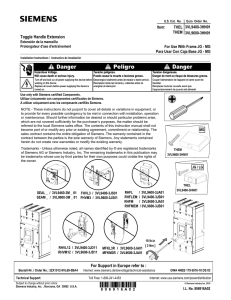

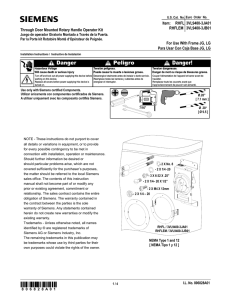

© Siemens AG 2013 Weighing Electronics SIWAREX - PLC-based weighing modules SIWAREX WP231 ■ Overview ■ Design SIWAREX WP231 is a compact technology module in SIMATIC S7-1200 and allows direct connection to S7-1200 components via a sliding connector. The rail mounting of the 70 mm (2.76 inch) wide weighing module means that it is extremely easy to mount/wire. The power supply, load cells, the RS 485, digital input/outputs and the analog output are connected via the screw connector of the weighing module. A RJ45 connector is used for the Ethernet connection. ■ Function The primary task of SIWAREX WP231 is the measurement and conversion of sensor voltage into a weight value. Up to three interpolation points are used for the weight calculation. The signal can also be digitally filtered if required. Weighing functions SIWAREX WP231 is a versatile weighing module for all simple weighing and force measuring tasks. The compact module is easy to install in the SIMATIC S7-1200 automation system. It can also be operated without a SIMATIC CPU. ■ Benefits SIWAREX WP231 offers the following key advantages: • Uniform design technology and consistent communication in SIMATIC S7-1200 • Uniform configuration with TIA Portal • Operation without SIMATIC CPU possible • Direct connection of an operator panel via Ethernet • Direct connection of a remote display via RS 485 interface • Four digital inputs and outputs, one analog output • Measurement of weight or force with a high resolution of 1 part per million and an accuracy of 0.05 % • Simple adjustment of scale using the SIWATOOL V7 program via the Ethernet interface • Supports automatic adjustment without adjustment weights • Supports replacement of module without renewed adjustment of scale • Use in hazardous area zone 2 ■ Application SIWAREX WP231 is the optimum solution wherever strain gauge sensors, such as load cells, force sensors or torque measuring shafts, are used for measuring tasks. The following are typical SIWAREX WP231 applications: • Non-automatic weighing machines • Fill level monitoring of silos and bunkers • Measuring of crane and cable loads • Load measuring for industrial lifts and rolling mills • Scales in zone 2 hazardous areas • Force measuring, container weighing, platform scales and crane scales There are commands available for zeroing and taring. Up to three different tare default values can be activated for this. SIWAREX WP231 is factory-calibrated. This means the scale can be automatically adjusted without adjustment weights, and modules can be replaced without the need to readjust the scale. Monitoring and control of the scale signals and states In addition to weight determination, the SIWAREX WP231 monitors two freely programmable limits (optionally min/max) as well as the empty range. It signals violations of the limits. Consistent and uniform communication between all system components enables fast, reliable and cost-effective integration and diagnostics in process plants. Integration in the plant environment SIWAREX WP231 is directly integrated into the SIMATIC S7-1200 via the SIMATIC bus. A wide variety of connection options are provided via the RS 485 and Ethernet interface. Via Modbus TCP/IP or Modbus RTU, control panels can be connected and it is also possible to communicate with various automation systems. A remote display can also be connected to the RS 485. A PC for configuring the SIWAREX WP231 can be connected to the Ethernet interface. Weight value, status, tare, commands and messages are transmitted via the SIMATIC I/O area. The parameters of the data records can be set via SIWATOOL or with an operator panel connected directly to the weighing electronics. SIWAREX WP231 can be integrated into the system software via the PLC programming language SCL (Structured Control Language) . In contrast to serially linked weighing electronics, SIWAREX WP231 does not need costly additional modules to link it to SIMATIC. Used in conjunction with SIWAREX WP231, it is possible to configure freely programmable, modular weighing systems in SIMATIC, which can be adapted to company-specific requirements as needed. Siemens WT 10 · November 2012 1 © Siemens AG 2013 Weighing Electronics SIWAREX - PLC-based weighing modules SIWAREX WP231 ■ Function (continued) It is also extremely helpful to analyze the diagnostics buffer which can be saved together with the parameters following reading out from the module. Trace mode is provided to optimize the weighing sequences in the SIWAREX WP231 weighing module. The recorded weight values and associated states can be displayed as trends using SIWATOOL V7 and MS Excel. Upgrading firmware An additional program function can be used to download a new firmware version onto the SIWAREX WP231 on site. This means that firmware upgrades can be carried out on site as required anywhere in the world. ■ Technical specifications SIWAREX WP231 Integration in automation systems In addition to the configuration package, a fully-featured SIWAREX WP231 "Ready for use" software is also available freeof-charge. It shows beginners how to integrate the module in a STEP 7 program and offers a basis for application programming. This allows you to connect the scale either directly to the SIMATIC CPU or to an operator panel connected directly to the SIWAREX WP231. Software SIWATOOL V7 is a special program for commissioning and servicing and runs with Windows operating systems. The program enables the user to perform scale adjustment without requiring automation engineering skills. During servicing, the technician can use a PC to analyze and test the procedures in the scale. Reading the diagnostics buffer from the SIWAREX WP231 is extremely helpful when analyzing events. The following are just some of the tasks that can be carried out using SIWATOOL V7: • Parameterization and adjustment of the scale • Testing of scale properties • Recording and analysis of weighing sequence S7-1200 • Operator panel • Automation systems from other manufacturers (possible with limitations) Directly via SIMATIC bus Via Ethernet (Modbus TCP/IP) or RS 485 (Modbus RTU) Communication interfaces • SIMATIC S7-1200 backplane bus • RS 485 • Ethernet Connection of remote displays (via RS 485) Display for weight value Adjustment of scale settings PC configuration software SIWATOOL (Ethernet) or directly connected operator panel (Modbus) Measuring accuracy Error limit acc. to DIN 1319-1 of fullscale value at 20 °C ± 10 K (68 °F ± 10 K 0.05 % Internal resolution 1 million parts Number of measurements/second 100 Filters • Low-pass filter 0.1 ... 50 Hz • Mean value filter Weighing functions Weight values • Gross • Net Limits • Min/max • Empty Zeroing function Per command Tare function Per command Tare specification Per command Load cells Strain gauges in 4-wire or 6-wire system Load cell excitation Supply voltage (regulated via feedback) SIWATOOL V7 calibration software, layout of the individual program windows 2 Siemens WT 10 · November 2012 4.85 V DC Permissible load resistance • RLmin • RLmax > 40 Ω < 4 100 Ω With SIWAREX IS Ex interface • RLmin • RLmax > 50 Ω < 4 100 Ω Load cell characteristic 1 … 4 mV/V Permissible range of measuring signal (at greatest set characteristic value) -21.3 ... +21.3 mV Max. distance of load cells 500 m (229.66 ft) Connection to load cells in Ex zone 1 Optionally via SIWAREX IS Ex interface © Siemens AG 2013 Weighing Electronics SIWAREX - PLC-based weighing modules SIWAREX WP231 ■ Technical specifications (continued) SIWAREX WP231 Ex approvals, Zone 2 • ATEX Zone 2 • UL, FM in preparation Auxiliary power supply Remote display (optional) The digital remote displays can be connected directly to the SIWAREX WP231 via the RS 485 interface. The following remote display can be used: Rated voltage 24 V DC S102 Max. power consumption 200 mA Siebert Industrieelektronik GmbH Max. power consumption SIMATIC Bus 3 mA IP degree of protection to DIN EN 60529; IEC 60529 IP20 P.O. Box 1180 D-66565 Eppelborn, Germany Tel.: +49 6806/980-0 Fax: +49 6806/980-999 Internet: http://www.siebert.de Climatic requirements Tmin (IND) ... Tmax (IND) (operating temperature) Detailed information is available from manufacturer. Vertical installation -10 ... +55 °C (14 ... 131 °F) Accessories Horizontal installation -10 ... +40 °C (14 ... 104 °F) EMC requirements according to EN 45501 SIWAREX JB junction box, aluminum housing Dimensions 70 x 75 x 100 mm (2.76 x 2.95 x 3.94 inch) For connecting up to 4 load cells in parallel, and for connecting several junction boxes Order no. SIWAREX JB junction box, stainless steel housing 7MH4960-2AA01 For connecting up to 4 load cells in parallel ■ Selection and ordering data SIWAREX WP231 Weighing electronics for scales in SIMATIC S7-1200 7MH4710-1BA 7MH4710-1EA Ex interface, type SIWAREX IS SIWAREX S7-1200 device manual With ATEX approval, but without UL and FM approvals, for intrinsicallysafe connection of load cells, including device manual Available in a range of languages Free download on the Internet at: http://www.siemens.com/ weighingtechnology Suitable for the SIWAREX U, CS, MS, FTA, FTC, M, CF and WP231 weighing modules SIWAREX WP231 "Ready for Use" Complete software package for nonautomatic scale (for S7-1200 and a directly connected operator panel) Free download from Internet at: http://www.siemens.com/ weighingtechnology Approved for use in the EU • Short-circuit current < 199 mA DC • Short-circuit current < 137 mA DC 7MH4710-5BA 7MH4710-5CA Cable (optional) Configuration package SIWAREX WP231 on CD-ROM for TIA-Portal V11 • "Ready for Use" software for operating a scale with SIWAREX WP231 and a touch panel (in a variety of languages) • SIWATOOL V7.0 calibration tool • Device manuals (PDF files in a variety of languages) 7MH4960-2AK01 Ethernet cable patch cord, 2 m (7 ft) for connecting SIWAREX WP231 to a PC (SIWATOOL), SIMATIC CPU, panel, etc. 6XV1850-2GH20 Cables Li2Y 1 x 2 x 0.75 ST + 2 x (2 x 0.34 ST) – CY, orange sheath 7MH4702-8AG To connect SIWAREX U, CS, MS, FTA, FTC, M, CF and SIWAREX WP231 to the junction box (JB), extension box (EB) or Ex interface (Ex I) or between two JBs, for fixed laying, occasional bending permitted, approx. 10.8 mm (0.43 inch) outer diameter, for ambient temperature -40 ... +80 °C (-104 ... +176 °F) Cable Li2Y 1 x 2 x 0.75 ST + 2 x (2 x 0.34 ST) – CY, blue sheath 7MH4702-8AF To connect the junction box (JB) or extension box (EB) in a potentially explosive atmosphere to the Ex interface (Ex I), for fixed laying, occasional bending permitted, blue PVC insulating sheath, approx. 10.8 mm (0.43 inch) outer diameter, for ambient temperature -40 ... +80 °C (-104 ... +176 °F) Siemens WT 10 · November 2012 3 © Siemens AG 2013 Weighing Electronics Notes 4 Siemens WT 10 · November 2012