![普通商用泳池机说明书(2)[1]](http://s2.studylib.es/store/data/009442933_1-8ba5a5d6b8760f6cbab248ed701a92de-768x994.png)

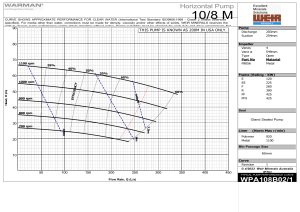

Installation & Operation Manual Swimming Pool Heat Pump Commercial Type Model Number : YC-050TA1 YC-075TA1,YC-155TA1 YC-TA1C- Thank you very much for purchasing our product, please keep and read this manual carefully before you install heat pump. Packing List No. Name Qty. 1 Installation & Operation Manual 1 2 Wire-controller 1 3 A.C adaptor for wire controller 1 4 Wire-controller signal wire 1 5 Heat Pump Unit 1 -3- Photos Please keep installation manual properly, and read it carefully before using. The unit must be installed by professional personnel, and install it based on this manual as possible. Special reminding: if the unit would be installed where is vulnerable to lightning stroke, lightning protection measurements must be carried out. Special reminding: The unit is not suitable for using in the Winter (< -7 °C), when the unit leave unused in Winter, the water reserved in the pipe network system must be drained. Content 1. Accessories Description ........................................................................... 4 2. Attention for safety.................................................................................... 4 3. Heat pump unit working principle ............................................................ 6 4. Installation of the unit ............................................................................... 7 5. Installation of the pipeline ...................................................................... 11 6. Installation of optional accessories ....................................................... 13 7. Installation of electric devices................................................................ 14 8. Instruction of operation .......................................................................... 19 9. Adjusting and Initial operation ............................................................... 38 10. Operation and maintenance ................................................................. 39 11. Fault analysis and elimination method ................................................ 41 12. Technical parameter.............................................................................. 42 -4- 1. Accessories Description Each unit produced by our factory with the following accessories: No. 1 2 3 3 4 Name Installation & Operation Manual Wire controller Wire controller power adapter Wire controller connecting cable Heat pump unit Qty. 1 PC 1 PC 1 PC 1 PC 1 SET Use Guide users to install the system Used for the man-machine operation interface Power supply for controller Connect wired controller to heat pump unit For heating water For function you need to purchase at least the following parts for each unit: No. Name Qty. use 1 Water circulation pump Drive the water cycle 2 Swimming pool filter system Protect the heat pump heat exchanger and pipes 3 Water pipe and valves Connect the equipment and make circulation NOTE The types and quantity of the water pump, filters, pipes and water tank, refer to the real project design. We do not suggest to install auxiliary electric heaters in the system, if must install auxiliary electric heaters, should install the electric heaters by the specialized persons, and our company has no responsibility for all the problem cause by the auxiliary electric heater. 2. Attention for safety Range of application: 1.Power supply: 380V/3N~50Hz. 2.Operation ambient temperature range: -7°C〜43°C : 3.Water temperature range: Min. inlet water temperature 8°C, Max. outlet water temperature 40°C. If the system is always used beyond the available water range, please contact with the local agent. ● The installation shall be done by the professional persons, to prevent leaking, electric shock, or fire disaster. ● Confirm the ground connection, if the ground connection is not correctly done, it may cause electric shock. -5- ● When install the heat pump in a narrow space (equipment room), must keep well ventilated. ● Don't put finger or sticker into the air inlet or air outlet. Because the internal rotor high-speed operation may cause injury. ● When an exception happens (burning smell), turn off the manual power switch immediately, stop operating, and contact with after-sale service department. If continue the abnormal operation, it may cause electric shock or fire disaster. ● When the unit needs to be removed or re-installed, please entrust after-sale service department and specialized personnel to do it. If the installation is not well done, it may cause unit operation failure, electric shock, fire, hurt, leaking, etc. ● Must not be unauthorized reformed, otherwise it may cause electric shock or fire. ● When needs to be repaired, please entrust after-sale service department or a specialized personnel to implement. If improper repaired, it may cause unit operation failure, electric shock, fire, hurt, leaking, etc. ● Can not install the unit in combustible gas easy-leaking places, once the combustible gas leaks around the unit, it may cause a fire. ● Confirm if the installation base is strong enough, if it is not strong and has been used for a long time, it may cause falling and injuries. ● Confirm if leakage protection switch is installed, if don't install a leakage protection switch, may cause electric shock or fire. ● When cleaning the unit, the operation should be stopped, and power switch should be turned off. -6- 3. Heat pump unit working principle 3.1 Heat pump working process ● First, the low pressure and superheated gas in the evaporator is inhaled into the compressor then becomes the high temperature and high pressure overheated vapour. ● Second, the overheated vapour is exhausted into the condenser and exchange the heat with the water, then the refrigerant is condensed and becomes the saturated or over cooling high pressure and high temperature refrigerant liquid. The water is heated up by heat pump when absorbing the heat energy which released by the refrigerant. ● Third, the refrigerant liquid releases the pressure by passing the expansion valve, then becomes the low temperature and low pressure liquid. ● Fourth, the refrigerant liquid flows into the evaporator and absorb the energy from the air, then is vaporized and became the low pressure and overheated vapour. The refrigerant working repeatedly as described above, then the water which flows through the condenser is heated up constantly, the temperature rise and can get the hot water. 3.2 Air source heat pump working principle 4 way valve Fa n un i t Water inlet Condenser Ev ap or a to r Water Outlet Gas-liquid separator Compressor Filter Filter Expansion valve Figure 1 Qc (Heat energy get) =Qa (Compressor consumption) +Qb (Heat energy absorbed from ambient environment) -7- 4. Installation of the unit 4.1 Installation attention ● Avoid installations in such locations with mineral oil. ● Avoid installation in locations where air contains salt or other corrosive gas. ● Avoid installation in locations with serious power supply voltage fluctuation. ● Avoid installation in an unstable place, such as car or cabin ● Avoid installation near flammable items. ● Avoid installation in locations with strong electromagnetic wave. ● Avoid installation in locations with special harsh environmental conditions. 4.2 Installation check ● Check the model, number, name etc, avoid incorrect installation. ● Make sure enough space for installation and maintenance. ● Make sure barrier-free for air inlet and outlet, also dry ventilated place. ● Make sure the bearing surface can meet the requirement and avoid shocks. ● The power supply and its capacity, wire diameter choice should be in accordance with the electrical installation requirements. ● Electrical installation must comply with the relevant technical standards of electrical equipment, and electrical insulation work must be done. ● The unit must be power on for at least eight hours before running and debugging. -8- 4.3 Installation space Keep the following indicated space for operation and maintenance first before installation >2000 Unit: mm Figure 2 The distance to top barrie r Unit: mm >600 >500 >1200 >1200 >500 Unit: mm >500 >600 >1200 >1200 >500 Figure 3 Installation space -9- 4.4 Heat pump unit size YC-050TA1 YC-075TA1,YC-155TA1 Figure 4 Size - 10 - Size (mm) L W H YC-050TA1 1410 748 1050 YC-075TA1 1590 850 1500 YC-155TA1 2150 1078 2258 Model No. 4.5 Reserve the installation base for the heat pump Please refer to Figure 5. A n c h o r b o lt Anchor bolt Screw nut/washer Drainage tray Heat Pump Drainage tray Heat Pump Shock absorb Installation base Concrete Figure 5 Reserved installation base 4.6 Hoisting attention ● Please use four or more soft lifting belts to move the sets Figure 6. ● Please use protective plate on the surface of the sets when moving, to avoid scratch and deformation. ● Recheck whether the foundation is correct before hoisting the unit. ● The heat pump will produce condensation water,please consider the drainage channel when make the installation base. ● Please put shock absorb on base surface. - 11 - Figure 6 Hoisting diagram 5. Installation of the pipeline 5.1 Attention ● Prevent air, dust and other sundries from going into the water pipes. ● Fix the whole system before install the water pipes. ● Water inlet and outlet pipes shall be protected by the insulation layer. ● Stable water velocity shall be ensured, so that excessive throttling can be avoid. ● When moving, water inlet and outlet pipe shall not be used for hanging, only the holes on the beam of the base can be used, please refer to Figure 9 ● When connect the water inlet and outlet pipes, two pipe wrenches shall be used to control the two parts of the pipes, and ensure the water inlet and outlet pipes not turning around, please refer to the Figure 7 ● Pipeline anti-freezing in case the environmental temperature drops to 3°C. Figure 7 - 12 - 5.2 Instruction 5.2.1 Marginal data 5.2.2 Pipeline installation diagram Figure 8 Diagram I(Single unit for reference) - 13 - Figure 9 Diagram II(Multiple units for reference) ● The one-way valve is suggested for each unit, to prevent the water back flow. ● The system can be combined with multiple units, but should be controlled by each unit independently. ● Regarding the installation of backup pump, maintenance valve and temperature measure point, please consider it yourself. ● All pipes and valves of the unit need the heat preservation. ● The reference diagram used non-pressure water tank, the system also can be pressurized system, use the pressurized water tank. 5.2.3 Selection of the water pipes Model No. Inlet Outlet YC-050TA1 65 mm 65 mm YC-075TA1 65 mm 65 mm YC-155TA1 100 mm 100 mm ● The pipe press and flow rate should be calculated before the diameter selection. ● The hydraulic calculation should be made after the selection of pipe diameter, if the resistance is more than pump head, then need to choose a more power pump, or choose a bigger pipe. 6. Installation of optional accessories 6.1 Selection of the water pump - 14 - ● The circulation pump is necessary for the system operation, the power port is prepared for the pump inside the unit. NOTE Please check the Electric Diagram which located inside of the unit ● The head of circulation pump = height difference between water level and main unit + total pipelines resistance (determined by the hydraulic calculation) + pressure loss of main unit (see the nameplate on heat pump ). NOTE When multi paralleled, the water pump head is subject to the worst working condition loop. 6.2 Selection of the flow switch ● The selection of the flow switch is based on the actual system, the target flow switch is recommended. Temperature of fluid: 0-120 °C , max working pressure 13.5 bar. ● The flow switch can be installed on the horizontal pipeline or the vertical pipeline which the fluid flow direction is upward, but should not be installed on the vertical pipeline which the fluid flow direction is downward. ● The flow switch must be installed on a straight pipeline, there must be more than five times the length of the pipe diameter at its two sides. And, the direction of fluid must follow the arrow on the controller. The terminal block should be in an easy operation position, (Figure 10) ● The pannier is absolutely forbid to touch the flow switch floor, or the switch will be deformed and invalid, (Figure 11) A ● Please be sure that the model of target sheet is determined by the system rated flow, diameter of outlet pipe and the adjustable range of the target(see the user manual). And the target sheet can not contact the in-wall of pipe or other throttlers in pipe, or will cause the switch can not reset. 5A 5A Figure 10 - 15 - Figure 11 7. Installation of electric devices 7.1 Electrical wiring ● The unit should use a dedicated power supply, power supply voltage with rated voltage. ● Unit power supply circuit must be ground, power supply wire and external grounding reliable connection, and the external grounding is effective. ● Wiring must be constructed by the professional installation technicians in accordance with the circuit diagram. ● Power line and signal line layout should be neat, reasonable, can not interfere with each other, but not with the connecting pipe and the valve body contact. ● If the unit is not matching the power line, please supply specifications refer to provisions, wires connecting is not allowed. ● After all wiring construction is completed, please check it before switch on the power supply carefully. Screw out the bolt and open the panel which with the danger label, will find the electrical box. Figure 11 Power In 380V/50Hz/3phases Figure 12 Power cable terminal - 16 - 7.2 Electrical Wiring Specification Model No. Electrical Wiring Specification YC-050TA1 3*6mm²+2*4mm² YC-075TA1 3*16mm²+2*10mm² YC-155TA1 3*25mm²+2*16mm² 7.3 Circulation pump installation The heat pump only provide the signal for circulation pump, must use an a.c. Contactor to connect the circulation pump. U V W N NOTE: Here only for signal control never drive it directly. Circ ulation Pump Signal Figure 15 - 17 - Figure 16 7.4 Wire controller connection Adaptor Power in: 220VAC Wire Controller GND BA B A GND AB PCB Figure 17 - 18 - 7.5 Electric control schematic diagram of parallel connection of multiple units (Online) Adaptor Power in: 220VAC GND BA B A GND Wire Controller Slave unit 1 (PCB) A B Connect to other slave units (A to A,B to B) Max.15 units on-line GND AB PCB Figure 18 - 19 - Y/GN T1 T2 T3 1#COMP AP1 current1 Y GN RD Y GN RD TA1 Y/GN Y/GN T3 2#COMP T1 T2 Y GN RD AP1 current2 TA2 Y GN RD KM4 Y/GN 1# Fan Y/GN 2#Fan Y GN RD KM5 Y GN RD RD RD RD BL RD GN BK Y OR ( Y GN RD ) KM3 Y GN RD XT3 U W Circulation Pump Y/GN V U V W KM6 Y GN RD Figure - 20 - OFF OFF OFF ON ON OFF OFF ON OFF ON OFF ON No.1 No.2 ON OFF OFF OFF OFF ON OFF OFF ON ON OFF ON OFF OFF ON ON ON OFF ON ON OFF ON ON ON ON ON ON ON No.3 No.4 No.5 No.6 No.7 ON ON OFF OFF ON OFF ON OFF OFF ON ON OFF ON ON ON OFF No.15 No.14 No.13 No.12 No.11 No.10 No.9 No.8 High speed Low speed Water supply pump Comp Comp 4WV Bypass valve Bypass valve Heat tap GN S OFF OFF ON OFF OFF OFF OFF OFF No.0 Pump Feeding valve Return valve E-heater Base heater 1 phase Heat Cycle heat 1 system Reserved RD RD Y null wire High pressure switch 1 Low pressure switch 1 High pressure switch 2 Low pressure switch 2 Circulation water flow switch Emergency switch Feed water pressure switch Reserved Reserved High water level Pool Low water level Direct heat 2 systemsMid. water level 3 phases ***WATER-COM null wire WH Transformer TC output Power in:220VAC Coil temp. sensor 1 Coil temp. sensor 2 connect TA2 connect TA1 Adaptor null wire Supply water pump 220Vac A.C contactor Auxiliary E-heater 220Vac A.C contactor Return water solenoid valve, 220Vac Feeding solenoid valve, 220Vac Bypass valve 2 Bypass valve 1 4 way valve null wire Low pressure 2 High pressure 2 High temp. 2 null wire Low pressure 1 High pressure 1 High temp. 1 Water flow switch Norma:l On Failure: Off null wire High water level switch Low water level switch Connect to next slave unit (A to A,B to B) Slave unit(s) Note: If multi units online, please connect the signal wire as follows: Connect the wire at site Connect to No. 0 unit Communication address(Dial) 1 2 3 4 Unit No. 1 2 3 4 Unit No. TRAN-OUT TC Transformer Connect control panel N N2N3 Special Requirement: 1. When ambient temp. below 0C, and the heat pump not be used,then empty the water from the system, prevent the pipes burst caused by freezing. 2. When the ambient temp. below -7C, don't allow the heat pump run, empty the water from the system and cut off the power. 3. Put the water tank senor into tank, and make it test the inside water temperature. 4. If the circulation pump power supply is 220V/50Hz, then the live wire connect the terminal U, V or W on the terminal block XT3 , and the null wire connect to the phase N on terminal block XT1. 5. Between heat pump unit and water tank, there must be circulation pump ( on the heat pump water inlet pipe), between circulation pump and heat pump unit, the water flow switch and pressure gage is necessary. Technical Description: 1. The low water level switch and water flow switch has been shorted when delivery, when install the heat pump should take down the shorting wire. 2. Dashed line means that need the installer connect it at site, the power cable should meet the requirement which please refer to the user manual. 3. Only provide circulation pump and electric heater power signal, never connect them directly to heat pump. 4. Water flow switch, normal off, when water flow is normal, then the flow switch on, water flow failure, switch off. 5. Put return water temp. sensor on the water return pipe to test the return water temp. and control the solenoid valve on/off. Power In Electric Diagram 1 BL T OUT6 GN RD R 4 3 2 A 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 CN9 COM2 XT1Y 7.5 Electric wiring diagram Connect the wire at site Connect to No. 0 unit GND CN9 Suction temp. sensor 2 Exhaust temp. sensor 2 Suction temp. sensor 1 Exhaust temp. sensor 1 Return water temp. sensor 1, No. 0 unit Hot water outlet temp. sensor Ambient temp. sensor Water tank temp. sensor 1, No. 0 unit 8. Instruction of operation 8.1 Control system specifications 8.1.1 Operating condition ● Voltage: 220V~±10%,50Hz±1Hz. ● Ambient temperature: -7~+43℃ ● Storage temperature: -20~+75℃ ● Relative humidity: 0~95%RH ● Temperature accuracy: ±1℃ 8.1.2 Main function ● Three operation mode: heating,cooling and constant temperature mode. ● Display the pool temperature and setting temperature, and also can query the coil temperature, ambient temperature and exhaust temperature and so on. ● Power cut memory function. ● When power cut, the clock will still work. ● Timing on/off. ● Automatic defrosting. ● Forced to defrost. ● Large LCD display. ● Has perfect protection function. ● The error code display and query ● Key-Lock Function ● Anti-freezing function ● When there is no wire controller or wire controller is broken, the system can recognize it, and control the heat pump to run automatically. - 21 - 8.2 Wire controller and operation 8.2.1 Appearance and button functions of wire controller ● Appearance When there is no failure, the main interface will show on/off status,operation mode, water tank water temperature, setting temperature, date and time; When there is failure, the main interface will show the error code and error details. If there is no operation within 60 seconds, the display backlight will be off, we can press any key to turn on the light. Status: Heating Water temp. 25°C Set 50°C Supply Feeding Heater 2013/05/15 16:03 NOTE If the signal wire connection is fault, signal wire A connect to signal wire B, then the controller will not work, and only shows “欢迎使用”, please exchange the wire connection, it will work correctly. - 22 - 欢迎使用 ● Button functions On/Off key Press this key for five 5 seconds to turn on /off the power Menu key: Press this key to enter the next menu under the main interface Return key: Press this key return to the upper interface Go Up Key Enter key Go Down key 8.2.2 On/Off key Press on/off key for 5 seconds to turn on/off heat pump. 8.2.3 Menu key Press menu key to enter the next menu under the main interface. Running Status Parameter Setting Time Setting Timer Set When entry into this menu, press , key can choose each sub-menu. - 23 - ● When chose the Running status, press can choose one machine and press #1 #2 #3 #4 #5 #6 #7 #8 key to entry into the on-line menu, and then key to check the running status about the machine. On On #9 #10 #11 #12 #13 #14 #15 #16 Water Temp. Water Outlet Temp. 1# Evaporator 1# Exhaust Temp. ● When chose the Parameter Setting, press interface, press key to entry into the parameter query key to check each parameter, when choose a parameter and press key to set the parameter, press press 25°C 25°C 25°C 25°C can change the value, when finish setting, return to the upper menu. Water Temp.Drop 5°C Water Outlet Set 70°C Start Heater Set 50°C Ambient Temp. Set 10°C ▼ ● When chose the Time Setting, press key to entry into the time set interface, press key to choose date or time setting, when the cursor over the Date, then press key entry into the date setting( year first), press key entry into the month setting, press key change value, then press key to change the value, then press key entry into the day setting, same method, and then press - 24 - key will finish the date set and back to upper interface; When the cursor over the Time, press the key entry into time setting (hour first), press key to change the value, press setting, press the key again will entry into minutes key to change the value, finally press key to confirm time set, it will back to upper interface. Date:2013/05/15 Time: 13:58 ● When chose the Timer Set, press key to entry into the timer set interface, press key to choose three kinds of setting. Unit Timing Supply Timing Feeding Timing NOTE Unit timing mean the heat pump unit timing on/off Supply timing means hot water supply timing on/off Feeding timing means feed cold water to tank timing on/off ● When the cursor over the Unit Timing, press setting, when the cursor over the 1#Timing On, press to choose no or yes, when choose yes, press the press key to change the value, press the - 25 - key entry into the unit timer on/off key and press key key entry into time setting (hour first), key again will entry into minutes setting, press key to change the value, finally press key to confirm the 1#Timing On setting and back to the upper menu. About 1#Timing Off, 2#Timing On, 2#Timing Off, 3#Timing On, 3#Timing Off, the setting method is the same as the above setting method. 1#Timing On: No 1#Timing Off: No 2#Timing On: No 2#Timing Off: No 3#Timing On: No 3#Timing Off: No ● When the cursor over the Supply Timing, press key entry into the Supply Timing, setting method is the same as Unit Timing. ● When the cursor over the Feeding Timing, press key entry into the Supply Timing, setting method is the same as Unit Timing. ● When the cursor over the Failure Logging, press key to check the failure record. 1:#2E35 2013/05/15 09:17 2:#1E35 2013/05/15 09:16 3: 4: 5: 6: 7: 8: NOTE When checking the failure record, press key for 5 seconds, can cancel all the previous - 26 - failure record. 8.2.4 Return key When entry into a menu, press can return to the upper menu, finally will back to the main interface. 8.2.5 Go up/Go down key When entry into a menu or parameter setting interface, press , can change the parameter value. 8.2.6 Enter key Confirm the execution command entered 8.2.7 Turn on the water supply function Press key for 5 seconds will turn on the hot water supply function, press again for 5 seconds then will turn off this function. 8.2.8 Lock the screen Press key for 5 seconds will lock the screen, press again for 5 seconds then will unlock the screen. 8.2.9 Feeding water by manual Press key for 5 seconds will feed cold water by manual, press again for 5 seconds then stop feeding cold water. 8.2.10 Operation Mode Change Press key for 5 seconds will change the operation mode, there are three models: Heating mode, Cooling mode or Constant temperature mode(Auto mode). ● Dial Switch on PCB - 27 - ● Dial switch 1 Dial switch 8 Single/Three phase(s) Dial switch 7 Single/Double system Dial switch 6 Direct/Cycle heating 0:Single (OFF) 1:Three ON) 0:Single 1:Double 0:Cycle 1:Direct Dial switch 5 Swimming pool / Hot water 0:Hot water 1:Swimming pool ● Dial switch 2 ( On-line setting) Dial switch 4 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 Dial switch3 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 1 Dial switch 2 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1 Dial switch 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 On-line Unit No. 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 8.2.11 Turn On The Auxiliary Electric Heater By Manual Press key for 5 seconds will turn on the auxiliary electric heater, press again for 5 seconds will turn off it. 8.2.12 Forced to defrost Entry into the Running Status interface, choose the on-line machine no.,press seconds, the selected machine will be forced to defrost. 8.2.13 Parameter setting When the cursor over the Parameter Setting, press - 28 - for 5 key for 5 seconds, will entry into the factory settings, input the password 0814 will entry into the factory setting interface, input the password 6688 will entry into the factory limited time setting interface, when finish inputting the password, the press , key to entry the parameter query interface, press keys to choose the parameter, when choose a target parameter, the press key to set it., press , keys to change the value, while finish setting, press to confirm and go back to the query interface. Enter Password **** Low Temp. Set Defrosting Cycle Defrosting Temp. Defrosting Time -7 ℃ 45M -3 ℃ 8M ▼ 8.2.14 Language Set and More Setting/Query interface ● Chinese-English shift : First press press key for 5 seconds to lock the screen, and then key for long time to change the language (Chinese or English) ● More Setting/Query interface 1) Initial Interface - 29 - WELCOME 2) Main Interface Status: Heating Water temp. 25 ℃ Set 50 ℃ Supply Feeding Heater 2013/05/15 16:03 NOTE Mode: Heating / Cooling / Auto Hot water supply by manual= Supply Feeding cold water to tank=Feeding Auxiliary electric heater=Heater 3) Press entry into Function Interface Running Status Parameter Setting Time Setting Timer Set Failure Logging 4) Under main interface choose the Running Status and press - 30 - #1 #2 #3 #4 #5 #6 #7 #8 On On #9 #10 #11 #12 #13 #14 #15 #16 NOTE On means the machine is running Off means the machine stop run 5) Running Status Interface Water Temp. 25°C Water Outlet Temp. 25°C 1# Evaporator 25°C 1# Exhaust Temp. 25°C ▼ 1# Back Temp. 25°C ▲ Ambient Temp. 25°C Water Return Temp. 25°C 1#Condenser Temp. 25°C ▼ 1# Comp. Current 0A ▲ 1# EEV 350 Standby Temp. -30°C 2# Evaporator 25°C ▼ NOTE EEV= Electronic expansion valve - 31 - 1# / 2# means the first system or second system for the double system 2# Exhaust Temp. 25°C ▲ 2# Back Temp. 25°C 2# Condenser Temp. 25°C 2# Comp. Current 0A ▼ 2# EEV Water level 1# Comp. 2# Comp. 350 ▲ High On On ▼ Fan Motor Four-Way Valve Circulating Pump 1#By-Pass Valve On ▲ Off On Off ▼ 2#By-pass Valve Feed Valve Supply Valve Return Valve Off ▲ On Off Off ▼ NOTE Water Level : High/Medium/Low Electric Heater Off ▲ Crankcase Heater Off Coil Heater Off Feed-SW Open ▼ - 32 - Emergency SW Flow SW 1#High-Press. 1#Low-Press. Close ▲ Close Close Close ▼ 2#High-Press. 2#Low-Press. Close ▲ Close NOTE SW=Switch, status : Close / Open 6) User Parameter Setting Interface Water Temp.Drop Water Outlet Set Start Heater Set Ambient Temp. Set 5°C 70°C 50°C 10°C▼ NOTE Water Temp.Drop= The heat pump restart to work temperature difference against to the setting target temp. Water Outlet Set: Target setting hot water temp. Start Heater Set: Auxiliary electric heater target hot water temp. Setting Ambient Temp. Set: Auxiliary electric heater start-up ambient temp. Water Return Set 40°C ▲ WR Temp.Drop 5°C Feeding Set 20°C Feeding Temp.Drop 5°C ▼ - 33 - Comp. Current Set ▲ By-Pass Valve Set BV Temp.Drop WR Mode Temp. 0A 98°C 6°C ▼ WR Cycle 60min ▲ WR Time 15min WS Mode Duration Water Supply Set 40°C ▼ WS Temp.Drop 5°C ▲ Feeding Mode Level Exhaust Temp.Set 115°C Exhaust Temp.RST 85°C▼ Crankcase Heater 15° ▲ C H Temp.Drop 2°C Fan Speed Change 25°C Auto Change Delay 30M▼ NOTE WR=Water Return ,WS=Water Supply, BV=By-Pass Valve CH=Crankcase Heater 30M=30 Minutes Feeding Mode: Level=Water Level , Temp.=Water Level + Water Temp. WR/WS Mode: There are three modes, 0=duration; 1=Cycle; 2=Temp. 7) Factory Parameter Setting Interface - 34 - Enter Password **** Low Temp. Set Defrosting Cycle Defrosting Temp. Defrosting Time -7°C 45M -3°C 8M ▼ Exit Defrost 20°C ▲ EEV Cycle 45S EEV Superheat 5°C EEV Exhaust Temp. 85°C ▼ Defrost EEV Set EEV Least Value EEV Mode EEV Manual 400 ▲ 100 Auto 350 ▼ Max Water Temp. Choice Pump Temp. Offset Flow Switch Mode 55°C ▲ Yes 0°C All ▼ NOTE Choice Pump: Yes=Choose a water pump, No=Don’t choose the water pump Flow Switch Mode: All=Independent, Main=Shared - 35 - Feeding Timing No ▲ NOTE Feeding Timing: Yes=Available Function, No=Not Available Function 8) Time Setting Interface Date:2013/05/15 Time: 13:58 9) Timer Setting Interface Unit Timing Supply Timing Feeding Timing 1#Timing On: No 1#Timing Off: No 2#Timing On: No 2#Timing Off: No - 36 - 3#Timing On: No 3#Timing Off: No 10) Error Code And Description Warning #1 E01 Phase fault Warning #1 E05 1#Over-Pressure Warning #1 E02 Phase lack Warning #1 E06 1#Pressure Low Warning #1 E03 Flow Switch Off Warning #1 E07 2#Over-Pressure Warning #1 E04 Anti Freezing - 37 - Warning #1 E08 2#Pressure Low Warning #1 E16 1#Evaporator Fault Warning #1 E09 Comm. Fault Warning #1 E17 2#Evaporator Fault Warning #1 E11 Limit Power Off Warning #1 E18 1#Exhaust Fault Warning #1 E12 1#Over-Exhaust Warning #1 E19 2#Exhaust Fault Warning #1 E13 2#Over-Exhaust Warning #1 E21 Ambient Fault Warning #1 E15 Water Temp. Fault Warning #1 E22 Water Return Fault - 38 - Warning #1 E37 In-out Over-Temp. Warning #1 E23 Under cooling Fault Warning #1 E32 Outlet Over-temp. Warning #1 E25 Water level Fault Warning # E35 1#Comp. Overload Warning #1 E27 Water Outlet Fault Warning #1 E36 2#Comp. Overload Warning #1 E29 1# Back Temp. Fault Warning #1 E42 1# Condenser Fault Warning #1 E30 2# Back Temp. Fault Warning #1 E43 2# Condenser Fault Warning #1 E31 Water Switch Fault - 39 - Warning #1 E44 Ambient Temp. Too Low 9. Adjusting and Initial operation 9.1 Attention ● Within 12 hours after running, please connect the circuit breaker, and make the crankcase heater be preheated. ● Open the valve of water system, and the valve of assistant tank, inject water into the system, and exhaust air inside. ● Do adjustment after electrical safety inspection. ● After the power is switched on, start the test running of heat pump, to see if it can function well. ● Forced operation is forbidden, because it is very dangerous to work without protector. 9.2 Preparation Before Adjustment ● The system is installed correctly. ● Tubes and lines are putted in the right place. - 40 - ● Accessories are installed. ● Ensure the smooth drainage. ● Ensure the perfect insulation. ● Correct connection of ground lead. ● The supply voltage can meet the requirement of rated voltage. ● Air inlet and outlet function can work well. ● Electrical leakage protector can work well. 9.3 Adjustment Process ● Check if the switch of the line controller can work well. ● Check if the function keys of the line controller can work well. ● Check if the indicator light can work well. ● Check if the drainage system can work well. ● Check if the system can work well after starting up. ● Check if the water outlet temperature is acceptable. ● Check if there is vibration or abnormal sound when the system is functioning. ● Check if the wind, noise and condensate water produced by the system affect the environment around. ● Check if there is refrigerant leakage. ● If any fault occurs, please check the instructions first, to analyze and remove the fault. 10. Operation and maintenance 10.1 Personals shall possess professional knowledge or operate according to professionals from our company. To ensure the well functioning, the system shall be checked and maintained after a period of time. During the maintenance, please pay attention to some points below: ● Control and protect the equipment, please do not adjust any settings discretely. ● Pay close attention to whether all the operation parameters is normal during system working. ● Examine regularly whether the electrical connection is loose, if yes, fasten it on time. ● Examine regularly the reliability of the electrical components, change all the failed or unreliable components on time. ● There will be calcium oxidized or other mineral substance deposition on the surface of - 41 - water heat ex-changer copper coil after long period of operation, which will influence the heat exchange performance and lead to high electrical consumption, discharge pressure increasing and air suction pressure drop, unit hot water volume produced is less. We can adopt formic acid, citric acid, acetic acid or other organic acid to clean. ● The dirt retention on the surface of evaporator fin should be blowed by more than 0.6Mpa compressor air, brushed by fine copper wire, or flushed by high pressurized water, usually one time per month; if too much dirt, we can use paintbrush dipping gasoline to clean. ● After long downtime, if we restart the equipment, we should make following preparations: examine and clean the equipment carefully, clean the water pipeline system, examine the water pump, and fasten all the wire connections. ● Replacement parts must use our company original accessories, can not be replaced by other similar accessories. 10.2 Refrigerant filling Examine the refrigerant filling condition through reading the data of liquid level from display screen, also the air suction and exhaust pressure. If there is leakage or changing components of the refrigeration circulation system, we have to make air tightness examination first. 10.3 Leak detection and air tightness experiment During leak detection and air tightness experiment, never let the refrigeration system filling oxygen, ethane or other flammable harmful gas, we can only adopt compressed air, fluoride or refrigerant for such experiment. 10.4 To remove the compressor, please follow the following steps ● Turn off the power supply ● Exhaust the refrigerant from the low pressure end, attention to reduce the exhaust speed, and avoid frozen oil leakage. ● Remove the compressor air suction and exhausting pipe. ● Remove the compressor power cables. ● Remove the compressor fixing screws. ● Remove the compressor. 10.5 Conduct regular maintenance according to the user manual instruction, to make sure the unit running in good condition. ● Fire prevention: if there is a fire, please turn off the power switch immediately, put the fire out with fire extinguisher. ● To prevent flammable gas: the unit working environment should stay away from gasoline, ethyl alcohol and other flammable materials, to avoid explosion accident. - 42 - ● Malfunction: if malfunction occurs, should find out the reason, eliminate it and then reboot the unit. Never boot the unit forcibly if the malfunction has not been eliminated. If refrigerant leakage or frozen liquid leakage, please turn off all the power switch, if the unit can not stop buy controlling switch, please turn off the general power switch. ● Never short connect the wire for protection required device, or else, in case unit malfunction, it can not be protected normally and will damage the unit. 11. Fault analysis and elimination method - 43 - 12. Technical parameter 12.1 Parameter Model No. YC-050TA1 YC-075TA1 YC-155TA1 Power Supply 380V/3/50Hz 380V/3/50Hz 380V/3/50Hz Heating Capacity(kW) ¹ 50 75 155 Power Input(kW) ¹ COP ¹ 8.7 5.75 13.5 5.56 27.8 5.58 Heating Capacity(kW) ² 42 65 126 Power Input(kW) ² 8.6 13.5 27.0 COP ² Heating Capacity(kW) ³ 4.88 32 4.81 48.8 4.67 100 Power Input(kW) ³ 7.8 12.2 24.0 COP ³ 4.09 4.01 4.17 Max Power Input(kW) 13.2 20.1 48.5 Max Current(A) 23.5 35.9 87.0 Refrigerant Type Compressor Type R410A R410A R410A Scroll Scroll Scroll Scroll Scroll Scroll Titanium alloy heat ex-changer Titanium alloy heat ex-changer Titanium alloy heat ex-changer Scroll Scroll Scroll Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve Scroll Type Scroll Type Scroll Type Vertical Vertical Vertical Scroll Scroll Scroll Vertical Vertical Vertical 20,000 30,000 65,000 Scroll Scroll Scroll Vertical Vertical Vertical 1410×748×1050 1590×850×1500 2150×1078×2258 Heat Exchanger Expansion Valve Air Flow Direction Water Flow Volume(m3/h) Net Dimensions(L*W*H)(mm) Working temperature range(°C) Net Weight(kg) Vertical -7~43 Vertical ≤65 Vertical 250 Vertical -7~43 Vertical ≤68 Vertical 550 Vertical -7~43 Vertical ≤72 Vertical 900 Water connection(mm) 65 65 100 Noise(dB) - 44 - NOTE 1).Testing condition : ¹ Heating Capacity at Air 27°C/24°C, Water 27°C ² Heating Capacity at Air 15°C/12°C, Water 26°C ³ Heating Capacity at Air 7°C/6°C, Water 26°C 2).The specifications, technical parameter please refer to the product nameplate, if by the technological upgrading, and the above parameters to change without prior notice to product nameplate shall prevail. After-sale service If your hot water heater can not operate normally, please turn off the unit and cut off the power supply at once, then contact with our service center or technical department. - 45 - - 46 -