets resumed once wind speed is lower than 8 m/s for a constant interval of 180 seconds. Gale mode – warning in place from the day before – trackers flat and moving to nose down tilt if wind speed is more than 12 m/s (30 sec) 18 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 8.POWER SUPPLY 8.1. POWER SUPPLY 300-1500 V During the day and under normal circumstances, the controller is powered from the strings with negligible impact on the power generation. To ensure the system works at any time, the lithium battery remains fully charged during the day and supplies power at night. Even then, the battery is in a shallow charge-discharge state which protects and extends the battery life. To protect the system, there is an inline fuse (DC 1500 V) outside the box. 8.2. FROM STRINGS Power comes to the AI controller directly from the PV strings, from a parallel circuit. This way we can see the cost in power supply cables reduced and have a more efficient method which does not rely on any external devices. The power loss generated by this system is insignificant: In a day, the tracker will go through 2 round trips (+30° -> +60° -> 0° -> -60° -> 0° -> +30°) and it takes 10 seconds for the motor to rotate the tracker by 2 degrees. Daily power consumption of the motor -> 10s * (240/2 times) * 24W = 8 Wh. Daily power consumption of the internal circuit of the controller -> 0.5W * 24h = 12 Wh Daily power consumption of the control system -> 8 Wh + 12 Wh = 20Wh There are normally 30 Skyline trackers for a 1MW project. 19 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME Daily power consumption of a 1MW control system -> 0.6kWh / day, Comparing it to the average daily power generation of most PV plants, which is 3000 ~ 5500kWh / MW / day, it only takes up to 0.01 ~ 0.02%, and most existing PV power plants have AC and DC over-provisioning. Battery back-up At night and under special circumstances, the system is powered by the lithium battery. These circumstances may be heavy wind or snow, which cause heavy load. Also, if the PV power supply fails for any reasons, the system will automatically switch to battery supply so there is no loss which could affect power generation. For low temperature environments, the controller has a pre-installed heating module which assures the right functioning of the battery. If the supply falls, the battery mode will be activated to ensure power generation for approximately 3 days. 20 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 9.AI CONTROLLER AND COMMUNICATIONS The Artificial Intelligence controller is located next to the slew drive attached to the torque tube completely integrated in the system and with the safety button facing South. There is no need to open the box, as it can be operated remotely. If any internal components must be replaced, please refer to the “Troubleshooting” section of this manual for more information. 9.1. GENERAL SPECIFICATIONS: ELECTRICAL SPECIFICATIONS Input power 15 - 30 W Input voltage 300 - 1500 V Input current 0 - 0,02A DC Output current 24 Vdc Max. Output power 150 W Rated output power 80 W Max. Output current 6A Rated output current 3A Battery type Battery capacity Daily energy consumption Static power Li - ion battery 77,7 Wh < 0,02 kWh/day < 0,5 W SELF LEARNING AND WORKING MODE Cloudy mode Optional Terrain correction Optional Bifacial module mode Optional Backtracking mode Yes 21 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project Wind protection mode S kyLine O&M Manual 1 .4 PROJECT NAME Yes GENERAL DATA Certification TUV, UL, CE Operation temperature -20ºC to 60ºC (-30ºC to 60ºC Optional) Communication method Lora/RS485 Protection level Weight Dimensions IP65 2,5 Kg 400*128*132 mm (L*W*H) AI Controller installation The AI controller is mounted under the torque tube with the emergency button facing south. 22 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 9.2. POWER-CONTROL COMPONENTS: 1 Emergency stop switch - External rotation release 2 DC rotatory switch 3 Communication cable port 4 Reserved 5 Reserved 6 PV connection to positive terminal of module string 7 PV connection to negative terminal of module string 8 Motor cable port Connecting the AI controller to check parameters or activating manual working mode: 23 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME a) Using USB – wireless module and Lora Wireless setting software, set the same frequency, Net ID and air rate in the module and the controller. b) Open Tracker Software. c) Check parameters are ok. / Activate desired working mode by clicking on them. For preventive maintenance check the proper section of this manual. 9.3. COMMUNICATIONS One Communication Box for up to 96 controllers connected by Lora following this diagram: 24 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME Each Communication Box has two wind sensors, one for direction and one for speed, to provide real-time weather data, and a GPS unit which updates GPS information of the controllers. Check Protocol Explanation for more information. 25 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 10. CONTROLLER INTERFACE AND WORKING MODES 10.1. WORKING MODES: 1. AUTO MODE In this mode the tracker rotates automatically according to the set parameters and AI algorithms yielding best performance. If the tracker is in auto mode and some occurrence happens, such as strong winds, snow, etc, the system will start operating in a specific mode according to the occurrence. 2. MANUAL If the tracker needs to be moved to a specific direction, this can be done with the keys “East” and “West”. Select the key to rotate the tracker in the needed direction and click again to make it stop. 3. MANUAL (TARGET) If the tracker needs to be moved to a particular tilt, this can be set in this mode. 4. WIND When the systems are working in auto mode, if there are strong winds, this mode will be automatically triggered, and the trackers will be sent to stow position (30 degrees from horizontal). This mode can also be activated manually by clicking the key “wind” in the Arctech’s software or from the SCADA interface. 5. RAIN If it starts raining heavily, this mode can be manually triggered, and the trackers will start rotating from East to West continuously. To protect the motors, this rotation will pause for 2 minutes every 10º. 26 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 6. SNOW If there are heavy loads of snow, this mode can be manually triggered and the trackers can be moved to the maximum tilt by selecting snow mode in the Arctech’s software or from the SCADA interface. 7. MAINTAIN If this mode is selected, the trackers will move to the flat position (0 degrees, facing the sky). 8. CLEAN In this mode the trackers will move to the inclination set during commissioning to ease the cleaning process of the modules. 11. GENERAL TROUBLESHOOTING Please, use the procedures in this section if: 1. A SYSTEM IS NOT WORKING 2. A SYSTEM IS NOT WORKING PROPERLY OR AS EXPECTED 3. THERE IS AN ALARM IN SCADA AND/OR IN THE ARCTECH SOFTWARE The abnormal situations on the project site can be divided into two categories: tracking abnormality and communication abnormality. Tracking abnormalities are classified into tracking stopping and tracking angle anomalies; communication abnormalities are classified into control box anomalies and communication box anomalies. Because the AI control box system is a highly integrated and modular system, the on-site troubleshooting needs to be connected to the upper computer of the control box. Abnormal communication Troubleshooting steps for abnormal communication found from the communication box side or background monitoring 1. Check the wireless module transmission of the communication box. The antenna connection and placement of the communication box are correct, and the parameter settings of the communication box are normal. For details, refer to the troubleshooting section of the communication box in "About Common Problems and Solutions on Site". 2. Check the control box side: a) Check whether the antenna connection and placement are normal b) Use the wireless debugging module (the parameter configuration is consistent with the wireless module configuration on the communication box side) to try communicating with the control box c) Turn off the emergency stop switch and DC breaker, wait for 5S and then turn it on again. d) If the above steps cannot solve the communication problem, replace the control box. 27 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME Abnormal tracking Connect the host computer and the control box to communication through the wireless debugging module, check the alarm information, see Table 1 for details FAULT DESCRIPTION POSSIBLE SOLUTION CAUSES AngleNoCom Abnormal Abnormal angle Power off the control angle sensor box and wait for 5S to communication power it on again AngleNoChange The system angle value is unchanged SoftLimit-E SoftLimit-W Exceed the east-west soft limit 1. Tilt sensor failure. 2. Motor stop working. 1. Check whether the appearance and function of the motor are normal 2. Check whether the cables from the control box end to the motor end are well connected tilt sensor failure Power off the control box and wait for 5s to power it on again 28 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME MotorOverCur Motor overcurrent The motor is blocked, the resistance of the support shaft is too large, and the shock absorber is damaged 1. Check for mechanical obstructions 2. Check Motor vibration / noise. MotorReversal Motor reverse rotation The positive and negative poles of the motor drive output are reversed EmergencyStop Emergency stop switch is off System time lost / 1. Check the polarity of Motor section. 2.Upgrade the control box firmware or modify the motor rotation direction through the upper computer Turn on the emergency stop switch TimeLost System outage time is too long and button battery is too low 1.Update time by upper computer software RTCError RTC clock failure RTC clock chip failure 1.Power off the control box and wait for 5s to power it on again BatSOCLow battery is low 1. Bad weather or abnormal input voltage of control box 2. Abnormal charging BatError Battery failure Undetectable battery 1. Check whether the input voltage of the control box is normal 300-1500vdc 2. The upper computer checks whether the charging is normal Power off the control box and wait for 5s to power it on again 29 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project BatNoCom Abnormal battery charging Damage to onboard power management chip S kyLine O&M Manual 1 .4 PROJECT NAME Power off the control box and wait for 5s to power it on again Table 1 Tracking abnormal alarm comparison table Note: If the above suggested measures do not resolve the issue, please contact Arctech Solar for further assistance. MAINTENANCE 12. PREVENTIVE MAINTENANCE PREVENTIVE MAINTENANCE EVERY 6 MONTHS 1 YEAR 2 5 YEARS YEARS VISUAL INSPECTION MECHANICAL Coating Torque marks Slew drivers and motor · Corrosion · Breaks · Abnormal sounds · Blockages Dampers & Springs Rotation bearings ELECTRICAL Grounding Cables/Plugs Controllers Antennas Wind sensors TORQUE REVISION 5% trackers Torque values SLEW DRIVERS LUBRICATION Check If during checking is needed, lubricate. Lubricate 30 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 12.1. BIANNUAL - VISUAL INSPECTION Every 6 months the systems must be checked for small damage due to normal performance, natural events, time-passing erosion, or other causes. Being aware of this deterioration can prevent plant downtime consequently leading to overall yield improvement. Both mechanical and electrical components must be checked and repaired or even replaced if any damage is found. MECHANICAL: 1.1.1 COATING – if corrosion appears on any surface or the galvanisation has been damaged, it must be cleaned and repaired. 1.1.2 TORQUE MARKS – Arctech Solar selects high reliability fasteners but it is recommended to check whether the marks on them have been displaced. 1.1.3 SLEW DRIVERS and motors– any abnormal noise could mean the system is not working properly. In addition, it is recommended to check for signs of organic intrusion. 1.1.4 DAMPERS – check for corrosion, dents, etc. 1.1.5 ROTATION BEARINGS – check that they remain on their original position and that no damaged has been caused by friction. ELECTRICAL: 1.1.6 GROUNDING – Grounding cable are not misplaced, broken or damaged. 1.1.7 CABLES/PLUGS - check if they are in good condition and plugs are connected properly. 1.1.8 CONTROLLERS – they must remain as they were installed. The bottom plate of the AI control box should be perfectly aligned with the edges prior to torqueing. Refer to CONTROLLER CHECKLIST. 1.1.9 ANTENNAS – check for obstructions or general damage. 1.1.10 WIND SENSORS – Wind velocity sensor should be above the wind direction sensor. Wind sensor holder should be toward north. 12.2. ANNUAL INSPECTION Torque value inspection of 5% of the trackers randomly chosen. The percentage of fasteners to be checked in one tracker is going to be based on the size of these fasteners according to the following table: RANDOMLY CHECKING PROPORTION FOR THE FASTENERS IN ONE TRACKER Fastener size Inspection proportion M20 M16 M12 M10 M8 100% 30% 30% 25% 25% The values of the torques must be the same as the ones given in the installation manual. However, there will be a maximum and a minimum value in order to increase the criteria of acceptance to an interval. Please refer to torque value table in ‘3 general tracker description’ 31 | Page OPERATION & MAINTENANCE MANUAL Doc. Rev. Project S kyLine O&M Manual 1 .4 PROJECT NAME 12.3. SLEW DRIVER LUBRICATION The slew drive must be checked for reducing grease levels every 2 years with recommended grease infusion every 5 years. The way to inject grease is through the plug hole while rotating the slew driver. RECOMMENDED TYPE OF LUBRICANT: HF7B(150)-00#, Exxon Mobil SHC Polyrex series 005, Klueber PEG46-1200 . CONTROLLER CHECKLIST CONTROLLER VISUAL INSPECTION OK NOT OK COMMENTS 1 Correctly mounted and fixed 2 Fixation bolts in place with correct torque value 3 Perfectly sealed with no water filtration 4 Cables properly connected 5 No surface damage or corrosion 6 DC Power switch and safety button 7 No natural or organic disturbing elements End of Manual 32 | Page