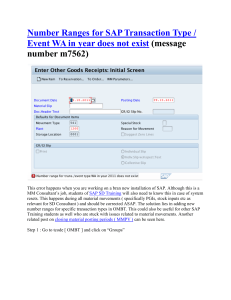

ORGANIZATIONAL MANUAL FOR THE REGISTRATION OF FAILURES IN DIFFERENT MACHINES BORGWARNER URI ARTURO SOTO LUNA TECNOLOGIAS DE MANUFACTURA 701 Arturo Soto Arturosoto58@hotmail.com BorgWarner History The company originated in 1928 from the merger of Warner Gear, founded by Thomas Warner in 1901, and Borg & amp; amp; Borg. The company was known as a supplier of the Warner Gear overdrive gearbox for automobiles of the 1930s, and for developing the Studebaker three-speed automatic gearbox introduced in the 1950s, along with the Borg & Beck brand ''Holley'' carburetor. Ford developed Studebaker automatic transmissions in 1955, derived from Borg Warner. The Warner Gear name is still used on Borg Warner marine and industrial transmissions under the ''Velvet Drive'' brand name. A variable geometry turbocharger was also developed in collaboration with Porsche, the Variable Turbine Geometry (VTG), used in the Porsche 997. Since 2002, Peugeot, Ford and Renault have become the largest turbocharger customers along with the Volkswagen Group since 1999, with BorgWarner KSeries turbochargers. In 2006, the European transmission and engine control division of Eaton Corporation was acquired. In January 2020, the acquisition of Delphi Technologies by BorgWarner for us. Objective To ensure compliance with customer requirements, service, expectations and promote continuous improvement. Utilize systems and methodologies that effectively prevent and correct deviations from expectations. To provide solutions to the organization by continuously improving the performance of the processes within the quality system. Mission To create growing and lasting business experiences with all our customers, business partners, suppliers, shareholders, and collaborators, offering with professionalism lines of automotive engine parts of high quality in each of its products and components, every time we produce, market and deliver our products. Vision To be a primary engine of economic, social and human growth in Mexico and the rest of the world, continuing the great trajectory of the BW brand in the automotive aftermarket. Values Customer service, Passion for our work, Honesty, Respect and Transparency. Organigrama Introduction to the organization The purpose of this document is to make the day-to-day running of a factory as easy as possible, making the best use of time and the necessary tools and programs to be able to carry out a better organization. Every day and at all hours, the different machines present failures: in their mechanism, logic, programming, etc. That is why we must have a control over them. Some of these failures are repeated during different days and the fact of having them registered can be a great help to identify them and to know how to solve them. In the world of industry, time is very important, since it depends on it if material is lost, if the established number of parts to be made per day is reached, and when a machine is out of order, time is running. For engineers or technicians, sometimes it is not an easy thing to solve it, certainly there are some who with their practice, time in the industry and their experience solve these problems quickly, but what about the people who do not have this knowledge? That's why having a record of machine failures helps to get an idea of how to fix them. Distribution of the organization My point of view about the distribution of this organization is that from the university we are taught programs that we will use in the industry, see the case of the SAP program, but what is SAP? SAP is an Enterprise Resource Planning (ERP) system that provides the best market practices to companies of different segments, with the intention of improving the efficiency, control and management of information and data of the companies. In my weeks at the BorgWarner factory, I was taught a little about this program, in which they recorded the failures of the machines with their downtime, who was the technician who did it, description of the failure and the solution to this failure. In my opinion it is a good idea to do this, because you have a total control of the failures occurred in the machines and it gives the technician or engineer how to solve them. The fact that they teach us this program is a great advantage for us, since it is a good tool for the industry, but if not, I propose that the factories give a course on how to use this program or that they have a manual. In this case, the BorgWarner factory did have a manual, which helped us greatly to understand the program and be able to perform the work we were asked to do. Process flow diagrams In the following, we will explain how to use SAP in case of a failure Daily activities During my time there, I took the personnel transport every morning at 4:30 AM and arrived at the plant at 5:50 AM. When I arrived, I would enter through security and there I would answer a COVID questionnaire. After entering the plant, I would go to my workstation and greet my coworkers. Then I would turn on the computer and see the faults that had occurred the day before and had to be entered into the SAP program. Then, when it was 8:30 AM we would go to breakfast in the cafeteria, where they had 3 different breakfasts. I would always pick the one that looked the best. After I finished my breakfast, I would go back to work to continue with what I was doing since there were always a lot of failures. At 1:00 PM we would go to lunch, and they always gave us dessert at the end. At 4:00 PM the work shift would end, and we would get on the transport. Many people take the opportunity to get some sleep and rest while they are on the bus to get home. Relationship of activities with the career During my stays I was able to observe the work environment very closely and I can say that I like what I am studying, and I want to continue doing it. The activities I did were about programs that I still do not see in my career, although I would like to learn them to have a better preparation than others. I was also able to take times from a machine. From the beginning of the action until it ends and so, to be able to see what can be improved to cut times and increase the production of parts. Evidencia fotográfica This is a video of me, where you can see what I used to do in my visits: to register the failures that occurred during the previous shift. https://drive.google.com/file/d/18AFC_oKcZb064RVHlCIehR8OaecR6Mtj/vie w?usp=sharing General Conclusions In conclusion, I want to make it clear that these visits were a great personal and work experience for me, being able to be close to technicians, engineers, the work environment and learn a little more about the factories in which I can get to work when I finish my studies. Having been able to go was very gratifying for me, since it has served as motivation to continue studying. What my coworkers have taught me has been very valuable, from the courses given about the plant on the first day, to learning a new program. I think that knowing the SAP program is very important, since it can be very useful in the future. I don't know if UPRA University teaches any subject where programs like these, which are used by companies in real life, are covered. If not, I suggest making a space for them, since they will be useful in the future. I thank UPRA University for the attention and for wanting to involve us more in the work environment, as well as the company BorgWarner, which has allowed me to spend some time working with them and learning new things. Their performance and commitment is unmatched. I am very grateful to all the people who helped me and taught me. I am not leaving empty handed but with a lot of knowledge gained thanks to all of you. Thank you very much.