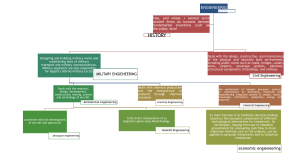

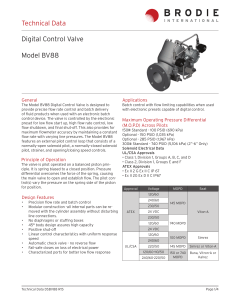

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/245307311 An Engineering Method for Air-Cooling Design of 2Seat Propeller Driven Aircraft Powered by Fuel Cells Article in Journal of Aerospace Engineering · January 2010 DOI: 10.1061/(ASCE)AS.1943-5525.0000055 CITATIONS READS 24 3,189 4 authors: Giulio Romeo E. Cestino Politecnico di Torino Politecnico di Torino 52 PUBLICATIONS 834 CITATIONS 82 PUBLICATIONS 1,266 CITATIONS SEE PROFILE SEE PROFILE F. Borello G. Correa Politecnico di Torino CITCA-CONICET 21 PUBLICATIONS 325 CITATIONS 28 PUBLICATIONS 594 CITATIONS SEE PROFILE All content following this page was uploaded by G. Correa on 24 July 2015. The user has requested enhancement of the downloaded file. SEE PROFILE Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. Engineering Method for Air-Cooling Design of Two-Seat Propeller-Driven Aircraft Powered by Fuel Cells G. Romeo1; E. Cestino2; F. Borello3; and G. Correa4 Abstract: The application of fuel-cell technology to aircraft propulsion and/or energy supply is becoming of great interest for undoubted advantages in terms of pollution emissions and noise, features particularly important for commuter airplanes that usually take off and land from and in urban areas. The conversion of conventional aircraft into more/all-electric one tends to be based on the installation of such innovative systems. A better understanding of problems related to fuel cells applied to aeronautics is sought by the European Commission funded project environmentally friendly intercity aircraft powered by fuel cells 共ENFICA-FC兲. The main objective of the ENFICA-FC project is to develop and to validate the use of a fuel-cell based power system for propulsion of an all-electric aircraft. The fuel-cell system will be installed in a light sport aircraft 共Rapid 200兲 that will be flown and performance tested as a proof of functionality and future applicability. Specific aspects have to be investigated in the onboard installation of the innovative system and new design indications have to be pointed out in order to fulfill the conversion. One of the key items under investigation is the simulation of existing cooling system and the evaluation of motor and fuel-cell temperature; the temperature has to be maintained within the limits established by manufacturers of critical systems during all likely operating conditions as indicated by aeronautic regulations for general aviation. The computational problem addressed in this paper is the numerical computational fluid dynamics 共CFD兲 simulation of the existing air-cooling system that satisfies air request for cooling and venting. An engineering model has been developed and it is used to support air inlet and outlet design. The flow is reasonably approximated by a potential flow plus boundary layer; hence, total upstream pressure losses are neglected except for those within the thin boundary layer. Pressure recovery of incoming cooling air and pressure coefficient distribution have been studied by using VSAERO panel code, and the optimal position of cooling and venting intakes is defined according to aerodynamic results. Propeller effects are included by referring to an optimal propeller specifically designed for the ENFICA-FC project. Propeller slip-stream wake is modeled by an actuator disk plus a swirl membrane and used to study the problem of motor, electronic, and fuel cells’ cooling during takeoff. DOI: 10.1061/共ASCE兲AS.1943-5525.0000055 CE Database subject headings: Aircraft; Design; Heat exchange; Fuels; Cooling. Author keywords: Fuel-cell aircraft; CFD analysis; Propeller design; Heat-exchanger design; Intakes design. Introduction Protecting the environment is becoming an important factor in many decisions made by the public, industry, and government. The growing attention to environmental issues is likely due to an increased understanding of how both today’s quality of life and the future public health and welfare can be adversely impacted by human activities. The growing attention to aviation related environmental issues is demonstrated by numerous reports on this 1 Full Professor, Dept. of Aerospace Engineering, Politecnico di Torino, Corso Duca degli Abruzzi 24, 10129 Torino, Italy. E-mail: giulio.romeo@polito.it 2 Assistant Professor, Dept. of Aerospace Engineering, Politecnico di Torino, Corso Duca degli Abruzzi 24, 10129 Torino, Italy 共corresponding author兲. 3 Research Assistant, Dept. of Aerospace Engineering, Politecnico di Torino, Corso Duca degli Abruzzi 24, 10129 Torino, Italy. 4 Research Assistant, Dept. of Aerospace Engineering, Politecnico di Torino, Corso Duca degli Abruzzi 24, 10129 Torino, Italy. Note. This manuscript was submitted on October 13, 2009; approved on March 10, 2010; published online on March 24, 2010. Discussion period open until June 1, 2011; separate discussions must be submitted for individual papers. This paper is part of the Journal of Aerospace Engineering, Vol. 24, No. 1, January 1, 2011. ©ASCE, ISSN 0893-1321/ 2011/1-79–88/$25.00. topic 共Romeo et al. 2004, 2007a,b; Glover 2005; Volker 2006兲. One of the first proposals to use hydrogen fuel for aircraft was detailed in 1938 by Igor Sikorski, who later founded Sikorski aircraft. The U.S. Army and Air Force began investigating using liquid hydrogen as a rocket fuel in 1943 and it is still used in liquid form for the current fleet of space shuttles. A U.S. Air Force B-57 bomber was the first U.S. aircraft to be modified to use liquid hydrogen fuel. The modification was undertaken in cooperation with National Aeronautics and Space Administration in 1956. EADS Airbus started, within the 5th FP of European Commission 共EC兲, in 2000 the CRYOPLANE project that will assess the technical feasibility, safety, environmental compatibility, and economic viability of using liquid hydrogen as an aviation fuel. The main goals are the delineation of aircraft configurations for all categories of commercial aircrafts, from business jets to A3XXtype very large long-range aircrafts, as well as new concepts. In the same research field, the EC funded a totally innovative program focused on the definition of a new idea of unmanned aircraft 共HELIPLAT兲 powered by a regenerative cycle system consisting of solar cells and hydrogen fuel cells for continuous flight during day and night 共Romeo et al. 2004兲. Research was focused on the following topics, mainly from the aeronautical point of view: 共1兲 to preliminary design an autonomous HALEUAV platform capable of remaining aloft for very long periods of JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 / 79 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. time 共between 6 and 9 months兲 using a solar-powered and fuelcell system and to gain a complete understanding of the feasibility of a near term aerodynamic HALE concept, in particular, as far as stratospheric platforms are concerned 共mainly dependent on high efficiency and reliability of solar cells, fuel cells, and electric motors兲; 共2兲 to verify the production costs of each and the service costs and to assess the safety and regulatory aspects of the platform; and 共3兲 to manufacture a scale-sized technological demonstrator and to perform static tests up to the ultimate load. Hydrogen is the lightest of all elements. Hydrogen has an extreme low boiling temperature 共20.3 K兲 and in liquid form a density of 70.8 kg/ m3. However, when hydrogen vaporizes and the gas is warmed to the normal temperature 共293 K兲 a major variation in density occurs as it expands to 0.0838 kg/ m3. The consequence is that it must be stored in liquid form either at around 20 K and slight overpressure or at higher temperature but much higher pressure. The latter solution is not always practical for aeronautical applications due to the weight penalty. It depends on the mass quantity positioned onboard and on the mission requirements. The extremely low temperature poses serious problems for the fuel system 关insulation, material embrittlement, pipes, valves, gauges, and heat exchanger 共HEX兲兴 and its handling 共monitoring systems and refueling procedures兲. Due to their high energy density, proton exchange membrane 共PEM兲 fuel-cell systems are becoming increasingly attractive as the primary power plant for low-power, long endurance aircraft applications. Although PEM fuel-cell technology has been applied for automotive and stationary use, limited design and experimental work have been performed and documented for actual aircraft applications. A research was carried out by the Foundation for Advancing Science and Technology Education’s 关FASTec—USA, sponsored a research on designing, building, and testing a safe airplane, powered by direct current 共DC兲 electricity from fuel cells and advanced rechargeable batteries兴. The electric airplane, or Eplane, was manufactured around an all-carbon DynAero Lafayette III, which was powered by an advanced electric motor supplied by UQM Corp. No flight was indeed carried out. In an effort to develop environmentally progressive technologies for aerospace applications, Boeing researchers and industry partners throughout Europe are working from 2003 on a piloted airplane 共a converted Dimona motor glider built by Diamond Aircraft Industries of Austria兲 powered only by a fuel cell and lightweight batteries using a PEM fuel cell and lithium-ion battery hybrid system to power an electric motor, which is coupled to a conventional propeller. The Boeing Company, for the first time in aviation history, flown in April 2008 an experimental piloted airplane powered by hydrogen fuel cells for approximately 20 min with power solely generated by the PEM fuel cells. At the moment, the EC has funded environmentally friendly intercity aircraft powered by fuel cells 共ENFICA-FC兲 共Aeronautics and Space priority of the 6th Framework Program兲 with the main objective to develop and validate the use of a fuel-cell based power system for the propulsion of more/all-electric aircraft. The fuel-cell system has been installed in a selected aircraft which will be flight and performance tested as a proof of functionality and future applicability for intercity aircrafts. Through this project, the research and industrial consortium partners will focus on developing and providing operational zero-pollution solutions to the immediate needs of aircraft services. The ENFICA-FC consortium is led by Politecnico di Torino and comprises 10 partners. The project brought together industrial and academic players in the design and development and validation of intercity aircraft together with fuel-cell expertise for propulsion systems and hy- drogen storage. The overall budget is 4.5 M€, of which 2.9 M€ will be funded by the EC. The final scope of the project is to perform a flight test with the converted aircraft to demonstrate the ability of the new innovative system to cope with aircraft stringent requirements and operations. The installation of the new innovative propulsion concept on a conventional two-seat aircraft requires specific analysis and adaptation of existing elements/ configuration important for the success of the conversion. Among these, the cooling system is one of the most critical both for the FC stack and for electronic power management equipment connected to electric motor. The first high speed taxiing tests were successfully carried out on the Rapid 200-FC aircraft between 10 and 18 December 2009. The next step will be the first flight test 共Romeo et al. 2009兲. The preliminary study of ENFICA-FC new cooling system and venting system is the main topic of this paper and they serve as a contribution for the design/adaptation of new configuration. The cooling system design of general aviation piston engine installations has received attention in the past as fuel efficiency has become a more important factor in aircraft development. As a result, engine installation research, originally directed at solving power plant cooling problems, was concerned with nacelle drag reduction as well. These studies differ from the studies of the World War II era and before in that most general aviation aircraft now use horizontally opposed engine configurations, whereas most pre-World War II aircraft use air-cooled radials or in-line layouts. Wind-tunnel tests and studies of the so-called “cooling drag” are cited in Corsiglia et al. 共1981兲 and Katz et al. 共1982a,b兲. Some experimental tests on a semispan wing with nacelle 共no propeller兲 from a typical, general aviation twin engine aircraft are presented in Corsiglia et al. 共1981兲. The conclusion was that the cooling airflow accounts for 13% of the total estimated aircraft drag during both cruise and climb conditions, and the internal cooling drag accounts for about 30% and the other 70% is due to the nacelle external shape. Wind-tunnel tests have been performed on the same configuration in a subsequent study 共Katz et al. 1982a兲 in order to study the effect of propeller on system drag and performance. They showed that the addition of a propeller to a wing nacelle configuration reduces the amount of flow separation over the aft part of the nacelle and at the inlet of the cooling flow. This leads to a reduction in the configuration drag when the cooling air-mass flow rate is increased. The improvement is due to propeller slipstream pressure rise, but the major effect is the reduction of the amount of flow separation inside the inlet especially pronounced at high angle of attack. Different inlet and exit geometries have been studied in a third paper 共Katz et al. 1982b兲; they showed that the cooling air inlet geometry of opposite piston engine installations has a major effect on inlet pressure recovery, but only a minor effect on drag. The exit location geometry showed a large effect on drag, especially for those locations on the side of the nacelles where the suction characteristics were based on the interaction with the wing surface pressures. The numerical simulation of all the flow details of the cooling problem is extremely complex. A computational fluid dynamics 共CFD兲 engineering model has been developed in this paper by using the VSAERO code and it is used to support the air inlet and outlet design. It is assumed that the flow can be reasonably approximated by a potential flow plus boundary layer. The two main computational problems addressed in this paper are the numerical CFD simulation of aerodynamic of fuel-cell HEX inlet duct with and without the propeller effect and the definition of flow properties of different intakes necessary for the cooling of electronics 80 / JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. Fig. 1. Basic scheme of power supply system equipment and venting of the stacks. A preliminary analysis of the take-off phase has also been performed in order to verify temperature limits in the take-off phase. Energy System Power Plant and Problem Definition The ENFICA FC project has two main key goals: 1. A feasibility study of a FC intercity airplane in order to provide a preliminary definition of new and innovative power systems based on different fuel-cell technologies. The investigation concerns also the feasibility from the safety, certification, life cycle cost, and maintenance point of view. 2. The conversion of a modern and conventional two-seat aircraft into an all-electric airplane powered entirely by fuel cell. For this application the whole power system needs to be redesigned, built, and installed in a properly selected commercial aircraft. The existing two-seat aircraft Rapid 200, manufactured by Jihlavan Aircraft, was selected for conversion. The whole power supply drive system is supposed to consist of 共Fig. 1兲 the following: • A fuel-cell system producing about 20–22 kW; • Batteries producing about 20 kW at takeoff and climbing; • A DC/DC converter system managing fuel cell and batteries; • A DC/alternating current 共ac兲 inverter driving the electric motor; • An aircraft power management unit and distribution; • A 43-kW electric motor with 95% of efficiency; and • A high efficiency propeller specifically designed for the project. The air supply system and fuel-cell stack venting system are studied with the CFD model presented in this paper, and possible configurations for the ENFICA-FC new engine cowl are investigated. The FC stack and the hydrogen storage system are considered as self-standing systems. The rest of the power plant includes the battery pack, the DC/DC converter, the inverter, the electric motor, the propeller, and the power control unit. The fuel-cell balance of plant represents the air delivery, hydrogen delivery, regulation, and water cooling. Fuel-cell water cooling is guaranteed through a HEX that receives the necessary flow rate and pressure drop from a main intake 共Inlet 4兲 of about 0.0346 m2 positioned in the frontal part of the engine cowl. The air sent to the stack through a compressor is collected from a circular opening realized in the lower part of the engine cowl 共Inlet 5兲. Preliminary investigation about management of H2-gas propulsion systems reveals that specific requirements from the safety point of view have to be fulfilled and applied. In order to successfully implement a renewable hydrogen application, the safe production, storage, transport, handling, and use of hydrogen are imperative. The ventilation of onboard potential hydrogen accumulation sites becomes essential in order to avoid the formation of dangerous mixtures and is obtained by the definition of specific intake configurations. A preliminary evaluation of typical strategic area in the front of the aircraft includes venting action through two lateral openings 共Exit 1兲 in the upper part of the engine cowl in order to avoid possible buoyancy effects and allow any leak to pass through the top vent safely. A negative pressure at the outlet with respect to the engine bay 共Inlet 7兲 pressure would aid the top vent exits. The intake system shown in Fig. 1 has also to guarantee a cooling of the motor system and electronics equipment just in front of the stack position. Aeronautic regulations for general aviations CS-VLA 1041 prescribe that “The power plant cooling provisions must be able to maintain the temperatures of power plant components and engine fluids within the temperature limit established by the engine constructor during all likely operating conditions.” The electric motor chosen for the ENFICA-FC converted aircraft is a 43.8-kW brushless motor with a nominal torque of 192 N m, a maximum speed of 3,000 rpm, and an efficiency of 95%. Constructor specifications indicate a maximum environment temperature of 40° C and an operating temperature of 120° C 共Phase Motion Control 2007兲. The motor will be cooled by forced air from frontal intakes 共Inlet 3兲 obtained with some modifications of the original engine cowl leading edge profile; the case is designed including 8-mm-high fins in order to increase the exchange surface. The air request should be not less than 2 m3 / min in the preparatory phase up to 20 m3 / min during climb and level flight operations 共Schouten 1999兲. The power electronics unit is composed essentially by a DC/DC converter 共chopper兲 and a DC/ac inverter including an aircraft management unit. The chopper converts the power coming from FC stack, with voltage depending on the FC characteristics, in a form adequate for coupling with electrical battery, with a voltage depending not only on the delivered current but also on the battery state of charge. The inverter has the purpose of controlling electric motor in terms of output power to propeller. The power electronics specifications indicate values of about 90° C as typical maximum operating temperature 共Power One 2007; Liu 2004兲. When operating a converter or an inverter with an external forced air, the flow rate must be maintained in order to keep the module base plate at or below the maximum operating temperature specified by the electronic supplier in all the flight conditions. The cooling of the electronic system can be efficiently obtained by some National Advisory Committee for Aeronautics intakes 共Inlet 2兲 installed in the cowl at about 0.6 m from the spinner tip as in Fig. 1 to obtain flow rates that are of the order of 2 m3 / min and in accordance with electronic requirements. The present CFD model is able to study the effect of the outgoing air 共Exit 6兲 on the overall pressure distribution. The exit flow velocity can modify the local pressure distribution that in turn can modify also the JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 / 81 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. incoming flow characteristics. An example of this type of analysis with a preliminary exit area of about 0.18 m2 is included in the present paper. The final configuration for the exit duct will be defined considering the influence of the outlet flow on the inlet cold flow, and the exit shape will be optimized in order to reduce aircraft drag cooling penalties. Basic Method for Air-Cooling Design All the analyses were performed by VSAERO panel code. VSAERO is a computer program for calculating the nonlinear aerodynamic characteristics of arbitrary configurations in subsonic flow 共Natham 2005兲. Nonlinear effects of wake shape are treated by means of an iterative wake relaxation procedure, while the effects of viscosity are treated by means of an iterative loop coupling potential flow and integral boundary layer calculations. The flow is described by a velocity potential ⌽ whose gradient is the velocity ⵜ⌽ = − V 共1兲 When a solution for the velocity potential has been found, a wake shape iteration loop can be executed. In this loop the wake is repositioned so that the streamwise edges of wake panels are aligned with the local calculated flow directions. When the shape iteration is completed the viscous/potential iteration loop can be run. Use of the boundary layer procedure requires surface streamline to be traced. The boundary integral equations used to determine the potential distribution are solved by first dividing the surface into many panels, each with its own local coordinate system 共x⬘ , y ⬘ , n兲. Within each panel, the potential can be described by a local series expansion ⌽ = ⌽0 + ⌽x⬘x⬘ + ⌽y⬘y ⬘ + O共x⬘2,y ⬘2兲 共2兲 It is the point that the distinction between a low-order code and a high-order code is made. VSAERO assumes that the contribution from the linear and higher terms of potential expansion can be neglected compared with the constant term. This leaves only the unknown ⌽0 to be found for each panel. The two main computational problems addressed in this paper are as follows: 共1兲 the numerical CFD simulation of the aerodynamic of the fuel-cell HEX inlet duct with and without the propeller effect and 共2兲 the definition of flow properties of different intakes necessary for the cooling of electronics equipments and venting of the stack. HEX Preliminary Evaluation The numerical simulation of all the flow details of the HEX cooling problem is extremely complex 共Summa 1987; Romeo et al. 2008兲. In order to develop an engineering model that can be used at the design stage, several approximations of the real fluid mechanics are required. For this purpose it is assumed that the flow to the HEX face can be reasonably approximated by a potential flow plus boundary layer; hence, total pressure losses upstream of the HEX are neglected except for those within the thin boundary layer. However, since changes in duct geometry during the course of the design process will also affect the mass flow, some additional assumptions are made in order to include this effect in the calculation method. That is, the pressure losses through the HEX are derived from empirical formulas and computationally modeled by parametric variation with the velocity components calculated at the HEX face. Furthermore, the actual flow through the HEX is Fig. 2. Computer-aided design 共CAD兲 geometry and hybrid mesh certainly affected by the pressure in the engine bay which is in turn determined by the pressures in the location where the engine bay is exhausted. Since the velocity variation in the engine bay area is quite small, pressure losses in the engine bay could be neglected. The pressure losses across the HEX can be derived from experimental data and written as ⌬p = AV2ni + BVni + C 共3兲 where A, B, and C = empirically determined constants and Vni = inlet flow velocity component normal to the HEX face. An example reported in this paper refers to typical values for a commercial HEX and assumed the following values: A = 112.25, B = 66.75, and C = 0. The reference geometry used for the preliminary HEX analysis was supplied by Jihlavan Airplane Industries and corresponds to the original version of Rapid 200 “long” engine cowling. The original “short” version is older and it is used rarely now. The model shows three air intakes: a main rectangular intake with frontal dimensions of 330⫻ 105 mm, a smaller rectangular intake of 165⫻ 80 mm, and a circular one with a diameter of 80 mm. The first analysis considered in this phase concerns only this geometry. A proper outlet flow area definition is necessary in order to improve the actual model with the effect of outlet flow speed. The propeller has been optimized by Politecnico di Torino in order to obtain a very high efficiency propeller for the specific application. A scheme of the geometry under study is reported in Fig. 2共a兲. The mesh has been obtained by means of preprocessor Gridgen 共Pointwise software兲 关Fig. 2共b兲兴. A multiblock grid is created by dividing the overall region to be gridded into one or more subregions called blocks. The grid is a hybrid grid 共with either structured or unstructured blocks兲. A structured grid consists entirely of hexahedral cells that have been arranged in an ordered array. An unstructured grid consists of tetrahedral, pyramid, and prism cells having no implicit order. The unstructured grid has been used in the bottom part of the air intake to accelerate the meshing time when several openings are present. The main intake has been extended to uniform the flow inside the main duct under study. The other two openings are considered at this stage completely porous. The details of the fore body geometry can be simplified if the interest is only in the airplane frontal aerodynamics calculation; since its effect in the frontal part should be very small, a closed separation wake placed at the end of the body was used to extend the body downstream from this point. The presented method requires that panels associated with the HEX face need to be identified. HEX panels are associated with a Vni; the design point and consequently the size of the HEX will be determined through a parametric variation of the flow rate at the end of the duct, coupling the intake characteristics and the corresponding HEX pres- 82 / JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. Fig. 3. HEX design point from CFD analysis sure drop 共Fig. 3兲. Different flow rates are obtained by parametric variation of normal velocity components at the closure face of the duct 共Vni兲 and different aircraft speeds as defined in CS-VLA 335 and here reported in order to cover the range between the stall velocity and the cruise velocity 共22–25–30–35–40 m/s兲. Flow conditions at the cowl exit 共flow speed, density, geometry of the exit, temperature, etc.兲 are not completely established at the moment. The exit velocity can be simply included into the VSAERO model as the exact geometry of the exit will be defined, and a Vne will be associated with the panels corresponding to the exit area. A first tentative has been done by considering as exit area the bottom semicircular surface of 0.18 m2 共as indicated in Fig. 4兲 and an exit velocity Vne perpendicular to the exit area with Fig. 4. Streamline C P behavior 共aircraft reference speed of 22 m/s兲 the constraint of equality between the inlet and outlet flow rates. The exit flow effect has been studied, and a small influence on C P, locally confined in the proximity of the exit area, has been found; the dotted red line shown in Fig. 4 corresponds to the case with included exit flow. The shape of the exit could have a higher effect on the cowl drag, as illustrated in Corsiglia et al. 共1981兲 and Katz et al. 共1982a,b兲. Off-body streamlines can be calculated by VSAERO with a variable step-size predictor/corrector procedure. The trajectory is advanced from point n by predicting the position Rn+1 from the velocity vector and step size. The velocity is then calculated at Rn+1 and the trajectory is corrected. The off-body streamline procedure has been used to study the approaching flow. Considering, for instance, Streamline N.4 共a streamline entering the main intake兲 as reported in Fig. 4 it is possible to follow the C P behavior at different longitudinal locations 共X direction兲 and choose the right position for the HEX. C P behavior for other two streamlines is reported in Fig. 4: one on the upper surface and one on the bottom surface. The bottom streamline is the streamline that could be influenced by the exit flow; the continuous line is a streamline corresponding to an exit condition of Vne / Vref = 0 and the dotted line corresponds to the streamline C P behavior when Vne / Vref = 0.18. The upper streamline seems not to be affected by the out coming flow. At this stage of analysis the main intake is studied by considering that the flow is not decelerated in the small rectangular and in the circular opening; the frontal part of the cowl is, in fact, under study and should be modified in order to define the motor cooling intakes. When all the intakes will be defined a subsequent analysis will be performed in order to study the mutual influence of the adjacent openings. Results of parametric variation of the HEX intake flow rate are shown in Fig. 5 where C P distribution is reported for a Vref of 22 m/s and for four different flow rates in the main intake: Vni / V = 1 correspond to the case in which the HEX is not present or the HEX surface is completely porous; on the other hand Vni / V = 0.25 is the case in which a small flow rate enters in the HEX and a high pressure drop is verified at the HEX location. The C P value shows an increment for flow that approaches the main intake, and the value is practically the same for all the Vni / V conditions up to X ⬃ 0.2. Considering stations that are closer to the HEX intake opening 共X ⬎ 0.2兲, the effect of different Vni / V conditions becomes more important and C P continues to increase up to the internal duct where it reaches a constant value related to specific Vni / V conditions. The pressure variation in the main rectangular intake is shown in Fig. 3 as function of flow rate and reported for the aircraft Fig. 5. Parametric variation of the HEX flow rate 共Vref = 22 m / s兲 JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 / 83 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. Fig. 6. Definition of FC venting scoops speed range considered above. In the same figure the typical curve representing the pressure behavior of the HEX cold side as function of flow rate is reported. The intersection between intake curve and HEX curve represents possible design points. Considering, for example, the curve corresponding to 35 m/s at the design running condition, the cold side flow rate will be 1.04 m3 / s at a pressure drop of about 200 Pa. Inlet Definition for Different Cooling Necessity and H2 Venting Airflow is required through the stack from the bottom to the top under all conditions for hydrogen ventilation. At zero flow, a hydrogen leak could cause buoyancy free convection through the FC stack and out of the engine cover. Under motion, flow must be induced from inside the engine cover to outside the top vents. The pressure distribution on the upper part of the cowl is reported in Fig. 6共a兲, and a cross section is identified as Section A-A. The pressure distribution all around the cross section A-A is reported in Fig. 6共b兲. It is located at about 0.9 m from the spinner tip. The yellow line represents the C P in the lower part of the aircraft nose section 共Z ⬍ 0兲, and the fuchsia curve is the pressure coefficient in its upper part 共Z ⬎ 0兲. The other two curves at positive C P are the pressure coefficient inside the main intake. From the pressure coefficient distribution, it is clear that the best location for the extract scoops is on the lateral part of the engine cowl. At Y ⬃ 0.3/ 0.35 m from the symmetry plane the C P is at its minimum and it shows a negative value of about ⫺0.25. With scoops fitted to the top engine cowl at Y ⬃ 0.3/ 0.35 m, it is possible to create the necessary flow, and the negative pressure coefficient during motion would aid the top vent exit. The design of scoops for electronic power unit air cooling will consider also the results coupled with the propeller in order to define which is the worst condition by referring to the power absorbed in different take-off strategies 共constant power, constant thrust, and constant rpm兲. Results about this activity are presented in the following sections. Effect of Propeller The propeller data are taken from Romeo et al. 共2007b兲 where two algorithms were used for optimal propeller design: the first allows for the determination of the geometric characteristics of the maximum efficiency propeller for a given operative condition and profile distribution along the blade. The output of this first analysis is the chord and twist angle distributions along the blade, efficiency, torque, and thrust for the selected operative condition. The second algorithm allows for the evaluation of the propeller efficiency, torque, and thrust for a given geometry when the blade pitch and operative condition are changed 共D’Angelo et al. 2002兲. Since the objective of the ENFICA-FC project is to perform an experimental flight, the propeller has to work in few different conditions. For this reason, the design of the optimized blade has been carried out in two different conditions: cruise 共Case A兲 and climb 共Case B兲. The two designs are then compared. In both cases, the design of the optimized blade requires the a priori knowledge of the number of propeller blades: the analysis is carried out for two and three blades. The optimization algorithm uses an aerodynamic theory based on classical results 共D’Angelo et al. 2002兲 obtained from the integration of vortex theory, wing theory, and momentum theory. A compressibility correction is used by introducing a semiempirical factor which corrects the lift and drag coefficients. For more details the reader can refer to D’Angelo et al. 共2002兲. The cruise condition is a level flight at an altitude of about 1,000 m, flight speed is 40 m/s, and electric motor working at ⍀ = 2 , 000 rpm. In this condition the propeller should supply a thrust of T = 340 N. The propeller 共two blades兲 optimized in cruise condition has a radius of 0.8 m selected equal to the original one in order to respect geometrical bounds and a weight of about 4 kg. This propeller was designed to be optimal in cruise condition. During the climb phase, the propeller should generate a thrust of about 784 N, and the aircraft velocity has to be 33 m/s at an altitude of 500 m. Since all the other parameters are fixed, the angular velocity has to change to ⍀ = 2 , 490 rpm. Results in terms of thrust coefficient and efficiency of the two blade optimal propeller are reported in Fig. 7 and used for the CFD subsequent analysis. The efficiency of the optimal propeller during the cruise phase is 90%, and the torque and power at the propeller shaft are C = 72 N m and P = 32.1 kW, respectively. The efficiency of this propeller during the climb phase is 80.2%, and the torque and power at the propeller shaft during climb condition are C = 123 N m and P = 32.1 kW, respectively. CFD results with this propeller installed are presented in Fig. 8. The advantage of panel 84 / JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. Fig. 7. Thrust and power coefficient and efficiency of the optimal two-blade propeller methods is that they are easy to use and inexpensive in terms of CPU time. When a propeller slip-stream capability is added to a panel program, the extension should also have these two properties. The flow in the slip stream is much more complicated than ordinary freestream flow, and simplifications in the computational model are necessary. Therefore, we cannot expect to obtain the same accuracy in the predictions with the slip stream as we are used to without the slip stream. This is also true for wind-tunnel experiments. In this section a propeller slip-stream model is described and incorporated in the previous analysis. The flow behind the propeller is generated by a simplified model constituted by an axial flow model and a swirl model as in Natham 共2005兲. The propeller slip-stream model is a vortex tube that provides the increase in axial velocity 2⌬V at the propeller plane where the velocity is Vnorm = Vout + ⌬V, where ⌬V = velocity increment at the propeller disk. The ⌬V value is related to the propeller thrust level and local velocity. If the incompressible Bernoulli equation is applied across the walls of the vortex tube and equality of static pressure is specified, then an increase in total pressure coefficient is established within the slip stream. The ⌬C P is also the pressure across the actuator disk and is related to the propeller thrust T Fig. 8. CFD model with propeller included JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 / 85 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. correlated to the flow speed behind the propeller. Three different cases have been considered in this paper: a constant power takeoff 共39 kW兲, a constant thrust takeoff 共T = 1 , 100 N兲, and a constant rpm condition 共2,745 rpm兲. In order to compare three different strategies the optimal propeller previously described 共constant pitch angle of 22.8°兲 was adopted, and levels of thrust, power, and rpm were calibrated to guarantee that all the strategies lead to a take-off length of about 400 m. Motor Temperature Fig. 9. Propeller simplified model ⌬C P = 共V2in − V2out兲 1 T = 2 Vref 0.5Vref R2 共4兲 The motor/inverter/converter temperature computation has been performed by considering a preliminary geometry for the motor and inverter fins 共Romeo et al. 2008兲. During the computation a total motor/inverter/converter efficiency of about 90% 共constant during the take-off phase兲 was considered with a remaining 10% of heat losses 共Qloss兲. Preliminary temperature calculus is derived from Lienhard and Lienhard 共2000兲 and Holman 共2009兲 The local undisturbed “velocity” Vout can be approximated by the onset flow V⬁. For more precise results the value can be obtained using a velocity survey from previous run with the configuration without actuator disk. The downstream interior axial velocity Vin is obtained as Vin = 冑 V2out + T 0.5R2 共5兲 In order to represent a more general case with velocity distribution not uniform across a section of the vortex tube, a number of coaxial vortex tubes of appropriate strength can be used. Swirl velocity considered in VSAERO is derived from Natham 共2005兲, Ferrari 共1957兲, and Schouten 共1999兲 and can be expressed as Vswirl = ⌬V R V⬁ r 2nR 共6兲 The simplified model is also reported in Fig. 9. Some results in terms of pressure coefficient at the same aircraft speed of 22 m/s and two different levels of thrust 共T = 450 N and T = 700 N兲 are reported in Fig. 8. CFD results with propeller included, reported in Fig. 8, for the main rectangular intake 共Intake 4兲 showed that intake C P value can be effectively higher than 1 due to the flow from the aircraft propeller. The increase of the intake C P value due to the propeller effect is also presented in Katz et al. 共1982a兲, but the real increment in C P is expected to be lower than the one predicted by the present analysis due to difficulty to properly model the flow separation at the intake inlet. Moreover the propeller analysis showed that future reduction in HEX dimensions and weight is possible by considering the propeller beneficial effect on the inlet flow conditions. The CFD analysis, with propeller included, gave also support in decision about power electronics unit air-intake position. Electric Motor and FC Temperature Analysis Takeoff Analysis of Temperature A simplified method to compute the motor/inverter and fuel-cell temperature during the most critical mission phase 共takeoff兲 is described in previous sections. The worst condition has to be defined by considering the different power consumption levels T f = T0 + Qloss h0共SNOfins + Sfins · a兲 共7兲 The air speed is included in the Nu number through Reynolds and Prandtl numbers. For Re numbers in a range 2 ⫻ 105 ⬍ Re⬍ 5 ⫻ 106, a simplification of the general Nu equation is reported in Lienhard and Lienhard 共2000兲 and Holman 共2009兲 as NuL = 0.0370 ReL0.8 Pr0.43. Fig. 10共a兲 presents temperature as function of aircraft speed. In the case of constant power 共39 kW兲 the minimum of axial speed corresponds to the minimum of aircraft flight speed; in this case the maximum of the temperature is about 100° C. The minimum is reached at the end of the ground roll phase and is about 84° C. The case of constant thrust shows very different behavior because the best cooling situation is at the starting point, while the temperature at the end of the ground roll phase is quite similar to the other strategies 共86° C兲. The last case corresponds to a takeoff at constant rpm. This case is studied by considering a takeoff at 2,745 rpm within the motor limits. The minimum speed at the disk is in this case about 19 m/s and the maximum temperature is 98° C. The last strategy 共rpm= const兲 is better with respect to the constant power. Fuel-Cell Temperature Even for low-temperature fuel cells such as the protonexchange membrane 共PEM兲, thermal management is necessary. The heat associated with the range of required power for a typical passenger vehicle cannot be passively dissipated by convection and radiation through the external surfaces of the FC. Consistent lowtemperature 共70° C兲 operation thus requires a cooling system similar to the one used in internal combustion engines. The lowtemperature difference between the FC and the environment limits the effectiveness of the heat transfer from the coolant to the ambient and requires either a large radiator surface area or many cooling fans. Hence, a sophisticated controller of the fuel-cell temperature becomes vitally important to ensure optimal system performance. In order to do a first-law control volume analysis, all contributions to the energy balance have to be determined. These are the sum of energy flows due to mass flows into and out of the control volume, the net rate of heat transfer, and the net rate of work. The first law of thermodynamics is represented by the following differential equation: 86 / JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. Fig. 10. Motor and FC temperature at the three strategies M FCCFC · dT = dt 兺i Gi · hi − Qamb conv − Pel 共8兲 where Pel = electrical output power; M FC = total mass of the fuelcell stack; and CFC = overall specific heat capacity of the stack. 兺iGi · hi represent the sum of the reaction enthalpy rate and Qamb conv the heat transfer to the environmental area. The FC model is a dynamic model developed by the writers based on Lienhard and Lienhard 共2000兲, Holman 共2009兲, Caisheng et al. 共2005兲, and Jay et al. 共2004兲 and used in this particular computation by considering subsequent equilibrium states and different initial conditions due to different starting power levels for the three strategies considered 共constant power T0 = 67° C, constant thrust T0 = 57° C, and constant rpm T0 = 67° C兲. A complete dynamic model is under study and results published in a subsequent step when a final cowl geometry will be designed. In Fig. 10共b兲 the FC temperature is reported as function of aircraft speed as in the case of motor 关Fig. 10共a兲兴. The maximum temperature is reached at the starting point for all the three strategies but it is possible to observe a different behavior with more stable temperature values with respect to the motor/inverter temperature. The difference may be attributed to different types of cooling; in the case of motor the cooling is a pure air cooling while in the case of FC is a water cooling with a higher thermal inertia. In Fig. 10 power, rpm, and thrust for the three strategies are shown as well. Conclusions An engineering CFD model was developed and used to support the air inlet and outlet design. A preliminary definition of the air intake and venting scoop was obtained by means of the wide range of aerodynamic data obtained from the preliminary CFD analysis. The propeller effect is studied by referring to an optimal propeller designed specifically developed for the ENFICA-FC project and using a slip-stream wake modeled by an actuator disk plus a swirl membrane. Results of this preliminary CFD have been used for a first stage definition of the FC converted aircraft air-cooling and venting system. Preliminary results indicate that a good design for FC HEX intake could be obtained by small changes of the actual cowl by using the main intake in the lower part of the cowl capable to supply about 0.5 m3 / s in the design condition. The propeller simplified model showed a high increment of the intake pressure coefficient when different thrust levels are considered. An efficient location of hydrogen venting system can be derived from the CFD analysis to create the necessary flow and negative pressure coefficient during motion to aid the top vent exit. Some changes of the actual cowl are required in order to increase the frontal area behind the propeller for engine cooling system intake installations. The electronic cooling intake could be efficiently installed in the upper part of the existing cowl at about 0.6 m from the spinner tip. A preliminary temperature analysis was conducted for the take-off phase and for the motor/inverter system as well for the FC stack. JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 / 87 J. Aerosp. Eng. 2011.24:79-88. Downloaded from ascelibrary.org by UNIVERSITY OF AKRON on 10/04/12. For personal use only. No other uses without permission. Copyright (c) 2012. American Society of Civil Engineers. All rights reserved. Acknowledgments The activity has been developed within the ENFICA-FC project. The writers acknowledge the important contribution of European Commission by the funding programs ENFICA-FC, EC 6th FP— Contract No. AST5-CT-2006-030779. Notation The following symbols are used in this paper: CFC ⫽ fuel-cell overall specific heat capacity; C P ⫽ pressure coefficient; h0 ⫽ heat-transfer coefficient; l ⫽ motor characteristic length; M FC ⫽ fuel-cell stack total mass; Nu ⫽ Nusselt number; n ⫽ propeller rotation rate; Pr ⫽ Prandtl number; Pel ⫽ electrical output power; Q ⫽ flow rate; Qamb conv ⫽ heat transfer; R ⫽ propeller radius; Re ⫽ Reynolds number; T ⫽ propeller thrust; T f ⫽ motor temperature; T0 ⫽ ambient temperature; Vin ⫽ inner velocity; Vne ⫽ exit flow velocity component; Vni ⫽ inlet flow velocity component; Vout ⫽ local undisturbed velocity; Vref ⫽ reference flow velocity; Vswirl ⫽ swirl velocity; V⬁ ⫽ onset flow velocity; ⌬V ⫽ velocity increment at the propeller disk; ⌬p ⫽ pressure losses across the HEX; a ⫽ fin efficiency; ai ⫽ thermal conductivity; ⫽ air density; and ⌽ ⫽ velocity potential. References Caisheng, W., Hashem, N., and Steven, R. S. 共2005兲. “Dynamic models and model validation for PEM fuel cells using electrical circuits.” IEEE Trans. Energy Convers., 20共2兲, 442–451. Corsiglia, V. R., Katz, J., and Kroeger, R. A. 共1981兲. “Full-scale windtunnel study of the effect of nacelle shape on cooling drag.” J. Aircr., 18共2兲, 82–88. D’Angelo, S., Berardi, F., and Minisci, E. 共2002兲. “Aerodynamic perfor- mances of propellers with parametric considerations on the optimal design.” Aeronaut. J., 106共1060兲, 313–320. Ferrari, C. 共1957兲. “Interaction problems.” Aerodynamic components of aircraft at high speeds, A. F. Donovan and H. R. Lawrence, eds., Princeton University Press, Princeton, N.J. Glover, B. 共2005兲. “Fuel cells opportunity.” Proc., AIAA/AAAF Aircraft Noise and Emissions Reduction Symp., AIAA, Reston, Va. Holman, J. P. 共2009兲. Heat transfer, McGraw-Hill, New York. Jay, T., Pukrushpan, H., Peng, A., and Stefanopoulou, G. 共2004兲. “Control-oriented modeling and analysis for automotive fuel cell systems.” J. Dyn. Syst., Meas., Control, 126共1兲, 14. Katz, J., Corsiglia, V. R., and Barlow, P. R. 共1982a兲. “Cooling air inlet exit geometries on aircraft engine installations.” J. Aircr., 19共7兲, 525– 530. Katz, J., Corsiglia, V. R., and Barlow, P. R. 共1982b兲. “Effect of propeller on engine cooling system drag and performance.” J. Aircr., 19共3兲, 193–197. Lienhard, J. H., IV, and Lienhard, J. H., V 共2000兲. A heat transfer textbook, Phlogiston Press, Cambridge, Mass. Liu, J. 共2004兲. “Design and control of a kilo-amp DC/AC inverter for integrated starter-generator 共ISG兲 applications.” IEEE-IAS’04, IEEE, New York, 2754-2761. Natham, J. K. 共2005兲. “A code for calculating the nonlinear aerodynamic characteristic of arbitrary configuration.” VSAERO user’s manual, JK Ananlytical Methods, Washington. Phase Motion Control. 共2007兲. “Technical information on TK frameless motors.” 具http://www.phase.eu/典 共2007兲. Power One. 共2007兲. “Cooling DC-DC converters power-one application note.” 具http://www.power-one.com典 共2007兲. Romeo, G., Borello, F., Cestino, E., Moraglio, I., and Novarese, C. 共2007a兲. “ENFICA-FC environmental friendly inter-city aircraft and 2-seat aircraft powered by fuel cells electric propulsion 共DEU兲.” AIRTEC 2nd Int. Conf. Romeo, G., Cestino, E., Frulla, G., and Correa, G. 共2008兲. “Summary of support effort activity to new engine cowl design and intakes definition.” ENFICA FC EU-Project Contract No. 30779 Internal Rep. No. D7/6, ENFICA. Romeo, G., Correa, G., Borello, F., and Pacino, M. 共2009兲. “Integration on board of aircraft and functional ground testing of propulsion system and subsystems. Taxi test.” ENFICA-FC Internal Rep. No. 9/2-3. Romeo, G., Frulla, G., Cestino, E., and Corsino, G. 共2004兲. “HELIPLAT: Design, aerodynamic, structural analysis of long-endurance solarpowered stratospheric platform.” J. Aircr., 41共6兲, 1505–1520. Romeo, G., Novarese, C., and Cestino, E. 共2007b兲. “Design of optimal propeller for the RAPID 200-FC.” ENFICA FC Internal Rep. No. D8/2, ENFICA. Schouten, G. 共1999兲. “Theodorsen’s propeller performance with rollup and swirl in the slipstream.” J. Aircr., 36共5兲, 892–895. Summa, J. M. A. 共1987兲. “Method for computing ducted heat-exchanger flows and its validation for a “front breather” model.” Analytical Methods Rep. No. 8709, Analytical Methods, Washington. Volker, H. 共2006兲. “Airbus fuel cell systems for aeronautic applications. A clean way from kerosene to energy.” Proc., 25th ICAS Congress. 88 / JOURNAL OF AEROSPACE ENGINEERING © ASCE / JANUARY 2011 View publication stats J. Aerosp. Eng. 2011.24:79-88.