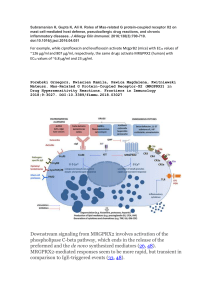

Cleaner Logistics and Supply Chain 4 (2022) 100046 Contents lists available at ScienceDirect Cleaner Logistics and Supply Chain journal homepage: www.elsevier.com/locate/clscn Green supply chain practices and sustainable performance of mining firms: Evidence from a developing country Benedict Ofori Antwi a, Daniel Agyapong b, Dominic Owusu a,⇑ a b Department of Marketing and Supply Chain Management, University of Cape Coast, Cape Coast, Ghana Department of Finance, University of Cape Coast, Cape Coast, Ghana A R T I C L E I N F O Keywords: Green supply chain management practices Eco innovative practices End‐of‐Life Practices Internal Environmental Management Strategic Supplier Partnership Sustainable performance A B S T R A C T The negative impact of mining activities on mining communities has received increased calls for mining firms to engage in management practices that are deemed to be environmentally friendly. Using the ecological modernisation theory, the study sought to examine which of the environmentally accepted supply chain management practices should be encouraged to ensure that mining firms are able to sustain their performance economically, socially and environmentally. The current study, therefore, used the explanatory study design to gather primary data from 200 respondents. Data were analysed by means of PLS‐SEM to model the relationship between green supply chain management practices and sustainable performance. The findings of the study indicated that all the four constructs of sustainable supply chain management practices predict the sustainable performance of mining firms. The study, therefore, recommends the adoption of green supply chain management practices by mining firms in order to sustain their performance. Details of the findings are discussed. 1. Introduction The mining sector of Ghana continues to make significant contributions to the economy in numerous ways. The sector according to Emmanuel et al. (2018) makes significant contributions to government tax earnings and GDP. These significant contributions of the extractive sector to the Ghanaian economy are a result of the stable multi‐party democracy the country has been enjoying since the return of democracy in 1992 (Adu‐Baffour et al., 2021). The sector employs about 28,000 and 1000,000 people in large‐ and small‐scale mining respectively (Barenblitt et al., 2021). Despite these significant contributions, the mining sector is bedevilled with several challenges that threaten the sustainability of the sector (Kumi et al., 2020). The mining firms engage in many activities such as surface mining, digging deep pits, the use of mercury and other waste minerals in washing the minerals have threatened the sustainability of the environment (Kpienbaareh et al., 2020). For example, a study in five selected mining communities in the Obuasi Municipality of Sanso, Anyinam, Anyinamadokrom, Abomba, and Tutuka found many health‐related issues suffered by these residents as a result of the mining activities. Mining pits left unattended to breed mosquitoes and spread other skin‐related diseases, diarrhoea from polluted drinking water of residents resulting from mining activities (Osei et al., 2021). The dust that emanates from these mining activities has also contributed to increasing records of colds and catarrh among residents of these mining communities (Gyamfi et al., 2021). The Ghana living standard report (2017) reported that most river bodies in the Obuasi Municipality have all been affected due to unsustainable mining practices. In 2017, the World Health Organization reported that during the extraction and amalgamation process of mining firms, mercury and other waste materials are washed into rivers and their tributaries (Wassa Amenfi East District Assembly, 2018). These communities used this as their primary source of drinking water thereby resulting in health challenges (Wireko‐Gyebi et al., 2020). These sustainability issues also threaten the continued existence of these mining firms (Antwi‐Boateng & Akudugu, 2020). In the long run, it is likely to affect their profitability (Bansah et al., 2018). Once profitability is affected, the sustainability of such firms is also threatened (Abdulai, 2017). Likewise, when mining activities affect the health of the mining communities, the quality and strength of their human resources are also likely to be affected resulting in compensations, sick leaves, and high turnover (Kansake et al., 2019). There is, therefore, the need for mining firms to consider sustainability issues serious and attach the needed importance to them (Osei et al., 2021). Mining firms need to survey their production processes as well as supply chains from time to time, to be sustainable because of the pres- ⇑ Corresponding author. E-mail addresses: bantwi009@stu.ucc.edu.gh (B. Ofori Antwi), dagyapong@ucc.edu.gh (D. Agyapong), dowusu@ucc.edu.gh (D. Owusu). https://doi.org/10.1016/j.clscn.2022.100046 Received 19 June 2021; Revised 22 February 2022; Accepted 6 April 2022 2772-3909/© 2022 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). B. Ofori Antwi et al. Cleaner Logistics and Supply Chain 4 (2022) 100046 to Hobson and Lynch (2018), firms that incorporate ecological modernisation into their supply chain activities are conscious of whom to partner as a supplier for their inputs. They ensure that such a supplier is also environmentally friendly and this cumulatively contributes to environmental performance. Society is thus protected, contributing to social performance. Such firms tend to be eco‐innovative by employing environmentally friendly machines, emphasizing the use of reverse logistics as they seek not to release harmful waste into the environment but strive to seek alternative use of such outputs. Fernando and Wah (2017) posit that when firms engage in such activities as part of their supply chain, the benefits are multifaceted affecting their economic, social as well as environmental well‐being. On the contrary, the failure of firms to incorporate such practices into their supply chain activities turn to cause harm to society by releasing hazardous substances into the environment, huge sums of monies are spent to clear such substances from the environment which could have been used to undertake other projects that would have benefited the society at large. Economically, such firms are made to pay huge fines which affect their sustainability economically, socially and environmentally (Dauda, 2019; Bergendahl, Sarkis, and Timko, 2018; Ewing, 2017). sure from the government and the community in which they operate (Heinemann et al., 2018; Kusi‐Sarpong et al., 2016). In addition, pressure groups such as some non‐governmental organizations, are attracting global thoughtfulness regarding environmental occurrences in several places of local community’s and even shut down mines (Heinemann et al., 2018). The Ghana Revenue Authority in 2019 reported a decline in mining revenue in 2017–2018. The decline in revenue was attributed to the inability of the management of mining firms to incorporate sustainable supply chain practices. Although studies have reported that mining, in general, is unsustainable in the long, (Raut et al., 2019; Silva et al., 2019; Çankaya and Sezen, 2019; Rashid et al., 2019), on the contrary, it has also been suggested that when mining firms incorporate green supply chain practices in their mining activities, they are likely to experience sustainable performance. The study, therefore, looks at the applicability of this assertion to mining firms in Ghana. The study also seeks to look at the predictability of green supply chain practices on the sustainable performance of mining firms in Ghana. As suggested in the study of Kusi‐Sarpong et al. (2016) more empirical studies should be conducted in the area of green supply chain practices of mining firms to confirm its effect on sustainable performance. Further, not all the six green supply chain practices used in the analysis of Kusi‐ Sarpong et al. (2016) are still applicable to the mining sector. For example, most of the mining firms have outsourced some of their non‐core activities to specialist organisations. Tarkwa Goldmine announced reported in 2018 that it had outsourced mining and maintenance of its mining equipment to specialist companies (Goldfields Integrated Annual Report, 2018). This study thus contributes to providing such empirical knowledge. The findings of the study will provide managers of mining firms insight on the sustainable practices to focus on to record sustainable performance in the sector. Further, contributes to the debate on the applicability of sustainable practices on the performance of mining companies in Ghana. Findings will also contribute to policy on which of the green supply chain practices mining firms should be encouraged to practice to enhance their sustainable performance. 2.2. Hypothesis development Bansah et al. (2017) posited that when miners engage in activities that are not environmentally friendly, it is difficult if not impossible to sustain immediate gains made through such activities. Though mining has been considered to contribute significantly to economic growth through exports of the minerals mined (Emmanuel et al., 2018), the increasingly negative impact of mining activities on communities and ecological developments in Ghana also makes it imperative for mining firms to consider using practices that are considered to be environmentally friendly. Studies have identified some supply chain management practices that are considered green. For example, Kusi‐ Sarpong et al. (2016) indicate that practices such as green information technology and systems, strategic supplier partnership, operations and logistics integration, internal environmental management, eco‐ innovative practices, and end‐of‐life practices are considered green. Studies have also established that when mining firms engage in practices such as those posited in the study of Kusi‐Sarpong et al. (2016) performance can be sustained economically, socially, and environmentally. The focus of this paper is on green supply chain management practices because when mining firms foster strategic partnerships with suppliers, engage in end‐of‐life practices, practice environmental management, and are eco‐innovative, their activities are likely to impact positively economically, socially, and environmentally. It is, therefore, posited that sustainable performance which comprises economic, social, and environmental can be achieved by mining firms when they engage in supply chain management practices like end‐of‐life practices, eco‐innovative practices, strategic supplier partnership, and internal environment management that are considered green. Though studies have reported in their findings on the influence of green supply chain management practices on sustainable performance, (Kusi‐Sarpong et al., 2016; Eton et al., 2019; Owusu et al., 2021) the current study goes further to determine which of the specific green supply chain management practices should be encouraged for mining firms to sustain their performance economically, socially and environmentally. Drawing on the ecological modernization theory (Huber, 1982), it is anticipated that when firms institutionalize practices that are considered environmentally friendly in their supply chain management activities, the performance of such firms can be sustained over time. It is expected in the study that the adaption of strategic supply partnerships, the use of reverse logistics, internal environmental management, and eco‐innovative practices by firms will influence the sustainable performance of mining firms in Ghana, because the mining firms are aimed at sustaining their performance 2. Theoretical review 2.1. Ecological modernization theory The ecological modernization theory is premised on the idea that firms must take coordinated efforts to reform their business practices to ensure the preservation and protection of the environment (Massa and Andersen, 2000). The theory postulates that firms are required to incorporate environmental reforms as part of their operations (Frijns et al., 2000). It has been suggested that when firms incorporate environmental concerns into their supply chain activities, it offers them several opportunities that contribute towards the economic, social and environmental development of the countries in which they are operating. The theory was developed as part of the industrialisation of Western Europe. However, Rinkevicius (2000) is of the view that the theory is also appropriate to countries that are in a transition to industrialise and this makes the use of the theory for this study well‐ grounded considering Ghana as a country that is in transition to industrialize. The theory indicates that firms must take pragmatic steps to reduce pollution. This the theory believes can be achieved only when firms use machinery and introduce ecological concerns as part of the efforts in acquiring, transforming and getting their output to their customers and users. This according to Massa and Andersen (2000) will ensure the preservation of the environment and thus contribute to environmental performance. This means that firms that can preserve the environment can avoid costly fines and contributes to societal wellbeing thereby solidifying their gains socially and economically. According 2 Cleaner Logistics and Supply Chain 4 (2022) 100046 B. Ofori Antwi et al. mance. Subsequently, Kusi‐Sarpong et al. (2016) modified the green supply chain management practices and came out with variables such as green information technology and systems, strategic supplier partnership, operations and logistics, internal environmental management, eco‐innovative practices and end‐of‐life practices. However, not all the practices identified in the previous studies are applicable to the mining sector, hence the modification. The model indicates that as firms engage in practices such as engaging strategic supplier partners, reverse logistics, internal environmental management, and practice eco‐innovativeness, it will translate into economic, social, and environmental performance. Thus, the current study, therefore, indicates that practices such as strategic supplier partnerships, end‐of‐life practices, internal environmental management, and eco‐ innovative practices constitute green supply chain practices. Sustainable performance constitutes economic, social, and environmental performance. and the only way to achieve that is by improving the economic wellbeing of Ghanaians, economically, socially and environmentally. Empirically, Kusi‐Sarpong et al. (2016) reported that firms that establish strategic partnerships with their suppliers can sustain their performance over time. Similar findings were also reported in the studies of Roychowdhury et al. (2019); Bansah et al. (2018). It was also reported in the study of Dong et al. (2020) and Jermsittiparsert et al. (2019) that reverse logistics activities of firms have the potency to enhance their sustainable performance. Similar findings were also reported in the study of Le (2020). Shahid et al. (2020) also reported that firms that practice environmental management are likely to sustain their performance economically, socially, and environmentally. Owusu et al. (2021) also reported similar findings on the connection between environmental management and sustainable performance. Nonetheless, Cousins et al. (2019); De Nadae et al. (2019) in their study could not establish any association between eco‐innovative practices and sustainable performance. Quite the reverse was reported in the study of Farjana et al. (2019) that eco‐innovative practices rather influence the sustainable performance of firms who engage in it. Analyses of these findings indicate that when firms engage in practices that are considered green, it leads to a certain outcome. This study further indicates that engaging in practices that are considered green should lead to favourable outcomes in social, economic and environmental. It is based on these findings that the current makes the following assumptions: 4. Methodology 4.1. Research design The investigation employed the explanatory study design to be able to explain the nature of the connection between green supply chain management practices and sustainable performance (Zikmund et al., 2013). This, therefore, informed the choice of the study design used for the investigation. H1: strategic supply partnership positively influences economic, social and environmental performance. H2: end‐of‐life practices positively influence economic, social and environmental. performance. H3: environmental management positively influence economic, social and environmental performance. H4: eco‐innovative practices positively influence economic, social and environmental performance. 4.2. Participants and procedures Before undertaking the main data collection, a pre‐test of the instrument for data collection was carried out in Accra to test the reliability of the instruments. The pretest gathered data from the corporate offices of some of the mining firms. This ensured that the instrument was sufficiently understood by the respondents (Baxter & Babbie, 2003). In all, 30 respondents from mining firms with corporate offices in Accra were involved in the pretest. This helped in rephrasing some of the questions and those that recorded low Cronbach alpha figures were also deleted. For example, “my firm collaborates with suppliers to manage reverse flows of materials and packaging” which was part of the items measuring strategic supplier partnership was taken out. The study avoided bias through the use of common method bias. This was measured using Collinearity Statistics (VIF ≤ 5). Since reflective models are susceptible to biases and mistakes (Afum et al., 2020), 3. Research model Fig. 1 illustrates the model used for this study. The model was developed from the literature review. Green et al. (2012) developed a similar model of green supply chain management practices on performance and came out with variables such as internal environmental management, green information system, green purchasing, cooperation with customers, eco‐design, investment recovery, environmental performance, operational performance and organisational perfor- Fig. 1. Conceptual Framework. Source: Authors Construct, (2020). 3 B. Ofori Antwi et al. Cleaner Logistics and Supply Chain 4 (2022) 100046 always switches from ”dirty“ to cleaner technologies”. Constructs used to measure green supply chain practices recorded a Cronbach alpha of 0.781, 0.892, 0.724, and 0.709 for strategic supplier partnership, internal environmental management practices, end‐of‐life practices, and eco‐innovative practices respectively. For sustainable performance, the dependant variable, the triple bottom measurement of sustainable performance was used. The triple bottom measures performance using social, economic, and environmental. Likert‐scale items developed by Das (2018); Laari et al. (2016); Mutingi et al. (2014); Quori, Mujkic, Gashi, and Kraslawski (2018) was used to measure the three areas of sustainable performance. In all, 10 questions were asked to assess sustainable performance. Out of the ten questions, four assessed environmental performance, two assessed economic performance, and four also assessed social performance. Examples of items used included “my firm has decreased cost for material”, for economic performance; “my firm has approved investments in social projects” for social performance, and “my firm has reduced air emissions” for environmental performance. it was important to analyze the collinearity statistics test and report the same statistics on collinearity (Hair et al., 2012). Generally, it is acknowledged that when collinearity statistics are above 3.3 thresholds, it generally implies the model is prone to be affected by common method bias. On the other hand, when the VIF is less than 3.3, such reflective models are deemed to be without common method bias (Afum et al., 2020). However, Kock (2015) further argued that VIF needs to have a score of 5 or lower to keep away from multicollinearity problems (Kock & Lynn, 2012; Hair et al., 2012) in circumstances where calculations consolidate estimation mistake, especially for factor‐based PLS‐ SEM algorithms. The study was conducted in Ghana. Data for the study were collected from three regions that are noted for mining. Specifically, data was collected from the Western, Western North, and Ashanti regions. Mining firms were appropriate for this study because their activities destroy the environment a lot as a result leading to the ban on their operations. Also, the population was readily accessible. The study targeted 413 mining firms in Ghana. The sample frame was grouped into registered (1 0 8) and unregistered (3 0 5) mining firms in Ghana. It was further grouped into different forms of mining firms which are the large‐scale mining firms, medium‐scale mining firms, and small‐scale mining firms. The study targeted top‐level management employees of the mining firms who were considered appropriate because of the position they occupied and their level of involvement in supply chain management activities. A sample of 102 mining firms was selected for the study. These mining firms were grouped into large‐scale mining firms (60), medium‐scale mining firms (30), and small‐scale mining firms (12). The sample size comprised of a top‐level manager from the level of general manager to the Chief executive officer and an employee engaged in mining activity or is directly linked to the implementation of mining policies from the 102 mining firms sampled for the study. Therefore, 204 respondents from these mining firms were randomly selected for the study and the questionnaire was distributed to them. Out of the total issued questionnaires, 200 were returned representing a response rate of 98%. The use of the simple random sampling technique gave all members of the sampling frame an equal chance of being selected (Zikmund et al., 2013). Additionally, considering the predictive nature of the study, the use of the simple random makes it a pre‐imperative for predictive studies (Creswell & Clark, 2017; Creswell, 2014). 4.4. Data analysis The analyses of data collected for the study were undertaken in three phases. Primarily, responses received were analyzed and uncompleted questionnaires were taken out if found not to have addressed the issues the study sought to analyze. Next, the questionnaires were coded and entered into an SPSS software to examine missing values. PLS‐SEM was then used to model the proposed hypotheses. PLS‐SEM was used because of its ability to handle a multiplicity of models and its predictive power (Peng and Lai, 2012). The use of PLS‐SEM was also further influenced by the explanatory study design used for the study. Since the study sought to explain and not only describe, the use of PLS‐SEM was more appropriate because of its ability to handle reflective and formative models (Hair et al., 2010). 5. Findings A model was developed to examine the hypotheses formulated. The model considered the four constructs of green supply chain practices as antecedents to sustainable performance. The model's quality was assessed using the quality criteria prescribed for reflective models. The Cronbach alpha, discriminant validity, average variance extracted (AVE), and the factor loadings for each of the constructs were assessed. Details of the quality assessment of the model are presented in Fig. 1 and Tables 1‐2. Table 1 presents the results of the quality criteria used in assessing the model. Cronbach alpha figures indicated that of all the variables under consideration, eco‐innovative and end of life practices recorded figures below 0.7 but were within the threshold of 0.642 and 0.684 respectively. The reliability of the constructs was, therefore, adjudged to be highly reliable as recommended by Pallant (2001) who indicated that reliability values above 0.6 are considered highly reliable and acceptable. Composite reliability for all the constructs was above 0.7. The average Variance Extracted for all constructs was also above 0.5. The quality assessment indicated that the model was deemed appropriate for the study. Next, the discriminant validity of the variables was also assessed. Results are presented in Table 2. Table 2 presents the discriminant validity using the Fomell‐Larcker Criterion. The results specified the existence of discriminant validity between all the constructs. The quality criteria and discriminant validity results asserted that the model was appropriate for the analysis. Fig. 2 presents the structural model developed to predict the effect of green supply chain practices of mining firms on sustainable performance. As presented in Fig. 2, numbers within the circle explained how much variance of economic, environmental, and social perfor- 4.3. Measures Sustainable supply chain management practices were measured using four constructs; strategic supply partnerships, internal environmental management, eco‐innovative practices, and end‐of‐life practices (Kusi‐Sarpong et al., 2016). These four constructs were used because they were found to be most applicable to the mining sector. In all, five Likert‐scale items were used to measure all the four constructs with response options where 1 represents (not at all) and 5 (to a very great extent). Five items were used to measure strategic supplier partnerships (Chou et al., 2012, Setterstrom, 2008; Sarkis et al., 2011; Uddin & Rahman, 2012). An example of the item used is “my firm monitors environmental compliance status and practices of supplier’s operations”. Eight items were used to measure internal environmental management practices (Vachon & Klassen, 2008; Azevedo et al., 2012; Simpson et al., 2019; Vachon and Klassen, 2006; Baram & Partan, 1990). An example of the item used is “my firm ensures audit and environmental assessment programs according to regulations”. End‐of‐Life practices were also measured using four items developed from the works of Stock (2001); Sarkis (2003); Bell et al. (2013). An example of the item used was “my firm ensures mining of tailings”. Eco‐innovative practices were also measured using three items developed from Carter and Easton (2011); Azevedo et al., (2012); Paulraj (2009); Rao & Holt (2005). An example of the item used was “my firm 4 Cleaner Logistics and Supply Chain 4 (2022) 100046 B. Ofori Antwi et al. Table 1 Quality Criteria. Constructs Cronbach's Alpha rho_A Composite Reliability Average Variance Extracted (AVE) Eco-Innovative Practices Economic Performance End of Life Practices Environmental Performance Internal Environmental Management Social Performance Strategic Supplier Partnership 0.642 0.727 0.684 0.848 0.798 0.868 0.749 0.651 0.733 0.753 0.863 0.808 0.870 0.641 0.847 0.879 0.859 0.908 0.881 0.919 0.832 0.735 0.785 0.754 0.767 0.711 0.792 0.624 R2 Adjusted R2 0.690 0.684 0.726 0.720 0.599 0.591 Source: Field survey (2020). Table 2 Discriminant validity (Fomell-Larcker Criterion). Constructs Eco-Innovative Practices Economic Performance End of Life Practices Environmental Performance Internal Environmental Management Social Performance Strategic Supplier Partnership Eco-Innovative Practices Economic Performance End of Life Practices Environmental Performance Internal Environmental Management 0.858 0.735 0.704 0.752 0.886 0.780 0.795 0.868 0.732 0.876 0.734 0.666 0.729 0.804 0.843 0.645 −0.013 0.591 0.219 0.675 0.223 0.820 0.174 0.736 0.154 Social Performance Strategic Supplier Partnership 0.890 0.216 0.790 Source: Field survey, (2020). mance is explained by the four green supply chain practices. The findings as presented in Fig. 2 indicated that the predictors explained 68.4%, 72%, and 59.1% of economic, environmental, and social performance respectively. Further, the weight of each path coefficient was also assessed. Based on the findings as presented in Fig. 2, internal environmental management recorded the highest path loadings of 0.435 and 0.437 for environmental performance and social performance respectively. On the contrary, end‐of‐life practices recorded the highest path loading for economic performance (0.457). eco‐ innovative practices recorded the second‐highest path loading of 0.303 and 0.398 for environmental performance and economic performance respectively. To check the significance of the path loadings, bootstrapping was run. Findings are presented in Table 3. Table 3 presents the bootstrapping results. Results indicate that eco‐innovative practice significantly predicts the economic, environmental, and social performance of mining firms in Ghana (0.000, 0.000, and 0.012 respectively) which affirms H4. End‐of‐life practices also recorded a significant effect on economic, environmental, and social performance which also confirms H2. However, internal environmental management practices recorded a significant effect on environmental and social performance. It, however, was not significant in predicting economic performance. H3 cannot, therefore, be accepted as a whole. Similarly, strategic supplier partnership was significant in predicting economic and social performance but was not significant in predicting environmental performance. H1 cannot be accepted as a whole. To affirm the significance of the predictive effect of green supply chain practices on sustainable performance, the effect size, as well as the predictive relevance of the model, was ascertained. The effect size as shown in Table 4 indicates that eco‐innovative practices record medium effect size for economic and environmental performance (0.190 and 0.124) and a weak effect size for social performance (0.030) End‐of‐life practices also recorded a medium effect size of 0.257 for economic performance and weak effect size for environmental and social performance (0.048 and 0.041) in predicting economic performance. Internal environmental management recorded a medium effect size for environmental and social performance (0.253 and 0.175). Strategic supplier partnership also recorded weak effect sizes for all three sustainable performance indicators (0.040, 0.016, and 0.024). This goes to confirm that strategic supplier partnership as a green supply chain practice is not a predictor of all three measures of sustainable performance as it recorded weak effect sizes in all three. 6. Discussion This study provided empirical evidence on which of the green supply chain practices can influence the three sustainable performance indicators. With pressure mounting on mining firms by the government and the local communities, the study was able to address which of the green supply chain practices influenced the sustainable performance of mining firms. Analysis of the study shows that when mining firms engage in eco‐innovative practices such as using environmentally friendly inputs, undertaking internal recycling of inputs, and are efficient with the quantities of input used, it is likely to record significant increases in social, economic, and environmental performance. This confirms the findings in the study of Bansah et al. (2017) that when activities of mining firms are environmentally friendly, they can sustain gains made. In this regard, mining firms can make significant contributions to the economy thereby reducing pressures mounted on them by community members and governments. For the use of end‐of‐life practices also referred to as reverse logistics, if mining firms can restore water bodies to their pre‐mining state, it is likely to contribute to all three measures of sustainable performance. This, therefore, goes to confirm government resolve to ensure that mining activities that destroy water bodies are stopped as most of the mining firms are unable to restore the state of the water bodies after their mining activities. Destruction of water bodies as a result of mining activities can thus be reduced if these firms can inculcate reverse logistics into their operations. These findings, therefore, corroborate the assertions made by Kusi‐Sarpong et al. (2016) that when mining activities are considered green, they can record economic, social, and environmental performance. However, the findings of the study also show that though internal environmental management practices of mining firms contribute to 5 B. Ofori Antwi et al. Cleaner Logistics and Supply Chain 4 (2022) 100046 Fig. 2. Structural model. Source: Field survey (2020). Table 3 Path Coefficient. Constructs Original Sample (O) Sample Mean (M) Standard Deviation (STDEV) T Statistics (|O/ STDEV|) P Values Eco-Innovative Practices -> Economic Performance Eco-Innovative Practices -> Environmental Performance Eco-Innovative Practices -> Social Performance End of Life Practices -> Economic Performance End of Life Practices -> Environmental Performance End of Life Practices -> Social Performance Internal Environmental Management -> Economic Performance Internal Environmental Management -> Environmental Performance Internal Environmental Management -> Social Performance Strategic Supplier Partnership -> Economic Performance Strategic Supplier Partnership -> Environmental Performance \Strategic Supplier Partnership -> Social Performance 0.398 0.303 0.180 0.457 0.186 0.207 0.023 0.435 0.392 0.304 0.185 0.460 0.181 0.205 0.024 0.439 0.073 0.063 0.071 0.063 0.059 0.070 0.057 0.062 5.446 4.822 2.536 7.218 3.160 2.968 0.399 6.996 0.000 0.000 0.012 0.000 0.002 0.003 0.690 0.000 0.437 0.119 0.070 0.105 0.433 0.119 0.074 0.110 0.078 0.052 0.057 0.052 5.624 2.267 1.224 2.031 0.000 0.024 0.221 0.043 Source: Field survey, (2020). This finding, therefore, contradicts the assertion by Owusu et al. (2019) that environmental management practice leads to economic, social, and environmental performance. Concerning the use of strategic supplier partnerships, the study findings indicated that of all the three measures of sustainable performance, economic and social performance reacts positively when mining firms engage in such a practice. However, the same cannot be reported on the effect of strategic supplier partnership on environmen- achieving environmental and social performance, the same could not be reported on economic performance. This means that economic performance suffers when mining firms promote internal environmental management thus reducing the profit of mining firms. However, such firms can meet their social and environmental targets. Though, such achievement does not contribute directly to profit, it rather seeks to enhance the corporate image of such firms and thereby reduce the likely attack that local community members may mount on such firms. 6 Cleaner Logistics and Supply Chain 4 (2022) 100046 B. Ofori Antwi et al. Table 4 Effect size (f2). Constructs Eco-Innovative Practices End of Life Practices Internal Environmental Management Strategic Supplier Partnership mental management practices. This will ensure that all aspects of sustainable performance are addressed in the long run. Economic Performance Environmental Performance Social Performance 0.190 0.257 0.001 0.124 0.048 0.253 0.030 0.041 0.175 0.040 0.016 0.024 7.3. Implications for future studies Future studies could focus on introducing a third variable which is the presence of institutional pressure to find out whether mining firms on their own practice green supplier chain or are forced to do so. 8. Conclusions Source: Field survey (2020). This study sought to address the concern of green supply chain practice can achieve either sustainable performance in whole or in part. The study thus confirmed that when firms practice eco‐ innovative and end‐of‐life, they can achieve sustainable performance as a whole. However, environmental and social performance is achieved only when firms engage in internal environmental management. Likewise, firms can achieve economic and social performance when they forge strategic partnerships with their suppliers. The findings, therefore, add to the existing literature on the predictive importance of practising a green supply chain on sustainable performance. Since the study focused on only four green supply chain practices, future studies could also focus on how the presence of institutions either motivates or discourages mining firms from practising green supply chain. tal performance. This means that when businesses forge partnerships with their suppliers, their motive is more on their economic and social gain. In Ghana, there is a general understanding that mining firms generate enough money and that firms in that sector are rich. When they forge partnerships, the partners are interested in how they can also make good fortunes and this explains why they can record good returns economically and socially but the same cannot be said about their environmental performance. 7. Theoretical implications and recommendations The current study provides greater insights into which of the green supply chain practices can enhance the sustainable performance of mining firms. The study confirms existing knowledge on the effect of green supply chain practices on sustainable performance and also contributes to the empirical knowledge on the association between green supply chain practices and sustainable performance. As suggested in the study of Kusi et al. (2014), more research should be conducted in the area of green supply chain practices in the mining industry. The study thus contributes to this in that regard. It further highlights which of the green supply chain practices contributes specifically to the three measures of sustainable performance. The study findings contribute to existing knowledge and indicate that eco‐innovative practice, end‐of‐life practices can explain all three measures of sustainable performance. However, internal environmental management practice contributes to environmental and social performance and not economic performance. On the other hand, the use of strategic supplier partnerships contributes to economic and social performance and not environmental performance. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. References Abdulai, A.-G., 2017. Competitive clientelism and the political economy of mining in Ghana. SSRN Electronic Journal. https://doi.org/10.2139/ssrn.2986754. Adu-Baffour, F., Daum, T., Birner, R., 2021. Governance challenges of small-scale gold mining in Ghana: Insights from a process net-map study. Land Use Policy 102, 105271. https://doi.org/10.1016/j.landusepol.2020.105271. Afum, E., Osei-Ahenkan, V.Y., Agyabeng-Mensah, Y., Amponsah Owusu, J., Kusi, L.Y., Ankomah, J., 2020. Green manufacturing practices and sustainable performance among Ghanaian manufacturing smes: The explanatory link of Green Supply Chain Integration. Management of Environmental Quality: An International Journal 31 (6), 1457–1475. https://doi.org/10.1108/MEQ-01-2020-0019. Michael S. Baram and Daniel G. Partan, Butterworth Legal Publishers, 1990, pp. 359. Yearbook of International Environmental Law, 2(1), 483–485. https://doi.org/ 10.1093/yiel/2.1.483.. Antwi-Boateng, O., Akudugu, M.A., 2020. Golden Migrants: The Rise and Impact of Illegal Chinese Small-Scale Mining in Ghana. Politics & Policy 48 (1), 135–167. Autry, C.W., Bell, J.E., Mollenkopf, D.A., Stolze, H.J., 2013. Natural resource scarcity and the closed-loop supply chain: a resource-advantage view. International Journal of Physical Distribution & Logistics Management 43 (5/6), 351–379. Azevedo, J.M., Almeida, R., Almeida, P., 2012. Using data mining with time series data in short-term stocks prediction: A literature review. International Journal of Intelligence Science 02 (04), 176–180. https://doi.org/10.4236/ijis.2012.224023. Azevedo, S.G., Carvalho, H., Duarte, S., Cruz-Machado, V., 2012. Influence of green and lean upstream supply chain management practices on business sustainability. IEEE Transactions on Engineering Management 59 (4), 753–765. Bansah, K.J., Dumakor-Dupey, N.K., Kansake, B.A., Assan, E., Bekui, P., 2018. Socioeconomic and environmental assessment of informal artisanal and smallscale mining in Ghana. J. Cleaner Prod. 202, 465–475. https://doi.org/10.1016/j. jclepro.2018.08.150. Bansah, K. J., Dumakor-Dupey, N. K., & Sakyi-Addo, G. B. (2017). Digging for survival: female participation in artisanal and small-scale mining in the Tarkwa mining district of Ghana. In SME Annual Meeting-Feb (pp. 19-22).. Barenblitt, A., Payton, A., Lagomasino, D., Fatoyinbo, L., Asare, K., Aidoo, K., Pigott, H., Som, C.K., Smeets, L., Seidu, O., Wood, D., 2021. The large footprint of small-scale artisanal gold mining in Ghana. Sci. Total Environ. 781, 146644. https://doi.org/ 10.1016/j.scitotenv.2021.146644. Baxter, L. A., & Babbie, E. R. (2003). The basics of communication research. Cengage Learning.. Bergendahl, J.A., Sarkis, J., Timko, M.T., 2018. Transdisciplinarity and the Food Energy and Water Nexus: Ecological Modernization and Supply Chain Sustainability Perspectives. Resour. Conserv. Recycl. 133, 309–319. https://doi.org/10.1016/j. resconrec.2018.01.001. 7.1. Practical Implications: Mining firms seeking to promote all three measures of sustainable performance equally must be eco‐innovative and practice reverse logistics. These practices maximize the economic, social, and environmental benefits of mining firms. However, mining firms that seek to enhance environmental and social performance should rather promote internal environmental management. Further, when firms form strategic partnerships with their suppliers, it can only enhance the social and economic benefits. This will help reduce the fee for waste treatment and discharge, fines and consumption of harmful materials related to mining operations. Mining firms should also ensure that they comply with environmental standards specified by ISO 45001. When these measures are put in place, mining firms will be able to reduce possible future risks of lawsuits, ban and reputation. 7.2. Policy Implications: The findings of the study also suggest that mining firms should incorporate environmental performance contracts when developing strategic supplier partnerships. Further, efforts should be put in place to address economic performance when promoting internal environ7 B. Ofori Antwi et al. Cleaner Logistics and Supply Chain 4 (2022) 100046 telecommunications sectors. The Extractive Industries and Society 7 (1), 181–190. https://doi.org/10.1016/j.exis.2019.12.008. Kusi-Sarpong, S., Sarkis, J., Wang, X., 2016. Assessing green supply chain practices in the Ghanaian mining industry: A Framework and evaluation. Int. J. Prod. Econ. 181, 325–341. https://doi.org/10.1016/j.ijpe.2016.04.002. Laari, S., Töyli, J., Solakivi, T., Ojala, L., 2016. Firm performance and customer-driven Green Supply Chain Management. J. Cleaner Prod. 112, 1960–1970. https://doi. org/10.1016/j.jclepro.2015.06.150. Massa, I., Andersen, M.S., 2000. Special issue introduction: Ecological modernization. J. Environ. Plann. Policy Manage. 2 (4), 265–267. https://doi.org/10.1002/15227200(200010/12)2:4<265::aid-jepp63>3.0.co;2-j. Mutingi, M., Mapfaira, H., Monageng, R., 2014. Developing performance management systems for the Green Supply Chain. J. Remanuf. 4 (1). https://doi.org/10.1186/ s13243-014-0006-z. Osei, Boakye Kwame, Ahenkorah, Isaac, Ewusi, Anthony, Fiadonu, Etornam Bani, 2021. Assessment of flood prone zones in the Tarkwa mining area of Ghana using a GISbased approach. Environmental Challenges 3, 100028. https://doi.org/10.1016/j. envc.2021.100028. Owusu, O., Bansah, K.J., Mensah, A.K., 2019. “Small in size, but big in impact”: socioenvironmental reforms for sustainable artisanal and small-scale mining. Journal of Sustainable Mining 18 (1), 38–44. Owusu, O., Bansah, K.J., Mensah, A.K., 2021. “small in size, but big in impact”: Socioenvironmental reforms for sustainable artisanal and small-scale mining. J. Sustainable Min. 18 (1) https://doi.org/10.46873/2300-3960.1073. Paulraj, Antony, 2009. Environmental motivations: A classification scheme and its impact on environmental strategies and practices. Business Strategy and the Environment 18 (7), 453–468. https://doi.org/10.1002/bse.v18:710.1002/bse.612. Peng, D.X., Lai, F., 2012. Using partial least squares in Operations Management Research: A practical guideline and summary of past research. J. Oper. Manage. 30 (6), 467–480. https://doi.org/10.1016/j.jom.2012.06.002. Rao, P., Holt, D., 2005. Do Green Supply Chains lead to competitiveness and economic performance?. International Journal of Operations & Production Management 25 (9), 898–916. https://doi.org/10.1108/01443570510613956. Rashid, I., Fiaz, M., Ikram, A., Farooq, A., 2019. Impact of Green Supply Chain Management Practices on Economic, Environmental, and Social Performance of Frozen Food Companies. Dialogue (Pakistan) 14 (3). Raut, R.D., Mangla, S.K., Narwane, V.S., Gardas, B.B., Priyadarshinee, P., Narkhede, B. E., 2019. Linking big data analytics and operational sustainability practices for Sustainable Business Management. J. Cleaner Prod. 224, 10–24. https://doi.org/ 10.1016/j.jclepro.2019.03.181. Wassa Amenfi east municipal assembly. Wassa Amenfi East Municipal Assembly. (n.d.). Retrieved February 22, 2022, from https://waema.gov.gh/.. Rinkevicius, L., 2000. Transitional economies. Environmental Politics 9 (1), 171–202. https://doi.org/10.1080/09644010008414516. Roychowdhury, Sugata, Shroff, Nemit, Verdi, Rodrigo S., 2019. The effects of financial reporting and disclosure on Corporate Investment: A Review. Journal of Accounting and Economics 68 (2-3), 101246. https://doi.org/10.1016/j. jacceco.2019.101246. Sarkis, J., 2003. A strategic decision framework for Green Supply Chain Management. J. Cleaner Prod. 11 (4), 397–409. https://doi.org/10.1016/s0959-6526(02)00062-8. Sarkis, J., Zhu, Q., Lai, K.-hung, 2011. An organizational theoretic review of Green Supply Chain Management Literature. Int. J. Prod. Econ. 130 (1), 1–15. https://doi. org/10.1016/j.ijpe.2010.11.010. Setterstrom, A., 2008. The natural resource-base view of a firm: Strategic opportunities in IT. In Annual Academy of Management Meetings, Anaheim, CA. Shahid, Muhammad Naeem, Abbas, Aamir, Latif, Khalid, Attique, Ayesha, Khalid, Safwan, 2020. The mediating role of board size, philanthropy and working capital management between basic corporate governance factors and firm's performance. Journal of Asian Business and Economic Studies 27 (2), 135–151. https://doi.org/ 10.1108/JABES-07-2018-0050. Silva, Graça Miranda, Gomes, Paulo J., Sarkis, Joseph, 2019. The role of innovation in the implementation of Green Supply Chain Management Practices. Business Strategy and the Environment 28 (5), 819–832. https://doi.org/10.1002/bse. v28.510.1002/bse.2283. Simpson, G.B., Badenhorst, J., Jewitt, G.P., Berchner, M., Davies, E., 2019. Competition for land: The water-energy-food nexus and coal mining in Mpumalanga Province. South Africa. Frontiers in Environmental Science 7. https://doi.org/10.3389/ fenvs.2019.00086. Uddin, M., Rahman, A.A., 2012. Validation of green IT framework for implementing Energy Efficient Green Data Centres: A case study. International Journal of Green Economics 6 (4), 357. https://doi.org/10.1504/ijge.2012.051499. Vachon, S., Klassen, R.D., 2006. Extending green practices across the supply chain: The impact of upstream and downstream integration. International Journal of Operations & Production Management 26 (7), 795–821. Vachon, S., Klassen, R.D., 2008. Environmental Management and Manufacturing Performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 111 (2), 299–315. https://doi.org/10.1016/j.ijpe.2006.11.030. Wireko-Gyebi, R. S., Asibey, M. O., Amponsah, O., King, R. S., Braimah, I., Darko, G., & Lykke, A. M. (2020). Perception of small-scale miners on interventions to eradicate illegal small-scale mining in Ghana. SAGE Open, 10(4), 215824402096366. https:// doi.org/10.1177/2158244020963668.. Yildiz Çankaya, S., Sezen, B., 2019. Effects of Green Supply Chain Management Practices on Sustainability Performance. Journal of Manufacturing Technology Management 30 (1), 98–121. https://doi.org/10.1108/jmtm-03-2018-0099. Zikmund, W.G., Babin, B.J., Carr, J.C., Griffin, M., 2013. Business research methods. South-Western Cengage Learning. Cousins, P.D., Lawson, B., Petersen, K.J., Fugate, B., 2019. Investigating Green Supply Chain Management Practices and performance. International Journal of Operations & Production Management 39 (5), 767–786. https://doi.org/10.1108/ijopm-112018-0676. Creswell, J.W., 2014. A concise introduction to mixed methods research. SAGE. publications. Creswell, J. W., & Clark, V. L. P. (2017). Designing and conducting mixed methods research. Sage publications.. Carter, C. R., & Liane Easton, P. (2011). Sustainable Supply Chain Management: Evolution and Future Directions. International Journal of Physical Distribution & Logistics Management, 41(1), 46–62. https://doi.org/10.1108/09600031111101420.. Das, D., 2018. The impact of sustainable supply chain management practices on firm performance: Lessons from indian organizations. J. Cleaner Prod. 203, 179–196. https://doi.org/10.1016/j.jclepro.2018.08.250. Dauda, M., 2019. Ecological Modernization Theory and Sustainable Development Dilemmas: Who benefits from technological innovation?. The African Review 46 (1), 68–83. de Nadae, J., Carvalho, M.M., Vieira, D.R., 2019. Exploring the influence of environmental and social standards in integrated management systems on economic performance of firms. Journal of Manufacturing Technology Management 30 (5), 840–861. https://doi.org/10.1108/jmtm-06-2018-0190. Dong, L., Sun, D., Shu, W., & Li, X. (2020). Exploration: Safe and clean mining on Earth and asteroids. Journal of Cleaner Production, 257, 120899.. Downloads. Gold Fields Integrated Annual Report 2018 | downloads. (n.d.). Retrieved February 22, 2022, from https://www.goldfields.com/reports/annual-report-2018/ downloads.php.. Emmanuel, A.Y., Jerry, C.S., Dzigbodi, D.A., 2018. Review of Environmental and health impacts of mining in Ghana. Journal of Health and Pollution 8 (17), 43–52. https:// doi.org/10.5696/2156-9614-8.17.43. Eton, M., Ayiga, N., Moses, A., Fabian, M., & Benard, P. O. (2019). Small Medium Enterprises (SMEs), Environmental Management and Poverty Reduction in Western Uganda.. Ewing, J.A., 2017. Hollow Ecology: Ecological Modernization Theory and the death of nature. Journal of World-Systems Research 23 (1), 126–155. https://doi.org/ 10.5195/jwsr.2017.611. Farjana, Shahjadi Hisan, Huda, Nazmul, Mahmud, M.A. Parvez, Lang, Candace, 2019. Life-cycle assessment of Solar Integrated Mining Processes: A sustainable future. J. Cleaner Prod. 236, 117610. https://doi.org/10.1016/j.jclepro.2019.117610. Fernando, Y., Wah, W.X., 2017. The impact of eco-innovation drivers on environmental performance: Empirical results from the green technology sector in Malaysia. Sustainable Production and Consumption 12, 27–43. https://doi.org/10.1016/j. spc.2017.05.002. Frijns, J., Phuong, P.T., Mol, A.P.J., 2000. Developing countries. Environmental Politics 9 (1), 257–292. https://doi.org/10.1080/09644010008414519. Ghana - Ghana Living Standard Survey (GLSS 7) 2017 - overview. (n.d.). Retrieved February 22, 2022, from https://www2.statsghana.gov.gh/nada/index.php/ catalog/97/study-description.. Green, K.W., Zelbst, P.J., Meacham, J., Bhadauria, V.S., 2012. Green Supply Chain Management Practices: Impact on performance. Supply Chain Management: An International Journal 17 (3), 290–305. https://doi.org/10.1108/ 13598541211227126. Gyamfi, Opoku, Sørensen, Peter Borgen, Darko, Godfred, Ansah, Eugene, Vorkamp, Katrin, Bak, Jesper Leth, 2021. Contamination, exposure and risk assessment of mercury in the soils of an artisanal gold mining community in Ghana. Chemosphere 267, 128910. https://doi.org/10.1016/j.chemosphere.2020.128910. Hair, J.F., Ortinau, D.J., Harrison, D.E., 2010. Essentials of marketing research, Vol. 2. McGraw-Hill/Irwin, New York, NY. Hair, J.F., Ringle, C.M., Sarstedt, M., 2012. Partial least squares: The better approach to structural equation modeling?. Long Range Plan. 45 (5–6), 312–319. https://doi. org/10.1016/j.lrp.2012.09.011. Heinemann, K., Zwergel, B., Gold, S., Seuring, S., Klein, C., 2018. Exploring the supplydemand-discrepancy of sustainable financial products in Germany from a financial advisor’s point of View. Sustainability 10 (4), 944. https://doi.org/10.3390/ su10040944. Hobson, Kersty, Lynch, Nicholas, 2018. Ecological modernization, techno-politics, and social life cycle assessment: a view from human geography. The International Journal of Life Cycle Assessment 23 (3), 456–463. Huber, G., 1982. Organizational information systems: Determinants of their performance and behavior. Management science 28 (2), 138–155. Jermsittiparsert, K., Siriattakul, P., & Sangperm, N. (2019). Predictors of environmental performance: mediating role of green supply chain management practices. International Journal of Supply Chain Management, 8(3), 877-888.. Kansake, B. A., Kaba, F. A., Dumakor-Dupey, N. K., & Arthur, C. K. (2019). The future of mining in Ghana: Are stakeholders prepared for the adoption of autonomous mining systems?. Resources Policy, 63, 101411.. Kock, N., Lynn, G.S., 2012. Research article electronic media variety and Virtual Team Performance: The mediating role of task complexity coping mechanisms. IEEE Trans. Prof. Commun. 55 (4), 325–344. https://doi.org/10.1109/tpc.2012.2208393. Kock, N. (2015). Common method bias in PLS-SEM. International Journal of eCollaboration, 11(4), 1–10. https://doi.org/10.4018/ijec.2015100101.. Kpienbaareh, D., Kansanga, M.M., Konkor, I., Luginaah, I., 2020. The rise of the Fourth Estate: The Media, Environmental Policy, and the fight against illegal mining in Ghana. Environmental Communication 15 (1), 69–84. https://doi.org/10.1080/ 17524032.2020.1799050. Kumi, E., Yeboah, T., Kumi, Y.A., 2020. Private sector participation in advancing the Sustainable Development Goals (sdgs) in Ghana: Experiences from the mining and 8