automatismos prácticas de programación s7300 en lenguaje de

Anuncio

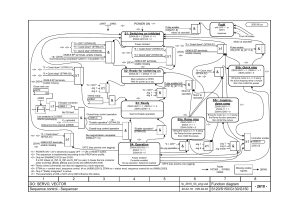

AUTOMATISMOS 5º Ingeniero de Telecomunicación Curso 2003/2004 PRÁCTICAS DE PROGRAMACIÓN S7300 EN LENGUAJE DE CONTACTOS KOP 1. Control de motores 2. Control de Válvulas 3. Guía de selección de temporizadores MOTOR CONTROL EXAMPLE Introduction This article is designed to provide a practical example of software coding of motors for use in Programmable Logic Controllers (PLC). This example can be used for most applications for the control of motors via a PLC including pumps, conveyors, mixers, etc. This article discusses the states a motor can be detected, it control and PLC Software Programming. This example is designed in in the most common PLC Programming Language - Ladder Logic. Digital Inputs For this example we have considered the following Digital Inputs to the PLC. Inputs may be excluded where the signal is not available or not required by your application Symbol Description AUTO Automatic Selection MAN Manual Selection ON State OFF State AUTO ------ MANUAL ------ START_PB Manual Start Push-Button START ------ STOP_PB Manual Stop Push-Button ------ STOP RESET Alarm Reset Push-Button RUN Motor Running, contactor feedback. RUNNING STOPPED ESTOP Emergency Stop, aux contact from emergency stop circuit. STOP HEALTHY TRIP Motor Tripped Signal, aux contact from motor overload. TRIPPED HEALTHY Notes: • • For this article we have assumed that the auxiliary contacts for the emergency stop and the motor overload will be ON for the trip condition. The automatic controls have not been shown in this article as these signals will be derived from the sequencing software. Digital Outputs For this example we have considered the following Digital Inputs to the PLC. Inputs may be excluded where the signal is not available or not required by your application Symbol Description MOTOR_RUN Motor Run Signal ON State OFF State RUN STOP Note: For this article we have used a single output for the control of the motor. Motor States From the inputs available the following states of the motor can be derived. We have shown the automatic states in the following table, each state exists for manual mode and the auto text replaced by manual. Symbol Description Motor Stopped (Symbol either black on a white background else white) Motor Running Motor Alarm (Emergency Stop/Failed - symbol can be flashed to draw the operators attention) Motor Tripped Control Logic Detecting, Latching and Reporting Alarms The first alarms that will be detected within the logic are Emergency Stop and Tripped. This is simple digital logic. These signals must be hardwired into the motor control circuit, but the software will duplicate the hardwired logic to report the alarm to the operator. Detect and Latch Emergency Stop | ESTOP ESTOP_AL | |---| |-------------+--------------------------------( )---| | | | ESTOP_AL RESET | |---| |------|/|----+ Detect and Latch Motor Overload Trip | TRIP TRIP_AL | |---| |-------------+--------------------------------( )---| | | | TRIP_AL RESET | |---| |------|/|----+ The first two rungs of the above ladder diagram are used to detect and latch the Emergency Stop conditions. When the alarm is detected then the condition is latched until 1. The alarm condition is cleared 2. The operator resets the alarm. The next alarm condition is detecting that the motor has failed. That is that the PLC has requested for the drive to start but the contactor has not closed. This could be due to a number of reasons, motor isolated, fuse blown etc. Detect Motor Failed To Start/Stop | MOTOR_ _________________ | RUN RUN |ON DELAY | | |---| |------|/|----+--------------------|TIMER M1_DELAY|-| | MOTOR_ | |TIME 1.0S | | RUN RUN | |_________________| |---|/|------| |----+ Latch Motor Failed To Start/Stop | M1_DELAY MOTOR_AL | |---| |-------------+--------------------------------( )---| | | | MOTOR_AL RESET | |---| |------|/|----+ In the first rung we use a timer to time the conditions when the motor is contactor does not match the required PLC output. That is PLC run output is and the contactor is not closed and visa versa. In the second rung we latch the alarm condition. Combining The Alarms | ESTOP_AL M_ALARM | |---| |--------+-------------------------------------( )---| | | | TRIP_AL | |---| |--------+ | | | MOTOR_AL | |---| |--------+ Here we use simple "OR" logic to combine the alarms, when any one of the alarms are detected the M_ALARM is "ON". Automatic and Manual Status We use the selection of the automatic and manual for the control of the drive. It is written to ensure that their is a scan difference during change over from automatic to manual so that the drive is stopped. This is used in the Low Level Plant Driver. Automatic Selected | AUTO MAN_SEL AUTO_SEL | |---| |------|/|----+--------------------------------( )---| | Manual Selected | MAN AUTO_SEL MAN_SEL | |---| |------|/|----+--------------------------------( )---| | Low Level Plant Driver The low level plant driver is the final software which drives the output to the motor having considered all the input output signals. Control Motor | AUTO_SEL AUTO_RUN M_ALARM MOTOR_RUN | |---| |------| |----------------+----|/|--------------( )---| | | | MAN_SEL START_PB STOP_PB | |---| |---+---| |-----+---|/|---+ | | | | | MOTOR_RUN | | +---| |-----+ When Automatic is selected then sequence flag (AUTO_RUN) is used to control the drive. When manual is selected the drive will start when the start push-button is pressed, latched with the output from the PLC (MOTOR_RUN). The drive will continue to run until the stop push-button is pressed. Should any of the alarms be detected then the motor is stopped. The alarm must be reset before the motor can be restarted. EJEMPLO DE CONTROL DE VALVULAS Realice en lenguaje KOP y empleando la guía adjunta de selección de temporizadores de Step 7, el control del sistema de válvulas descrito a continuación. ENTRADAS DIGITALES Estado ACTIVO Símbolo Descripción OPEN_REQ Selector de solicitud de apertura de válvula ABRIR LSO Final de carrera abierto ABIERTA LSC Final de carrera cerrado CERRADO RESET Pulsador de cancelación de alarma RESET ESTOP Pulsador (botón) de emergencia PARAR SALIDAS DIGITALES Estado ACTIVO Estado INACTIVO Indicación al panel de operación de maniobra de apertura en curso ABRIENDO ---------- V_CLOSING Indicación al panel de operación de maniobra de cierre en curso CERRANDO ---------- OV Apertura de válvula ABRIR CERRAR Símbolo Descripción V_OPENING ESTADOS DE LA VÁLVULA La válvula puede estar en cinco estados diferentes: a) b) c) d) e) cerrada (CERRAR_RET) abriéndose abierta (ABRIR_RET) cerrándose Situación de alarma (ALARMA) LÓGICA DE CONTROL La alarma se puede disparar por las siguientes razones: 1. Pulsador de emergencia 2. Fallo al abrir válvula 3. Fallo al cerrar válvula. Para cada posición de las válvulas el sistema detecta condiciones de alarma. Estas son: 1. Fallo en apertura - La salida de apertura de válvula está activa (OV=1) y tras 10 segundos no se activó LSO ó - Estando la válvula en estado abierto (marca ABRIR_RET automantenida que se activa cuando la válvula termina de abrirse y se desactiva cuando OV=0), se desactiva LSO durante más de 1 segundo. 2. Fallo en cierre - La salida de apertura de válvula está inactiva (OV=0) y tras 10 segundos no se activó LSC ó - Estando la válvula en estado cerrado (marca CERRAR_RET similar a ABRIR_RET para la maniobra de cierre), se desactiva LSC durante más de 1 segundo. La situación de alarma se mantendrá hasta que se cumplan las dos siguientes condiciones: 1. La condición de disparo de la alarma ya no está presente. y 2. Pulsación del botón de cancelación de alarmas. CONTROL A BAJO NIVEL DE LA VALVULA La señal OV estará activa cuando el selector del panel de operación OPEN_REQ esté activo y no haya activa ninguna alarma. PANEL DE INDICACIÓN/OPERACION Indicación mediante V_OPENING y V_CLOSING de la maniobra que se está realizando antes de que ésta concluya (suponga que no existen averías). GUIA DE SELECCION DE TEMPORIZADORES CONEXION EJEMPLO DE UN TEMPORIZADOR GENERICO EN KOP